Redeveloped DOD Site Treated with Turn-Key ISCO Remediation

PersulfOx® Applied at Four Locations on Former Air Force Base in Ohio

Project Highlights

- RRS applied PersulfOx in four separate areas of this former air base, including the parking lot of an active business ensuring litlle disturbance to the commercial operation

- RRS was able to redesign the project from the field achieving maximum injection without downtime and cost over-runs

Project Summary

Regenesis Remediation Services (RRS) was contracted to remediate this former DOD facility. Perchlorethene (PCE) levels of 400 ppb were treated with in situ chemical oxidation (ISCO) employing PersulfOx Catalyzed Persulfate technology. The application included two injection events which involved working within an active parking area of an operating business. The original site design included utilizing direct-push injections, but RRS readjusted the plan in the field after product surfacing was observed in one area that was under construction. Despite the redesign, the application was completed ahead of schedule and under budget

Remediation Approach

Two injection events included the application of 50,000 pounds of PersulfOx through 85 injection points per event in a grid design with treatment 18-31 feet below ground surface. RRS had initially designed the project to use only direct-push injection points. But after surfacing was witnessed, RRS redesigned the project to include the installation of five injection wells.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Regenesis Remediation Services™ – PCE Plume Treated with 3-D Microemulsion®

Enhanced Reductive Dechlorination & Bioaugmentation Used to Remediate Chlorinated Solvents at a Brownfield Site

A real estate developer and their environmental consultant selected RRS to design and implement an in situ enhanced reductive dechlorination (ERD) remediation plan for this Brownfield site originally developed in the 1890s, called Belknap Crossings. The site was impacted by two groundwater plumes averaging 300 ug/L trichloroethylene (TCE). The remediation design included the use of 3-D Microemulsion® as a controlled-release electron donor and bioaugmentation using BDI® Plus. The two TCE plumes at this

former manufacturing facility covered an area of 58,000 square feet (ft2). A total of 26,000 pounds of 3-D Microemulsion and 22 liters of BDI Plus with over 1011 Dehalococcoides (DHC) cells per liter were injected over a period of less than two weeks on site.

Taking advantage of 3-D Microemulsion’s unique subsurface distribution characteristics, direct-push injection points were advanced every 480 ft2. RRS utilized retractable screen-tip injection tooling to apply the pH neutral 3-D Microemulsion with BDI Plus at discrete intervals across the vertical treatment interval from 24 feet below ground surface (bgs) to 34 feet bgs in a bottom-up approach. The RRS trailer and equipment configuration allowed for low pressure application of the remediation chemistry at up to three injection points simultaneously, up to 200 feet from the trailer while monitoring flow rates and injection pressures at each application point.

Regenesis Remediation Services™ – PCE Plume Treated with 3-D Microemulsion®

Combined Treatment Remedies Used to Reductively Dechlorinate Contamination at Former Dry Cleaners Site

Regenesis Remediation Services (RRS) was contracted to design and implement the treatment of groundwater contaminated by residual chlorinated volatile organic compounds (cVOCs) at this former dry cleaner site. The design included the use of 3-D Microemulsion® as a controlledrelease electron donor and bioaugmentation using BDI® Plus. The treatment area covered approximately 600 square feet (ft2), and a total of 800 pounds of 3-D Microemulsion and 18 liters of BDI Plus with over 1011 (Dehalococcoides) DHC cells per liter were injected throughout the treatment area in one day of work.

Taking advantage of 3-D Microemulsion’s unique ability to distribute in the subsurface via micellar movement, twelve direct-push injection points were advanced every 50 ft2. RRS utilized retractable screen-tip injection tooling to apply the pH neutral 3-D Microemulsion with BDI Plus at discrete intervals across the injection vertical treatment interval from 6 to 13 feet below ground surface (bgs). The RRS trailer and equipment configuration allowed for low pressure application of the remediation chemistry while monitoring flow rates, reagent distribution, and injection pressures at each application point.

Regenesis Remediation Services™ – TCE Plume Treated with 3-D Microemulsion®

Enhanced Reductive Dechlorination & Bioaugmentation Used to Remediate Chlorinated Solvents at a Brownfield Site

A real estate developer and their environmental consultant selected RRS to design and implement an in situ enhanced reductive dechlorination (ERD) remediation plan for this Brownfield site originally developed in the 1890s, called Belknap Crossings. The site was impacted by two groundwater plumes averaging 300 ug/L trichloroethylene (TCE). The remediation design included the use of 3-D Microemulsion® as a controlled-release electron donor and

bioaugmentation using BDI® Plus. The two TCE plumes at this former manufacturing facility covered an area of 58,000 square feet (ft2). A total of 26,000 pounds of 3-D Microemulsion and 22 liters of BDI Plus with over 1011 Dehalococcoides (DHC) cells per liter were injected over a period of less than two weeks on site.

Taking advantage of 3-D Microemulsion’s unique subsurface distribution characteristics, direct-push injection points were advanced every 480 ft2. RRS utilized retractable screen-tip injection tooling to apply the pH neutral 3-D Microemulsion with BDI Plus at discrete intervals across the vertical treatment interval from 24 feet below ground surface (bgs) to 34 feet bgs in a bottom-up approach. The RRS trailer and equipment configuration allowed for low pressure application of the remediation chemistry at up to three injection points simultaneously, up to 200 feet from the trailer while monitoring flow rates and injection pressures at each application point.

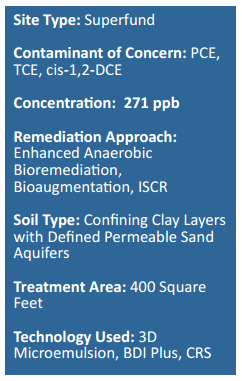

Combined Remedies Treat Chlorinated Solvents at Gulf Coast Superfund Site

Former Industrial Facility and Landfill Pilot Test Shows Rapid Reduction in PCE, TCE and 1,2 DCE

Project Highlights

- Superfund Site once housed an industrial facility and landfill.

- Rapid reduction needed to avoid off-site migration of daughter products.

- Simultaneous application of Enhanced Aerobic Biodegradation, Bioaugmentation and In Situ Chemical Reduction (ISCR).

Project Summary

This former industrial property had a landfill that was used in the mid-1900s for disposal of magnesium dross and refractory brick as well as breakout material from electrolytic chlorine cells. As much as 254,000 cubic feet of material were removed from the landfill although a large chlorinated solvent plume remains both from landfill waste below the water table and from industrial operations on-site. A feasibility study for the site was approved in 2012 which evaluated the use of enhanced reductive dechlorination to treat dissolved chlorinated solvents at the site and to prevent off-site migration past the property boundary and beneath a highway. A pilot test to evaluate at least two different biological amendments was conducted and Regenesis supplied 3D Microemulsion, BDI, and CRS for the evaluation. Three aquifers exist at the site, but the pilot test was performed in the first groundwater bearing unit only.

Remediation Approach

After a review of sulfate concentrations, other natural attenuation data, and cVOC concentrations it was determined that the optimal treatment choice would be to test a combination of an electron donor in the form of 3-D Mircoemulsion®, a bioaugmentation culture called Bio-Dechlor INOCULUM® Plus, and the use of Chemical Reducing Solution® (CRS) to prevent any hydrogen sulfide toxicity and to promote a level of beneficial in situ chemical reduction (ISCR). For the pilot test 10 injections points were used to place 800 pounds of 3-D Microemulsion, 18 liters of BDI Plus and 400 pounds of CRS. The product was injected over a 10-foot interval.

The goal for this project was to attain as rapid reduction as possible for the site specifically to avoid off-site migration of daughter products such as vinyl chloride. Therefore, it was deemed beneficial to inject all three proposed products at once. The product was injected in March 2014 and results at roughly 1 month post injection are extremely promising. PCE has been reduced from 134 ppb to 1.57 ppb, TCE from 271 ppb to 1.77 ppb, and cic-1,2-DCE from 235 ppb to 4.25 ppb. Vinyl Chloride has shown some increase from non-detect to 13 ppb.

However, Dehalococcoides has increased from non-detect to 7 x 10×5 cells/bead and vinyl chloride reduced from nondetect to 9 x 10×4 cells per bead which strongly correlates to the rapid enhanced reductive dechlorination.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory emulsified product.

BDI Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

CRS (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

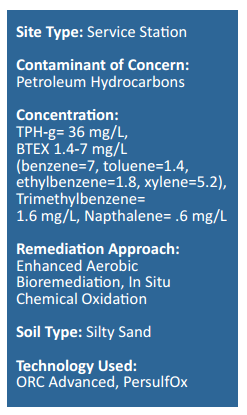

Former Service Station Treated on Native American Reservation Land

Combined Remedies Used to Remediate BTEX Contamination

Project Highlights

- Enhanced Aerobic Bioremediation and In Situ Chemical Oxidation used to treat high BTEX levels on-site

- Previous remediation activities included soil excavation but contamination persisted

- One application area located in lot used for beef cattle on reservation land and special approvals were required

- Project was state-funded by Pollution Liability Insurance Agency (PILA) of Washington but regulated by Region 10 EPA resulting in extensive coordination between both agencies

Project Summary

This Wapato, Washington site was a former gas station with historical releases dating back to at least 1995. It is located on a Native American Reservation so the site is regulated through Region 10 of the EPA.

The initial remedial activities consisted of excavation of source area soil but contamination remained. Considering the persistent contamination, the goal of the site was to reduce the remaining concentrations to meet regulatory goals.

Remediation Approach

A combied remedies strategy was devised for this site, including in situ treatment in three separate areas. Two areas were treated with both PersulfOx® and ORC® Advanced.

The third area was an empty lot that was used for ranging beef cattle. The client had concerns about how the treatment might affect the cattle, so only ORC Advanced was applied to this area because it is both insoluable and non-toxic. Because the entire site was located on reservation land it required special approvals by the tribal irrigation office before the injections could occur. A total area of 4,100-square-feet was treated for high levels of BTEX. Monitoring is ongoing.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator

PersulfOx® ISCO Remediation Reduces BTEX F1 & F2 Concentrations at Alberta Municipal Affairs Site

ISCO Solution Results in Cost Savings and Treatment Area Reduction at Former Service Station

Project Highlights

- In Situ Chemical Oxidation (ISCO) used as a cost-effective alternative to excavation remediation methods

- In Situ treatment using direct push resulted in reduction in treatment area

- ISCO solution met time and budget goals

Project Summary

BTEX contaminated soil was found at an Alberta Municipal Affairs (AMA) site. The former service station located in Central Alberta, Canada had left a petroleum leak creating a smear zone with F1 and F2 concentrations at the source of the plume. Since the AMA site had limited funding and time constraints, a persulfate-based ISCO solution using PersulfOx was recommended to significantly reduce high petroleum concentrations in the soil and groundwater. This site marked the first time the engineering firm working with REGENESIS had employed an ISCO solution, having used excavation remediation methods as their recommended approach in the past. An expedited remediation plan was created and included multiple rounds of PersulfOx injections to treat the site.

Remediation Approach

PersulfOx was applied in seven existing monitoring wells. Working with the engineering firm, using direct-push injection of PersulfOx, REGENESIS strategically focused the application around two of the existing monitoring wells. Due to the saturated soil type and an increased risk for surfacing, precise application-volume monitoring was required. After the first round of two applications was completed, overall contaminant concentrations decreased.

REGENESIS Solution Applied

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

The REGENESIS ISCO plan incorporating direct-push injections of PersulOx significantly reduced the level of BTEX contaminant concentrations following the first round of application. The PersulfOx solution effectively addressed the plume in the saturated smear zone, while meeting the goals of the project, as well as the client’s time and budget constraints.

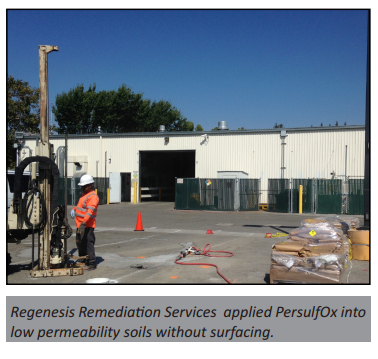

Former Paint Manufacturing Facility Treated for MIBK, BTEX

RRS Implements Cost-Effective, Turn-Key Remediation in Low-Permeability Soils

Project Highlights

- Soil and groundwater impacted with both BTEX and MIBK.

- Low-permeability soil was of a concern to the client, however very little surfacing was witnessed post-injection.

- Regenesis Remediation Services (RRS) finished the project in half the time and nearly half the cost of competing firms.

Project Summary

Site operations at a former paint manufacturing facility in Northern California caused soil and groundwater to be impacted with MIBK and BTEX compounds. The site was under an order for clean-up through the regional water quality board and the treatment was designed to use in situ chemical oxidation (ISCO) to reduce contaminant mass in the source area before transitioning to MNA.

Remediation Approach

Comprised of what the consultant described as “San Francisco Bay Muds” or essentially clay soil with sand stringers, the site had challenging geologic conditions. At first, the client was apprehensive about the ability to inject PersulfOx® into the tight soils without surfacing. However, a turn-key approach was devised during the design of this project, with an emphasis on minimizing product application costs and addressing any possible surfacing issues. A total of 29,644 pounds of PersulfOx was applied by RRS in two applications, through a total of 58 directpush points and 2 injection wells at the site. The product was applied at a 20% solution for a total injection volume of 15,691 gallons.

The injections were completed in half the time and nearly half the cost of what other injection contractor firms proposed. The capabilities of the RRS team, trailer and ability to manifold and inject into four points at one time resulted in significant time and cost savings for the client. Monitoring is ongoing.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solventtype contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

RRS is a dedicated team of scientists and engineers whose primary function is to provide environmental engineering and consulting firms with specialized groundwater and soil remediation planning, design, verification and application services.

In Situ Chemical Oxidation Treats High TPH Concentrations

Over 114,000 Pounds of PersulfOx® Applied to Illinois Manufacturing Facility

Project Highlights

- High levels of TPH and TCE were detected on-site after a suspected cutting oil/degreasing solvent spill.

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility.

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site.

- Tight treatment deadline met through the use of PersulfOx in 2,204-pound SuperSacks, which were delivered within a few days’ notice.

Project Summary

An Illinois metal fabrication manufacturing facility has been in operation since the early 1900s and is still active today. The use of cutting oils and degreasing solvents lead to high levels of TPH and TCE on-site. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent waterbody. A mechanical oil recovery system was installed and absorbent booms were used to mitigate the oil from reaching the river. ISCO was selected as the remediation approach to address the contamination below the active facility through a series of applications. Additionally, the TCE area was treated with PersulfOx® via injection wells and a soil mixing application.

Remediation Approach

Prior to the start of remediation activities, the primary consultant was removed from the project and a new firm was brought in. The remediation firm placed a tight deadline (a couple of months) to complete the full scope of activities. REGENESIS was able to assist with keeping the project on-deadline through the delivery of 2,204-pound PersulfOx SuperSacks, which were delivered within a few days’ notice. The consultant had a series of injection wells installed inside and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation, and Oxygen Release Compound (ORC®) Advanced Pellets will be used as a long-term oxygen source for enhanced bioremediation of the residual TPH.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

Site Closure Achieved at Colorado Service Station

Benzene Levels Reduced to Below 5 PPB in Clay Soils through Use of ORC® Advanced

Project Highlights

- Benzene concentrations remained on-site despite previous excavation efforts.

- Enhanced aerobic biodegradation using ORC Advanced produced a 99.8% reduction over 12 months.

- Benzene reduced to below detection limits.

- “No Further Action” letter granted in October 2010.

Project Summary

Three underground storage tanks (USTs) were removed at a former tire store as part of corrective measures. Roughly 108 cubic yards of soils were excavated to reduce contamination levels. However, the excavation did not extend below the groundwater interface and residual sorbed contaminant mass remained, resulting in a lingering benzene plume. The client was interested in an in situ approach to reduce the remaining benzene contamination to below the Tier 1 risk based screening level of 5 ppb.

Remediation Approach

A direct-push injection of Oxygen Release Compound Advanced (ORC® Advanced) was chosen to reduce remaining soil and groundwater contamination at the location of the former excavation and well BW-1. Maximum TVPH and benzene concentrations in the prior two years were as high as 2.4 mg/L and 0.48 mg/L, respectively. Due to tighter soils, a 7-footon-center grid pattern with 15 injection points was implemented on-site. ORC Advanced was injected from approximately 6 to 13 feet below ground surface with about 1 foot of the injection interval extending above groundwater in the event of rising water levels. A total of 725 pounds of ORC Advanced was injected for this project.

Despite the relatively tight soils and high potential for contaminant back diffusion, the ORC Advanced treatment resulted in consistent downward trends of benzene contamination. A 96.3% reduction in benzene after only 3 months was observed. By month 12, a 99.8% reduction to below detection limits (The site was granted a no further action letter.)

Technology Description

ORC Advanced® is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español