Efficient Application of Combined Amendments Reduces PHC Concentrations Below Washington MCTA Levels

Project Highlights

- In Situ injection application of PlumeStop® Liquid Activated Carbon™ and ORC Advanced® brings closure to facility identified as Leaking Underground Storage Tank (LUST) site

- REGENESIS® Remediation Services (RRS) used a multi-point approach to efficiently inject the combined amendments, completing the application within 24 hours

- PHCs in groundwater and soil reduced below Washington Department of Ecology’s Model Toxics Control Act (MTCA)

2m 34s reading time

Project Summary

An active gas station in Bothell, Washington was listed as a LUST site by the State of Washington Department of Ecology after two subsurface investigations detected petroleum hydrocarbon (PHC) impacted soil and groundwater. Entering into the state’s Voluntary Cleanup Program (VCP) in 2001, the site continuously failed to meet regulatory requirements defined in the MTCA, despite several years of cleanup efforts using a soil vapor extraction (SVE) system and an air sparge (AS) system to remove contaminant concentrations from beneath the site. Charged with remediation, Antea® Group partnered with REGENESIS to implement a solution, which included in situ injection applications of PlumeStop and ORC Advanced technologies.

REGENESIS injected approximately 200 gallons of PlumeStop using strategically placed point locations to rapidly reduce contaminant concentrations. Direct Push Technology (DPT) was employed to advance injection points throughout the treatment zone. The following day, the solution was increased, for a total of 835 gallons of PlumeStop solution (as applied with water) injected within the targeted treatment interval to deliver the full volume of remediation ammendment and complete the application on schedule. A total of nine (9) PlumeStop DPT injection points were cleared to 5 ft. bgs pre-injection.

Additionally, 120 lbs. of ORC Advanced were applied in cleared boreholes via a backfilling method, which involved drilling to the target depth, retracting the rods and pouring the ORC Advanced slurry down open boreholes to approximately 5 ft. bgs in order to properly abandon points.

Technology Description

PlumeStop – An innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation. PlumeStop is composed of very fine particles of activated carbon (1-2μm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and enhancing permanent contaminant biodegradation.

ORC Advanced – An engineered, oxygen-release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced produces a controlled release of molecular oxygen accelerating aerobic biodegradation processes up to 100 times f aster than natural degradation rates.

Results

During the course of the injection and at the end of the application, increases in groundwater levels, ORP (oxidation reduction potential), and dissolved oxygen were observed in monitoring wells in the treatment area. The successful application of both technologies was achieved within approximately 24 hours, despite the challenging glacial till geology known to the region. With field modifications, RRS was able to not only mitigate surfacing issues by switching to injection via injection-well application, but also achieve the desired distribution of the remediation substrate in the subsurface. The first quarter sampling results indicate that the contaminant concentrations are at non-detect. Following monitoring events over the next three quarters, this site will be closed and issued a No Further Action (NFA) from the Washington Department of Ecology.

About the Client

Antea Group is an international engineering and environmental consulting firm specializing in full-service solutions in the fields of environment, infrastructure, urban planning and water. With more than 3,000 employees in over 100 offices around the world, Antea Group serves clients ranging from global energy companies and manufacturers to national governments and local municipalities.

HRC Barrier Applied Successfully Reduces TCE Levels to Non-Detect in Fractured Bedrock Site

Project Highlights

- Based on successful pilot test results, full-scale implementation of HRC barrier was applied

- TCE levels reduced by 99% within one year & at non-detect levels within 18 months

- Innovative design was effective in addressing contaminants of concern

Project Summary

At a manufacturing facility in Virginia, HRC® was injected into a crystalline bedrock aquifer contaminated with TCE and its daughter products. The industrial site had been in operation for over 30 years. Groundwater flow was controlled by fractures in the crystalline rock with little to no permeability present beyond these fractures. Contamination levels had reached a high of 220 ppb of TCE. REGENESIS® recommended an HRC pilot test in conjunction along with excavation of the impacted geology.

The design using an HRC barrier focused on reducing TCE concentrations within a bedrock formation. Injection of HRC was accomplished using a single and double packer array and an appropriate delivery pump. The packer application method allowed HRC to be focused on the fractures controlling groundwater flow. A single packer system was used to apply HRC to the lower fracture (32 ft. bags) and a double packer system was used to apply HRC to the upper fracture zone (22-28 ft. bags). HRC was effectively injected at volumes ranging from 120-160 pounds per injection well.

Technology Description

HRC® is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils.

Results

Over a period of less than a year, TCE concentrations decreased from 220 ug/L to 3 ug/L (a 99% reduction) and within 18 months, were at non-detect levels. Over the same period, concentrations of daughter products DCE and VC initially increased as expected (due to sequential reductive de-chlorination) but then subsequently decreased. In addition, concentrations of the de-chlorination end product, ethene, increased by 10x during the same time frame. The pilot test resulted in favorable results and continued through full-scale implementation. HRC’s proven effectiveness at treating chlorinated solvents within the fractured bedrock system and its significant cost advantage over all other technologies allowed the environmental firm to select HRC for their full-scale implementation resulting in reducing concentrations to non-detect and meeting site goals.

Back Diffusion of VOCs from a Fractured Sandstone Aquifer Treated at Former Industrial Facility

Project Highlights

Large-scale pilot tests confirm management of chlorinated VOC back diffusion from fractured bedrock aquifer

- Tests concluded degradation along biotic and abiotic reductive pathways

- Advanced sorbent technology extends treatment longevity to manage to manage long-term back diffusion

2m 20s reading time

Project Summary

Fractured bedrock aquifers can be extremely heterogeneous which not only results in complex dissolved plume behavior, but can also hinder in situ remediation efforts that rely on an injection of amendments to promote microbial activity and abiotic degradation. However, due to the potentially high cost of a pump and treat remedy at a former industrial site in Arkansas, WSP determined that an in situ pilot test with advanced substrates was warranted.

At the Arkansas site, a 2016 pilot study was conducted using a multifunctional amendment formulation. REGENESIS® 3D-Microemulsion®, BDI Plus®, and CRS® were injected to remediate affected groundwater within a fractured sandstone bedrock aquifer impacted by chlorinated solvents. The contaminants at the site included trichloroethene (TCE), 1,1,1-trichloroethane (TCA), and degradation products. The plume on site underlies several developed properties and threatens a stream located approximately 1,500 feet from the source area. Results of the first pilot study yielded an 82% reduction within 9 months was measured approximately 80 feet from the application location.

A second pilot study was undertaken in 2017 to emplace a sorbent technology with long-lasting treatment capacity (PlumeStop®) on bedrock fracture faces to manage back diffusion from the bedrock primary porosity. This test also included the addition of bioremediation amendments to permanently degrade the sorbed contaminants. The 2017 treatment included PlumeStop and bioremediation amendments. After only one month, an 81% reduction was achieved in samples located 50 feet downgradient.

Preliminary indications of these amendment formulation tests are extremely promising in treating contaminant back diffusion emanating from the fractured bedrock matrix in this aquifer. WSP is confident that favorable performance monitoring results will continue and the full-scale remedy for this complex geologic setting will include REGENESIS products that extend treatment longevity.

Technology Description

PlumeStop® is an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation.

3-D Microemulsion® is an engineered electron donor material that offers a novel three-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory emulsified product.

HRC® is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils.

BDI Plus® is designed for use at sites where chlorinated contaminants are present and unable to be completely biodegraded via the existing microbial communities.

CRS® is a liquid iron-based reagent for the enhanced biogeochemical in situ chemical reduction (ISCR) of chlorinated contaminants.

Former Dry Cleaning Site Makes Way for Community Hospital Following Successful Treatment Using a Combined Remedy Approach

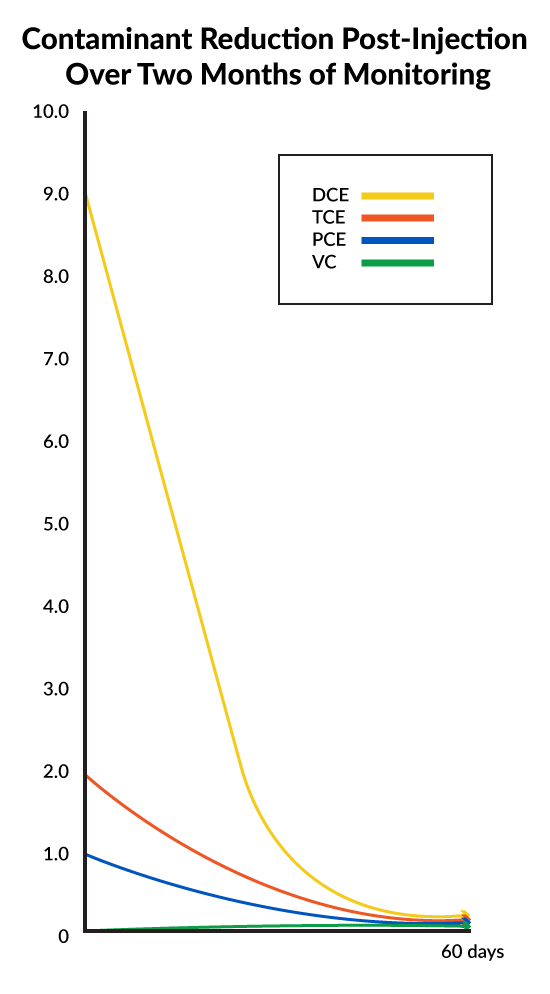

cVOC Contaminants Reduced by 97% After Two Months

Project Highlights

- Two months’ post injection results show contaminants were reduced by 97%

- Combined remediation approach used to successfully keep project on budget and on schedule

- Remediation design and amendments applied provided speed and certainty allowing for project to move forward

1m 55s reading time

Project Summary

A former dry cleaning site in Western New York was targeted for redevelopment to make way for a multidisciplinary, world-class cancer center. Before redevelopment could get underway, the developer needed to address the cVOC levels found on site which exceeded state regulatory standards. The developer engaged Benchmark/Turnkey, a leading environmental firm in the Northeast, to develop a solution to address the contaminant levels found. Benchmark/Turnkey worked with REGENESIS® to design a remedial strategy that included 3D-Microemulsion®, Bio Dechlor Inoculum® Plus, and Chemical Reducing Solution® to reduce the PCE, DCE and TCE contaminants. The design focused on speed and certainty, since the site was tagged for immediate redevelopment. Using a direct push application of the amendments, Benchmark/Turnkey was successful in applying the combined remedial approach on budget and on schedule.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel three-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory emulsified product.

Bio Dechlor Inoculum Plus (BDI-Plus) is an enriched natural microbial consortium species of Dehalococcoides sp. (DHC). This microbial consortium has been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Chemical Reducing Solution is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

Results

Following the injection event, the team monitored the results and at two months found that total cVOC contaminant levels had been reduced by 97%. Based on the progress to date and the concentration of contaminants versus nutrients remaining in the groundwater, Benchmark/Turnkey expects to collect groundwater samples for two intervening semi-annual events then petition the New York Department of Environmental Conservation to discontinue groundwater monitoring.

About the Client

Benchmark Environmental Engineering & Science, PLLC is a licensed professional engineering company that provides comprehensive civil and environmental engineering services. TurnKey Environmental Restoration, LLC is a “sister” company that provides site investigation, remediation and infrastructure construction, and environmental and site management service.

Site Goals Achieved in Two Months Using PlumeStop® at a Santa Barbara Manufacturing Facility

Client avoids additional in situ chemical oxidation (ISCO) injections with combined remedy approach using PlumeStop, Bio-Dechlor Inoculum Plus® (BDI Plus) and Hydrogen Release Compound® (HRC) to reach non-detect.Read More

ORC Advanced® and PersulfOx® Application Reduces BTEX, TPHg, and TPHd at an Active Service Station in Las Vegas

Significant cost savings to client achieved using enhanced aerobic biodegration and In Situ Chemical Oxidation (ISCO)Read More

Contaminant Concentrations at an Active Gas Station Reduced by 90% Using PersulfOx® and ORC Advanced®

REGENESIS Uses an Outside-In Application to Push 30-Year Old LUST Case to Closure in Remote Region of Arizona

Project Highlights

- Innovative “Outside-In” approach incorporated injection design working from perimeter of the treatment area first, and progressively working toward the center

- First event application completed within seven days with a second event completed in nine days the following month without disruption to active site

- Closely managed injection wells to ensure proper distribution and avoid surfacing

Project Summary

An active gasoline station in Springerville, AZ was listed as a hazardous Leaking Underground Storage Tank (LUST) site by the state of Arizona. After 30 years of unsuccessful remediation using a number of approaches, REGENESIS Remediation Services (RRS) was contacted to perform two separate injection events approximately one month apart. Both events included injections at 15 injection points over a range of depths. The first round of injections included a combination of PersulfOx and ORC Advanced. The second round of injections contained only PersulfOx.

During both injections PersulfOx and ORC Advanced were successfully applied within the treatment area and at the targeted treatment interval of 18 to 60 ft. bgs. Low to moderate injection pressures and application flow rates were observed at each of the injection well locations, indicating good distribution of the amendments. Increases in dissolved oxygen, conductivity, pH, and oxidation-reduction potential were observed, indicating good distribution and influence of the PersulfOx and ORC Advanced remediation chemistry.

Technology Description

PersulfOx is an advanced in situ chemical oxidation (ISCO) reagent that destroys organic contaminants found in groundwater and soil through abiotic chemical oxidation reactions. It is an all-in-one product with a built-in catalyst which activates the sodium persulfate component and generates contaminant-destroying free radicals without the costly and potentially hazardous addition of a separate activator. The patented catalyst enhances the oxidative destruction of both petroleum hydrocarbons and chlorinated contaminants in the subsurface.

ORC Advanced is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils.

Results

Since the two injections have been completed, three rounds of groundwater monitoring have been performed. Benzene concentrations have been reduced by 90% to 20 μg/L. A closure request has been submitted by the client awaiting regulatory approval.

State-Funded Cleanup of Former Service Station on Reservation Land

Enhanced Aerobic Biodegradation and In Situ Chemical Oxidation Provides Safe Approach to Remediate TPH-g and BTEX

Project Highlights

- Extensive coordination was required between state-funded Pollution Liability Insurance Agency (PILA) of Washington and US EPA Region 10

- Combined remedy approach using ORC Advanced® and PersulfOx® provided a safe solution for land used to raise livestock

Project Summary

The site located in Wapato, Washington is a former gas station situated on Reservation Land with historical releases dating back >20 years. The site is regulated through US EPA Region 10 and was previously an empty lot used for ranging cattle.

Initial remedial activities included excavation of source-area soil, however persistent contamination remained. Concerns were raised regarding how amendments might affect livestock. As a result, the remediation approach needed to be environmentally benign. The revised remedial plan included Enhanced Aerobic Biodegradation (ORC Advanced) and In Situ Chemical Oxidation (PersulfOx) to reduce the remaining concentrations and meet regulatory goals.

Technology Description

PersulfOx is a chemical oxidant that rapidly reduces the mass of the contaminants. This chemical consists of 90% sodium persulfate and 10% catalyst powder. PersulfOx is very effective in rapid oxidation of petroleum hydrocarbons in both soil and groundwater.

ORC Advanced is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils.

Results

An integrated treatment strategy was devised, which included injections in three separate areas. Two areas were treated with PersulfOx and ORC Advanced. The third area was treated with ORC Advanced only.

The by-products of ORC Advanced and PersulfOx are both insoluble and non-toxic, making the application safe and effective. Consequently, there were no issues relating to the landowner’s concern for amendments affecting livestock. A total area of 4,100 ft2 was treated for high levels of BTEX and TPH-g. Monitoring is ongoing.

Enhanced Reductive Dechlorination Showing Positive Returns at Indiana Dry Cleaning Site

Project Highlights

- Combined remedies approach using an Enhanced Reductive Dechlorination (ERD) process successfully remediated an Indiana drycleaning site

- ERD process chosen eliminates need for long-term monitoring

- Contaminant concentrations reduced from thousands of μg/L pre-injection to single digits one month post-injection

2m 38s reading time

Project Summary

While the surrounding Mooresville, Indiana community applauds Crest Cleaners for proactively cleaning up a previously unidentified hazardous mess that was left behind from historic dry cleaning practices, the workhorses remediating the contamination are grinding away below the subsurface. Tiny microorganisms are destroying the PCE in the groundwater and reducing the concentration of the contaminant. It’s all a part of the “Enhanced Reductive Dechlorination,” (ERD) process, which is the primary approach of the Remedial Work Plan (RWP) being implemented by EnviroForensics®.

In addition to the potential for human health risks at the site as a result of soil or groundwater exposure, the contaminant plume in the groundwater represented a potential vapor intrusion risk to an offsite building. The project team debated between two viable options:

- Install, monitor, and maintain a Sub-Slab Depressurization System (SSDS) at the offsite location to mitigate the potentially harmful vapors underneath the building, which would have required years of maintenance and groundwater sampling; or

- Implement an ERD application to reduce the concentration of the groundwater plume, and eliminate potential vapor intrusion issues.

Based on the overall benefit to the community and to reduce stress and aggravation to adjacent property owners that comes with long-term monitoring, the project team chose option two.

Here’s how the remediation at this site worked. Naturally occurring bacteria called Dehalococcoides ethanogenes (DHC) are in the groundwater completing a process called reductive dechlorination where the chlorine atoms are cleaved off and replaced by hydrogen atoms. This process continues until the resulting compound is no longer dangerous. At this site, the process was occurring, but not at a rate that would make the cleanup cost-effective for the client.

In order to complete this cleanup we utilized a process called bioaugmented enhanced reductive dechlorination (ERD) and in situ chemical reduction (ISCR). The process begins by sampling the groundwater across the remediation area for contaminant concentrations and geochemical parameters including DHC populations to determine the dosage of injected materials required in each area of the site. Different areas received modified doses of materials based on the calculations completed by EnviroForensic’s geochemist.

The ERD agent, 3-D-Microemulsion® (3DMe®) was injected along with Chemical Reducing Solution (CRS®), an ISCR augmentation. The ISCR agent delivers a source of ferrous iron, designed to precipitate as reduced iron minerals and provide an additional abiotic pathway for the destruction of PCE. The two work synergistically, increasing the cost effectiveness of the injection. The pre-sampling of DHC revealed that the population of DHC needed to be augmented. 10 gallons of BDI® Plus (DHC enhanced fluid) was injected at each of the 92 injection locations used for the ERD/ISCR. The combination of these three injected materials allows for minimal site disturbance and a high level of effectiveness for the cleanup of drycleaning solvents.

The ERD agent, 3-D-Microemulsion® (3DMe®) was injected along with Chemical Reducing Solution (CRS®), an ISCR augmentation. The ISCR agent delivers a source of ferrous iron, designed to precipitate as reduced iron minerals and provide an additional abiotic pathway for the destruction of PCE. The two work synergistically, increasing the cost effectiveness of the injection. The pre-sampling of DHC revealed that the population of DHC needed to be augmented. 10 gallons of BDI® Plus (DHC enhanced fluid) was injected at each of the 92 injection locations used for the ERD/ISCR. The combination of these three injected materials allows for minimal site disturbance and a high level of effectiveness for the cleanup of drycleaning solvents.

An often overlooked byproduct of the ERD process is methane. As a preventative measure, the field staff upgraded the site building SSDS with an intrinsically-safe fan and installed an intrinsically-safe SSDS at the offsite building as an interim measure. Soil gas points were also BDI Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes. Chemical Reducing Solution is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes. installed between the injection areas and the adjoining properties to the east. Additionally, extra intrinsically-safe fans and piping are ready to be installed.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory emulsified product.

BDI Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Chemical Reducing Solution is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

Results

The results from the first injection event were very promising. Groundwater contaminant concentration went down from thousands of μg/L pre-injection to single digits μg/L one month post-injection. Quarterly groundwater sampling will continue for a year or two to demonstrate that the contaminant plume is retreating or remediated. The ultimate goal of the ERD approach is to reach site closure quickly, and reduce the costs and health risks of this contamination.

REGENESIS Remediation Services’ Efficient ISCO Treatment Keeps Redevelopment Schedule of Former Gas Station On Track

Project Highlights

- Three distinct zones of contamination effectively treated by in situ chemical oxidation (ISCO) and enhanced aerobic bioremediation

- Benzene (BTEX) concentrations in groundwater reduced by >99% within three months, achieving site goals for Low-Threat Closure (LTC)

- The treatment, design and application efficiency provided by REGENESIS® Remediation Services allowed the redevelopment schedule to be maintained

Project Summary

Operations at the site of a former gas station in San Jose, California resulted in contamination of the subsoil and groundwater with benzene. Following demolition of the station after 15 years of operation, the site was approved for redevelopment into a commercial property. However, the site failed to meet the groundwater criteria of the Low-Threat Underground Storage Tank Case Closure Policy (LTCP) for benzene (<3,000 μg/L) concentrations, and remediation activities were quickly undertaken in order to maintain the schedule for site redevelopment.

A remediation plan was developed by REGENESIS® that utilized in situ chemical oxidation and enhanced aerobic biodegradation to address the residual petroleum contamination at the site. Due to the extended drought in the area that caused rapidly declining groundwater levels, three separate zones of contamination were targeted in the remediation plan: the groundwater zone and two newly-formed vadose zones that are separated by a low-permeability unit. The 3700 ft2 treatment area included full coverage by the groundwater treatment as well as two distinct regions of the shallow and deep vadose zones.

A bench test using soil and groundwater from the site was performed to verify the effectiveness of the planned course of treatment prior to full-scale application. A >99% reduction in benzene concentrations confirmed the remediation plan, and application of the remediation chemistry was performed by REGENESIS Remediation Services (RRS) over two injection events. Due to the prolonged drought in the area, recycled water was brought on site for use in the field activities. The two injection events were separated by one month and each spanned ten days. During the first event, PersulfOx® was applied via direct push technology to 54 injection points. In the second event, ORC Advanced® was co-applied with PersulfOx through 59 points.

Technology Description

PersulfOX is a sodium persulfate-based chemical oxidation technology that destroys both hydrocarbon and chlorinated solvent contaminants in the subsurface. PersulfOx contains a built-in catalyst that activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegradation.

Results

Three months after treatment of the site was completed, BTEX concentrations decreased by over 99% from the baseline concentrations of 3070 μg/L. Furthermore, concentrations of all contaminants have been reduced to below the criteria for Low Threat Closure, and as a result of this rapid achievement of site goals, the redevelopment schedule of the site has been preserved.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español