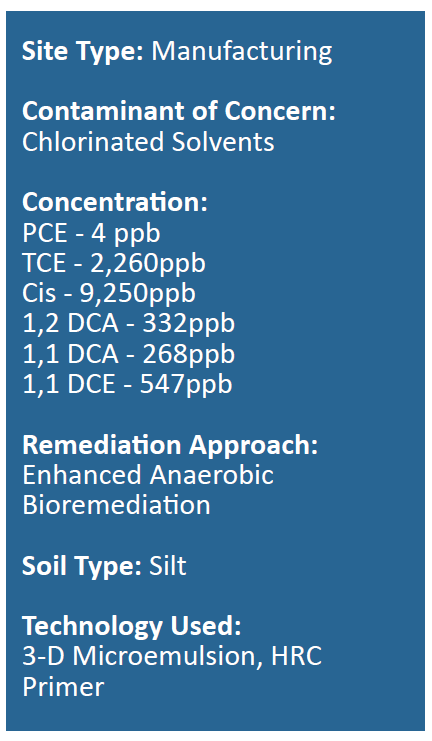

Historic California Site Treated with 3-D® Microemulsion and HRC® Primer

Project Highlights

- Site was open for over 20 years with the Central Coast Regional Board

- Immediate results showed a TCE decrease from 2,260 ppb to 12 ppb

- Site is currently under review for closure

- Cost per cubic yard was under $10 per cubic yard complete turn-key

Project Summary

This California site has been open with the Central Coast Regional Board for over 20 years with groundwater VOC concentrations thousands of times higher than the MCL. The site also had limited metal concentrations above MCL. A remediation plan was created to treat the groundwater plume using enhanced anaerobic bioremediation via Hydrogen Release Compound (HRC®) Primer and 3-D Microemulsion®. Immediate results showed a decrease in TCE concentrations from 2,260 ppb to 12 ppb.

Remediation Approach

Seven separate designs were developed to treat the 60,450-square-foot area. Several water bearing zones were treated throughout the site. Initial concerns for treatment included the possibility of a buildup of methane in the soil gas. However, because 3-D Microemulsion is a controlled-release, high-volume electron donor, no methane issues were observed. Cost for the product and application was less than $10 per cubic yard and the site is currently under review for closure.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

HRC Primer is a less viscous version of the standard Hydrogen Release Compound (HRC) product. It is a thinner, water-like compound that is typically injected into an aquifer where it releases lactic acid at a rate faster than standard HRC (several weeks), but at a slower, more controlled rate than dispersing aqueous simple sugar solutions or straight lactic acid (several days).

PlumeStop Application Pilot Study: Former Dry Cleaner Site, USA

Approach

A beta-test pilot evaluation of PlumeStop™ performance was conduced on chlorinated solvent groundwater contamination at a former dry cleaner site. PlumeStop was applied in conjunction with the slow-release electron donor, HRC® and the microbial bioaugmentation dechlorinator inoculum, BDI® for the treatment of residual PCE (550 μg/L). The test was conducted around a single well. Conditions prior to the test were aerobic (ORP +254 mV; DO 44%). Multiple parameters were monitored from groundwater samples to explore lines or evidence of solvent fate / degradation.

2m 27s reading time

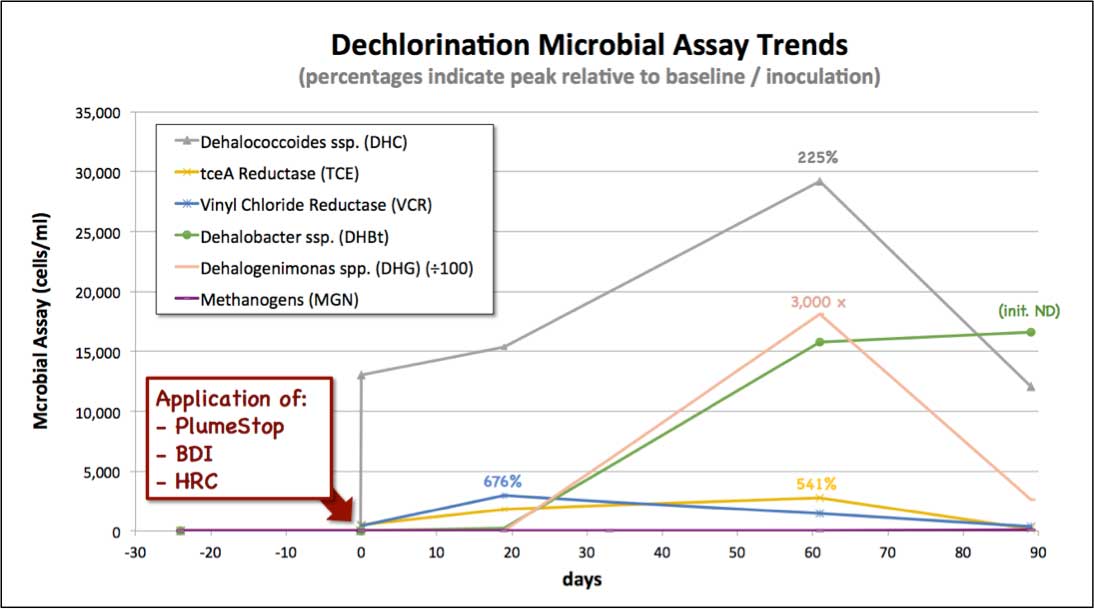

Results

Post-treatment solvent concentrations in groundwater were reduced by over 99% to non-detect (<5μg/L) by the first sampling round (19 days). Microbial quantitative array data revealed marked increases in reductive dechlorinator species from baseline conditions in the months following reagent application (several hundred percent or more). (Baseline taken as immediately post-inoculation for species included in BDI). Moreover, functional enzymes for dechlorination of PCE through to ethene similarly increased over the same period (i.e. including specific genes for the degradation of TCE, DCE and vinyl chloride). Through this time, groundwater concentrations of PCE and daughter products remained below detection limits (>15 months post treatment).

Electron donor status and redox potential post-application quickly stabilised at near-optimal conditions ( 150mV +/- 30 mV), with rapid decreases in competing electron acceptors observed within the first sampling intervals, albeit with some interplay with available iron, possibly reflecting an electron shuttle dynamic with iron naturally present within the formation. The redox remained below methanogen activity thresholds – methanogen numbers did not share the trends observed in dehalorespirers, and in fact were detected above quantitation thresholds (2 – 30 cells /ml) in one sampling event only, at significantly lower cell counts than Dehalococcoides (94 vs. 12,200 cells/ml).

Discussion

The continued expansion and proliferation of an active dechlorinating microflora in the months following inoculation are indicative of solvent biodegradation through this time. That no solvent was present above detection limits in groundwater through the same period would indicate the degradation to be proceeding ostensibly from the sorbed phase (i.e. PlumeStop/water interface). This would be consistent with the PlumeStop bio-matrix hypothesis. It is also of note that the dechlorinator numbers and activity peaked at approximately sixty days and declined thereafter. Although the data set is limited, this trend would be consistent with the presumed depletion of the solvent through degradation, the starting concentration having been only 550 μg/L.

Conclusion

These data provide lines of evidence for post-sorption degradation of the target solvents on the PlumeStop, and would further indicate that methanogenic conditions are not necessary for complete reductive dechlorination activity through to ethene. Moreover, all data were obtainable from groundwater samples presenting a straightforward means of performance tracking via wells using the lines of evidence approach.

What’s Special

- Depletion of groundwater solvent concentrations to non-detect within 19 days

- All Contaminants of Concern (PCE and daughter products) are remaining below detection limits 15 months post application (and counting)

- Multiple lines of evidence for post-sorption solvent degradation

- All data obtainable from groundwater samples alone

- No generation of methane / competition from methanogens

PlumeStop® Applied to Former Electronics Facility in Indiana Achieves 99.9% Reduction in 2 Months

Project Highlights

- 92% reduction within two weeks

- 99.9% reduction in two months

- Combined remedy approach reduced mixed VOC plume to non-detect within nine months (<5μg/L)

- No rebound in over 18 months of site monitoring

1m 31s reading time

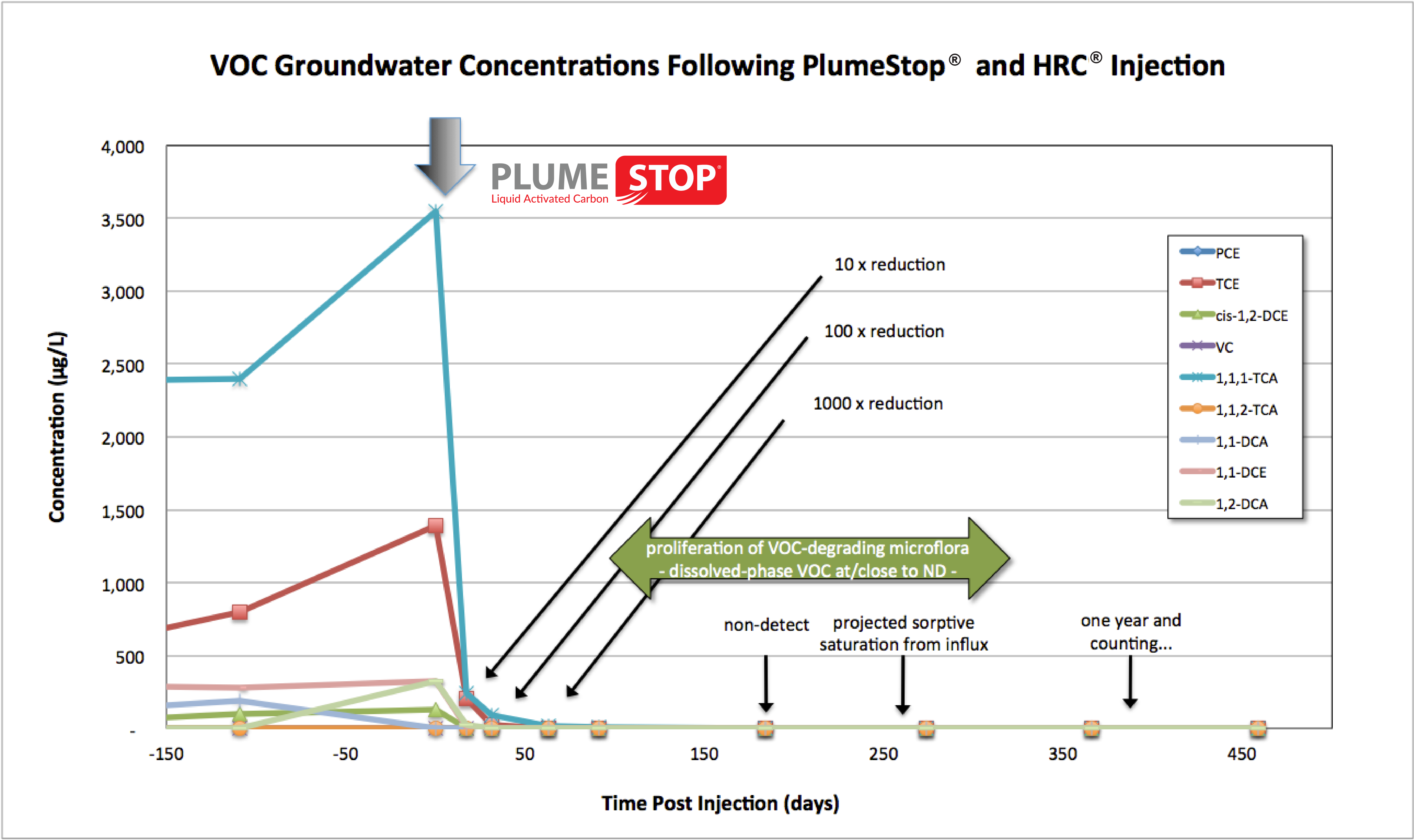

Project Summary

An evaluation of PlumeStop performance was conducted on a section of a mixed chlorinated solvent plume (cVOC) comprising trichloroethene (TCE – 1,390 μg/L) and 1,1,1-trichlorotethane (TCA, 3,550 μg/L) at a former electronics facility in Indiana. PlumeStop was applied in conjunction with the controlled-release electron donor, Hydrogen Release Compound (HRC®). Post-treatment solvent concentrations in groundwater were reduced in two weeks by 92% at the first sampling round. Concentrations were reduced by 99% by the second sampling round (one month) and 99.9% by the third sampling round (two months). No cVOCs were detected above analytical thresholds (<5μg/L) after three months. Source area treatment activities are being monitored for closure and the results are being evaluated as a potential larger scale plume treatment option.

Remediation Approach

PlumeStop was applied perpendicularly to the groundwater flow using 10 direct-push injections around a central monitoring point. Approximately 180 pounds of HRC was applied into three injection points.

REGENESIS Solution Applied

PlumeStop is an innovative in situ remediation technology designed to rapidly reduce contaminant concentrations, stop migrating plumes, eliminate contaminant rebound, achieve stringent clean-up standards and treat back-diffusing contaminants. PlumeStop provides a unique colloidal biomatrix platform which rapidly sorbs contaminants out of the dissolved-phase. Once contaminants are concentrated within the PlumeStop biomatrix, they can be completely biodegraded in place using compatible REGENESIS bioremediation products.

HRC is a controlled release, electron donor material, that when hydrated, is specifically designed to produce a controlled release of soluble lactate. The newly available lactic acid is highly efficient for the production of dissolved hydrogen to fuel anaerobic biodegradation processes in soil and groundwater.

Results

Using a combined remedy approach, the application of PlumeStop and HRC successfully reduced contaminant levels to non-detect and positioned PlumeStop as a viable solution for larger scale projects.

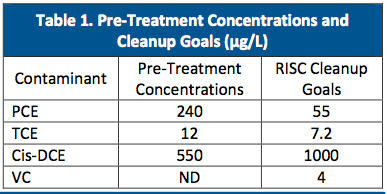

Long-Term Chlorinated Solvent Treatment using a Controlled-Release Microemulsion

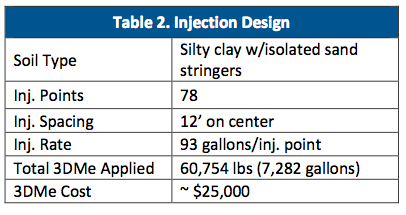

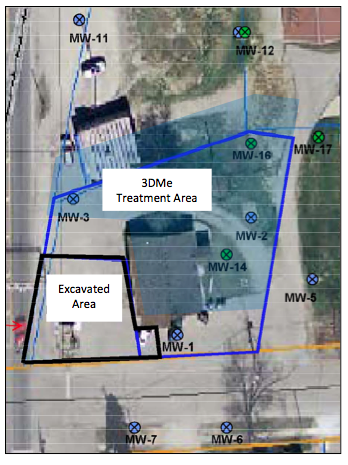

PROJECT SUMMARY

- Dry cleaning operations resulted in a chlorinated solvent plume with concentrations as high as 700 micrograms per liter (μg/L) in chlorinated solvents

- Typical Midwestern geology: Silty clay with intermittent sand stringers underlain by a clay till confining layer

- Contaminants of concern within the silty clay aquifer included tetrachloroethene (PCE) and trichloroethene (TCE) (see Table 1)

- High sulfate environment (~100 mg/L) – potential inhibitor for successful remediation

- Cleanup goals were based on the Industrial Risk Integrated System of Closure (RISC) levels

- Enhanced anaerobic bioremediation of chlorinated solvents in groundwater using 3-D Microemulsion (3DMe)®

- $195,000 (Costs include 3DMe® material, injection, field oversight, 2 yrs post injection monitoring, project management and report writing)

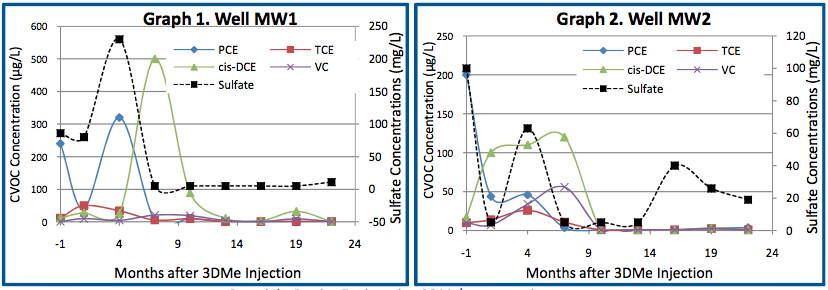

RESULTS

- The 3DMe application overcame high sulfate levels and resulted in a reducing environment lasting almost 2 years

- Sampling at 22 months post-3DMe indicated sustained low levels of ORP (-136mV) and DO (1.3mg/L)

- Reduction of chlorinated solvents by 83% to 98% in all impacted wells

- Site is pending closure from regulatory agency

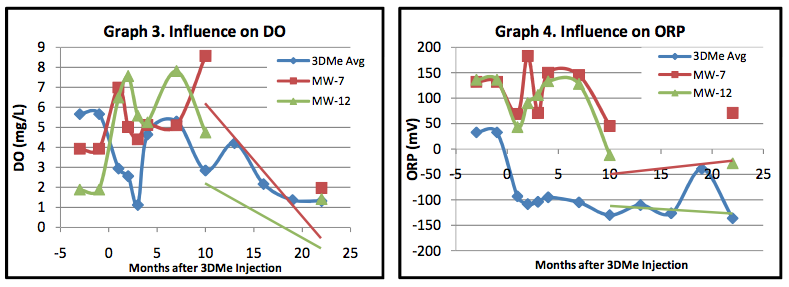

ELECTRON DONOR INFLUENCE

Analytical parameters including oxidation-reduction potential (ORP), dissolved oxygen (DO) and total organic acids (TOAs) were monitored to verify the influence of the electron donor post-injection. The monitoring wells likely influenced by 3DMe (MW1-3, MW5, MW14-17) were analyzed on average and compared to background wells MW7 and MW12.

Within the 3DMe influence area:

- On average, ORP reduced to -100mV and DO levels declined to ~2mg/L (Graphs 3 and 4)

- Concentrations of TOAs were detected at >1,000 mg/L during the first 10 months of

monitoring

DOD Treatability Study Documents Successful Carbon Tetrachloride Remediation using HRC®

Contaminant Concentrations Reduced by 99% Within One Year

Project Highlights

- Treatability study demonstrated effective reduction of carbon tetrachloride and benzene contamination

- Combined application of HRC® and HRC Primer® reduced carbon tetrachloride concentrations to below cleanup goal within one year

- Influx of additional carbon tetrachloride contamination to the site was buffered by enhanced anaerobic bioremediation

Project Summary

Historic operations at a Department of Defense site in Maryland resulted in soil and groundwater contamination with carbon tetrachloride, benzene, and chloroform at concentrations of 274 μg/L, 178 μg/L, and 21 μg/L, respectively. Monitoring at the site revealed decreasing trends in contaminant concentrations as a result of natural attenuation. However, the site was on a redevelopment schedule and monitored natural attenuation was deemed to be too slow and costly.

The Air Force, in conjunction with the Comprehensive Environmental Response, Compensation, and Liability (CERCLA) Partnering Team, agreed to perform a treatability study to observe the effectiveness of enhanced anaerobic bioremediation to reduce the contaminants. A focus was placed on the biodegradation of carbon tetrachloride due to its highly recalcitrant nature; if it could be treated, so could the other constituents, such as benzene1. Although benzene is commonly degraded under aerobic conditions, the destruction of the contaminant has also been known to occur under anaerobic conditions.1

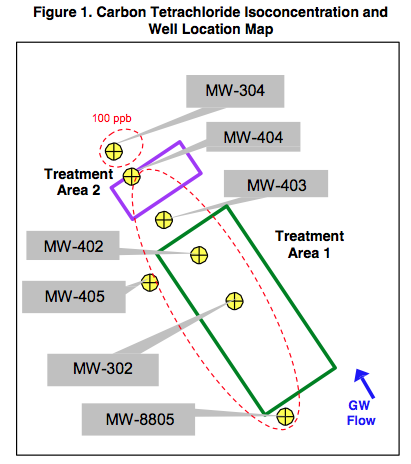

A mixture of HRC and HRC Primer was applied to the contaminated site to establish optimal reducing conditions in groundwater and thereby enhance the process of reductive dechlorination. Direct-push injections were applied in a grid pattern within the two treatment areas shown in Figure 1. Groundwater monitoring was conducted in and around the treatment areas to evaluate the distribution and treatment effectiveness.

Technology Description

HRC is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils.

HRC Primer is derivative of the standard Hydrogen Release Compound (HRC) product and is designed to provide a controlled but fast release of hydrogen to assist in initiating anaerobic biodegradation.

Results

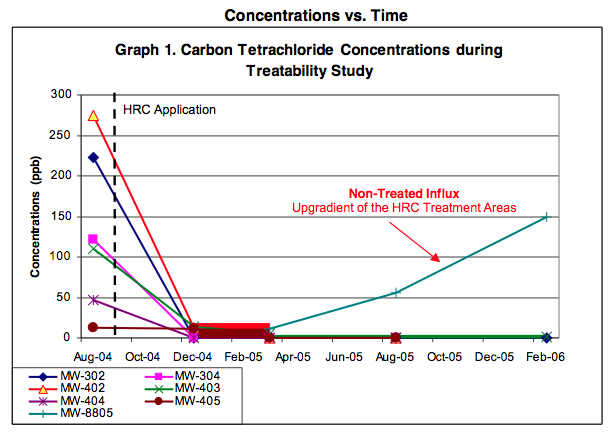

Carbon Tetrachloride Reduced up to 99% After 3 Months

Sampling results three months after the HRC/HRC Primer injection revealed carbon tetrachloride reductions of 87% – 99% within the treatment areas. Downgradient wells MW-403 and MW-304 were also affected by HRC, with carbon tetrachloride concentrations declining below the maximum contaminant level (MCL) of 5 μg/L. Continued reductions in the HRC-affected wells were observed over the following year, with levels dropping below the cleanup goal in 5 of the 6 wells. (Graph 1).

During the same sampling period, a continuous increase in the concentration of carbon tetrachloride was observed in well MW-8805 upgradient of the treatment areas. This increase is indicative of an influx of additional contamination to the area, which is assumed to have also occurred within the nearby treatment areas. Importantly, the contaminant levels within the HRC-affected wells remained below 5 μg/L during this period, indicating the effective treatment of both resident and influx carbon tetrachloride.

Benzene Concentrations Declined Up To 98%

Baseline benzene concentrations exceeded 150 μg/L prior to the treatability study. Reducing conditions were established shortly after the HRC/HRC Primer injection, and concentrations declined 56% – 98% over the following 18 months. Concentrations are expected to reach the cleanup goal of 5 μg/L as HRC continues to be effective in the subsurface.

Chloroform Concentrations Reduced to Cleanup Standards

Initial chloroform concentrations were above 20 μg/L. Six months post-HRC application, 3 out of the 6 HRC-treated wells sampled below the MCL of 0.15 μg/L. Within 12 months, the cleanup goal was reached in all wells except MW-403 (2.3 μg/L).

1 In the presence of certain microbes, Dechloromonas strain RCB and strain JJ, Benzene can be degraded anaerobically (Coates, J. D., Chakraborty, R., Lack, J. G., O’Connor, S. M., Cole, K. A., Bender, K. S., Achenback, L. A. “Anaerobic Benzene Oxidation Coupled to Nitrate Reduction in Pure Culture by Two Strains of Dechloromonas.” Nature June 28, 2001: 1039-1043.)

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español