Residential Redevelopment of Former Industrial Site, Helsingborg Sweden

Enhanced reductive dechlorination treats high concentrations of chlorinated solvents (TCE) in varying permeabilities at a former manufacturing facility. Read More

Remediation of Hexavalent Chromium in Bedrock at Former Saw Mill

Bedrock chrome VI contamination treated to non-detect levels in 2 months, expediting regulatory sign-off and unlocking the site for redevelopmentRead More

Hotspot Treatment of Petroleum Hydrocarbons – North West, UK

Phased, in situ treatment with PetroCleanze and ORC-A Socks allows main contractor to keep programme on trackRead More

PetroCleanze Increases Efficacy of Pump and Treat System – Reading, UK

Treatment example of LNAPL and smear zone in bedrock. PetroCleanze enhanced the efficacy of the existing P&T system, reducing P&T costs onsite.Read More

Enhanced Recovery & Biodegradation of Petroleum Hydrocarbons – Sweden

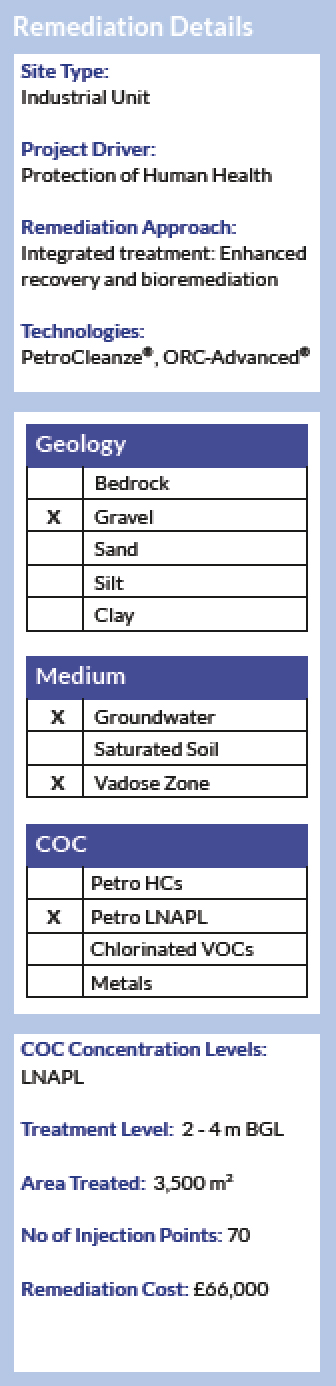

Summary

A site investigation undertaken by a remediation contractor in Växjö, Sweden, identified up to 1.4 m of LNAPL on top of the groundwater beneath an industrial unit. The source of the contamination was a boiler in the basement of the facility. It was determined that the contamination posed a vapour risk to the site users. The proposed strategy was therefore to remove the LNAPL, reduce the adsorbed mass and treat the dissolved phase contamination to low levels. This was to be completed within the building, it’s basement and the car park downgradient.

Treatment

In order to efficiently address both the free and dissolved phase petroleum hydrocarbon contamination an integrated in-situ remediation strategy was adopted. A Multi-Phase Extraction (MPE) system was installed across the target area. This was used firstly to extract the easily removable LNAPL observed at the site. Following this, several round of PetroCleanze® were applied into the subsurface to cause the temporary desorption of the soil contamination within the smear zone. The MPE system was then used to remove this ‘rebound’ each time.

Once no further LNAPL was observed after the PetroCleanze application, ORC Advanced® was applied to enhance the biological degradation of the residual dissolved phase contamination to reach the target values.

What’s Special

- An integrated in situ remediation method allowed for treatment of LNAPL down to low dissolved phase contamination under an industrial unit, avoiding any demolition or excavation.

- PetroCleanze enhanced the performance of the MPE in order to reduce the asymptote achieved and avoid rebound from residual sorbed contamination.

- Augmentation of the MPE reduced time onsite and the cost of the remediation programme.

- ORC Advanced was used once only dissolved phase contamination was observed, maintaining the efficiency of the remedial programme and successfully achieving stringent target values.

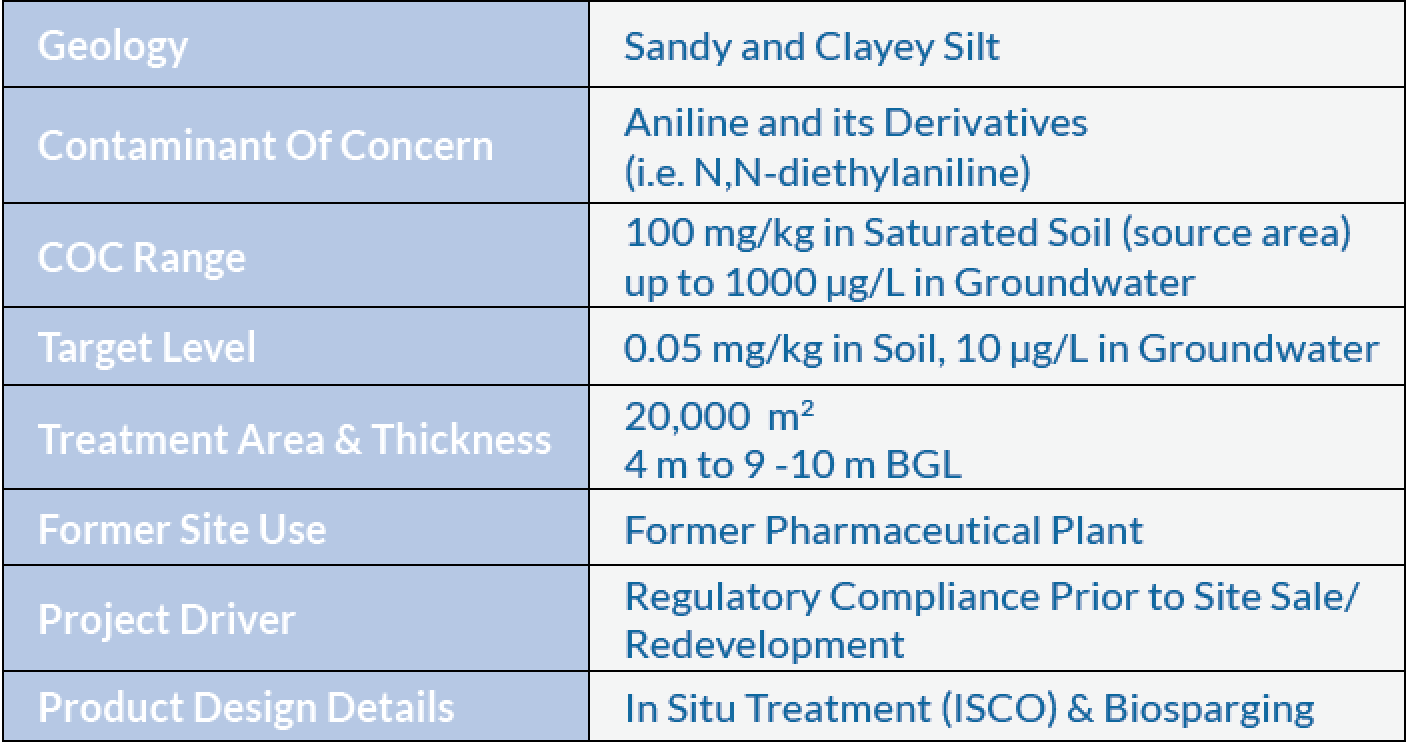

Treating Aniline Compounds at a Former Pharmaceutical Plant

Introduction

The soil and groundwater under a disused pharmaceutical plant in the North of Italy had become impacted with a mixture of aniline and its derivatives, due to historic spillages and leaks on the site. The contaminated unsaturated soil had been removed previously by excavation and disposal (approx. 1,000-1,500 m2) to a depth of 5 m BGL. However, some contamination had infiltrated through the vadose zone and impacted the groundwater, resulting in a 100-meter long plume. In the source area, residual contamination adsorbed to the saturated soil had been detected at 6-9 m BGL; below the maximum depth of the excavation previously completed. It was observed that during periods of high precipitation, the groundwater level would rise and promote recurrent desorption events from this contaminant mass into the groundwater.

Copernico S.r.l was engaged to delineate the contamination through additional site investigation using Membrane Interface Probe (MIP). They found that the main contaminant of concern (COC) was N,N-diethylaniline, which was present at concentrations of approx. 100 mg/kg in saturated soil in the source area, and up to 1,000 μg/L in groundwater across the whole of the site.

Fig. 1 Installation of injection points

Remediation Strategy

A laboratory study previously performed on material and contaminants from this site had shown that aniline was biodegradable under aerobic conditions (especially N,N-diethylaniline). Following this, a biosparge pilot scale study was completed, which proved unsuccessful at dealing with the high concentrations and contaminant loading in the source area. Copernico therefore determined that an integrated remediation approach would be required; initially using ISCO to rapidly address the higher concentrations and then enhanced biological degradation to treat the residual dissolved phase contamination.

It was determined that a persulphate-based ISCO agent was to be applied in two injection campaigns to treat the high levels of adsorbed contamination. After this, the biosparging system would then be operated both in the source and in the plume area. At the downstream boundary of the site, an ongoing pump & treat (P&T) system was used to provide hydraulic containment of the plume within the property, in line with regulatory requirements.

For the ISCO phase, Copernico selected PersulfOx®, a sodium persulfate oxidant with a patented catalyst already mixed into the product. Therefore, no hazardous activation products are required, making the treatment process much safer. The application volume is therefore also reduced, providing cost and time savings to the project.

PersulfOx promotes rapid and sustained ISCO of a wide range of organic oxidants including aniline, through both alkaline activation and surface mediated oxidation on the catalytic surface. This makes the treatment more efficient and effective compared to traditionally based persulfate based ISCO.

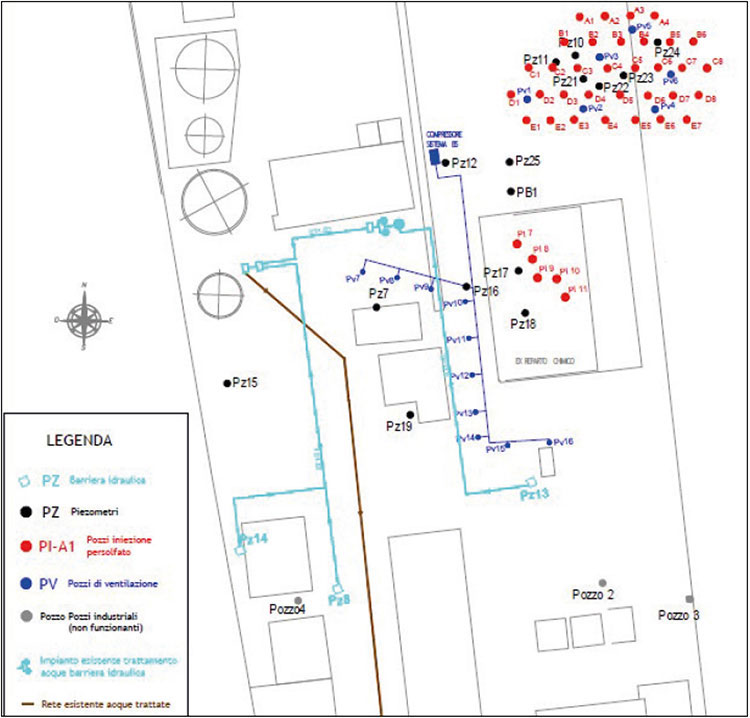

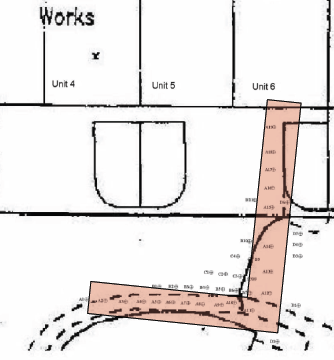

Fig.2 Map showing the PersulfOx injection points (red), Biosparging wells (blue), P&T system (light blue), monitoring wells (dark)

PersulfOx Injection Works

Within the target area 33 injection points (A1-E7), were installed within the vicinity of monitoring wells Pz11, Pz17, Pz18, Pz22, Pz23 and Pz24 (Fig.2).

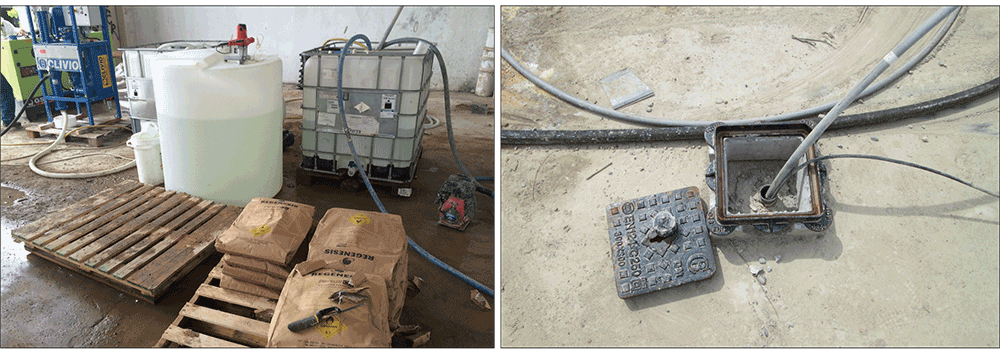

7,000 kg of PersulfOx was mixed with water to a 15-20% dilution prior to injection into the source area. PersulfOx is simply added to water and agitated, with no requirement for hazardous activation chemicals (such as caustic soda or hydrogen peroxide), making the process much safer, quicker and requiring a lower injection volume (see fig. 3 and 4).

PersulfOx was applied into the injection wells between 6 and 9 m BGL.

A special well completion was used that allowed the application to be completed in 500 mm vertical intervals, in order to ensure an even vertical distribution of the PersulfOx application (fig. 5 and 6). A dose of 25 kg PersulfOx to 175 L of water was applied within each section at approximately 5 Bar or less. A manifold system was used that allowed application into several wells at once in order to make the injection more efficient. The works were completed in 20 days.

Following the initial ISCO application to reduce the contaminant loading in the soils and groundwater in the source area, the biosparge system was operated to provide enhanced natural attenuation of the residual dissolved phase contamination. The biosparge system consisted of 5 ventilation points in the secondary source area, and a second line of 10 points in the plume area; all ventilation points are 15 meters deep.

Fig.3 and 4 Mixing activities

Fig. 5 and 6 Injection setup and multi-valve injection points

Results

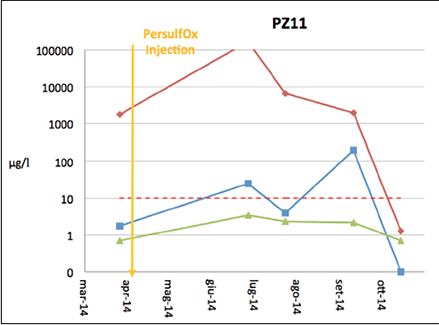

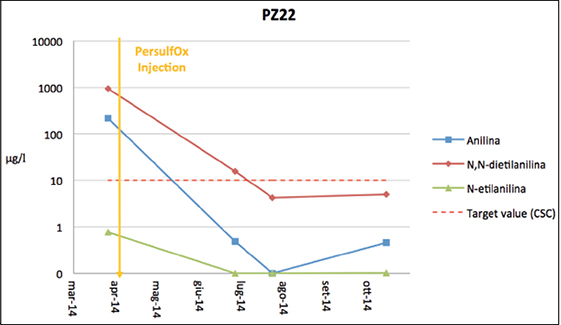

The first PersulfOx injection campaign was carried out during the months of May and June 2014. Monitoring results from October 2014 show significant, rapid and sustained reduction in all of the Contaminants of Concern (COCs) and remedial targets have been achieved for;

- Aniline (12 out of 12 wells in treatment area)

- N,N-diethylaniline (10 out of 12 wells in the treatment area)

- N-ethylaniline (11 out of 12 wells in treatment area)

The efficacy of the remediation has been monitored through a network of 20 monitoring wells across the site (20,000 m2). Periodical monitoring campaigns have been carried out, including chemical-physical field parameters and laboratory analysis.

Immediately following injection, a temporary increase in the groundwater concentrations of the aniline(s) was observed. This was due to desorption of part of the soil contamination due to the disturbance of the injection and the effect of the ISCO treatment. Once the contamination was in the groundwater, it was rapidly oxidised and the concentrations were then seen to reduce rapidly.

An example of this is well Pz11 (located in one of the most highly impacted areas (7,000 μg/L)), see Figure 7, producing a significant contaminant mass reduction of the whole system (sorbed and aqueaous phase), with a 99% reduction in dissolved phase concentrations by October 2014.

ISCO using PersulfOx not only provided contaminant mass reduction from both the soils and groundwater. Partial chemical oxidation of the COCs resulted in the contaminants becoming more bioavailable and biodegradable. This increased the efficacy of the biosparging system on the residual dissolved phase contamination.

Fig. 7 Total COC concentrations decreased below the target values in Pz11 and Pz22 (Shallow portion of the aquifer) with the use of PersulfOx in 6 months after application.

In the PersulfOx treatment area, all monitoring wells met the target goals within six months for all COCs except for two deep wells (Pz10 and PB1) that still show concentrations marginally higher than target. It is thought that these wells represent areas with higher contaminant mass than was anticipated. Subject to further groundwater monitoring results, a second PersulfOx application may be completed at the site, targeting the recalcitrant wells, as foreseen in the remediation plan. This treatment will be smaller than the first, accurately targeting source areas with higher total contaminant mass.

Biosparging will then be continued in these areas to enhance the biological degradation of the residual dissolved phase contamination. Downgradient of the biosparging system a significant decrease in groundwater aniline concentration has been observed reducing from 1,000 μg/L to <0.1 μg/L. After the remediation activities, aniline concentrations have not exceeded targets (10 μg/L) at the boundary pumping wells, despite periods of heavy rainfall. The remediation resulted in a significant reduction of contaminant mass across the treatment area for all COCs and the residual concentrations are expected to decline further over time.

Conclusions

An intelligent, staged approach was used to complete the site investigation and development of an integrated remediation strategy for the site. This comprised accurate contaminant delineation using Membrane Interface Probe (M.I.P.), evaluation of potential remedial strategy and verification of localised geological and geochemical conditions across the site. This resulted in an accurate in situ remedial design, integrating rapid mass reduction of the COCs

and enhanced biological degradation of the residual dissolved phase contamination.

The treatment successfully reduced COC concentrations to below target goals in the majority of the treatment area and continued to reduce the contaminant levels throughout the validation period.

This site is an excellent example of how good site investigation and an integrated treatment design strategy can provide cost effective and assured remediation of problematic contaminants.

About the Product

PersulfOx is an advanced in situ chemical oxidation (ISCO) reagent rapidly destroys a wide range of contaminants such as petroleum hydrocarbons and chlorinated solvents through abiotic chemical oxidation reactions.

It is an all-in-one product with a built-in catalyst which activates the sodium persulfate component and generates contaminant-destroying free radicals without the costly and potentially hazardous addition of a separate activator. The patented catalyst enhances the oxidative destruction of both petroleum hydrocarbons and chlorinated contaminants in the subsurface.

Benefits

- Promotes rapid and sustained in situ oxidation of a wide range of organic contaminants

- Contains a built-in catalyst that remains active through the entire lifespan of the persulfate oxidation reaction

- The catalyst also eliminates the need for the co-application of alternate and potentially hazardous activation chemistries

- Contaminant oxidation performance equivalent to best alternative persulfate activation methods

- Fewer health and safety concerns than with use of traditional activation methods such as heat, chelated metals, hydrogen peroxide or base

- Single component product results in simplified logistics and application

- No additional containers or multi-step mixing ratios required prior to application

- Compatible with combined remedy approaches including enhanced

biodegradation

PersulfOx Intellectual Property

With the purchase and proper use of PersulfOx Catalyzed Persulfate, Regenesis’ customers gain the benefits of the latest advancements in persulfate technology for environmental remediation.

Furthermore, through an arrangement between Regenesis and FMC Corporation, PersulfOx customers are free to use PersulfOx without any risk of patent infringement claims from FMC Corporation.

Fuel spill treated using RegenOx at a Swedish military base in Afghanistan

RegenOx® has been successfully used as an emergency response cleanup reagent by the Swedish Army to remediate a minor fuel spill in Afghanistan.Read More

Hexavalent Chromium Barrier Treatment Protects River

Summary

w_Reg_20916_MRC_8_inj-rig_UKOn an industrial estate in Ravensthorpe, West Yorkshire, a leak from a storage tank in a chrome-plating works, had resulted in contamination of the underlying groundwater. The contamination was found to be migrating off-site, under neighbouring properties, towards a nearby river. Regenesis was employed to design and install a barrier to protect the river for a guaranteed 12 months in order to allow the building to be cleared of other tenants prior to demolition and source removal.

Design & Application

Metals Remediation Compound (MRC) was used to immobilise the contamination by reducing soluble hexavalent chromium into solid, non-hazardous trivalent chromium, which settled out of the groundwater. The MRC was injected in an ‘L’ shaped barrier through the apron and road outside of the industrial unit. The corner of the ‘L’ consisted of three rows of direct push injection locations, in order to provide a wide treatment zone where maximum contaminant influx would occur. The MRC was applied using direct push injection in gravels, from the top of the groundwater at 5 m BGL to 12 m BGL (rock-head).

What’s Special?

- Within weeks of application, the barrier prevented the movement of hexavalent chromium contamination towards the river. Concentrations of 10,000 μg/L Cr(VI) were reduced by >98% to <200 μg/L 5m downgradient of the barrier and non-detect at the river.

- Regenesis provided a warranty on the barrier for a period of 12 months after the application, however the MRC barrier would remain effective between 2 to 3 years.

- The controlled-release mechanism of MRC meant that offsite receptors were protected for an extended period from a single, low-cost injection.

In Situ Remediation of PCE and DNAPL at Active Industrial Drycleaners

A highly sustainable form of remediation with estimated savings likely to exceed £500,000. Read More

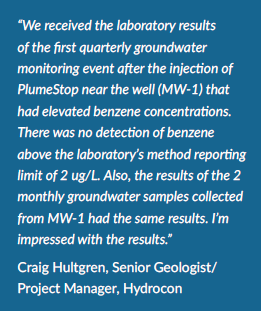

PlumeStop® and ORC Advanced® Treat BTEX to Non-Detect in 1 Month

Project Highlights

- Benzene (BTEX) and TPH-d (diesel) were reduced to non-detect within one month with no rebound

- Pre-project verification testing provided hydrogeological data to optimize the successful application of PlumeStop and ORC Advanced

- Active site did not impede remediation efforts

Project Summary

An active gas station in the Pacific Northwest was impacted with BTEX concentrations from a petroleum release. Following remediation of the source, residual BTEX concentrations persisted in a down gradient well. A new combined remedies in situ program using PlumeStop and ORC Advanced was designed. Following the verification testing, REGENESIS co-applied PlumeStop and ORC Advanced into the residual BTEX plume. After one month, sampling was conducted showing contaminants had been dramatically reduced to non-detect levels.

Remediation Approach

REGENESIS worked closely with the project consultant to complete a multi-step verification process prior to remediation. This procedure included a clear water injection to test aquifer properties and soil borings for detailed characterization of the proposed treatment area. This was followed by a pilot injection of PlumeStop to test distribution. The verification testing found that despite soils at the site being classified as clays and silts, there was a sufficient amount of sand present to allow for good distribution. Injection pressures remained below 5 psi for PlumeStop and below 10 psi for ORC Advanced. Distribution of greater than 12 feet was also observed. The verification process was an integral part of the project, helping to more accurately characterize true hydrogeologic conditions. Technical Engineers were able to take the information obtained from the verification process and optimize the PlumeStop and ORC Advanced design. The co-application of the two technologies quickly sorbed dissolved-phase contaminants and promoted aerobic biodegradation.

REGENESIS Solution Applied

PlumeStop Liquid Activated Carbon™ is composed of very fine particles of activated carbon (1-2μm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and enhancing permanent contaminant biodegradation. ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled release of molecular oxygen for periods of up to 12 months upon hydration.

Results

Residual BTEX and TPH-d concentrations lingering for years are common for gas station sites and often are the only obstacle to closure. The combined remedies application of PlumeStop and ORC Advanced demonstrates a unique ability to attain non-detect levels in a short time frame with substantial cost savings over other approaches, including natural attenuation.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español