HRC Barrier Applied Successfully Reduces TCE Levels to Non-Detect in Fractured Bedrock Site

Project Highlights

- Based on successful pilot test results, full-scale implementation of HRC barrier was applied

- TCE levels reduced by 99% within one year & at non-detect levels within 18 months

- Innovative design was effective in addressing contaminants of concern

Project Summary

At a manufacturing facility in Virginia, HRC® was injected into a crystalline bedrock aquifer contaminated with TCE and its daughter products. The industrial site had been in operation for over 30 years. Groundwater flow was controlled by fractures in the crystalline rock with little to no permeability present beyond these fractures. Contamination levels had reached a high of 220 ppb of TCE. REGENESIS® recommended an HRC pilot test in conjunction along with excavation of the impacted geology.

The design using an HRC barrier focused on reducing TCE concentrations within a bedrock formation. Injection of HRC was accomplished using a single and double packer array and an appropriate delivery pump. The packer application method allowed HRC to be focused on the fractures controlling groundwater flow. A single packer system was used to apply HRC to the lower fracture (32 ft. bags) and a double packer system was used to apply HRC to the upper fracture zone (22-28 ft. bags). HRC was effectively injected at volumes ranging from 120-160 pounds per injection well.

Technology Description

HRC® is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils.

Results

Over a period of less than a year, TCE concentrations decreased from 220 ug/L to 3 ug/L (a 99% reduction) and within 18 months, were at non-detect levels. Over the same period, concentrations of daughter products DCE and VC initially increased as expected (due to sequential reductive de-chlorination) but then subsequently decreased. In addition, concentrations of the de-chlorination end product, ethene, increased by 10x during the same time frame. The pilot test resulted in favorable results and continued through full-scale implementation. HRC’s proven effectiveness at treating chlorinated solvents within the fractured bedrock system and its significant cost advantage over all other technologies allowed the environmental firm to select HRC for their full-scale implementation resulting in reducing concentrations to non-detect and meeting site goals.

Back Diffusion of VOCs from a Fractured Sandstone Aquifer Treated at Former Industrial Facility

Project Highlights

Large-scale pilot tests confirm management of chlorinated VOC back diffusion from fractured bedrock aquifer

- Tests concluded degradation along biotic and abiotic reductive pathways

- Advanced sorbent technology extends treatment longevity to manage to manage long-term back diffusion

Project Summary

Fractured bedrock aquifers can be extremely heterogeneous which not only results in complex dissolved plume behavior, but can also hinder in situ remediation efforts that rely on an injection of amendments to promote microbial activity and abiotic degradation. However, due to the potentially high cost of a pump and treat remedy at a former industrial site in Arkansas, WSP determined that an in situ pilot test with advanced substrates was warranted.

At the Arkansas site, a 2016 pilot study was conducted using a multifunctional amendment formulation. REGENESIS® 3D-Microemulsion®, BDI Plus®, and CRS® were injected to remediate affected groundwater within a fractured sandstone bedrock aquifer impacted by chlorinated solvents. The contaminants at the site included trichloroethene (TCE), 1,1,1-trichloroethane (TCA), and degradation products. The plume on site underlies several developed properties and threatens a stream located approximately 1,500 feet from the source area. Results of the first pilot study yielded an 82% reduction within 9 months was measured approximately 80 feet from the application location.

A second pilot study was undertaken in 2017 to emplace a sorbent technology with long-lasting treatment capacity (PlumeStop®) on bedrock fracture faces to manage back diffusion from the bedrock primary porosity. This test also included the addition of bioremediation amendments to permanently degrade the sorbed contaminants. The 2017 treatment included PlumeStop and bioremediation amendments. After only one month, an 81% reduction was achieved in samples located 50 feet downgradient.

Preliminary indications of these amendment formulation tests are extremely promising in treating contaminant back diffusion emanating from the fractured bedrock matrix in this aquifer. WSP is confident that favorable performance monitoring results will continue and the full-scale remedy for this complex geologic setting will include REGENESIS products that extend treatment longevity.

Technology Description

PlumeStop® is an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation.

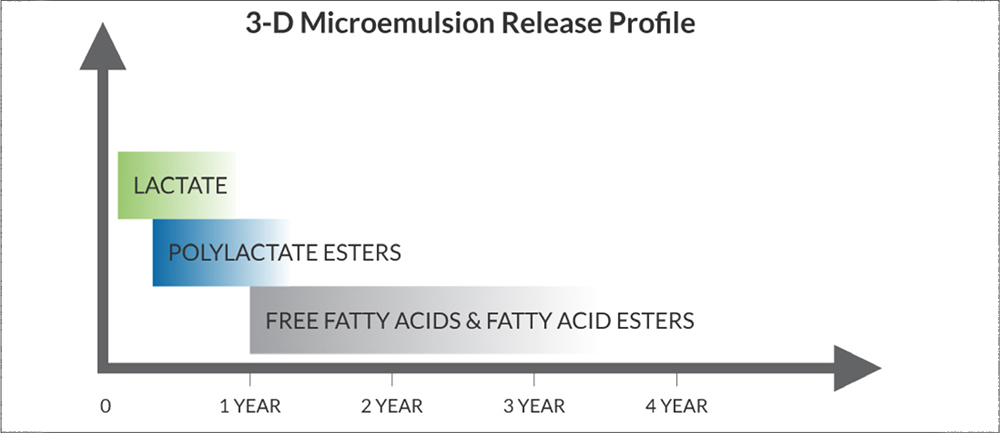

3-D Microemulsion® is an engineered electron donor material that offers a novel three-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory emulsified product.

HRC® is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils.

BDI Plus® is designed for use at sites where chlorinated contaminants are present and unable to be completely biodegraded via the existing microbial communities.

CRS® is a liquid iron-based reagent for the enhanced biogeochemical in situ chemical reduction (ISCR) of chlorinated contaminants.

Smear Zone Treatment at Former Factory in Madrid, Spain

At a former chemical works near Madrid, high soil and groundwater contamination had been observed at, and just below, groundwater level. In Situ Chemical Oxidation (ISCO) using RegenOx, was applied to target these and to avoid excavation into the saturated zone.Read More

Ongoing Remediation of TPH, BTEX and CVOC at Volvo Car Gent, Belgium

Ongoing remediation of mixed plumes at Volvo Car Gent in Belgium. Total BTEX Concentrations have seen a more than 99% reduction in the first pilot test. Read More

BTEX and CVOC Plume Treatment under Active Industrial Facility

PlumeStop Pilot proves stringent concentration targets for BTEX and CVOC are achievableRead More

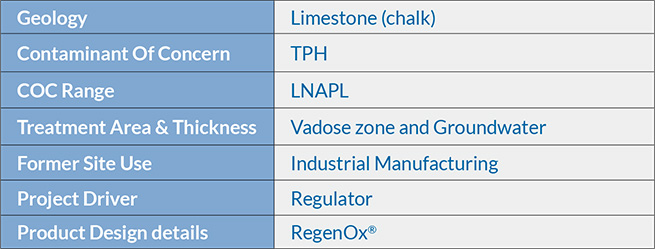

LNAPL Remediation in a Chalk Aquifer under a Residential Property

with BRD Environmental Ltd

Introduction

After completion of the redevelopment of former industrial land into residential properties, significant Total Petroleum Hydrocarbon (TPH) contamination was discovered in the groundwater and smear zone under the gardens and parking area. The TPH comprised diesel and heating oil, with up to 40mm of Light Non- Aqueous Phase Liquid (LNAPL) evident in the monitoring wells.

The original source of contamination (an above-ground storage tank) was removed during redevelopment; however, residual contamination had migrated into a lower chalk aquifer and after the discovery of LNAPL present within chalk fissures above the water table, remedial action was required.

Figure. 1 On site RegenOx® injections using a direct push injection rig

Figure. 2 Total TPH Concentration in Boreholes BH13 and BH14

Method

The two most highly contaminated boreholes, BH13 and BH14, were located in a back garden and a car parking space. As space was restricted and to minimise the impact of works on residents, an in situ remedial technique was deemed the only viable option.

RegenOx® is an In Situ Chemical Oxidation (ISCO) reagent capable of treating high concentrations of a broad range of soil and groundwater contaminants including both petroleum hydrocarbons and chlorinated solvents.

The alkaline nature of RegenOx enabled its use within the chalk aquifer without adverse matrix reaction.

The ability of RegenOx to deal with both LNAPL and dissolved phase contamination avoided the use of ‘pump and treat’ equipment onsite. This minimised both operational and disposal costs and negated the requirement for bulky equipment on the site. Applications were completed using a small direct- push injection rig (Figure 1). This meant that the resident’s parking area could be reinstated at the end of each working day, so that they could park overnight as usual.

The RegenOx injections were completed in three events at two week intervals during June and July.

Results

A 99% reduction of TPH concentrations occurred rapidly in boreholes BH13 and BH14 following the injection works, with LNAPL no longer observed on the site.

Conclusion

A short campaign of RegenOx applications at the site completely removed any LNAPL and reduced TPH concentrations by 99% in a chalk aquifer and regulatory closure was achieved within a short period.

At £55,000 for the product and application work, the project was extremely cost effective, avoiding the use of operational and disposal costs on the site. The in situ nature of the works avoided disturbing or inconveniencing residents living on the site.

Chlorinated Solvent Remediation via ISCO at Former Industrial Site in Barcelona, Spain

Due to the target area extending under the footprint of the proposed building and the short build programme, a grid of horizontal injection pipes was installed in the subsurface prior to construction commencing. The grid was then linked to a remote injection location, so that when the new building was constructed, injection was simultaneously completed underneath it. The intention of the remediation was to achieve a rapid and significant reduction of the contaminant concentrations in the groundwater. PersulfOx was selected as the preferred ISCO agent due to its efficiency and capability of moving through the vadose zone into the groundwater, guaranteeing a good distribution.Read More

In Situ Remediation at an Active Manufacturing Facility in Northern Italy

Historic leakages at an active manufacturing facility in Northern Italy resulted in the underlying groundwater becoming impacted with hexavalent chromium (Cr(VI)) contamination of up to 2,000 μg/L, and chlorinated solvents (CHC) concentrations of up to 10,000 μg/L. 3-D Microemulsion® (3DMe) and Metals Remediation Compound (MRC®) were selected to remediate the site because of:Read More

Pilot Test of ISCO Soils Treatment in Industrial Area, Italy

At a former oil refinery in Italy, leaks from several large Aboveground Storage Tanks (ASTs) had caused the soil to become impacted with fuel. Concentrations of up to 3,000 mg/kg of petroleum hydrocarbons were measured in the unsaturated soil within the immediate vicinity of the ASTs. Read More

Enhanced Reductive Dechlorination in a Fast Flowing Aerobic Aquifer

Introduction

Enhanced Reductive Dechlorination (ERD) through biostimulation and redox manipulation is a well-established treatment method for chlorinated solvent contamination in groundwater. However, it is sometimes considered inappropriate where natural conditions are not already conducive to anaerobic attenuation, such as highly aerobic aquifers or fast-flowing groundwater. The use of microbial assays or PCR testing can potentially reinforce this view, when baseline sampling shows little or no evidence of the presence of dehalorespirators or active reductive dechlorination. However, ERD can be achieved in these situations through the creation and maintenance of the ideal redox conditions, coupled with a long term supply of terminal electron donors. Regenesis has successfully remediated many sites via ERD, where initial conditions appear unpromising, using Hydrogen Release Compound (HRC) and 3-D Microemulsion (3DMe) substrate technologies. This case study exemplifies this approach and presents data from a site where treatment is ongoing.

Fig. 1 Metal fabrication works

The Site

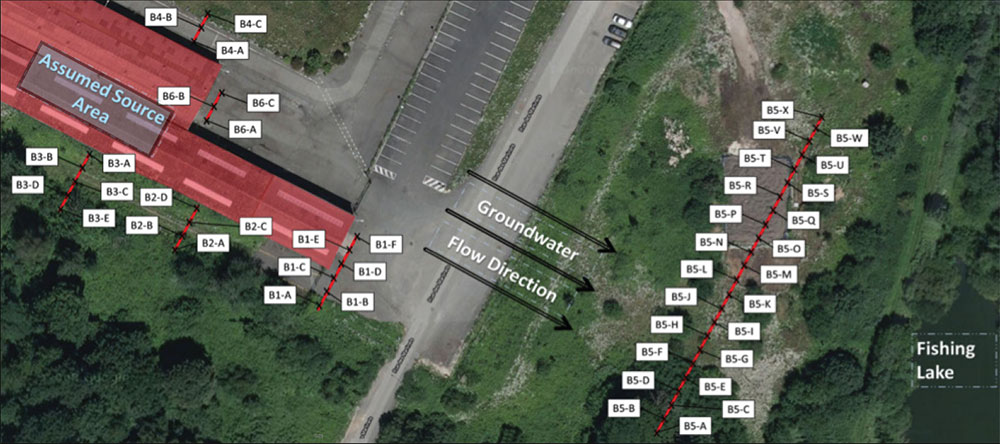

The groundwater under an active metal fabrication works in eastern France was impacted with tetrachloroethylene (also known as perchloroethylene (PCE)) following historic leaks and spillages at the facility. The underlying aquifer comprised a highly permeable sandy formation, which allowed a high groundwater seepage velocity of greater than 300 m/year. This had resulted in an extensive dissolved phase plume forming on the site. The contamination extended over 260 m, with concentrations of up to 1,300 μg/L and no obvious source, although multiple areas were suspected. The contamination also extended from the top of the groundwater at 3 m BGL to approximately 10 – 13 m BGL (chlorinated solvents, having a high specific gravity and a low viscosity, tend to move downwards through the water column). The groundwater in ux was also highly aerobic, hence very little natural biological attenuation of the PCE was occurring.

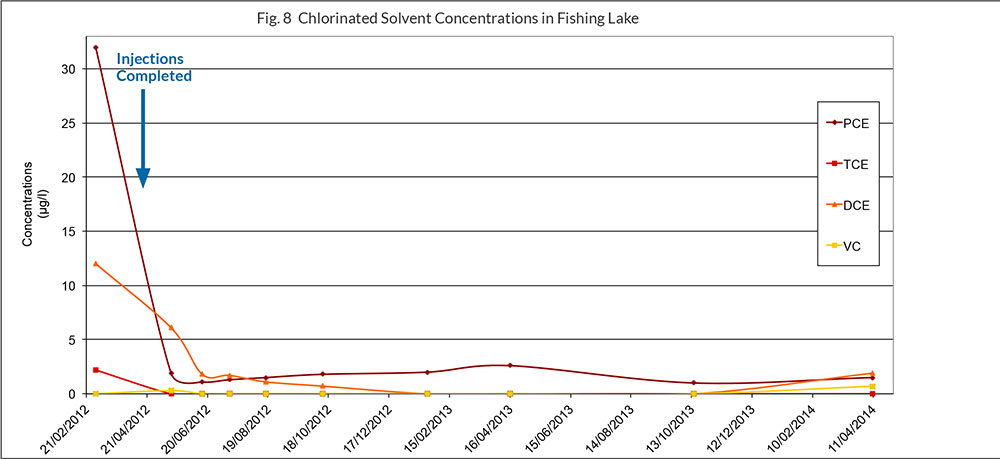

The main risk from the PCE plume was due to its migration beyond the site boundary into a nearby fishing lake. Where the contaminant concentrations could actually be measured in the lake water (32 μg/L PCE). The contamination also potentially posed a human health risk to site.

Fig. 2 Impacted nearby fishing lake

Remediation Strategy

Studio Maffezzoli and Regenesis designed, and Ortec implemented, a safe, economical and cost effective in situ ERD strategy, which was new to this part of France.

Although no site specific target values were set for the project, the intention of the remediation strategy is to prevent offsite migration of the plume, thereby mitigating the impact to the fishing lake and secondary, and to reduce the risk to human health onsite.

There are several potential spill locations at the site and as the high seepage velocity has created a large plume with low concentrations, it has proved difficult to accurately delineate the source areas. The buildings and activity on the site have also made access for site investigation, difficult in some areas. Therefore, a staged remedial strategy has been adopted, with a series of barriers used to treat as much of the plume as can be accessed in an economical manner. As monitoring continues, it may be the case that more recalcitrant areas may be observed, which will help to give better resolution on the source locations. Further site investigation during the validation period can also then be used to determine if a second locally tailored dose may then be completed in these areas.

The remedial approach was also intended to minimise the disturbance to this busy, active facility. It was therefore decided to use 3D Microemulsion (3DMe) as this stimulates ERD from a single application for up to 5 years (although it may be expected to be slightly less in a fast flowing site such as this), minimises the number of injection locations and avoids the use of any physical abstraction equipment at the site.

Fig. 3 The buildings and activity on the site made access difficult in some areas

Fig. 4 3DMe Electron Donor Release Profile

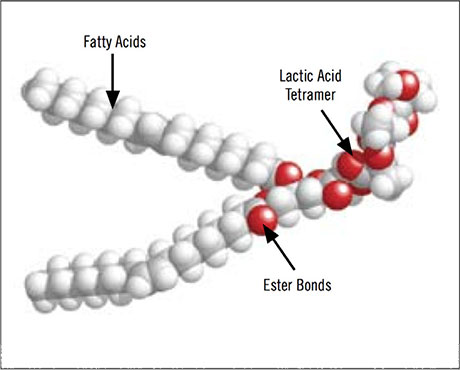

3DMe provides three stages of electron donor release from a single concentrate of specially designed polar molecules. When mixed with water on site, 3DMe forms a high-volume microemulsion, without the requirement of emulsifiers. Upon injection into the groundwater, 3DMe initially moves out into the formation and adsorbs to the soil particles. As the molecule is designed to be appropriately soluble, it then gradually dissolves back into the groundwater, where it ferments to drive ERD, but also reaches its critical micelle concentration (300 ppm), reforms as a microemulsion and moves further out from the injection point.

This process repeats to ‘self-distribute’ the 3DMe over large distances within the subsurface, without it washing away. This mechanism allowed for wider injection spacing which reduced the number of injection locations. This then allowed both the cost and disruption to the site to be minimised. The ability of 3DMe to coat the subsurface without being washed away, whilst still being soluble enough to provide an effective terminal electron donor concentration in the groundwater, made it ideal for this fast flowing site.

Fig. 5 3DMe Molecular Structure

Fig. 6 Treatment zones (‘barrier’) locations

The first phase of the treatment was applied in March 2012. 3DMe was applied in six ‘barriers’ installed perpendicular to the flow of the groundwater. Each injection involved driving a direct push injection rod into the subsurface and applying the requisite dose across the vertical target zone. The injections were then repeated in a row across the width of the plume. The 3DMe then self-distributes from these locations to create a wide radii of influence (ROI), which interlock, creating an anaerobic treatment zone in which reductive dechlorinating bacteria can flourish.

As the groundwater flows through the treatment zones (or ‘barriers’, see Fig. 6), the dehalogenators biologically degrade the dissolved contamination through reductive dechlorination, enhanced through the creation and maintenance of ideal redox conditions and a continual supply of dissolved hydrogen. A barrier approach was chosen to minimize costs whilst still ensuring treatment of the entire plume, through migration of contamination between barriers into the next treatment zone downgradient. In order to remediate a plume of 12,000 m2 to a depth of 13 m BGL, the treatment comprised a single injection into 45 points, spaced 4 m apart within 6 barriers. The works took only 15 days to complete, with in situ treatment expected to last several years.

Results

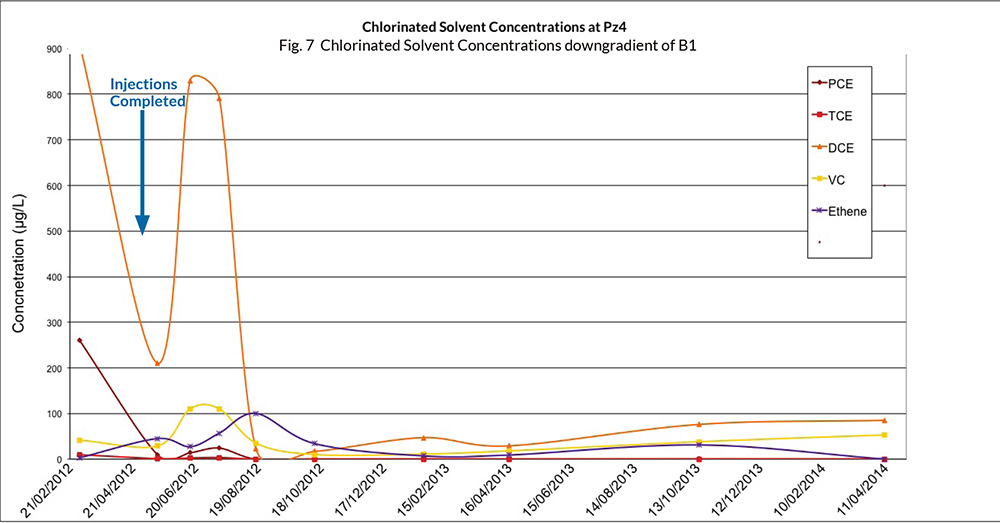

Following the application, a rapid reduction in PCE concentrations was seen in all wells downgradient of the barriers across the site. In Fig. 7, it can be seen that concentrations of PCE are non-detect after only 5 months. The application resulted in the sequential production and breakdown of daughter products and an increase in ethene production showing that full reductive dechlorination is being achieved.

Ongoing low levels of DCE and VC downgradient of the barrier show that there is a small residual in ux of PCE/TCE into the barrier, which is being fully dechlorinated. Ortec are completing further SI in order to locate the source and target further treatment.

In Fig 8, it can be seen that the PCE concentrations in the fishing lake were rapidly reduced after the application and have remained low ever since. The breakdown products have also reduced to almost non-detect and remain at a very low level. With the onsite barriers remediating the contamination before it reaches the lake, the residual concentrations in the lake water may be expected to attenuate over time.

Conclusions

24 months after treatment, the concentration of PCE onsite has been dramatically reduced on the site and within the fishing lake, without the build- up of daughter products. In the monitoring locations downgradient of the onsite barriers, parent compound concentrations have been reduced to non detect, preventing any further contaminant egress from the site. With only 15 days of onsite works, two years of remediation has so far been achieved, overcoming challenging aquifer conditions to successfully create and maintain ERD treatment.

Further intrusive investigation has recently started to locate any residual source areas on the site, which can then be accurately targeted. In the meantime, the 3DMe product applied on the site will continue to remain active for many months/years to come, continuing to degrade any contaminant in ux and protect both the offsite environment and site personnel.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español