Phased treatment allows main contractor to keep programme on track

Summary

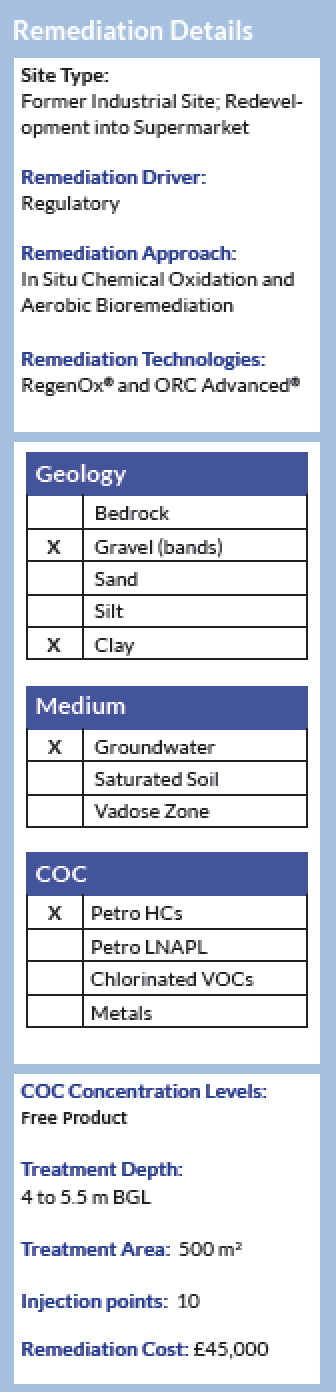

A former industrial site in the north of the UK was undergoing redevelopment to build a large supermarket. REGENESIS was employed to undertake treatment of an isolated petroleum hydrocarbon hotspot and treatment of the base of two excavations following removal of underground storage tanks. The treatment was carried out in three stages, whilst allowing the Main Contractor to continue with ground re-profiling and piling works. REGENESIS also carried out monitoring well installation works at the site.

Treatment

The hotspot of petroleum contamination containing high concentrations of TPH was treated with 3 rounds of RegenOx®, applied by direct push injection, to provide rapid in situ chemical oxidation. During the final round ORC Advanced® was also applied to provide a controlled release of dissolved oxygen and enhanced aerobic biological degradation of the residual dissolved phase contamination for a period of up to 12 months. ORC Advanced Pellets were also applied directly into to the 2 excavations to provide in-situ enhanced aerobic degradation of any residual contamination.

What’s Special

- The in situ nature of the treatment and the application using direct push injection avoided the requirement for remediation infrastructure at the site. This allowed the Main Contractor to continue with their enabling works, with no effect on project programme

- RegenOx used to rapidly reduce high concentrations of TPH

- ORC Advanced added to the final application in order to provide up to 12 months enhanced aerobic biological degradation of the residual dissolved phase contamination from a single injection.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español