ORC Advanced® and PersulfOx® Application Reduces BTEX, TPHg, and TPHd at an Active Service Station in Las Vegas

Significant cost savings to client achieved using enhanced aerobic biodegration and In Situ Chemical Oxidation (ISCO)Read More

Contaminant Concentrations at an Active Gas Station Reduced by 90% Using PersulfOx® and ORC Advanced®

REGENESIS Uses an Outside-In Application to Push 30-Year Old LUST Case to Closure in Remote Region of Arizona

Project Highlights

- Innovative “Outside-In” approach incorporated injection design working from perimeter of the treatment area first, and progressively working toward the center

- First event application completed within seven days with a second event completed in nine days the following month without disruption to active site

- Closely managed injection wells to ensure proper distribution and avoid surfacing

Project Summary

An active gasoline station in Springerville, AZ was listed as a hazardous Leaking Underground Storage Tank (LUST) site by the state of Arizona. After 30 years of unsuccessful remediation using a number of approaches, REGENESIS Remediation Services (RRS) was contacted to perform two separate injection events approximately one month apart. Both events included injections at 15 injection points over a range of depths. The first round of injections included a combination of PersulfOx and ORC Advanced. The second round of injections contained only PersulfOx.

During both injections PersulfOx and ORC Advanced were successfully applied within the treatment area and at the targeted treatment interval of 18 to 60 ft. bgs. Low to moderate injection pressures and application flow rates were observed at each of the injection well locations, indicating good distribution of the amendments. Increases in dissolved oxygen, conductivity, pH, and oxidation-reduction potential were observed, indicating good distribution and influence of the PersulfOx and ORC Advanced remediation chemistry.

Technology Description

PersulfOx is an advanced in situ chemical oxidation (ISCO) reagent that destroys organic contaminants found in groundwater and soil through abiotic chemical oxidation reactions. It is an all-in-one product with a built-in catalyst which activates the sodium persulfate component and generates contaminant-destroying free radicals without the costly and potentially hazardous addition of a separate activator. The patented catalyst enhances the oxidative destruction of both petroleum hydrocarbons and chlorinated contaminants in the subsurface.

ORC Advanced is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils.

Results

Since the two injections have been completed, three rounds of groundwater monitoring have been performed. Benzene concentrations have been reduced by 90% to 20 μg/L. A closure request has been submitted by the client awaiting regulatory approval.

State-Funded Cleanup of Former Service Station on Reservation Land

Enhanced Aerobic Biodegradation and In Situ Chemical Oxidation Provides Safe Approach to Remediate TPH-g and BTEX

Project Highlights

- Extensive coordination was required between state-funded Pollution Liability Insurance Agency (PILA) of Washington and US EPA Region 10

- Combined remedy approach using ORC Advanced® and PersulfOx® provided a safe solution for land used to raise livestock

Project Summary

The site located in Wapato, Washington is a former gas station situated on Reservation Land with historical releases dating back >20 years. The site is regulated through US EPA Region 10 and was previously an empty lot used for ranging cattle.

Initial remedial activities included excavation of source-area soil, however persistent contamination remained. Concerns were raised regarding how amendments might affect livestock. As a result, the remediation approach needed to be environmentally benign. The revised remedial plan included Enhanced Aerobic Biodegradation (ORC Advanced) and In Situ Chemical Oxidation (PersulfOx) to reduce the remaining concentrations and meet regulatory goals.

Technology Description

PersulfOx is a chemical oxidant that rapidly reduces the mass of the contaminants. This chemical consists of 90% sodium persulfate and 10% catalyst powder. PersulfOx is very effective in rapid oxidation of petroleum hydrocarbons in both soil and groundwater.

ORC Advanced is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils.

Results

An integrated treatment strategy was devised, which included injections in three separate areas. Two areas were treated with PersulfOx and ORC Advanced. The third area was treated with ORC Advanced only.

The by-products of ORC Advanced and PersulfOx are both insoluble and non-toxic, making the application safe and effective. Consequently, there were no issues relating to the landowner’s concern for amendments affecting livestock. A total area of 4,100 ft2 was treated for high levels of BTEX and TPH-g. Monitoring is ongoing.

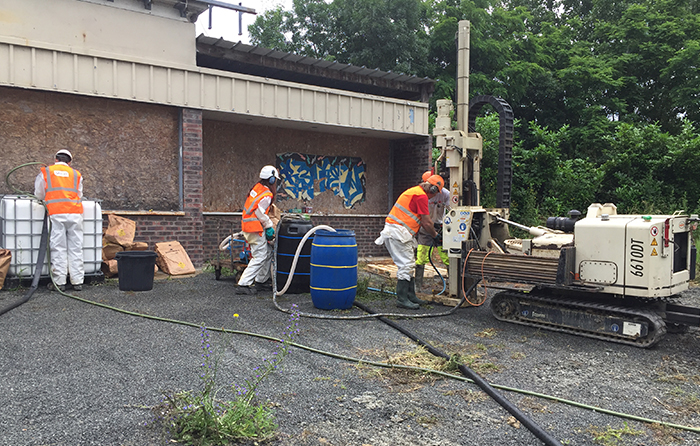

ISCO and Bioremediation at Former Petrol Station, Pays de la Loire, France

Under a former petrol filling station in the Loire Valley, in France the soil and groundwater was found to be contaminated with petroleum hydrocarbons (primarily BTEX). An integrated in-situ remedial solution has been put in place by a specialist remediation contractor, consisting of 26 PersulfOx injections in the source zone for fast and effective treatment of the most impacted soils and groundwater. ORC Advanced was also applied in the source zone to achieve long term in-situ bioremediation of any remaining petroleum hydrocarbons. In addition, an ORC Advanced barrier has been installed in the downstream plume area, to prevent off-site migration of the contamination.Read More

Remediation of PHCs and VOCs at a Former Dry Cleaner Site Using RegenOx®, ORC Advanced®, and ORC® Filter Socks

Former Dry Cleaning Site Redeveloped to Serve as New Home to Non-Profit Serving Homeless in Chilliwack B.C. Area

Project Highlights

- Introduction of RegenOx® and ORC Advanced® following in situ treatment using PulseOx1 resulted in the reduction in the initial concentrations of PHCs and dry cleaning chemicals in a sand and gravel aquifer, meeting site remediation goals

- Upon completion of remedial efforts, the project was awarded three British Columbia Ministry Environment instruments

Project Summary

A building occupied by a former dry cleaning business (1960s) located in Chilliwack, British Columbia was acquired by Ruth & Naomi’s Mission, (www.ranmission.ca) a non-profit organization serving Chilliwack. Environmental investigations to support the redevelopment of the former dry cleaner building revealed contamination of the soil and groundwater beneath the site and the offsite alley with petroleum hydrocarbons (PHCs) and dry cleaning related chemicals. Since the remedial excavation onto the offsite alley was not considered to be practical, RegenOx, along with ORC Advanced, was utilized for the in situ treatment of soil and groundwater within the excavation to reduce the remaining PHC and dry cleaning chemical concentrations.

Following treatment with RegenOx, reduction in the concentrations of PHC and dry cleaning related compounds were observed in soil and groundwater samples. RegenOx was additionally injected within the alley to treat the offsite plume. As a result, all post-remediation concentrations are below the applicable commercial land use standards. Additionally, ORC socks were applied to assist natural attenuation of any residual contaminants in groundwater. The successful investigation and remedial effort received three British Columbia Ministry of Environment instruments and now safely serves as a resource center and shelter.

Concentrations

- Volatile Petroleum Hydrocarbons VPH (up to 3,400mg/kg)

- EPH10-19 (8,200 mg/kg)

- Ethylbenzene (33mg/kg)

- Total Xylenes (160 mg/kg)

- Perchloroethylene (7μg/g)

- Trichloroethylene (2.8 mg/kg)

- VPHw (110mg/L)

- LEPH (5.6 mg/L)

- Ethylbenzene (2.14 mg/L)

- Toluene (2.7mg/L)

- Naphthalene (410μg/L)

- Perchloroethylene (2.76 mg/L)

- Xylenes (6.78mg/L)

- Vinyl Chloride (349 μg/L)

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

ORC Filter Sock is a permeable filter sock containing calcium oxy-hydroxide based chemical which produces a controlled release of molecular oxygen (17% by weight) when hydrated.

Results

PHC and dry cleaning compounds were reduced in concentrations to groundwater standards following the application of RegenOx and ORC Advanced, facilitating the redevelopment of the former dry cleaning business to house the not-for-profit homeless shelter, Ruth and Naomi’s Mission, serving the Chilliwack, B.C. community. Upon completion of investigation and remedial efforts, the project was awarded three British Columbia Ministry Environment instruments. Up to 200+ homeless are served dinner daily by this organization which provides both shelter and recovery programs to men and women, assisting them in their reintegration into the community and work place.

1 PulseOx is a registered trademark of APT Water, Inc.

ISCO and Enhanced Aerobic Bioremediation during Residential Development

Excavation works minimised through the use of RegenOx, ORC-Advanced and ORC-Advanced Pellets, allowing development to continue without interruption.Read More

Pilot Study at Former Gasworks, Southeast England, UK

Pilot study results on a former gasworks site show that within 10 weeks of injecting PetroCleanze and ORC Advanced, significant mass reduction can be achieved. The pilot study is scalable to the entire site. Targeted remediation to reduce the contaminant mass in the most sensitive areas has the potential to dramatically reduce remediation costs for the developer.

REGENESIS Remediation Services’ Efficient ISCO Treatment Keeps Redevelopment Schedule of Former Gas Station On Track

Project Highlights

- Three distinct zones of contamination effectively treated by in situ chemical oxidation (ISCO) and enhanced aerobic bioremediation

- Benzene (BTEX) concentrations in groundwater reduced by >99% within three months, achieving site goals for Low-Threat Closure (LTC)

- The treatment, design and application efficiency provided by REGENESIS® Remediation Services allowed the redevelopment schedule to be maintained

Project Summary

Operations at the site of a former gas station in San Jose, California resulted in contamination of the subsoil and groundwater with benzene. Following demolition of the station after 15 years of operation, the site was approved for redevelopment into a commercial property. However, the site failed to meet the groundwater criteria of the Low-Threat Underground Storage Tank Case Closure Policy (LTCP) for benzene (<3,000 μg/L) concentrations, and remediation activities were quickly undertaken in order to maintain the schedule for site redevelopment.

A remediation plan was developed by REGENESIS® that utilized in situ chemical oxidation and enhanced aerobic biodegradation to address the residual petroleum contamination at the site. Due to the extended drought in the area that caused rapidly declining groundwater levels, three separate zones of contamination were targeted in the remediation plan: the groundwater zone and two newly-formed vadose zones that are separated by a low-permeability unit. The 3700 ft2 treatment area included full coverage by the groundwater treatment as well as two distinct regions of the shallow and deep vadose zones.

A bench test using soil and groundwater from the site was performed to verify the effectiveness of the planned course of treatment prior to full-scale application. A >99% reduction in benzene concentrations confirmed the remediation plan, and application of the remediation chemistry was performed by REGENESIS Remediation Services (RRS) over two injection events. Due to the prolonged drought in the area, recycled water was brought on site for use in the field activities. The two injection events were separated by one month and each spanned ten days. During the first event, PersulfOx® was applied via direct push technology to 54 injection points. In the second event, ORC Advanced® was co-applied with PersulfOx through 59 points.

Technology Description

PersulfOX is a sodium persulfate-based chemical oxidation technology that destroys both hydrocarbon and chlorinated solvent contaminants in the subsurface. PersulfOx contains a built-in catalyst that activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegradation.

Results

Three months after treatment of the site was completed, BTEX concentrations decreased by over 99% from the baseline concentrations of 3070 μg/L. Furthermore, concentrations of all contaminants have been reduced to below the criteria for Low Threat Closure, and as a result of this rapid achievement of site goals, the redevelopment schedule of the site has been preserved.

Combined PlumeStop® and ORC-Advanced® Treatment Remediates Low Level Benzene Contamination

Project Highlights

- Persistent benzene contamination reduced from 530 μg/L to 4 μg/L

- Target Medium Specific Concentration (MSC) achieved within one quarter of treatment

- Application of PlumeStop® and ORC Advanced® successfully completed by REGENESIS® Remediation Services (RRS) within three days allowing for the project

1m 38s reading time

Project Summary

Operation activities at the site of an active gas station resulted in contamination of the groundwater with low levels of benzene. The concentration of benzene fluctuated, reaching 530 μg/L before remediation efforts were undertaken. REGENESIS designed a remediation plan to address the persistent low levels of benzene that combined the application of PlumeStop and ORC Advanced for in situ sorption and enhanced aerobic biodegradation.

The sorbent properties of PlumeStop make it possible to successfully treat low contaminant levels by creating local areas of high contaminant concentration that can then be colonized by contaminant-degrading bacteria. This co-localization of the contaminants and bacteria on the PlumeStop surface greatly improves the contact between the two components, thereby enhancing the speed and efficiency of the degradative reactions. Addition of ORC-Advanced further supports aerobic biodegradation by providing a long-lasting oxygen source.

RRS injected PlumeStop and ORC Advanced into 12 points around MW-6R (Fig. 1) that showed elevated benzene levels. A total of 1,200 lb of PlumeStop were first injected via direct push technology followed by injections of 240 lb of ORC Advanced into the same 12 holes. Treatment of the site was completed over the course of two days without any complications.

Technology Description

PlumeStop Liquid Activated Carbon (LAC) is an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation.

ORC Advanced is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

Results

In the first quarterly sampling event after the remediation chemistries were applied, benzene levels had dropped from the pre-application level of 530 μg/L to below the Medium Specific Concentration (MSC) of 5 μg/L set by the Pennsylvania Department of Environmental Protection. Furthermore, groundwater quality parameters in MW-6R indicated good distribution of the remediation chemistry through the subsurface and the establishment of optimum parameters for continued aerobic biodegradation.

RegenOx® and ORC Advanced® Application Reduces BTEX , MTBE, and TBA Concentrations to Below MCL

Site closure granted.Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español