Combined RegenOxTM and ORC Advanced® Application Treats TPH and BTEX

Introduction

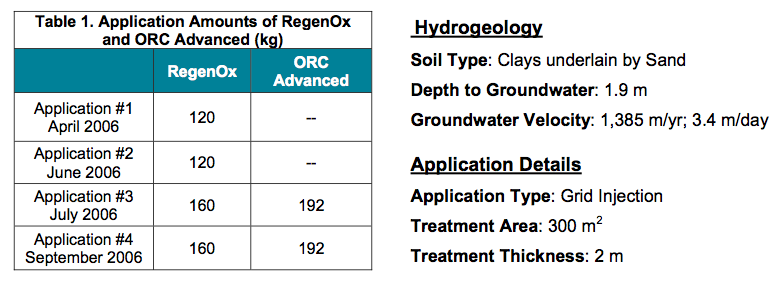

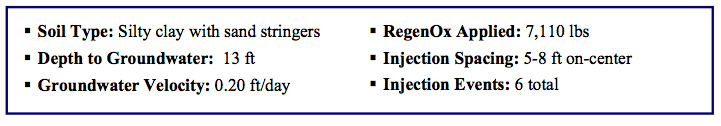

Operations at a former car dealership resulted in petroleum hydrocarbon contaminated soil and groundwater. In the source well SB7, groundwater concentrations of total petroleum hydrocarbons (TPH) had increased to 250 parts per million (ppm) and concentrations of benzene, toluene, ethylbenzene, and xylenes (BTEX) were present at more than 400 ppm. In order to reach the TPH site specific target level (SSTL) of 19.2 ppm, a combined remedial approach using chemical oxidation and enhanced aerobic bioremediation was implemented. Injections of RegenOxTM and ORC Advanced® were applied in four separate injection events (Table 1). The combined approach was designed to treat the high concentrations and promote aerobic bioremediation of any remaining residual contamination.

Remediation Approach

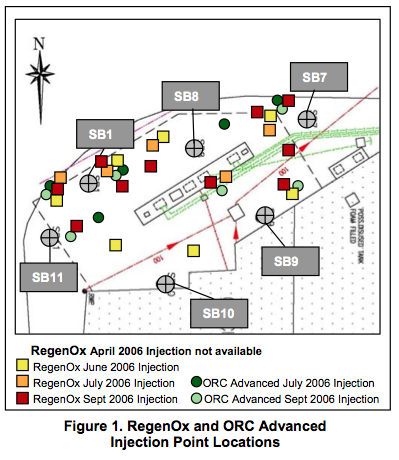

The remedial objective was to reduce high concentrations of TPH to below the SSTL of 19.2 ppm. RegenOx was applied in April 2006 and June 2006 across the plume (Figure 1). Both RegenOx and ORC Advanced were applied separately in July 2006 and September 2006. (Table 1)

In Situ Treatment Results

Shortly after the initial RegenOx chemical oxidation treatment, TPH was reduced by an average of 67% (Graph 1). As is typical following the first chemical oxidation application, contaminant rebound occurred after approximately one month. This is primarily a result of rapid desorption of sorbed phase contaminants from soil into groundwater and the 30 day longevity of RegenOx. Three follow up RegenOx injections were applied to continue treatment and eliminate the remaining contamination. Additionally, two ORC Advanced injections were performed to provide a long-term (12 months on average) oxygen source for enhanced aerobic bioremediation.

Shortly after the initial RegenOx chemical oxidation treatment, TPH was reduced by an average of 67% (Graph 1). As is typical following the first chemical oxidation application, contaminant rebound occurred after approximately one month. This is primarily a result of rapid desorption of sorbed phase contaminants from soil into groundwater and the 30 day longevity of RegenOx. Three follow up RegenOx injections were applied to continue treatment and eliminate the remaining contamination. Additionally, two ORC Advanced injections were performed to provide a long-term (12 months on average) oxygen source for enhanced aerobic bioremediation.

RegenOx was effective at reducing TPH to below the SSTL in all wells, excluding SB7 (Graph 1) which was located within the source area. However, a reduction of 95% occurred in SB7 within two weeks of the initial RegenOx injection. Rebound was observed in this area throughout the treatment, indicating that sorbed phase TPH was more prevalent around this well. RegenOx reduced the overall TPH loading of the soils and maintained TPH concentrations in groundwater to below 60 ppm. The ORC Advanced applications are expected to further TPH reduction in this area via enhanced aerobic biostimulation beyond the length of the monitoring program.

Conclusion

As a result of the RegenOx applications, concentrations were reduced quickly and cost-effectively within weeks of the injections. It is expected that the remaining concentrations above the SSTL in Graph 1 will be reduced as ORC Advanced continues to release oxygen. Successful closure was achieved due to the overall reduction in TPH concentrations, the observed reduction in contaminant concentrations in the source area, and the expected future reductions from the application of ORC Advanced.

RegenOx® Treats Benzene in Low Permeability Soils

Introduction

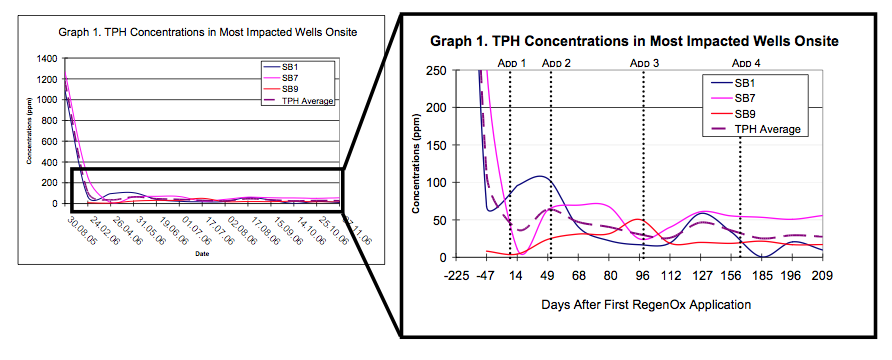

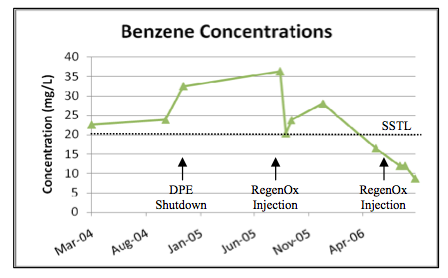

Service station operations created a benzene contaminant plume in tight subsurface soils. A dual-phase extraction system (DPE) was installed and removed a total of 9,965 pounds of petroleum hydrocarbons over two 90-day operational periods. However, contaminant removal reached asymptotic levels and a more effective remedial strategy was needed to address the remaining benzene concentrations. The DPE system was shut down in December 2004 and RegenOx® was selected to evaluate the effectiveness of reducing benzene and MTBE concentrations in tight soil lithology.

Description of Activities

RegenOx was pilot tested around well DPRW-6 to evaluate its effectiveness in tight soil. A total of 1,439 pounds of RegenOx was applied near well DPRW-6 as a pilot test in August 2005 (510 lbs) and July 2006 (929 lbs). Benzene concentrations declined within 15 weeks by 76% and successfully reached the Site Specific Target Level (SSTL) (Graph 1), prompting a design for full scale implementation.

The objective of full-scale treatment was to provide rapid mass reduction of benzene concentrations and reach the SSTL of 20.1ppm across the 9,100 ft2 source area. Benzene rebound at DPRW-6 (the original pilot test well) six months post-injection suggested that a previously unidentified plume had re- contaminated that area. After additional site characterization was completed, 7,110 pounds of RegenOx were applied during six injection events over five treatment areas (Figure 1).

The RegenOx injections were performed over a 6 month period due to weather delays. Monitoring was conducted to observe potential contaminant rebound from areas requiring additional injections. The applications targeted a treatment thickness of 14-20 feet bgs into silty clay with intermittent sand “stringers”. RegenOx was injected using a top-down direct-push injection technique with 5-15 lbs of RegenOx injected per vertical foot.

Results

Prior to the full-scale application, benzene concentrations exceeded the SSTL of 20.1ppm in all wells. Monitoring over a 7 month period prior to remedial treatment indicated an increase in concentrations from 12 – 32ppm to 20.4 – 44.1ppm.

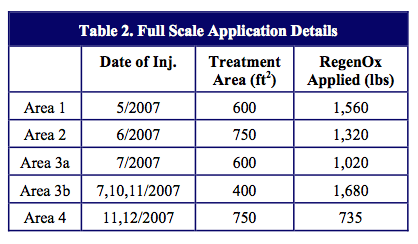

RegenOx was applied over six injection events as indicated in Table 2. Sampling conducted

after the final application event in December 2007 indicated a benzene reduction to at or below the SSTL in all wells (Graphs 2) including the original pilot test well DPRW-6. As monitoring continued, a decline in benzene concentrations persisted via natural attenuation and all wells sampled below 10ppm in August 2009. Based on the reducing trend observed over the past 12 months, the site was recommended for closure.

CASE STUDY: SOIL BOUND BTEX TREATMENT AND ACTIVE REMEDIATION SYSTEM INTEGRATION

Purpose:

The purpose of this pilot study was to demonstrate the feasibility of using PetroCleanzeTM to desorb petroleum contaminants from the soil into the dissolved phase where they can then be treated by physical extraction or an active remediation system.

Background:

A biosparge system was used at the site until groundwater concentrations dropped below cleanup target levels (approximately 2 years), then it was shut down. Rebound occurred during post-active remediation monitoring and groundwater concentrations increased above natural attenuation default concentrations. The observed increase in dissolved contaminant concentrations, combined with high organic vapor analyzer readings in saturated soil samples, and elevated fraction of organic carbon and total organic carbon concentrations in the soil, suggested petroleum contamination was likely absorbed to organics in saturated soils and was slowly desorbing into the groundwater. An approach was needed to liberate bound hydrocarbons for additional treatment using the biosparge system.

Pre-Injection Baseline Analytical:

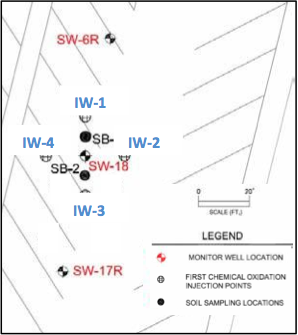

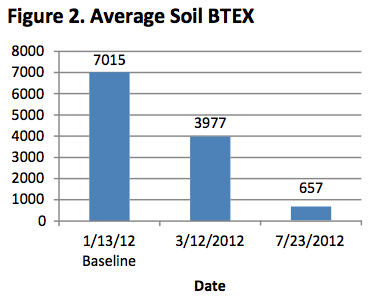

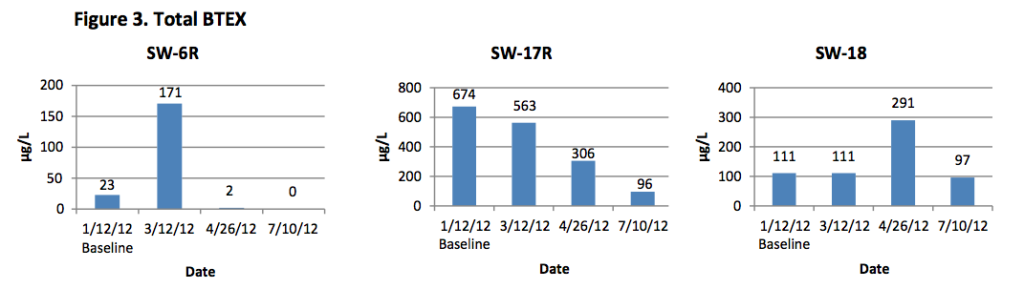

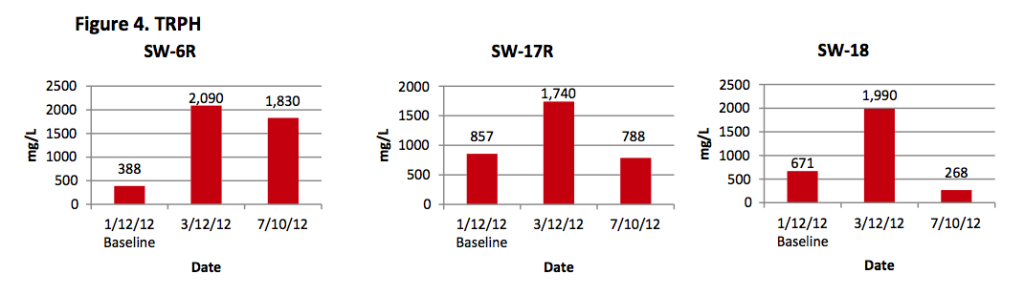

On January 12, 2012, baseline groundwater samples from monitoring wells SW-6R, -17R, and 18 (Figure 1) were collected for BTEX (benzene, toluene, ethylbenzene, xylene) and TRPH (total recoverable petroleum hydrocarbons) analysis (Figure 3, 4). On January 13, 2012, two soil borings (SB-1 and SB-2) were completed and baseline soil samples were collected from 12-14 feet below land surface for BTEX analysis (Figure 2). Figure 2 shows the average soil BTEX concentration for SB-1 and SB-2 before and after PetroCleanze injection.

PetroCleanze Injection:

On February 2-3, 2012, a total of 2,220 gallons of 5% solution of PetroCleanze was injected into four injection points surrounding SW-18. Each point received a total of 550 gallons of solution, including 220 lbs of RegenOx Part A, 240 lbs of PetroCleanze, and 500 gallons of water. The biosparge system was reactivated for the duration of the treatment event.

Post-Injection Analytical:

On March 12, 2012 and July 10th, 2012, groundwater samples from groundwater monitor wells SW-6R, -17R, and -18 were collected for BTEX and TRPH analysis (Figure 3, 4). Also on March 13th and July 23rd, 2012, two soil borings (SB-1 and SB-2) were completed and soil samples were again collected for BTEX analysis (Figure 2).

Results:

Performance parameters were evaluated for SW-6R, -17R, and -18 and a marked increase in ORP values was observed in each of the three wells following the PetroCleanze injection indicating chemical oxidation activity. Additionally, the pH in wells SW-17R and -18 increased significantly, providing evidence that alkaline conditions resulted from the application of PetroCleanze. As anticipated, increases in TRPH and BTEX concentrations in the sampled wells were observed following PetroCleanze injection as compared to baseline (Figure 3, 4). SW-17R was slightly unique in that BTEX concentrations went down. When looking at the average soil BTEX concentration of the two soil samples (Figure 2) in January, March, and July 2012 (7,015, 3,977, and 657 μg/kg, respectively) there was a 43% reduction between January and March and a 91% reduction between January and July 2012 after continued biosparging treatment.

Conclusion and Recommendations:

The PetroCleanze application was successful and the material easily applied. Performance exceeded expectations as only one injection was needed to strip 91% of the BTEX contamination from the soil into the dissolved phase. The reactivated biosparge system was able to treat the increased dissolved phase contaminants in the treatment area.

The current groundwater concentrations at the site are very low in key monitoring wells; therefore, the project does not require additional treatment at this time. However, should a change in contaminant concentration be observed at the site once active remediation has been ceased then additional treatment will be considered.

Combined Remediation Approach – Dual Phase Vacuum Extraction with In Situ Chemical Oxidation

Introduction

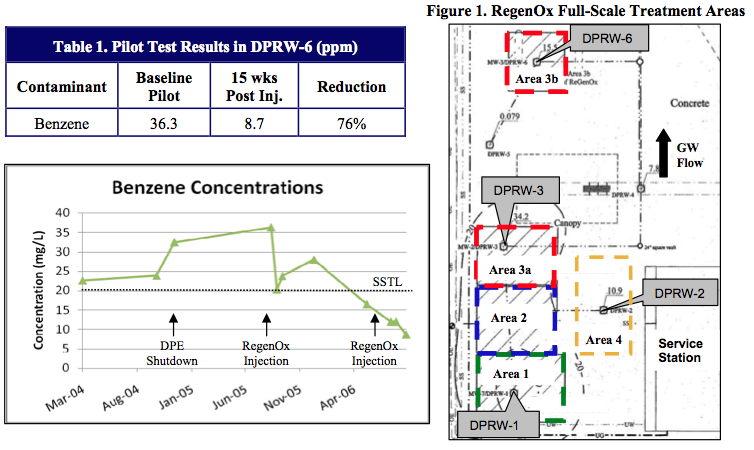

When redevelopment of an old service station was proposed, site investigations revealed a significant petroleum hydrocarbon impact within the soil and groundwater. The subsurface contamination threatened to derail the redevelopment program and a rapid remediation strategy was needed to reduce concentrations to acceptable levels. Geo2 Remediation was contacted to remediate the site in order to allow safe development for luxury residential properties while ensuring no impact to local protected controlled waters.

Figure 1. Successful Site Remediation Leads to Luxury Residence Redevelopment

Project Background

Geo2 Remediation carried out the treatment of a former service station following historic leakage from underground storage tanks (USTs). The tanks had been removed prior to the beginning of the site investigation. Free product was discovered at the surface of the saturated zone and elevated concentrations of total petroleum hydrocarbons (TPH) were observed within the groundwater. Concentrations of TPH as high as 290 mg/L were discovered within the source area.

In Situ Physical Remediation

Geo2 Remediation installed a dual phase vacuum extraction (DPVE) system, designed to rapidly remove phase separated product identified on the surface of the groundwater. The DPVE system began treatment in September 2007. Thicknesses of free product up to 50mm, identified around the former tank farm, were removed within 1 month of commencing treatment. Within the groundwater, TPH concentrations were reduced to between 300 mg/L and 150 mg/L over a 5-month monitoring period. In order to increase the efficiency of the DPVE system, Geo2 augmented the physical treatment system with RegenOx to provide a rapid reduction in soil and groundwater concentrations and allow redevelopment to proceed on schedule.

Combined In Situ Physical Remediation and Chemical Oxidation

Geo2 Remediation applied RegenOxTM, a safe and easy to apply proprietary in situ chemical oxidation (ISCO) designed to provide rapid concentration reduction of contaminants without a violent exothermic reaction or other handling difficulties common to ISCO reagents. RegenOx was injected into the subsurface around the dissolved phase impact following DPVE system shutdown using a direct-push injection rig. Two applications were completed within one week of each other using a modest dose of 326 kg RegenOx to achieve sorbed-phase desorption and partial chemical oxidation of the residual hydrocabons. The DPVE system was then restarted to remove the resulting desorbed contamination and partially oxidised hydrocarbon species from the groundwater – this enabled the Reagent requirements to be kept to a minimum (i.e. partial contaminant oxidation rather than full contaminant oxidation) whilst capitalising on the use of the DPVE system already in place. The total cost of the RegenOx application – including all fieldwork – was approximately £ 5,000, the cost of one month’s DPVE operation at the site.

RegenOx® Basics

RegenOx® is a proprietary two-part chemical oxidation product developed and sold by Regenesis for in situ groundwater treatment. It combines the use of a controlled-release percarbonate-based oxygen compound with a proprietary multi-part catalyst to generate surface-mediated free-radical generation and contaminant oxidation (e.g. perhydroxyl radical, hydroxyl radical and superoxide radical), with reactive power comparable to that of Fenton’s reagent but with greatly facilitated handling and subsurface delivery / longevity (up to 30 days). This provides an effective contaminant oxidation reaction without violent exothermic reaction, and can therefore be handled using a wide range of standard field equipment (e.g. direct push injection rigs) or applied directly to excavations. Furthermore, it is alkaline and can therefore be used in calcareous formations in addition to sands and gravels etc.

RegenOx-enhanced Contaminant Desorption

RegenOx has been designed as a bespoke remediation product to provide advantages in usage and application over commodity chemical products used for ISCO (e.g. permanganates, persulphates, peroxides). One of the design features it includes is reduced losses onto the aquifer matrix, commonly known as the matrix Natural Oxidant Demand (NOD). This is achieved by RegenOx through a powerful desorption / surfactant effect of the combined product (principally the catalyst) that draws the contaminant off the soil surface and into solution / onto the catalytic surface where localised free-radical generation occurs leading to focused contaminant destruction. This restricts the oxidant losses onto tightly bound and heavier soil organics such as humics, roots, and other natural or immobile fractions. At the same time, RegenOx is purely inorganic therefore adding no organic surfactant to the system that may prevent a competitive oxygen sink to on-going contaminant biodegradation.

The present project makes use of this product feature to combine in situ chemical oxidation with enhanced physical mass recovery. RegenOx-desorbed contaminant mass and partially oxidised (more soluble) organic species are recovered via groundwater abstraction using the DPVE system, whilst further contamination is destroyed in situ by oxidation.

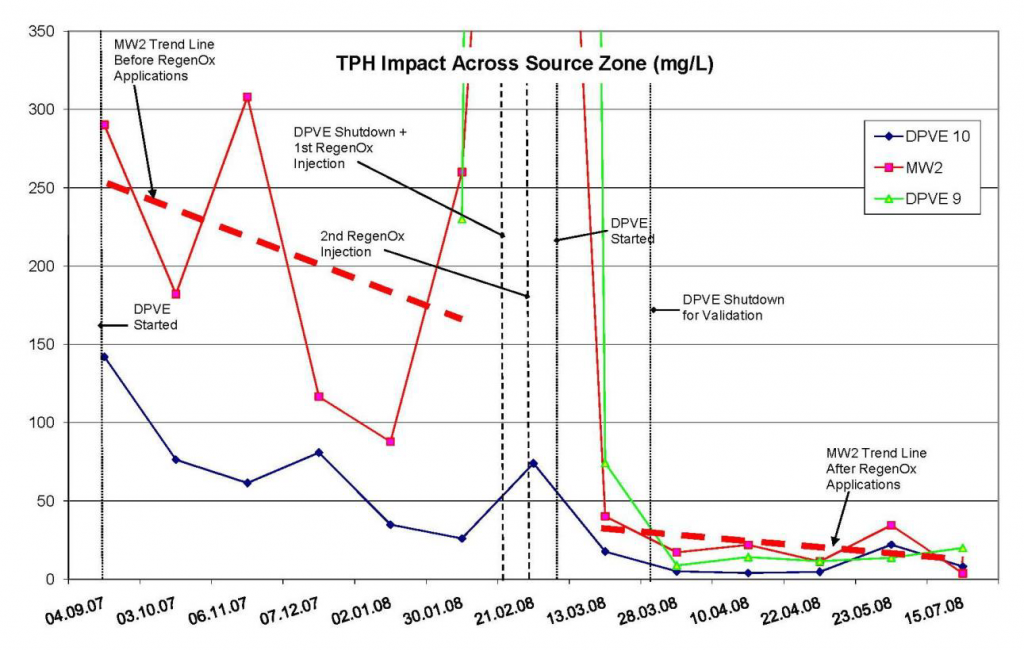

Results

Upon completing the RegenOx applications, desorption from the highly impacted soils produced a temporary increase in groundwater hydrocarbon concentrations to a maximum of 4,800 mg/L. One week after the second application was completed, the DPVE system was re-started, rapidly reducing the TPH concentrations in the groundwater to an average of 20 mg/L. The improved efficacy of the DPVE system can be seen in Graph 1 where the linear trendline of MW-2 before and after the RegenOx applications shows a conservative 80% reduction in contaminant concentrations within two months – effectively increasing the DPVE efficiency by more than 500% at this stage in its operation. Once the DPVE system was switched off, further monitoring showed that there was no rebound in groundwater hydrocarbon concentrations due to the augmentation process successfully reducing the sorbed TPH concentrations of the soils.

RegenOx Treats #2 Fuel Oil Plume Beneath Residential Home

CASE SUMMARY

Home Heating Oil, New Jersey

A 550-gallon leaking underground storage tank (UST) containing #2 fuel oil was removed from a single family residence in New Jersey (Figure 1). In addition, the surrounding soil was excavated and sampling was performed to determine the extent of the petroleum hydrocarbon plume within soil and groundwater. The plume was delineated at approximately 1,800 ft2 with

concentrations of total petroleum hydrocarbons as high as 40,000 parts per million (ppm) in soil and approximately 40,000 parts per billion (ppb) in groundwater. An estimated 20% of the plume was determined to be located beneath the home itself, eliminating the option for extensive soil excavation. Other remedial strategies such as pump & treat, monitored natural attenuation, and enhanced fluid recovery were ruled out as they did not provide a timely, cost-effective solution.

Figure 1. Residential Site

- Soil Type: Fine to Medium Sands

- Treatment Thickness: 5 to 12 feet bgs

- Free Product: 1” to 3” observed

- Contaminants of Concern:

- TPH – Total Petroleum Hydrocarbons

- TVOC – Total Volatile Organic Carbon

- TSVOC – Total Semi-Volatile Organic Carbon

| Contaminant | Concentration |

| TPH – soil | 40,000 ppm |

| TVOC – gw | 7,900 ppb |

| TSVOC – gw | 40,000 ppb |

REMEDIATION TECHNOLOGY

In Situ chemical oxidation (ISCO) using RegenOxTM was chosen as the most appropriate technology to treat the soil and groundwater plume. In addition, an application of a slow-release oxygen compound, ORC Advanced®, was applied following RegenOx to stimulate aerobic biodegradation of any residual contaminants. RegenOx was applied based on the following:

- Least disruptive to the homeowner

- Successful track record

- Feasible site conditions – sandy soils and a shallow water table paired well with direct-push injection

- Low natural organic carbon in saturated zone

- Safe to use and easy to apply

Ten permanent injection points were installed around the source area, at the edge of the plume and beneath the house in the crawl space as seen in Figure 2. During the installation, free phase product was observed in monitoring wells at approximately 1 to 3 inches. The NJDEP’s Permit-by- Rule prohibited the injection of any remediation technology should free product be present. Once the removal was complete, RegenOx could be applied as designed.

CONTAMINANT PLUME TREATMENT

Free Product Removal

The free product was removed using a mild surfactant and a high powered vacuum extraction truck within the source area. This process also effectively distributed the surfactant across the impacted zone for further desorption of contaminants from the soil matrix. Three free product recovery events were performed which effectively removed all free product from the wells and surrounding areas. TVOC concentrations in groundwater dropped only slightly as a result of the free product removal. However, concentrations of TSVOCs more than doubled in groundwater as a result of desorption from soil.

ISCO Injection for TPH Reduction

The application design included two RegenOx injection events and a third combined RegenOx and ORC Advanced injection for on-going biostimulation to treat residual contaminants. Using temporary and permanent injection points, a total of 6,210 pounds of RegenOx was applied from 5 to 11 feet bgs. The third injection included 650 pounds of ORC Advanced.

Conclusion

No free product, sheen or film was observed after the injections were completed (Figure 5). Levels of dissolved oxygen 30 days following the final application were measured at approximately 10-20 ppm indicating the presence of ORC Advanced in the subsurface.

Within 6 months, significant reductions in petroleum hydrocarbons were observed. TVOCs declined from 7,900 to <50 ppb and TSVOCs were reduced from 40,000 to <150 ppb. Further Action status from the NJDEP. The site is currently seeking No Further Action status from the NJDEP.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español