Treatment of mixed chlorinated ethenes and ethanes at an active site, UK

Introduction

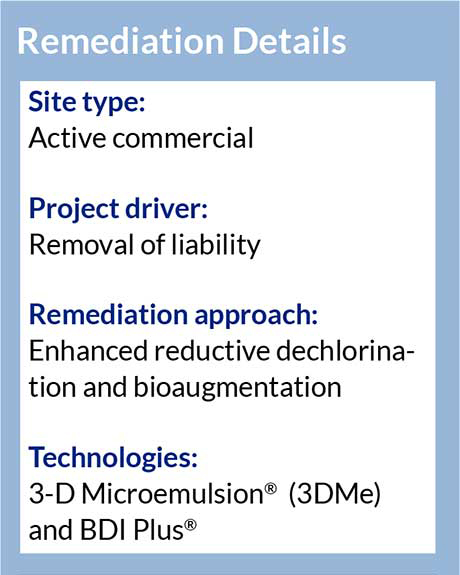

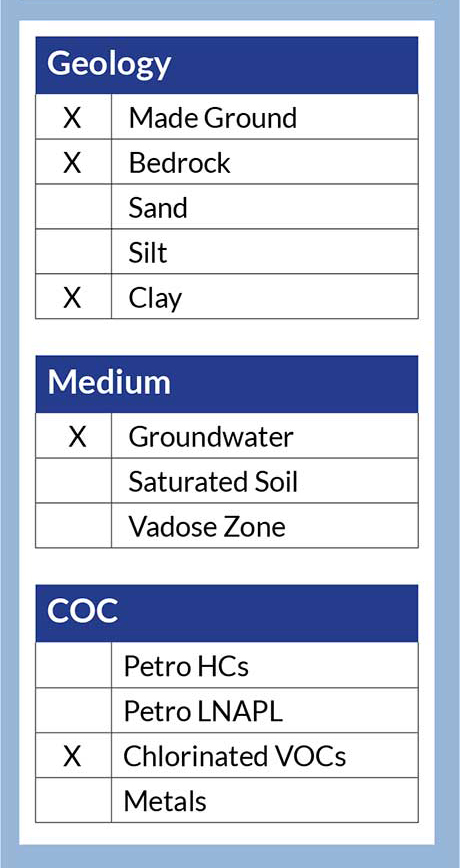

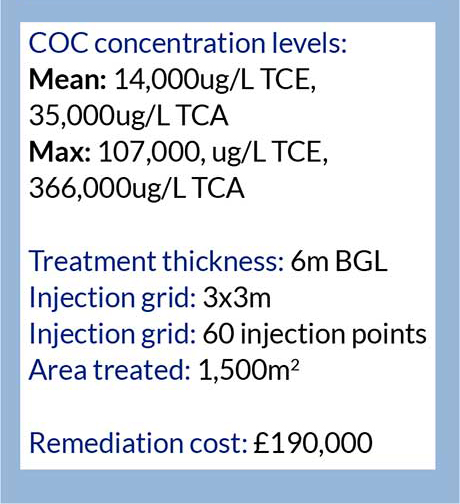

REGENESIS was approached to offer an in situ remedial solution to address high levels of mixed chlorinated solvent (TCA and TCE) contamination of the groundwater at a site in northeast Scotland. At the time, an ongoing DPVE system was operating, but was unable to achieve the remediation goal of a 75% reduction in chlorinated solvent mass. Furthermore, a supplementary MIP investigation showed that there was more contamination at depth (>6m) which the DVPE system was not able to reach.

Download pdf Fig. 1 REGENESIS Remediation Services applying 3DMe and BDI Plus on site

Fig. 1 REGENESIS Remediation Services applying 3DMe and BDI Plus on site

The initial design was based on treatment between 3 – 9m BGL of the aquifer across a 1,200m2 using 3DME and BDI with the preferred method of application being direct push injection. However, during the MIP investigation progression of the rods deeper than 6mBGL was found to be difficult. This raised concerns that (1) direct push injection would not be able to reach 9m BGL and (2) injection of the required dose of 3DMe may not be possible. REGENESIS were therefore asked to undertake a pilot study over a limited area to demonstrate that the works were possible. This was completed successfully and also showed excellent dose response and demonstrated to the site owners that the works (which were completed at night) would not have a deleterious effect on their operations.

Full Scale Application

The pilot trial was conducted over two days (see figure 1) during which the direct push injection rig had no problems getting the injection rod to the required depth of 9m BGL (unlike the MIP). Furthermore, the required volume of 3DMe was accepted by the aquifer with minimal daylighting/surfacing.

Following the MIP and pilot, the fullscale design was tailored to provide the most cost effective approach for the site. 60 direct push injection points were completed over 10 nights, with no disturbance to the site operations.

The direct push injection points were centred on BH 11, a pre-existing well, to ensure we had good baseline data. Both BH11 and the surrounding wells were monitored over 8 months to assess the effect and distribution of 3DMe.

Results

Following the injection works, quarterly validation monitoring was completed. Post injection monitoring showed no inhibition of parent compound degradation due to the mixed halogenated compound plume. 98% and 99% reduction in mean concentration of TCA and TCE respectively.

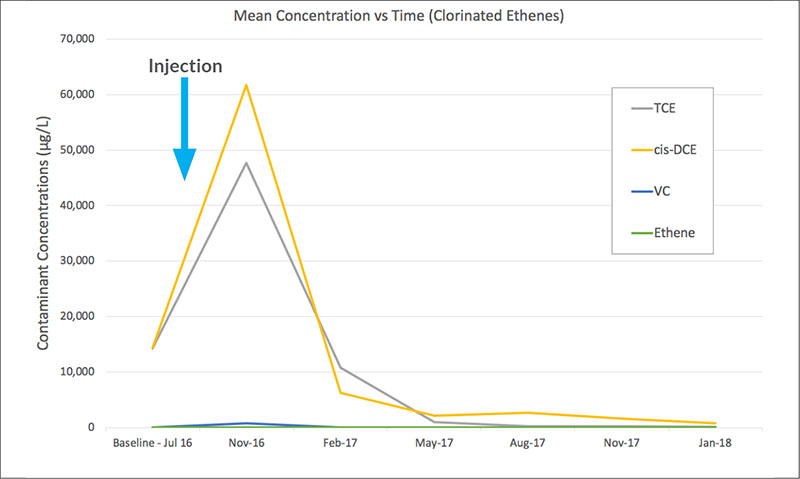

Full reductive dechlorination was achieved with no build up in daughter products (see fig 2 and 3). The validation curves suggest that both biotic and abiotic degradation occurred.

Fig. 2 Mean concentrations of Chlorinated Ethanes over time

Fig. 3 Mean concentrations of Chlorinated Ethenes over time

Abiotic degradation occurred through the production of reduced iron species by the production of low redox conditions created by the 3DMe.

What’s Special

- A limited pilot study was used to prove the practicality and efficacy of the proposed approach. This area did not require further injection, so added little extra cost to the remediation of the site.

- Bioaugmentation using BDI+ avoided any inhibition of either chlorinated ethenes and ethanes by ensuring that the microbial consortia contained viable counts of dehalogenating bacteria specialising in either contaminant group.

- Very high levels of contamination, suggestive of DNAPL, were reduced to very low concentrations within 18 months.

- No build up of degradation products occurred, showing full reductive dechlorination was achieved and sustained.

- No disturbance of the onsite operations occurred during the limited injection time onsite, with the remediation occurring under the site as it continued to function normally.

- Remediation goals were achieved.

Fig. 4 REGENESIS’s team onsite

Advanced Remedial Technologies Restore Neighborhood

Case study highlights:

- Application of combined REGENESIS technologies to biodegrade contaminants, prevent further plume migration, and protect occupants from the threat of vapor intrusion.

- Reduction of the total cVOC plume extent by 95% and reduced mass by 99.8%.

- Positive results indicating the degradation process is ongoing and processing.

This case study reviews a former plating facility in southwest Michigan that had released chlorinated volatile organic compounds (cVOCs) into shallow groundwater, resulting in a ¼-mile long contaminant plume. In response, the Michigan Department of Environmental Quality (MDEQ) and the environmental firm, DLZ, implemented a combined remedy which included mitigating vapor intrusion in the residential basements and treating the groundwater plume with a novel, multi-phase in situ bioremediation approach.

Site Goals Achieved Within Two Months

Case study highlights:

- This site has been an active case since 2007. REGENESIS was able to eliminate the contaminant quickly and effectively using a combined remedy approach.

- After conducting a pre-field remediation test, the injection interval was reduced from 12 feet to 9 feet with a bottom-up approach, reducing the project costs by 30%.

- The combination of PlumeStop, HRC and BDI+ successfully eliminated the contaminants and created conditions for sustained treatment at the site.

This case study reviews a contaminated manufacturing site in Santa Barbara, California. A former manufacturing operation had left PCE and TCE contaminant levels above regulatory limits with previous remediation approaches attempted without complete success. Applying a combined remedy approach, Haro Environmental chose to focus on incorporating a design to rapidly reduce contaminant concentrations for sustained treatment, and reduce the potential for further downgradient migration of the PCE and TCE contaminants.

RegenOx Application Quickly and Efficiently Lowered Diesel Range Organics (DRO) to Below ADEC Requirements

Project Highlights

- Two applications of RegenOx® reduced contaminants to a level below the Alaska Department of Environmental Conservation (ADEC) standards to protect against migration to groundwater

- Completed in 8 weeks, restoring agriculture viability

- Soil was safely and efficiently cleaned preventing fuel from contaminating a nearby sensitive receptor

Project Summary

A Hydaburg site in Alaska, owned by Alaska Power and Telephone, previously housed diesel fuel generators and is now being converted into a hydro-electric plant. The land was contaminated by a diesel fuel spill requiring remediation. Approximately 1,000 cubic yards of soil were impacted and the starting concentrations of DRO were approximately 1 500 ppm. The goal was to reduce concentrations to below the ADEC standard of 230 ppm.

Due to the cold weather encountered during this project and the sensitive infrastructure in the area, it was important that the technology work effectively in less than ideal conditions. Also, the technology could not be corrosive nor generate excess heat. RegenOx, produces minimal heat and pressure, is non-corrosive, and works well at any temperature above freezing making it ideal for this project. Additionally, RegenOx is a chemical oxidant which quickly and effectively destroys a range of contaminants-in this case, DRO. The soil was screened with a trommel and RegenOx was mixed in a cement truck before being sprayed onto the soil. RegenOx was applied twice, with the applications spaced a week apart. This site required 20 lbs of RegenOx per cubic yard, in total 20,000 lbs.

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

Results

After two applications of RegenOx, the concentrations of DRO went from 1,500 ppm to below 125 ppm, satisfying the ADEC requirement of below 230 ppm, within 8 weeks. After the remediation treatment, the soil was spread out, grass was planted and is now growing at the Hydaburg site, attesting to the renewed health of the soil.

Rapid, Effective Remediation of Free Product at an Active Rail Depot, UK

Augmented Pump and Treat, In Situ Chemical Oxidation (ISCO) and Enhanced Natural Attenuation (ENA) completed under rail lines by REGENESIS Remediation Services. Read More

In Situ Remediation of Petroleum Hydrocarbons at Rail Depot, Bristol, UK

Surface petroleum hydrocarbon contamination had resulted from historic and on-going leaks at a train maintenance depot near Bristol, where trains were stabled overnight. REGENESIS was asked to design a remedial approach for a hotspot treatment of this contamination within one of the rail tracks.ORC Advanced Socks were installed in wells for the treatment of the dissolved phase contaminants in groundwater. The quick application showed the ease of installation, with only validation of the groundwater required to provide evidence of treatment. The ORC Advanced provided a >90% reduction in the groundwater within the hotspot area.

In-Situ Bioremediation at a French Airport in Southwest France

Successful standalone treatment of a large plume with difficult site conditions. With a longevity of minimum 4 – 5 years, 3DMe was selected to remediate the site from a single application. This removed the need for further application on this busy factory site.

and allowed the contamination within the overlying clay layer to be addressed, avoiding a rebound due to back-diffusion.Read More

Treatment of a Widespread Plume Beneath a Metropolitan Area in Italy

A widespread plume of chlorinated solvents (CHC) has been monitored for more than a decade underneath the train station and extending out under the surrounding urban area of Bologna, Italy. The intention on this site was to treat all of the accessible ‘hot spots’ present within the plume, with the first area being used as a pilot test to confirm dose and distribution.Read More

Remediation of a Diesel Plume at an Active Rail Facility in Yorkshire, UK

Enhanced Natural Attenuation of a TPH Plume using ORC Advanced as part of an integrated treatment train solution provided by AECOM.Read More

Remediation of Chlorinated Hydrocarbons at Manufacturing Facility, UK

AECOM successfully applied a phased treatment train solution for chlorinated solvents under an operational manufacturing facility. After an initial Dual Phase Extraction (DPE) phase, REGENESIS and AECOM devised a remedial design based on the updated Conceptual Site Model including In Situ Chemical Oxidation (ISCO) using RegenOx®, and Enhanced Reductive Dechlorination (ERD) using HRC®, to treat the residual contamination in groundwater.

Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español