Innovative PersulfOx treatment under building during construction

Summary

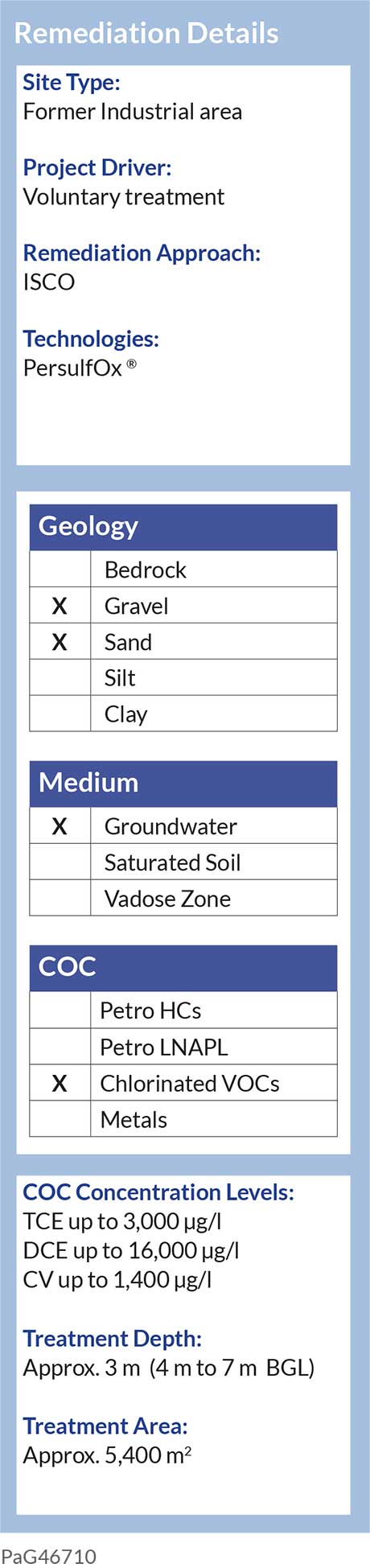

A site investigation at a brownfield redevelopment site in Barcelona revealed the presence of chlorinated solvent contamination in the groundwater. TCE was present as the parent compound, as well as elevated concentrations of daughter products DCE and VC. Due to the target area extending under the footprint of the proposed building and the short build programme, a grid of horizontal injection pipes was installed in the subsurface prior to construction commencing. The grid was then linked to a remote injection location, so that when the new building was constructed, injection was simultaneously completed underneath it.

The intention of the remediation was to achieve a rapid and significant reduction of the contaminant concentrations in the groundwater. PersulfOx was selected as the preferred ISCO agent due to its efficiency and capability of moving through the vadose zone into the groundwater, guaranteeing a good distribution.

Treatment

PersulfOx is a sodium persulfate based chemical oxidation agent in which a patented catalyst has already been premixed into the formulation. This allows for safe and simple fieldwork and avoids the delivery and handling of large amounts of hazardous activator chemicals onsite. The reduced eldwork complexity and smaller application volumes also provide cost savings for the remediation project.

Before the construction of the new building, a horizontal injection grid was created in the vadose zone covering the entire impacted area, at a depth of 3 m BGL, just above the groundwater.

The grid was formed by pipes laid out in an interlocking rectangular shape, with pipes spaced at 10 meter in one direction and 15 meters perpendicular to those. The pipes were perforated every 0.5m in length, through which the PersulfOx was injected. The feeding point was located outside of the new building’s footprint, to avoid any potential interference between the remediation activities and construction activities onsite.

The treatment performed has successfully removed the chlorinated solvents in the groundwater, with an overall decrease in concentrations of 1 order of magnitude.

What’s Special?

- PersulfOx contains a unique built-in catalyst to enhance the oxidative destruction of chlorinated hydrocarbons in the subsurface. The patented catalyst is already mixed in the product, so the application is much safer and easier to apply compared to other ISCO products.

- The horizontal distribution pipe network allowed excellent distribution of PersulfOx under a building whilst construction was taking place, therefore avoiding disturbance to the site or slowing the build programme.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español