Redevelopment of former gas works unlocked by combining technologies

Integrated remediation strategy provides rapid and cost-effective clean up

- During the construction of multiple residential dwelling it became apparent that a historical gas works had previously occupied the site.

- A targeted site investigation needed to be completed quickly to identify the areas requiring remedial action, enabling construction to continue in plots outside of the plume.

- A combined remedial strategy was required to address soil, LNAPL, DNAPL and dissolved phase contamination.

- The implementation of the treatment had to be completed around partially completed housing and live underground services.

- The remedial works had to be completed quickly in a manner as to not impact the build program.

- The strategy needed to provide appropriate protection to both human health and controlled waters.

- The need to respond and act quickly required excellent communication and good working relationships to be established between the consultant, stakeholders, regulators and multiple specialist remediation contractors and suppliers.

Remedial Approach

A wide range of remediation technologies were deployed sequentially and in parallel to provide the most rapid and cost effective clean up:

- Ex situ bio-piling of hydrocarbon impacted soils

- LNAPL skimming

- Pump and treat (P&T) of dissolved phase contamination

- DNAPL pumping and settlement/collection

- Enhanced abstraction of contaminant mass using PetroCleanze

- In Situ chemical oxidation (ISCO) using RegenOx, which is compatible with footings and services already in place

- Accelerated aerobic natural attenuation using ORC Advanced slurry

- Accelerated aerobic natural attenuation using a pelletised oxygen-release compound (ORC Advanced) placed in the backfill

- PlumeStop Liquid Activated Carbon injection to install a subsurface activated carbon filter to adsorb and biologically degrade dissolved phase contamination

- Gas vapour membrane installation

Ex situ treatment

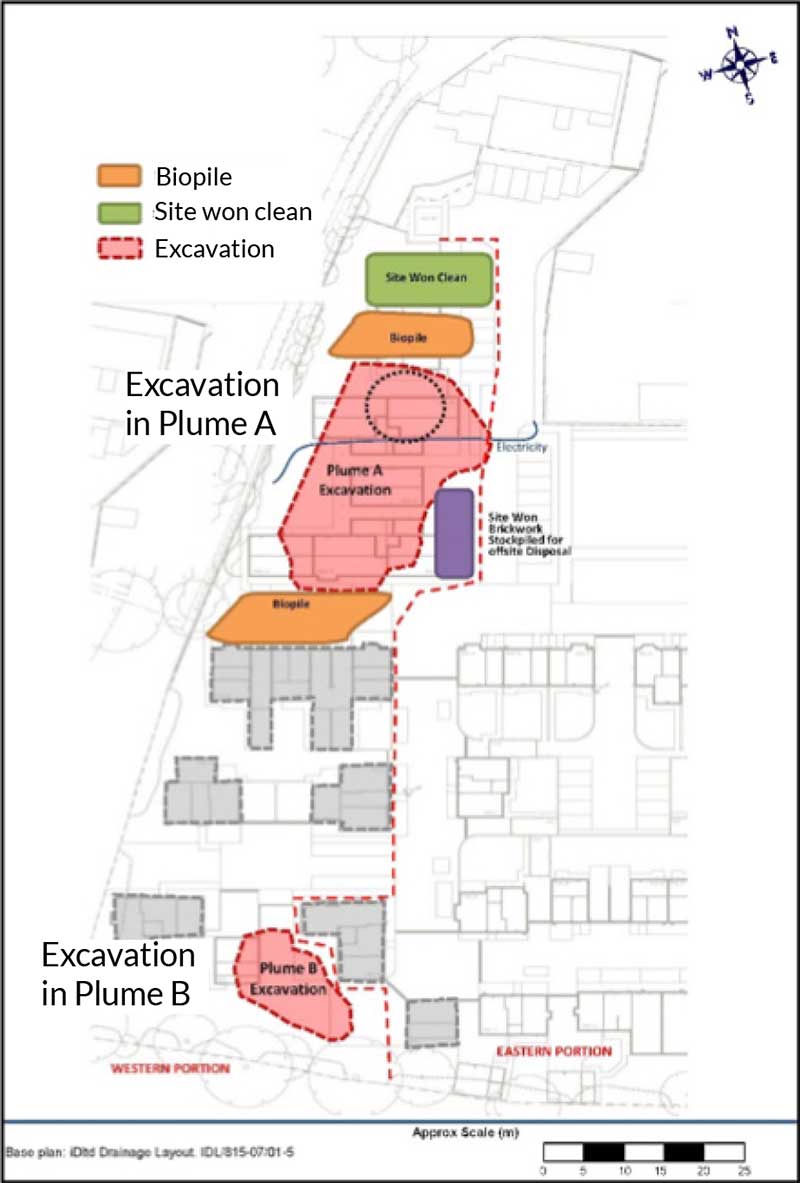

The impacted materials within the unsaturated zones within Plume A and B were excavated and placed in a biopile for onsite treatment (Figure 1). Nutrients were added and the biopile was turned until remedial targets were achieved. The soils were then backfilled under the CL:AIRE Code of Practice. Prior to backfill with the remediated soils, ORC Advanced Pellets were added to the base of the excavation. This provided a source of dissolved oxygen for up to a year, stimulating the growth of an effective aerobic biomass and accelerating the degradation of the petroleum hydrocarbon contamination.

In Situ Treatment

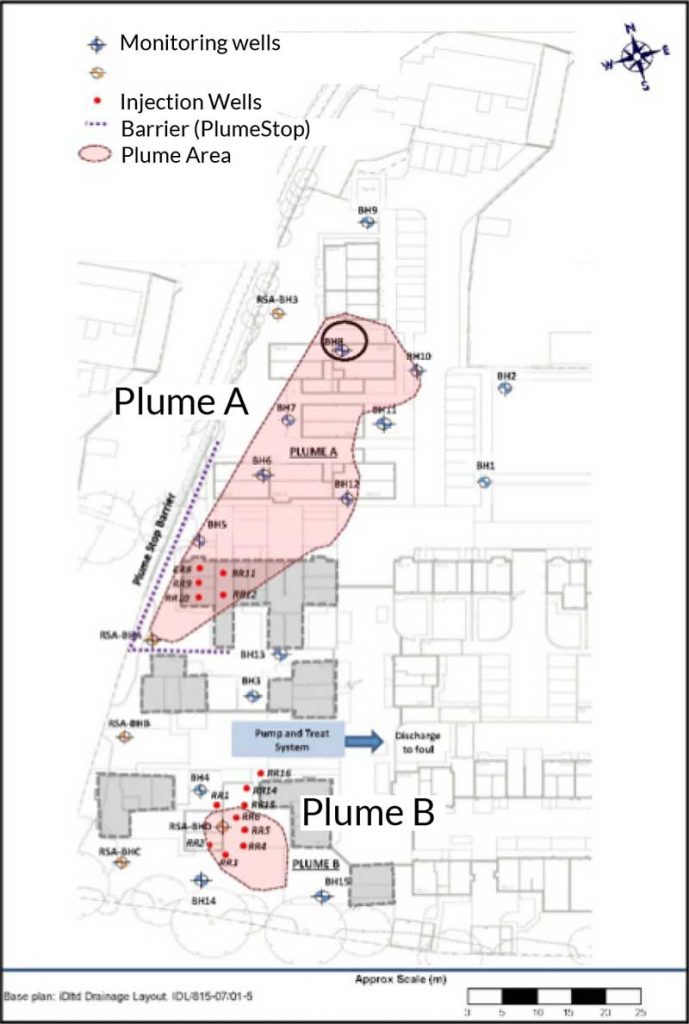

The southern part of Plume A was made inaccessible by footings and services; here in-situ treatment was completed accommodate these obstructions without compromising treatment efficacy. Within Plume B, where high levels of contamination had been encountered (Figure 2), several in situ remedial actions were taken as appropriate to concentration, location and sequence in the strategy:

- REGENESIS injected PlumeStop, a micron-scale colloidal Liquid Activated Carbon substrate along the western margin of the site via direct push to protect the offsite surface water. PlumeStop creates a subsurface activated carbon filter which adsorbs the contaminant influx, which is then degraded by the microbial growth on the carbon biomatrix. Biological degradation was also accelerated through co-application of ORC Advanced and the presence of the pelletised ORC placed in the base of the excavation upgradient, providing a controlled release of oxygen.

- Where LNAPL and high dissolved phase concentrations were observed, a network of injection boreholes were installed by Rake Remediation/REGENESIS. Many of the wells were installed by removing suspended floors and lifting in a mini-rig to complete the drilling beneath partially constructed dwellings. Through these wells, multiple applications of RegenOx were completed. This in situ chemical oxidant was chosen as it was safe to handle on this busy site and would not corrode services installed at the site, nor would it be detrimental to the concrete footings.

- Following the ISCO, ORC Advanced slurry was injected to enhance the natural attenuation (ENA) of the residual dissolved phase contamination to low levels.

- In Plume B, high levels of contamination in the form of both L- and DNAPL were encountered. This was removed using a P&T system augmented with PetroCleanze, an inorganic surfactant that uses a high pH, carbonates, silicates and partial oxidation to remove contaminants from soils. The PetroCleanze was injected to produce a temporary desorption event, which once observed, allowed the P&T system to be switched back for a short period to remove the contamination. This process was repeated three times to maximise the efficacy of the P&T and shorten the treatment programme.

- Once the NAPL was removed, multiple rounds of RegenOx were completed, followed by ORC Advanced via injection through wells.

- Long term groundwater monitoring programme was put in place to monitor the effectiveness of the clean-up.

Results

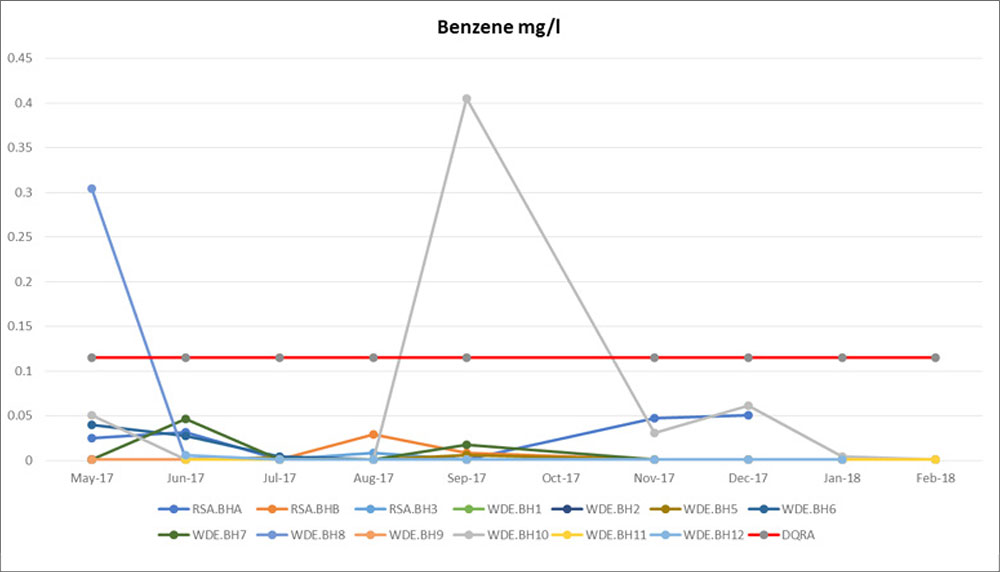

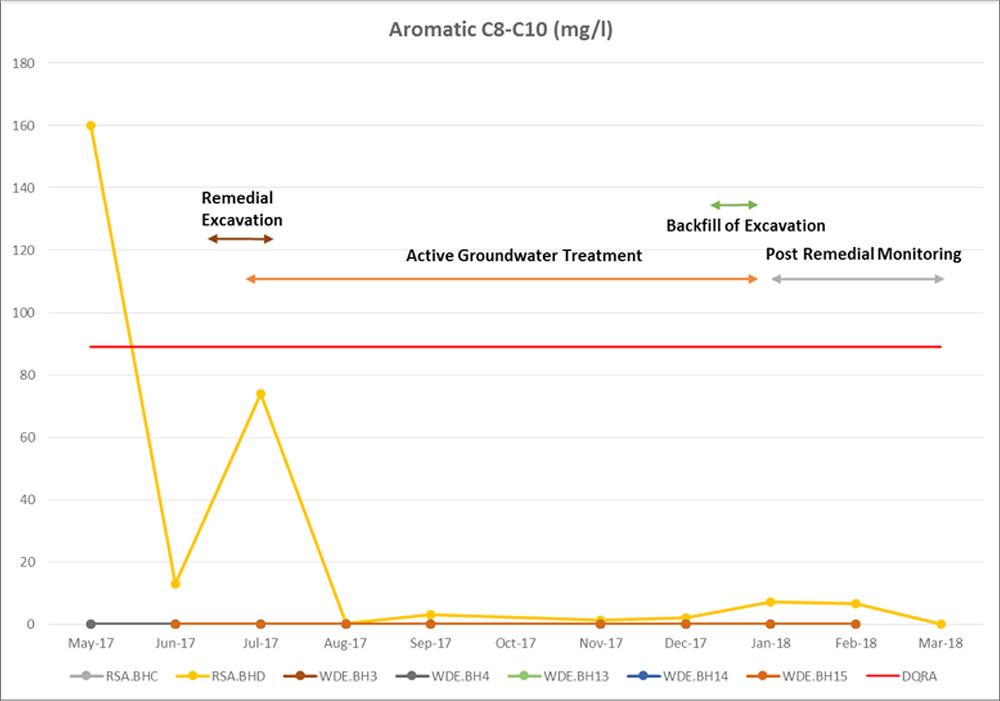

The following graphs (Figures 7 and 8) show the variations in concentrations for selected priority contaminants of concern over the monitoring period for Plume A and B. These show a marked reduction in the hydrocarbon dissolved phase concentrations over time, with compliance achieved with the remedial criteria.

Conclusion

Complimentary remedial technologies were combined successfully to achieve:

- Contaminant mass reduction to below remedial targets in the soil and groundwater within 6 months.

- Protection of onsite and offsite receptors.

- Written confirmation by the Environment Agency that they ‘agree with (the reports’) conclusions’ and that ‘development may proceed’.

- Remediation completed on a tight budget – as remediation had not been foreseen by the developer.

- Ex-Situ remediation of soils and their reuse on site under the CL:AIRE CoP avoided offsite disposal of ~800m3 to landfill.

- In Situ enhancement of the P&T system, minimising the time, cost and volume of abstraction required.

- By combining the technologies intelligently, both simultaneously and sequentially, the programme length was minimised – allowing construction to continue within only 6 months.

Combined Remedy Leads to Site Closure

Case study highlights:

- Significant contaminant reductions achieved in both the source area and core plume

- 8-10 weeks of time saved compared to alternative approaches

- $500,000 saved in project costs compared to alternative Electrical Resistance Heating (ERH) approach being considered

This case study reviews an active Underground Storage Tank (UST) case with the Arizona Department of Environmental Quality (ADEQ), where the site needed to meet ADEQ closure levels quickly in order to seek risk-based closure as part of a property transaction. After performing remedial assessment activities, the consulting firm Antea Group selected a combined remedy approach from REGENESIS, which included soil mixing using RegenOx® and H2O2 in the source zone and ISCO injections using PersulfOx® in the core plume. The solution from REGENESIS achieved ADEQ Closure levels for the site and now Antea Group is seeking a risk-based closure.

Combined Remedy Chosen for FDEP Innovative Technologies Program

Case study highlights:

- An in situ combined remedy approach that was chosen as the most technically-feasible and cost-effective strategy in a competitive bid scenario for the Florida Department of Environmental Protection’s Innovative Technologies Program

- High level of site complexity – flowable fill layer present over the treatment area, difficult geology (i.e., clays and limestone), and close proximity to structures, utilities and a roadway

- Use of PlumeStop, RegenOx, and ORC Advanced to successfully address a large BTEX plume

A former gas station site in Taylor County Florida had undergone prior remedial efforts over the years. The Florida Department of Environmental Protection (FDEP), through its Innovative Technologies Program, engaged the environmental consulting firm, Advanced Environmental Technologies LLC (AET) to design an alternative combined remedial approach employing PlumeStop®, RegenOx® and ORC Advanced®, to sorb, degrade, and destroy the existing petroleum contaminant plume. Prior to full-scale implementation, treatment of this site began with a thorough Design Verification Testing (DVT).

RegenOx Application Quickly and Efficiently Lowered Diesel Range Organics (DRO) to Below ADEC Requirements

Project Highlights

- Two applications of RegenOx® reduced contaminants to a level below the Alaska Department of Environmental Conservation (ADEC) standards to protect against migration to groundwater

- Completed in 8 weeks, restoring agriculture viability

- Soil was safely and efficiently cleaned preventing fuel from contaminating a nearby sensitive receptor

Project Summary

A Hydaburg site in Alaska, owned by Alaska Power and Telephone, previously housed diesel fuel generators and is now being converted into a hydro-electric plant. The land was contaminated by a diesel fuel spill requiring remediation. Approximately 1,000 cubic yards of soil were impacted and the starting concentrations of DRO were approximately 1 500 ppm. The goal was to reduce concentrations to below the ADEC standard of 230 ppm.

Due to the cold weather encountered during this project and the sensitive infrastructure in the area, it was important that the technology work effectively in less than ideal conditions. Also, the technology could not be corrosive nor generate excess heat. RegenOx, produces minimal heat and pressure, is non-corrosive, and works well at any temperature above freezing making it ideal for this project. Additionally, RegenOx is a chemical oxidant which quickly and effectively destroys a range of contaminants-in this case, DRO. The soil was screened with a trommel and RegenOx was mixed in a cement truck before being sprayed onto the soil. RegenOx was applied twice, with the applications spaced a week apart. This site required 20 lbs of RegenOx per cubic yard, in total 20,000 lbs.

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

Results

After two applications of RegenOx, the concentrations of DRO went from 1,500 ppm to below 125 ppm, satisfying the ADEC requirement of below 230 ppm, within 8 weeks. After the remediation treatment, the soil was spread out, grass was planted and is now growing at the Hydaburg site, attesting to the renewed health of the soil.

Integrated Remediation of a Petrol Filling Station, Middlesex, UK

Integrated remediation of a former petrol station using enhanced pump and treat, excavation application and barrier injection.Read More

Rapid, Effective Remediation of Free Product at an Active Rail Depot, UK

Augmented Pump and Treat, In Situ Chemical Oxidation (ISCO) and Enhanced Natural Attenuation (ENA) completed under rail lines by REGENESIS Remediation Services. Read More

Remediation of Chlorinated Hydrocarbons at Manufacturing Facility, UK

AECOM successfully applied a phased treatment train solution for chlorinated solvents under an operational manufacturing facility. After an initial Dual Phase Extraction (DPE) phase, REGENESIS and AECOM devised a remedial design based on the updated Conceptual Site Model including In Situ Chemical Oxidation (ISCO) using RegenOx®, and Enhanced Reductive Dechlorination (ERD) using HRC®, to treat the residual contamination in groundwater.

Read More

Innovative Combined Amendment Approach Successfully Applied to Treat PHC Levels

Project Highlights

- Site previously treated with a series of RegenOx® and ORC Advanced® amendments significantly reduces plume concentrations. Remaining hot spot was then treated with turn-key injection application of PersulfOx® and ORC Advanced technologies bringing closure to facility

- Successful turn-key treatment of offsite hot spot completed within five days

Project Summary

An active gas station, identified by the State of Washington Department of Ecology as one of five LUST sites within one mile of Vancouver’s three groundwater monitoring wells, had entered into the state’s Voluntary Cleanup Program (VCP) in 2006 subsequent to shutdown of the onsite air-sparge/vapor extraction (AS/VE) system. This system had historically been employed at the site to supply oxygen for remedial purposes and address subsurface contamination that was first discovered beneath the dispenser islands in 1993. While prior applications of RegeneOx and ORC Advanced were effective in mitigating onsite contamination, PHC levels remained above MTCA criteria offsite hindering achievement of regulatory closure.

Antea® Group—the environmental consulting firm charged with remediation—partnered with REGENESIS® to implement a remedial strategy and technical design, which included the turn-key injection application of PersulfOx and ORC Advanced technologies to address petroleum hydrocarbons (PHCs) using an in situ chemical oxidation (ISCO) and enhanced aerobic remediation approach. The hot spot injection application included one event of PersulfOx coapplied with ORC Advanced, using direct push technology (DPT) injection points throughout the 3200 sq. ft. treatment area through 40 DPT injection points.

Technology Description

RegenOx – An injectable two-part advanced in situ chemical oxidation (ISCO) reagent that combines a solid sodium percarbonate-based alkaline oxidant (Part A) with a liquid mixture of sodium silicates, silica gel and ferrous sulfate (Part B), resulting in a powerful technology that treats and destroys a wide range of target contaminants including both petroleum hydrocarbons and chlorinated compounds.

PersulfOx – An advanced ISCO reagent and all-in-one product with a built-in patented catalyst destroys organic contaminants found in groundwater and soil through abiotic chemical oxidation reactions.

ORC Advanced – An engineered, oxygen-release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced produces a controlled release of molecular oxygen accelerating aerobic biodegradation processes up to 100 times f aster than natural degradation rates.

Results

For the final application event, following five on-site working days, REGENESIS completed the hot spot application process during which 9,753 lbs. of PersulfOx and 2,240 lbs. of ORC Advanced were applied to the designated treatment area. First quarter sampling results post-application showed concentrations below MTCA criteria. Following three quarters of monitoring, remediation of this site will be complete.

About the Client

Antea Group is an international engineering and environmental consulting firm specializing in full-service solutions in the fields of environment, infrastructure, urban planning and water. With more than 3,000 employees in over 100 offices around the world, Antea Group serves clients ranging from global energy companies and manufacturers to national governments and local municipalities.

Treatment of a Diverse Range of Contaminants, Emilia Romagna, Italy

Treatment of a very low permeability geology with mixed contaminants at varying concentrations, using multiple application methods and a range of different REGENESIS products.Read More

Smear Zone Treatment at Former Factory in Madrid, Spain

At a former chemical works near Madrid, high soil and groundwater contamination had been observed at, and just below, groundwater level. In Situ Chemical Oxidation (ISCO) using RegenOx, was applied to target these and to avoid excavation into the saturated zone.Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español