Roadside Fuel Transport Spill Treated with Combined Remediation Approach

Project Highlights

- Combined remediation approach treats contaminants that remained following emergency excavation

- RegenOx® and ORC Advanced® selected to eliminate need for dedicated groundwater treatment infrastructure

- BTEX levels reduced by 97% to below non-detect levels in the two highest concentration wells

Project Summary

A rural site located in south-central North Carolina required remediation to treat petroleum contamination from an overturned tanker truck. Excavation activities during an emergency response removed much of the contaminant mass, however additional contamination in soil and groundwater remained after the excavation was completed.

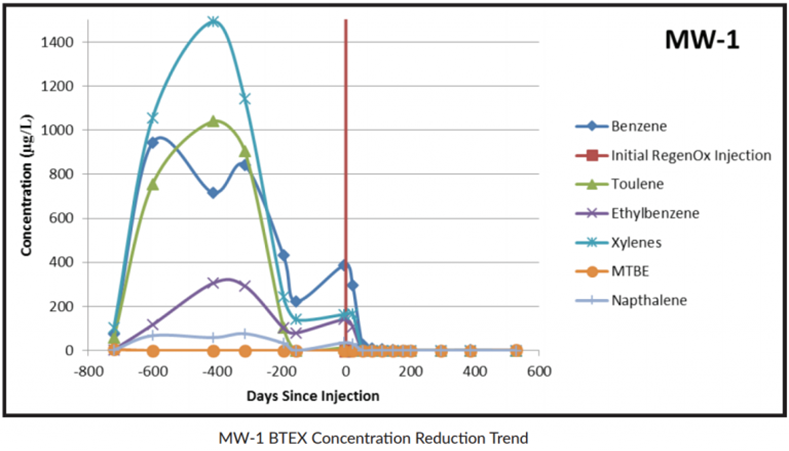

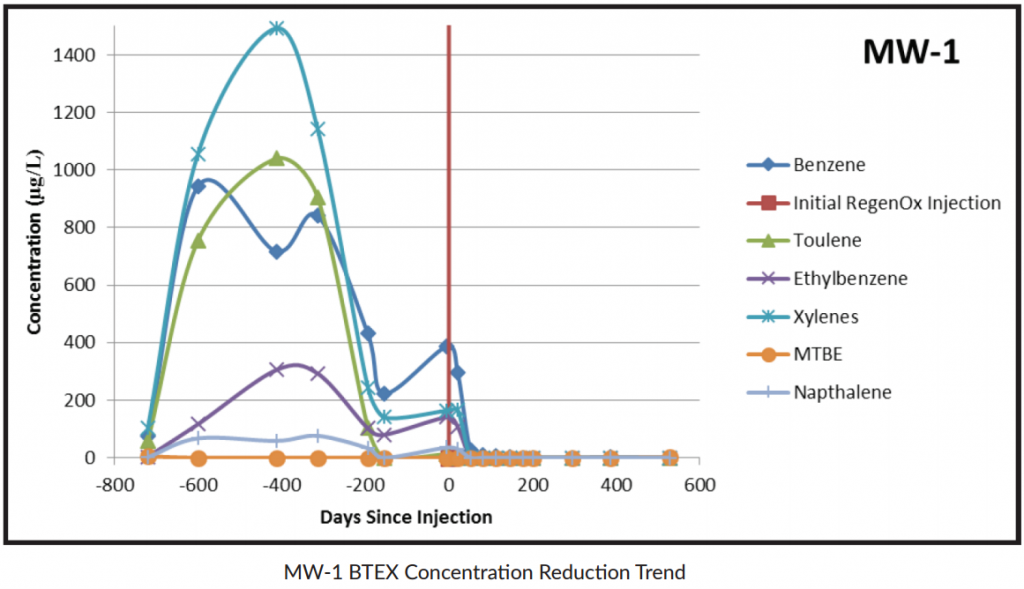

In the two highest-concentration wells, total BTEX averaged more than 1,300 μg/L in the four quarterly groundwater monitoring events prior to treatment.

A combined chemical oxidation and aerobic bioremediation treatment was employed to eliminate the need for dedicated groundwater treatment infrastructure at this roadside location to advance the site to regulatory closure.

The products selected were RegenOx, an in situ chemical oxidant, and ORC Advanced, an enhanced aerobic bioremediation product. The treatment covered a 3,900-square-foot area through 30 direct-push injection points in the former spill area.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

Results

Within 18 months of treatment, the site was under natural attenuation monitoring prior to regulatory closure with five of the six wells already below stringent regulatory requirements.

Excavation Treatment Reduces Contamination Below Clean-Up Target Levels

Project Highlights

- Remediation activities included excavating a 1,600-square-foot area contaminated with BTEX and TPH.

- ORC Advanced Pellets applied on-site to stimulate aerobic biodegradation during backfill activities.

- Two monitoring wells reduced to below groundwater contaminant targets.

Project Summary

The Bryant Grocery and Saw Co. site in the Florida Panhandle was the subject of excavation activities to remediate significant BTEX and TPH contamination as a result of historical releases from gasoline underground storage tanks (USTs). Excavation activities were planned for an area of approximately 1,600-square-feet to a depth of 14 feet below ground surface.

Remediation Approach

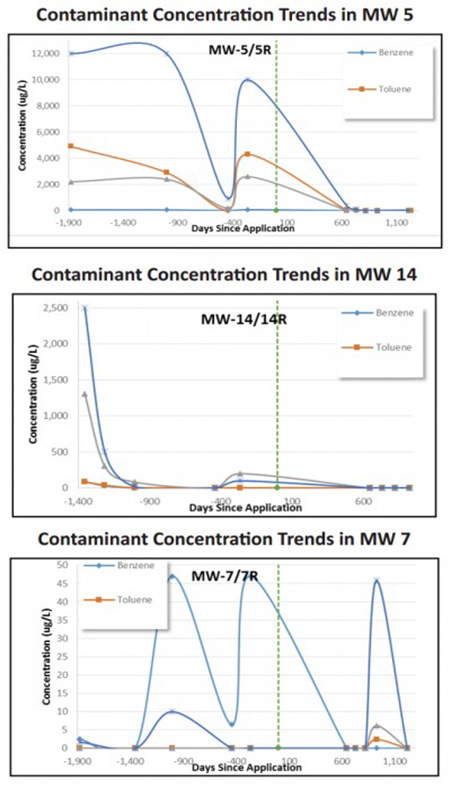

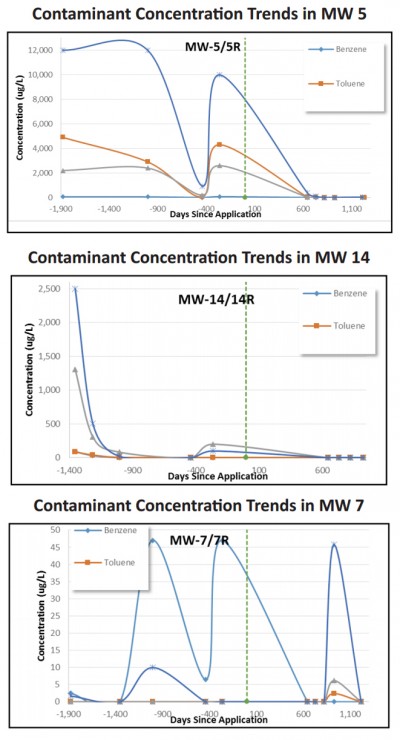

During backfill activities, ORC Advanced Pellets were added to provide a long-term source of oxygen to promote aerobic biodegradation of residual, dissolved-phase petroleum constituents remaining in the excavation area. A total of 520 pounds of ORC Advanced Pellets were applied to the saturated zone of the excavation. Both MW-7R and MW-14R have seen BTEX, TRPH, and MTBE reduced to stringent groundwater quality standards for Florida (Groundwater Contaminant Target Levels, or GCTLs). In MW-5R, Total Residual Petroleum Hydrocarbons (TRPH), MTBE, benzene, and ethylbenzene have been reduced to below GCTLs. Toluene and xylenes concentrations remain slightly above GCTLs but have declined by more than 99% related to both constituents.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration

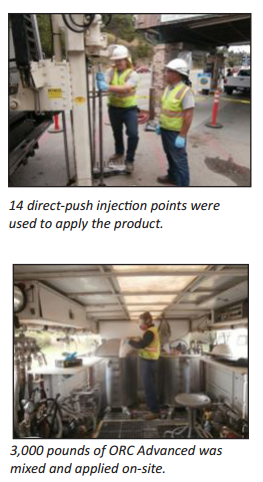

Residential Property Treated for TPHd Concentrations in Groundwater

Project Highlights

- Excavation and remediation injections performed in a tight residential setting with intense local community involvement.

- Treatment included shoring/excavation, soil handling and off-site disposal, in situ chemical oxidation (ISCO), bioremediation and sewer replacement.

- Groundwater sampling post-remediation indicates an overall decrease in TPHd concentrations and monitoring is ongoing.

Project Summary

An underground heating oil storage tank contaminated the groundwater below a residential property in Northern California. The two-story home, located near a downtown beach community, had a 100-gallon heating oil tank that was removed in 1994. Site investigation and groundwater monitoring activities were conducted since the removal, when apparent petroleum hydrocarbon impacts were identified. TPHd concentrations of 3,300 ug/L were detected on-site.

Remediation proved to be difficult considering the location of the residential property. The home was surrounded by other residences on three of its corners, with a bed and breakfast and swimming school located to the northwest of the property. A tight injection approach was required so the neighboring properties were not disturbed.

Remediation Approach

To meet the objective mass reduction of residual TPHd in both soil and groundwater, the remedial approach combined excavation/shoring and removal of TPHd impacted soils. It also included ISCO using RegenOx® and bioremediation using Oxygen Release Compound (ORC Advanced®). Approximately 233 cubic yards of soil were removed. A total of 2,350 pounds of RegenOx Part A and 1,320 pounds of Regenox Part B, along with 716 pounds of ORC Advanced® in slurry form, was injected into the subsurface via 16 direct-push injections.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

ORC® Advanced Pellets Utilized as Part of Combined Remedy Approach at Ohio Brownfield’s Project

Project Highlights

- Ohio VAP Certified Professional specified ORC® Advanced Pellets in Remedial Action Plan for purpose of obtaining grant through the Clean Ohio Revitalization Fund (CORF).

- $1.98 million in brownfield’s funding was granted through CORF as a result of Proposed Remedial Action Plan.

- Approximately 18,000 pounds of ORC® Advanced Pellets were applied to the base of 5 former underground storage tank excavation sites to address residual TPH and PAH impacts in groundwater

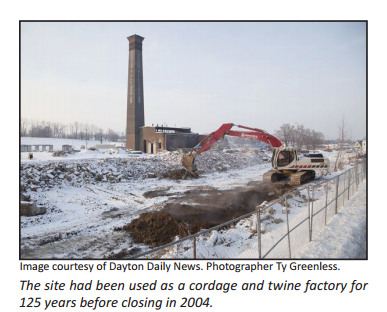

Project Summary

The site, a former cordage and twine factory in Ohio, was closed in 2004 after 125 years of operation. The city and developer secured $1.98 million in brownfield’s funding through the Clean Ohio Revitalization Fund (CORF). These funds were secured for demolition and remediation activities at the site included but not limited to asbestos removal, underground storage tank removal, and contaminated soil excavation and demolition activities.

Remediation Approach

Approximately 18,000 pounds of ORC Advanced Pellets were specified by the Ohio VAP Certified Professional responsible for this project. Per the CORF remedial plan the pellets were applied to the base of 5 former underground storage tankexcavation sites. As part of this combined remedy approach (excavation + biodegradation), ORC Advanced Pellets were included to promote enhanced aerobic biodegradation of residual TPH and PAH impacts in water for a period of 9-12 months.

Technology Description

ORC Advanced® Pellets (ORC-A Pellets) are a pelletized version of REGENESIS’ widely-used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications. ORC Advanced Pellets are approximately 3-10 mm in size.

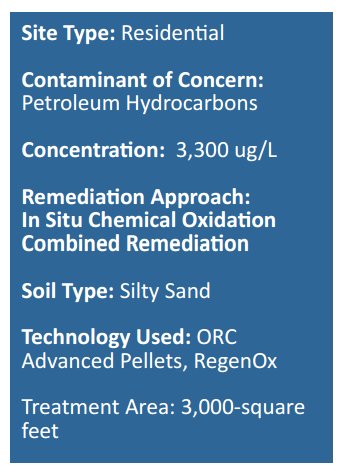

Combined Technologies Treat High TBA Levels

Site Closure Pending at Active California Retail Petroleum Service Station

Project Highlights

- A range of various remediation approaches were applied at the site over a span of 20 years.

- Enhanced Aerobic Biodegradation (EAB) remediation approach replaces soil excavation plan at site.

- Site closure pending.

Project Summary

An active service station in Southern California was contaminated with high levels of TBA and TPH-g. Various active remediation approaches took place on-site for nearly 20 years including excavation of the underground storage tanks and dispensers, soil vapor extraction and groundwater pump and treat. Although the active remediation reduced concentrations at the source, contamination levels remained high. Regenesis became involved with the site in 2011 and after two applications of enhanced aerobic biodegradation using ORC® Advanced and RegenOx®, site closure is pending.

Remediation Approach

In 1995, the underground storage tanks and dispensers were excavated and 257 tons of contaminated soil was removed. From 2003 to 2009, dissolved oxygen injection was applied into seven injection wells and in 2009, over 6,000 gallons of water was extracted from one well. In November 2011, Regenesis became involved in the project and proposed a combined remedies approach.

The remedy implemented at the site from November 2011 through November 2012 included introduction of a controlledrelease molecular oxygen into the subsurface water to promote bio-degradation of the fuel hydrocarbons. The implementation of the remedy was completed in two phases with the initial injection activities being completed in November 2011. A second injection event was completed at the site in November 2012. Approximately a total of 6,000 pounds of ORC Advanced and 480 pounds of RegeneOx were applied on-site.

Contaminant concentrations were analyzed in the most recent monitoring events and compared to pre-injection concentrations. Results for performance monitoring well MW 1 were the most significant as all contaminant concentrations decreased to below regulatory limits (Table 1). Closure has been requested and is currently pending.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Combined Remedies Replace Costly Mechanical Remediation Systems

RegenOx® and ORC® Advanced Treat MTBE/TBA at Five Active California Service Stations

Project Highlights

- In Situ chemical oxidation (ISCO), enhanced aerobic biodegradation replaced costly mechanical remediation systems.

- Underground infrastructure required extra precaution when applying remediation reagents on each site.

- Site closure or review of site closure at all five service stations

Project Summary

Five sites in Orange County, CA were selected for remediation using ISCO and enhanced aerobic biodegradation. All of the selected sites were gasoline service stations that were contaminated with low levels of hydrocarbons methyl tertiary butyl ether (MTBE) and elevated levels of the MTBE biodegradation daughter product tertiary butyl alcohol (TBA). The initial remediation approach consisted of soil vapor extraction, air sparging and dual phase extraction; however, contaminant concentrations remained elevated, impeding regulatory closure.

The decision was made to transition from mechanical-based remediation systems using a combination of ISCO and enhanced aerobic biodegradation to achieve site closure criteria with various regulatory agencies.

Remediation Approach

Initial mass reduction was achieved using mechanical systems, however concentrations remained too high for regulatory closure. The goal was to reduce the remaining levels of petroleum hydrocarbons, MTBE and TBA using RegenOx and ORC Advanced. The service station included up to three direct-push injection applications of the reagents into areas where underground infrastructure was present on each site. RegenOx and ORC Advanced are both highly compatible with subsurface infrastructure so it was more of a challenge from a physical injection vantage. O&M strategy required monitoring of REDOX and microbial shifts. All five sites have been closed or under review for closure under the local regulatory agencies.

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Dissolved-Phase Petroleum Hydrocarbons in Clay Treated with Enhanced Aerobic Biodegradation Using ORC® Advanced

Site Closure Pending Post-Treatment at California Retail Store Location

Project Highlights

- Dual-phase extraction had been used on-site, however BTEX contamination concentrations remained high.

- Enhanced aerobic biodegradation using ORC Advanced applied via directinjection into clay soils.

- Post-ORC Advanced Application, BTEX groundwater concentrations below 10 ug/L.

Site closure pending.

Project Summary

The Cambria General Store in Central California had a history of petroleum hydrocarbon contamination. Dual-phase extraction had been used in the past to treat the site and a total of 130 pounds of petroleum hydrocarbons were removed. However, contamination levels remained above regulatory levels. Contaminant concentrations included: benzene at 310 ppb, toluene at 8,000 ug/L, ethylbenzene at 2,700 ug/L and xyelene at 12,000 ug/L. THPg levels were measured as high as 14,000 ug/L on-site. The site was successfully treated with ORC Advanced which reduced BTEX groundwater concentrations below 10 ug/L. Site closure is pending.

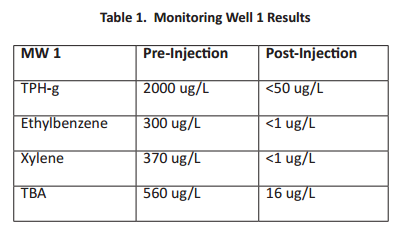

Remediation Approach

ORC Advanced was used to treat the residual dissolved-phase groundwater to California’s low threat groundwater levels. It was applied to two areas within a 1,200-square-foot treatment area. A total of 14 injection points were used to apply a total of 3,000 pounds of ORC Advanced with injection spacing of 7.5 feet on center.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration. This newly available source of oxygen is available for aerobic microorganisms to metabolize along with the unwanted petroleum hydrocarbons.

Regenesis Remediation Services™ – LNAPL Recovery at an Active Gas Station

Combined Treatment Remedies Reduce Contamination Concentrations at Michigan Service Station

Regenesis Remediation Services (RRS) was contracted to remediate a residual LNAPL and dissolved-phase petroleum plume from historic gasoline and diesel fuel releases at an active service station. RegenOx PetroCleanze™ (PetroCleanze) was chosen as the primary remediation technology to facilitate the recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure.

The design called for three (3) application events using PetroCleanze, with Oxygen Release Compound (ORC®) Advanced applied during the final application event in a down-gradient plume cut- off barrier, to promote the enhanced aerobic biodegradation of dissolved-phase petroleum hydrocarbons. Eight (8) injection/extraction wells and 28 direct-push technology (DPT) injection points were used to apply the remediation reagents in the silty-sand aquifer and smear zone. Vacuum extraction was conducted between PetroCleanze applications to recover residual freephase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring confirmed PetroCleanze was present throughout the targeted source area during each application event.

Prior to the first PetroCleanze application event, no measurable free product was observed at this site since 2006. Less than twenty-four hours after the first PetroCleanze application event, LNAPL up to three inches thick was observed in four of the eight wells. After completing the third application and extraction event, LNAPL was not observed in any wells on site, and BTEX concentrations in groundwater were showing reductions for the first time since the fuel releases first occurred. A total of 2,160 pounds of RegenOx PetroCleanze and 1,120 lbs. of ORC Advanced were injected.

Regenesis Remediation Services™ – LNAPL Recovery & In Situ Chemical Oxidation

Combined Treatment Remedies Reduce Contamination Concentrations at a Former Service Station

Regenesis Remediation Services (RRS) was contracted to remediate a dissolved-phase and residual LNAPL petroleum hydrocarbon plume resulting from historic petroleum fuel releases at a former service station. RegenOx® PetroCleanze™ (PetroCleanze) was chosen as the primary remediation technology in addition to Oxygen Release Compound (ORC®) Advanced, to facilitate recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure. ORC Advanced was applied during the second PetroCleanze application to promote the enhanced aerobic bioremediation of dissolved phase petroleum hydrocarbons.

Eighteen direct-push injection points were used to apply the reagents in the silty sand aquifer and saturated soil over the course of two application events. Vacuum extraction was conducted after each PetroCleanze application to recover residual free-phase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring during the application events confirmed PetroCleanze was present across the targeted source area. Remediation chemistry was applied via direct-push injection points with a bottom-up approach from 5 to 15 feet below ground surface (bgs). A total of 4,470 pounds (lbs.) of RegenOx PetroCleanze and 720 lbs. of ORC Advanced were injected throughout the course of the two applications.

Regenesis Remediation Services™ – PersulfOx® Treats Petroleum Hydrocarbons

In Situ Chemical Oxidation and Enhanced Aerobic Biodegradation Remediate Underground Storage Tank Site

Regenesis Remediation Services (RRS) was contracted to design and implement an in situ chemical oxidation (ISCO) treatment plan to remediate a diesel gas plume from a former leaking underground storage tank (UST) on a residential farm property. The defined treatment area comprised approximately 5,280 square feet (ft2), and the treatment of the gas plume included three application events using

PersulfOx®, with the final application immediately followed by an application with Oxygen Release Compound Advanced (ORC® Advanced). A total of 5,840.6 pounds of PersulfOx and 2,589 pounds of ORC Advanced were injected during the course of the project.

Utilizing PersulfOx remediation chemistry to distribute throughout the subsurface, 91 direct-push injection technology (DPT) injection points were advanced every 100 ft2 over the course of three application events. ORC-A was applied in 53 discrete DPT injection points approximately every 100 ft2. RRS utilized both expendable points and retractable screen-tip injection tooling to apply the PersulfOx and ORC Advanced at discrete intervals across the vertical treatment interval from 8 to 12 feet and 8 to 16 feet below ground surface (bgs) within the sandy saturated soils. Low pressures and moderate application rates were utilized to apply the remediation chemistry at up to four (4) injection point locations simultaneously. RRS personnel performed real-time reagent distribution diagnostics to optimize the distribution of the material.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español