PFAS and CVOC Remediation Paves the Way for Mixed-Use Tower

Case study highlights:

- Certificate of Completion Awarded through New York State’s Brownfield Cleanup Program

- Combined remedy approach using ISCO and colloidal activated carbon to successfully treat CVOC and PFAS contaminants

- Greater than 90% reductions in mass flux achieved at property boundary

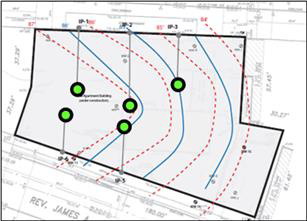

This case study reviews a legacy brownfield site in New York that was found to have high concentrations of chlorinated volatile organic compounds (CVOCs), petroleum hydrocarbons (PHCs), 1,4-dioxane, and PFAS (per- and polyfluoroalkyl substances). To address this contamination, a combined remedy was implemented: PersulfOx® was applied to reduce contaminant mass at the source, while a PlumeStop® barrier was installed to prevent residual migration beyond the site boundary. This approach resulted in a 90% reduction in groundwater contaminant concentrations and significantly lowered the mass flux at the property boundary. The success of the remediation effort earned the site a Certificate of Completion through New York State’s Brownfield Cleanup Program, paving the way for environmentally responsible redevelopment in this commercially valuable area

New York Brownfield Achieves Site Closure

Case study highlights:

- Based on successful performance results, a pump-and-treat system was decommissioned in 2020, and the NYSDEC granted the site closure in August 2021

- By not having to operate and maintain the pump-and- treat system, substantial energy and cost savings were realized in this period

- Roux’s agile site management, making the switch from an ex situ to a PlumeStop in situ approach, saved time and money for their client

This case study reviews a former metals manufacturing facility in upstate New York contaminated with chlorinated volatile organic compounds (CVOCs) from the plating operations, predominantly comprised of tetrachloroethene (PCE) and trichloroethene (TCE). A previously installed groundwater pump-and-treat system significantly reduced CVOC concentrations in groundwater. However, after a few years, the reinjection wells became clogged and no longer accepted water. This required modification of the approach. The ex situ pump-and-treat remedy maintained plume control. However, to continue this approach would have required well replacement. Additionally, these systems are well known to reach an asymptotic boundary condition above the low, part-per-billion cleanup targets for CVOCs and are prone to rebound once shut down. Such was the case at the site. In response to these conditions, Roux (formerly Benchmark), a leading engineering and redevelopment consulting company, quickly adapted the remedial strategy, favoring an in situ approach to achieve the project objectives and facilitate site closure.

New York Brownfield Site Treated for PFAS Achieves Closure

Case study highlights:

- NYSDEC certifies cleanup requirements achieved, making the site eligible for redevelopment

- Brownfield cleanup program’s green remediation policy leads to PlumeStop for PFAS treatment

- PlumeStop barrier for PFAS treatment is a key component in pursuit of site closure

- Skillfully managed PlumeStop application achieves GSR and cost reduction objectives

This case study reviews a 25-acre former refinery located in a mixed-use industrial/commercial area that was contaminated with PFAS. Benchmark Environmental Engineering & Science, PLLC & TurnKey Environmental Restoration, LLC (Benchmark & TurnKey), a leading engineering and redevelopment consulting company headquartered in Buffalo, New York, engaged REGENESIS for an in situ remedy that would effectively and economically cut off the plume and prevent migration of PFAS offsite. The site was entered into the New York State Department of Environmental Conservation’s (NYSDEC’s) Brownfield Cleanup Program (BCP) to facilitate its commercial redevelopment. Remedial alternatives were evaluated for a comprehensive site closure strategy, and approaches were scored based on NYSDEC’s Green Remediation Policy Document DER-31, which considers the “environmental impacts of treatment technologies and remedy stewardship over the long term.”

Excavation With RegenOx Successfully Treats Large PHC Plume

Case study highlights:

- After previous consultants attempted remediation without success, C&S created a remediation strategy that successfully reduced the plume.

- The combined remedy approach of excavation and ISCO exceeded the remediation goals.

- Successful remediation enabled the construction of a 350,000 sq. ft. $110 million facility at the Buffalo Niagara Medical Campus.

This case study reviews a former gas station site in Buffalo, New York that required remediation due to leaking underground storage tanks. Together with REGENESIS, C&S Consulting designed an in situ remediation strategy to target the residual contaminant plume. RegenOx® in situ chemical oxidant was chosen because of its ability to target petroleum hydrocarbons and its non-corrosive properties. As part of the New York State Department of Environmental Conservation (NYSDEC) Brownfield Cleanup Program, C&S designed a complex remediation program to ensure a quick and affordable solution. Petroleum contamination extended from 10 to 40 feet below grade. The site was excavated to 26 feet below ground surface to remove residual contamination and to enable equipment staging and material handling areas to support the deeper excavation area.

Former Dry Cleaning Site Makes Way for Community Hospital Following Successful Treatment Using a Combined Remedy Approach

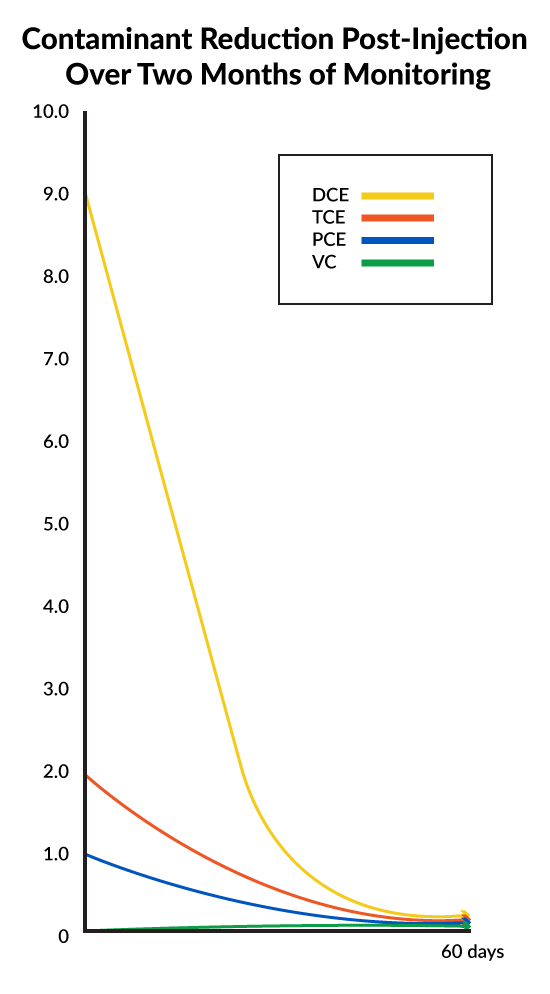

cVOC Contaminants Reduced by 97% After Two Months

Project Highlights

- Two months’ post injection results show contaminants were reduced by 97%

- Combined remediation approach used to successfully keep project on budget and on schedule

- Remediation design and amendments applied provided speed and certainty allowing for project to move forward

Project Summary

A former dry cleaning site in Western New York was targeted for redevelopment to make way for a multidisciplinary, world-class cancer center. Before redevelopment could get underway, the developer needed to address the cVOC levels found on site which exceeded state regulatory standards. The developer engaged Benchmark/Turnkey, a leading environmental firm in the Northeast, to develop a solution to address the contaminant levels found. Benchmark/Turnkey worked with REGENESIS® to design a remedial strategy that included 3D-Microemulsion®, Bio Dechlor Inoculum® Plus, and Chemical Reducing Solution® to reduce the PCE, DCE and TCE contaminants. The design focused on speed and certainty, since the site was tagged for immediate redevelopment. Using a direct push application of the amendments, Benchmark/Turnkey was successful in applying the combined remedial approach on budget and on schedule.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel three-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory emulsified product.

Bio Dechlor Inoculum Plus (BDI-Plus) is an enriched natural microbial consortium species of Dehalococcoides sp. (DHC). This microbial consortium has been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Chemical Reducing Solution is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

Results

Following the injection event, the team monitored the results and at two months found that total cVOC contaminant levels had been reduced by 97%. Based on the progress to date and the concentration of contaminants versus nutrients remaining in the groundwater, Benchmark/Turnkey expects to collect groundwater samples for two intervening semi-annual events then petition the New York Department of Environmental Conservation to discontinue groundwater monitoring.

About the Client

Benchmark Environmental Engineering & Science, PLLC is a licensed professional engineering company that provides comprehensive civil and environmental engineering services. TurnKey Environmental Restoration, LLC is a “sister” company that provides site investigation, remediation and infrastructure construction, and environmental and site management service.

Remediation at Multiple Service Stations using Badger Application System

RegenOx® Applied to Three Long Island Sites Contaminated with High BTEX Levels

Project Highlights

- BTEX levels higher than 20 mg/L observed on-site.

- Badger Injection System allowed for high volume applications of up to 700 gallons per injection point.

- In Situ chemical oxidation (ISCO) using 56,400 pounds of RegenOx® was used at three service station sites.

Project Summary

Several service station sites in Long Island, N.Y. were contaminated with high levels of BTEX. In heavily impacted areas, BTEX levels were higher than 20 mg/L. RegenOx was applied to the sites using the Badger Injection System, which is operated by Environmental Assessment and Remediation (EAR). The Badger injection process is used to deliver large volumes of reagent to targeted treatment zones. The objective is to obtain widespread distribution of reagent. Typical injection volumes are 500 to 700 gallons per injection point.

Remediation Approach

The Long Island sites range in size from 600-square-feet to over 4,000-square-feet.

Injection Amounts:

- Site 1 – 30,000 pounds of RegenOx; 4 Injection Events

- Site 2 – 24,000 pounds of RegenOx; 3 Injection Events

- Site 3 – 2,400 pounds of RegenOx; 2 Injection Events

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled direct oxidation and free-radical reactions. This product maximizes in situ performance through the use of a solid alkaline oxidant (a sodium percarbonate complex) and a multi-part catalyst. These oxidation reactions do not inhibit natural bacterial populations and are compatible with biological treatment methods.

REGENESIS® Achieves MCL Cleanup Goals at New York Manufacturing Facility

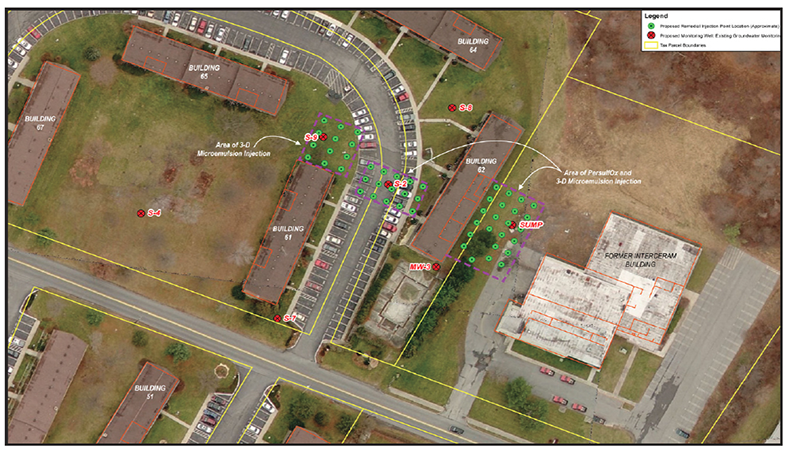

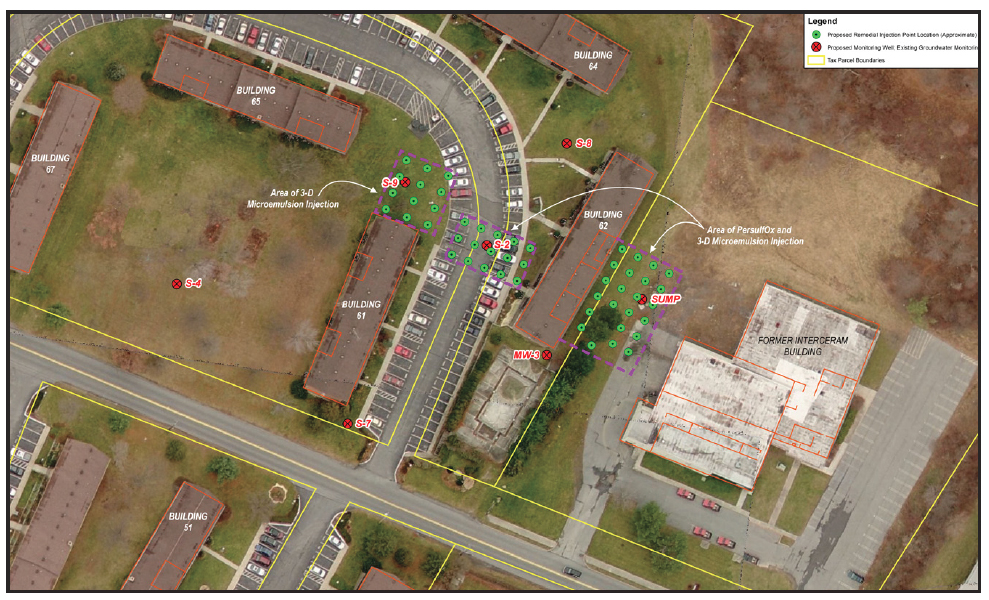

cVOC Contamination Successfully Treated Using PersulfOx® and 3-D Microemulsion®

Project Highlights

- 99% reduction of target compounds achieved on-site

- TCE levels reduced from 8,000 ug/L to <5 ug/L to meet site goals

- Integrated remediation approach using PersulfOx® and 3-D Microemulsion® (3DME)

Project Summary

A manufacturing facility in New York was contaminated with high levels of chlorinated solvents. TCE levels were as high as 8,000 ug/L. A combined remedies approach was established to address the migrating plume. The goal of the application design was to reduce cVOCs in the source area, reduce potential for vapor intrusion and address any cVOCs that may migrate into the area downgradient of the manufacturing facility.

An integrated remediation strategy using PersulfOx and 3DME was implemented on-site. Two PersulfOx applications were completed. Results from the In Situ Chemical Oxidation (ISCO) treated area showed >99% reduction of target compounds. A total of 11,600 pounds of PersulfOx was applied on-site. 3DME was applied to enhance anaerobic biodegradation in downgradient locations and within the PersulfOx-treated area. A total of 8,400 pounds of 3DME was applied. While groundwater contamination in the ISCO treated area was reduced to clean-up standards, the goal of the 3DME application was strictly preventative. The client wished to address any potential plume migration from any cVOCs that may be present beneath the building.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Results

The use of PersulfOx safely and effectively reduced TCE levels to regulatory standards providing a 99% reduction of cVOC’s achieved on-site. In addition, the integration of 3DME as a precautionary safety measure addressed the potential for plume migration that was thought to be present.

Petroleum Hydrocarbon and Chlorinated Solvent Treatment Using PersulfOx™ at a Former Service Station

Overview

Petroleum hydrocarbons and chlorinated compounds were discovered in groundwater at a former gasoline service station/auto-repair facility. This redevelopment site, located in Bronx County, New York, previously housed an underground storage tank (UST) used for gasoline storage. Following the discovery of groundwater contamination in excess of NYSDEC groundwater protection standards, the UST and soils were removed to bedrock at a depth of 11 feet. Further monitoring revealed toluene and benzene contamination as well as tetrachloroethene (PCE) and trichloroethene (TCE) impacts from parts cleaning associated with the on-site auto-repair shop. Remedial action was required to restore site groundwater and make way for redevelopment and construction of a new building. In Situ chemical oxidation (ISCO) using PersulfOxTM was chosen as the remediation approach.

- PersulfOx is a persulfate based ISCO reagent that promotes rapid and sustained in situ oxidation of a wide-range of organic contaminants.

- This patented technology utilizes a unique catalytic surface on which oxidants and contaminants react in a process known as “surface mediated oxidation.”

- PersulfOx also contains built-in activation which eliminates complex and potentially hazardous chemical addition required to achieve traditional persulfate activation.

- From a health and safety aspect, the use of PersulfOx alone is safer than traditional activation methods such as heat, chelated metals, hydrogen peroxide or base.

- If warranted, PersulfOx can also be activated through traditional means to achieve site remediation goals.

The ISCO treatment system consisted of a series of pipes extending below the basement level of the existing slab for the specific purpose of delivering PersulfOx directly onto the bedrock surface. The pipes terminated into dispersion pits scraped into the bedrock allowing PersulfOx to pool and enter the fractures (Figure 1). The ISCO delivery system design allowed for multiple reagent applications as often as required to complete the remediation process.

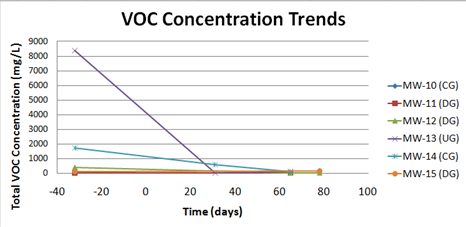

Current trends in the available monitoring well data indicate significant reductions in total VOCs (Figure 2).

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español