Combined PlumeStop® and ORC-Advanced® Treatment Remediates Low Level Benzene Contamination

Project Highlights

- Persistent benzene contamination reduced from 530 μg/L to 4 μg/L

- Target Medium Specific Concentration (MSC) achieved within one quarter of treatment

- Application of PlumeStop® and ORC Advanced® successfully completed by REGENESIS® Remediation Services (RRS) within three days allowing for the project

1m 38s reading time

Project Summary

Operation activities at the site of an active gas station resulted in contamination of the groundwater with low levels of benzene. The concentration of benzene fluctuated, reaching 530 μg/L before remediation efforts were undertaken. REGENESIS designed a remediation plan to address the persistent low levels of benzene that combined the application of PlumeStop and ORC Advanced for in situ sorption and enhanced aerobic biodegradation.

The sorbent properties of PlumeStop make it possible to successfully treat low contaminant levels by creating local areas of high contaminant concentration that can then be colonized by contaminant-degrading bacteria. This co-localization of the contaminants and bacteria on the PlumeStop surface greatly improves the contact between the two components, thereby enhancing the speed and efficiency of the degradative reactions. Addition of ORC-Advanced further supports aerobic biodegradation by providing a long-lasting oxygen source.

RRS injected PlumeStop and ORC Advanced into 12 points around MW-6R (Fig. 1) that showed elevated benzene levels. A total of 1,200 lb of PlumeStop were first injected via direct push technology followed by injections of 240 lb of ORC Advanced into the same 12 holes. Treatment of the site was completed over the course of two days without any complications.

Technology Description

PlumeStop Liquid Activated Carbon (LAC) is an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation.

ORC Advanced is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

Results

In the first quarterly sampling event after the remediation chemistries were applied, benzene levels had dropped from the pre-application level of 530 μg/L to below the Medium Specific Concentration (MSC) of 5 μg/L set by the Pennsylvania Department of Environmental Protection. Furthermore, groundwater quality parameters in MW-6R indicated good distribution of the remediation chemistry through the subsurface and the establishment of optimum parameters for continued aerobic biodegradation.

Ohio Brownfield Site Receives “No Further Action” Status within One Year of Implementation

Project Highlights

- Combined remedy approach allowed for immediate redevelopment within same year of implementation.

- Efficiencies resulted in vapor intrusion mitigation cost of $3.34 per sq. ft., with no long term operation and maintenance required.

- Cost for groundwater treatment approximately $10 per cubic yard (product + application).

1m 25s reading time

Project Summary

A former industrial magnet manufacturing facility in Ohio received a $2.34 million Clean Ohio Revitalization Fund (CORF) grant through the Ohio Department of Development in 2011. Site investigation activities identified chlorinated VOC’s in groundwater and vapors above the state standards, requiring remediation. Enhanced Reductive Dechlorination, using 3D Micro-Emulsion®, and BDI-Plus® were implemented within the defined 24,000 sq. ft. treatment area via direct push injection.

This work was conducted in the Spring of 2012. In the Fall of 2012, the Geo-Seal Vapor barrier system was installed below a 15,522 sq. ft. apartment complex raised at the site. Utilizing a combined approach of enhanced reductive dechlorination with vapor mitigation addressed the immediate risk of vapor intrusion, in addition to the long term risk of groundwater impacts. By implementing this strategy, the site was allowed to be redeveloped as an apartment complex roughly 6 months following the groundwater treatment. The cost for groundwater treatment was approximately $10/cy (product + application) and Geo-Seal® was $3.34/sq. ft. (product + installation).

Technology Description

BDI Plus is an enriched, natural microbial consortium containing species of Dehalococcoides sp. (DHC) which are capable of completely dechlorinating contaminants during in situ anaerobic bioremediation processes.

3-D Microemulsion is a wide-area distribution, staged release, electron donor emulsion for the optimized enhanced anaerobic biodegradation of chlorinated compounds.

Geo-Seal is a composite system that creates the ideal blend between constructability and chemical resistance by using both high density polyethylene (HDPE) and spray-applied asphalt latex.

Results

Housing developers face many considerations, including approvals for land excavation and required building permits. By implementing a combined remedy approach, consisting of enhanced reductive dechlorination with vapor mitigation, this site was able to qualify for NFA status in less than a year, allowing the developer to begin new construction without further delay.

Successful Bioremediation at a Former Air Force Base Fire Training Area

Project Highlights

- Air Force Base contaminated with high levels of carbon tetrachloride due to on-site firefighting training

- 97% reduction in contaminant within three months

- Carbon tetrachloride reduced to below detection limits

1m 20s reading time

Project Summary

Training exercises at Texas Air Force Base resulted in an impact to soil and groundwater by trichloroethylene (TCE) and carbon tetrachloride. A monitored natural attenuation study conducted indicated that chlorinated solvents at the plume would naturally decline to acceptable levels after 30 years of monitoring.

After over 14 years of monitoring, contaminant reductions were not proceeding as quickly as predicted and additional remediation was advised. It was determined that limited anaerobic activity was present and biostimulation was a viable option. A pilot test was conducted on-site.

The objective of the test was to determine the feasibility of injection into the shallow, discontinuous groundwater unit. The pilot test was also designed to determine if the residual TCE and carbon tetrachloride could be biodegraded through enhanced bioremediation and reduced to below 5 ppb (the Texas Risk Reduction Program limit). Follow-up injections were applied downgradient of the source area and also in a barrier configuration several hundred feet dowgradient of the source were implemented about 6 months after the pilot test.

Technology Description

3-D Microemulsion® is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory-emulsified product.

Results

The combination of the pilot test and full-scale application resulted in a 97.8% reduction in carbon tetrachloride 8 months post-injection, with chloroform, methylene chloride, and chloromethane remediation daughter products on a downward trend. High TCE concentrations were effectively treated as well with TCE peaking after injections to 126 ppb within a 3-month period to 0.2 ppb.

RegenOx® Technology Expedites Hollywood Brownfield Site Transaction

Project Highlights

- Reduction of TCE, naphthalene, and styrene levels to below risk-based closure levels via in situ chemical oxidation clears the way for property sale

- Flexibility of RegenOx® application allowed the remediation to be completed faster and more effectively

- Treatment of over 18,000 cubic yards of vadose soil completed within 30 days

Project Summary

A pending real estate transaction of a industrial property in Hollywood, CA was held up by contamination of the vadose zone with a mixture of chlorinated and petroleum solvents. Before the transaction could be finalized, high levels of perchloroethene (PCE), naphthalene, and styrene in the vadose zone soil had to be reduced to below risk-based closure levels. To achieve this, the engineering firm in charge of remediation selected chemical oxidation using RegenOx based on the product’s proven effectiveness, low-cost, and handling safety.

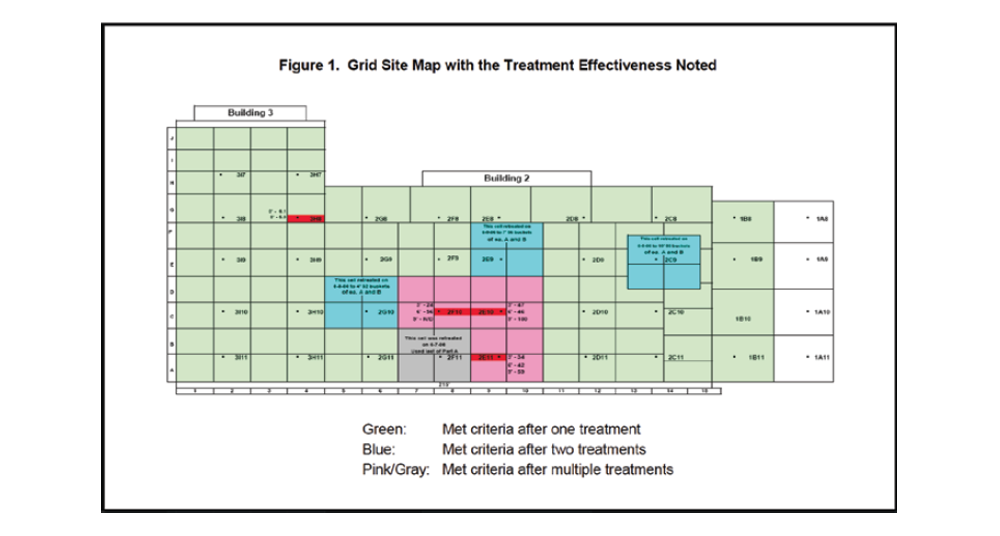

Direct-Push Injection

A remediation plan was developed for the contaminated site that involved two rounds of direct-push application of RegenOx separated by 4 to 6 weeks. The direct-push methodology uses specialized equipment to apply RegenOx to discrete areas of the subsurface without soil removal (i.e., in situ). In order to determine the effectiveness of the treatment, composite soil samples from various grid cells were taken before and after application of RegenOx. Before treatment, significant variation was seen in the contaminant concentrations, with maximum concentrations of 140 μg/kg for PCE, 1200 μg/kg for naphthalene, and 400 μg/kg for styrene. Following the first direct-push application of RegenOx, the average PCE concentration was reduced to 4 μg/kg, a decrease of 86%. Similar results were seen for the petroleum solvents and other chlorinated volatile organic compounds (cVOCs) in the composite soil samples.

Soil Mixing Applicationhollywood2

Despite the contaminant reductions achieved by the first direct-push application of RegenOx, REGENESIS® Remediation Services determined that the speed and effectiveness of the remediation effort could be significantly improved by switching to soil mixing application of RegenOx. In this more aggressive approach, RegenOx was mechanically blended into the vadose soil in order to maximize the contact between the product and the contaminated soil. RegenOx was added as an eight percent solution and mixed throughout the soil using soil mixing equipment. With this treatment method, approximately twice as much soil was treated per day compared to direct-push application.

Of the 111 grids treated with RegenOx by soil mixing (Figure 1), 83 required only one treatment (green) to achieve levels below risk-based closure, 12 required two treatments (blue), and 16 required more than two treatments (pink and gray).

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

Results

The mixed chlorinated and petroleum solvent contamination of the vadose soil was effectively reduced using RegenOx in both direct-push and soil mixing applications. Soil mixing was used to complete the remediation effort rather than a second round of direct-push injections because it maximized contact between RegenOx and the contaminated soil, achieving more rapid and effective treatment. In 74% of the treatment grids, concentrations of all the contaminants were reduced below the risk-based cleanup goal with a single application by soil mixing. Additional applications in the remaining 26% of the treatment grids also achieved the targeted levels for all the contaminants. This remediation approach successfully treated nearly 18,000 cubic yards of soil within 30 days. Using RegenOx and flexible application methods, the site was quickly and effectively remediated, allowing for the real estate transaction to be completed.

Non-Detect Levels Reached with Application of PlumeStop® at Former Dry Cleaning Site

Lines of evidence for post-sorption solvent degradationRead More

RegenOx® and ORC Advanced® Application Reduces BTEX , MTBE, and TBA Concentrations to Below MCL

Site closure granted.Read More

New Jersey Manufacturing Facility Achieves Non-Detect with PersulfOx® Application where Pump and Treat Solution Failed

Project Highlights

- Replacing a costly pump and treat solution, REGENESIS® was able to efficiently inject PersulfOx® into bedrock, saving time and money

- Maximum 580 μg/L levels of 1,1-DCE and 1,4-dioxane within the source area reduced to non-detect

- Low-level concentrations of 1,1-DCE surrounding the original treatment area also reduced to non-detect

Project Summary

A former manufacturing facility in New Jersey was contaminated with 1,1-dichloroethylene (1,1-DCE) and 1,4-dioxane in a fractured bedrock aquifer. The previous treatment approach utilized a pump and treat method that was successful at containing and reducing contaminant concentrations within the source area, but the associated off-site transportation and disposal of recovery water was expensive.

Historic concentrations for 1,1-DCE within the source area ranged from 43-580 μg/L, and concentrations outside of the immediate source area persisted at low levels above Ground Water Quality Standards. 1,4- dioxane concentrations within the source area peaked at 580 μg/L.

PersulfOx in situ chemical oxidation (ISCO) was selected as a lower-cost alternative to the pump and treat method and also as a way to address the diffuse contamination surrounding the immediate treatment area. After application of PersulfOx, both 1,1-DCE and 1,4-dioxane concentrations within the source area rapidly decreased below detection levels and remained non-detect. In addition, the low levels of 1,1-DCE surrounding the original treatment area were also reduced to non-detect. Quarterly groundwater sampling will continue to track treatment performance.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology that destroys both hydrocarbon and chlorinated solvent contaminants in the subsurface. PersulfOx contains a built-in catalyst that activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

Application of PersulfOx resulted in the rapid reduction of source area 1,1-DCE and 1,4-dioxane concentrations to below detection limits. Low concentrations of 1,1-DCE surrounding the original treatment area were also reduced to non-detect. The concentrations of contaminants in both areas have remained below groundwater quality standards, meeting site requirements.

Single Application of ORC Advanced® Results in 87% Reduction of Contaminated Groundwater Plume

Project Highlights

- Size of contaminated groundwater plume reduced by 87% through extensive injection of ORC Advanced, applied using vertical and horizontal wells.

- Total BTEX >62.5ppm (mg/l) concentrations were identified prior to site treatment.

- Final round of ORC injections approved by Illinois EPA and LUST Program and is in-progress.

Project Summary

This site had been a carwash and retail gasoline station in an industrial-commercial area. During the removal of two (2) 6,000- gallon gasoline underground storage tanks (UST) and two (2) fuel dispensers, a gasoline release was reported to the Illinois Management Emergency Agency, based on impacted soil observed during the excavation. Contaminants for this gasoline release were Benzene, Toluene, Ethylbenzene, and total Xylenes (BTEX). The release resulted in groundwater contamination that encompassed the entire property, and extended slightly off-site, impacting three businesses. The area covered by the groundwater plume was approximately 1.5 acres. The size of the groundwater BTEX plume posed a significant challenge in site treatment.

Remediation Approach

In this instance, LandTech, Inc. implemented an Enhanced Aerobic Biodegradation strategy using ORC Advanced. This included 12,800 pounds of ORC Advanced, 7 pounds of Nitrate, and 1 pound of Phosphorous nutrients applied to the site via direct injection through 242 vertical wells to 16 feet below ground surface, and 1,065 feet of horizontal wells beneath the existing structures. ORC Advanced® is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced provides remediation practitioners with a significantly faster and highly effective means of treating petroleum contaminated sites.

Results

This site presented significant challenges due to the extensive levels of BTEX contaminants and the large area of groundwater contamination. After one round of injections and a monitoring period of 1 year, analytical results for the groundwater demonstrated the ORC injections have reduced the 1.5 acre BTEX groundwater plume by 87%. A second/final round, 1,350 pounds, of ORC Advanced injections have been approved by the Illinois EPA to address a few recalcitrant performance wells.

PlumeStop® and ORC Advanced® Treat BTEX to Non-Detect in 1 Month

Project Highlights

- Benzene (BTEX) and TPH-d (diesel) were reduced to non-detect within one month with no rebound

- Pre-project verification testing provided hydrogeological data to optimize the successful application of PlumeStop and ORC Advanced

- Active site did not impede remediation efforts

Project Summary

An active gas station in the Pacific Northwest was impacted with BTEX concentrations from a petroleum release. Following remediation of the source, residual BTEX concentrations persisted in a down gradient well. A new combined remedies in situ program using PlumeStop and ORC Advanced was designed. Following the verification testing, REGENESIS co-applied PlumeStop and ORC Advanced into the residual BTEX plume. After one month, sampling was conducted showing contaminants had been dramatically reduced to non-detect levels.

Remediation Approach

REGENESIS worked closely with the project consultant to complete a multi-step verification process prior to remediation. This procedure included a clear water injection to test aquifer properties and soil borings for detailed characterization of the proposed treatment area. This was followed by a pilot injection of PlumeStop to test distribution. The verification testing found that despite soils at the site being classified as clays and silts, there was a sufficient amount of sand present to allow for good distribution. Injection pressures remained below 5 psi for PlumeStop and below 10 psi for ORC Advanced. Distribution of greater than 12 feet was also observed. The verification process was an integral part of the project, helping to more accurately characterize true hydrogeologic conditions. Technical Engineers were able to take the information obtained from the verification process and optimize the PlumeStop and ORC Advanced design. The co-application of the two technologies quickly sorbed dissolved-phase contaminants and promoted aerobic biodegradation.

REGENESIS Solution Applied

PlumeStop Liquid Activated Carbon™ is composed of very fine particles of activated carbon (1-2μm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and enhancing permanent contaminant biodegradation. ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled release of molecular oxygen for periods of up to 12 months upon hydration.

Results

Residual BTEX and TPH-d concentrations lingering for years are common for gas station sites and often are the only obstacle to closure. The combined remedies application of PlumeStop and ORC Advanced demonstrates a unique ability to attain non-detect levels in a short time frame with substantial cost savings over other approaches, including natural attenuation.

PlumeStop and ORC Advanced Treat BTEX to Non-Detect in 1 Month

Project Highlights

- Benzene (BTEX) and TPH-d (diesel) were reduced to non-detect within one month with no rebound

- Pre-project verification testing provided hydrogeological data to optimize the successful application of PlumeStop and ORC Advanced

- Active site did not impede remediation efforts

1m 53s reading time

Project Summary

An active gas station in the Pacific Northwest was impacted with BTEX concentrations from a petroleum release. Following remediation of the source, residual BTEX concentrations persisted in a down gradient well. A new combined remedies in situ program using PlumeStop and ORC Advanced was designed. Following the verification testing, REGENESIS co-applied PlumeStop and ORC Advanced into the residual BTEX plume. After one month, sampling was conducted showing contaminants had been dramatically reduced to non-detect levels.

Remediation Approach

REGENESIS worked closely with the project consultant to complete a multi-step verification process prior to remediation. This procedure included a clear water injection to test aquifer properties and soil borings for detailed characterization of the proposed treatment area. This was followed by a pilot injection of PlumeStop to test distribution. The verification testing found that despite soils at the site being classified as clays and silts, there was a sufficient amount of sand present to allow for good distribution. Injection pressures remained below 5 psi for PlumeStop and below 10 psi for ORC Advanced. Distribution of greater than 12 feet was also observed. The verification process was an integral part of the project, helping to more accurately characterize true hydrogeologic conditions. Technical Engineers were able to take the information obtained from the verification process and optimize the PlumeStop and ORC Advanced design. The co-application of the two technologies quickly sorbed dissolved-phase contaminants and promoted aerobic biodegradation.

REGENESIS Solution Applied

PlumeStop Liquid Activated Carbon™ is composed of very fine particles of activated carbon (1-2μm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and expediting permanent contaminant biodegradation. ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled release of molecular oxygen for periods of up to 12 months upon hydration.

Results

Residual BTEX and TPH-d concentrations lingering for years are common for gas station sites and often are the only obstacle to closure. The combined remedies application of PlumeStop and ORC Advanced demonstrates a unique ability to attain non-detect levels in a short time frame with substantial cost savings over other approaches, including natural attenuation.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español