RegenOx® and 3-D Microemulsion® Injections Treat VOC Impacted Soils

PCE Contamination at Former Dry Cleaning Site in Northern California Remediated

Project Highlights

- PCE soil concentrations of up to 16,095 ug/kg in the hot spot area

- After initial ISCO application, ERD was used to continue VOC concentration reduction

- Latest sampling event reported concentrations below clean-up target levels

- No further remediation needed on-site

Project Summary

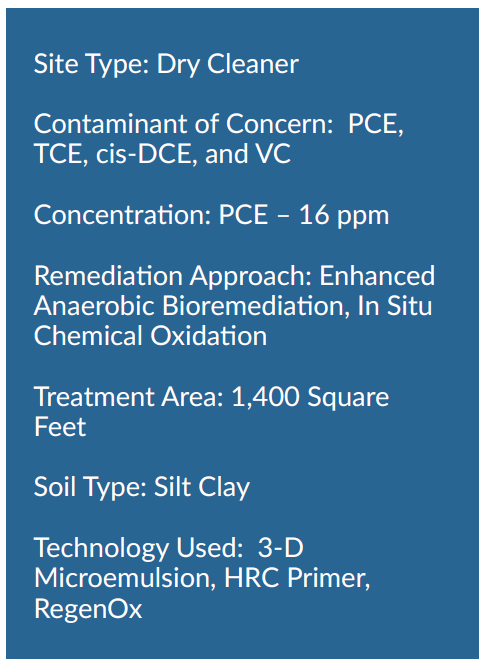

In 2007, VOCs including (PCE) and related compounds including (TCE), (cis-DCE), and vinyl chloride (VC) were detected in soil and groundwater samples collected at a site in Northern California. A comprehensive field investigation conducted under the Regional Water Quality Control Board identified a distinct VOC-impacted soil area behind the former dry cleaner. Site characterization work identified the presence of VOCs including PCE with soil concentrations of up to 16,095 ug/kg in the hot spot area. A combined technology remediation approach was

implemented on-site including injections of RegenOx®, 3-D Microemulsion® and HRC® Primer. At the most recent sampling event, approximately 2.5 years post-application, the maximum detected concentrations of PCE and related VOCs was 420 ug/kg and all soil sample results were below the Soil Cleanup Levels. These data suggest that the combination of in situ chemical oxidation (ISCO) with RegenOx, followed by enhanced reductive dechlorination with 3-D Microemulsion has been highly effective in reducing VOC concentrations in soil.

Remediation Approach

Three rounds of ISCO injections with RegenOx were applied on-site to treat the vadose zone soils. After the first round of injection, PCE was detected in soil samples collected in this area at maximum concentrations of 2,000 ug/kg, which, while substantially lower than initial concentrations indicated a need for further treatment. Enhanced reductive dechlorination (ERD) was performed by injecting 3-D Microemulsion and HRC Primer into vadose zone soil to treat PCE and related daughter products. The products were injected into 33 borings in the hot spot area with the treatment interval between 3 feet and 17 feet below ground surface. The most recent soil samples indicated a VOC concentration reduction to below the Regional Water Board’s soil to groundwater leaching ESLs (upon which the Site Cleanup Levels listed in the Site Cleanup Order were based). As a result, residual VOC concentrations in soil in the hot spot area do not appear to present a significant source for leaching to underlying groundwater. Continued groundwater monitoring being performed. No further remediation is required in this area.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

3-D Microemulsion factory emulsified is an engineered electron donor material that offers a novel 3-stage electron donor release

profile, pH neutral chemistry and is delivered on-site as a factory–emulsified product.

HRC Primer is a less viscous version of the standard Hydrogen Release Compound (HRC) product. It is a thinner, water-like compound that is typically injected into an aquifer where it releases lactic acid at a rate faster than standard HRC (several weeks), but at a slower, more controlled rate than dispersing aqueous simple sugar solutions or straight lactic acid (several days).

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español