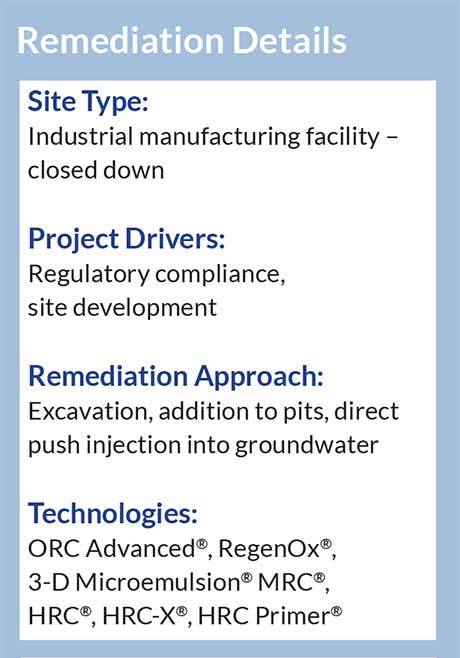

Multiple technologies deployed to remediate plumes under derelict site

Summary

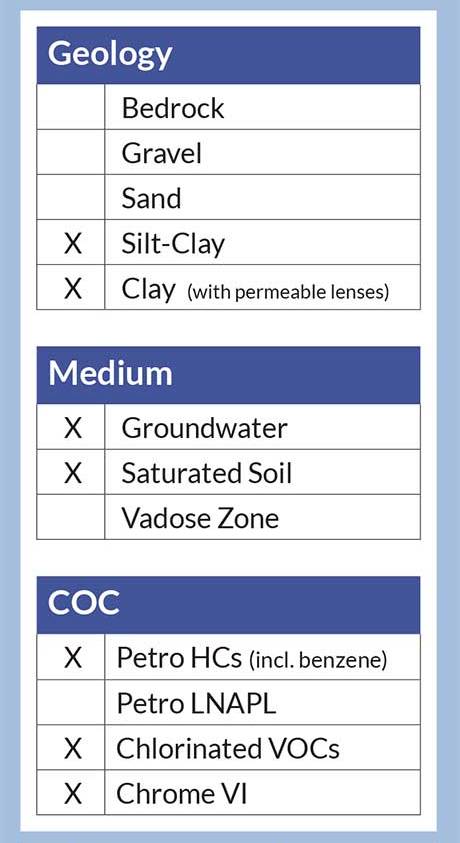

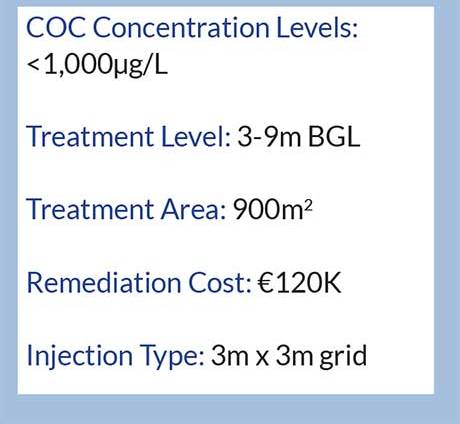

A derelict manufacturing facility required remediation before it could be sold to be redeveloped. Manufacturing activities had resulted in large areas of the subsurface being impacted with a range of contaminant including chlorinated solvents (CHCs), petroleum hydrocarbons (TPH), benzene, and hexavalent chromium (CrVI).

REGENESIS worked with the Environmental Contractor, to devise an accurate and multi-faceted approach to target all the contaminants of concern in the soils and groundwater of the site. The Environmental Contractor oversaw the excavation of the impacted soils and completed the in situ treatment across the site with REGENESIS (as detailed below).

Treatment in Excavations

A total of 4 excavations were made on site, of which two were shallow and the other two deeper, intersecting the impacted groundwater.

One excavation targeting TPH/benzene contamination

RegenOx and ORC-Advanced were placed directly into base of the excavation where it intersected the groundwater, to provide In Situ Chemical Oxidation (ISCO) and Enhanced Natural Attenuation (ENA) of the residual TPH and benzene contamination.

One excavation targeting CHCs

3-D Microemulsion (3DMe) was added to the base of the excavation in order to provide Enhanced Reductive Dechlorination (ERD) of the residual chlorinated solvent contamination (chlorinated ethenes and dichloropropane). 3DMe is a high-volume product and so could be used to easily cover the wide excavation base.

Direct Push Treatment

Targeting Chlorinated Solvents

The HRC product family was used in the low permeability clays adjacent to the excavations. HRC is a low volume product and so can be easily injected into tight formations. HRC will diffuse electron donor reagents into the clay’s pore spaces, degrading the contamination within. HRC-X was included in the design to provide longer-term treatment (5 to 7 years from application) and address the potential for back diffusion and prevent rebound.

A number of direct push injections were also completed underneath the excavated areas, where the excavations did not intersect the groundwater.

Targeting Chrome VI

Metals Remediation Compound (MRC) is designed specifically for the treatment of hexavalent chromium Cr(VI) in groundwater. On this site, it was co-applied with HRC Primer and HRC to target CrVI in two hotspot areas.

What’s Special?

- Treatment of a very low permeability geology has been achieved without operational issues, because of the use of low volume reagents;

- A range of different REGENESIS products have been used to target the different contaminants, concentrations and application methods;

- The wide range of (co-injectable) remedial technologies provided by REGENESIS offers flexibility, accuracy and the ability to treat sites with multiple contaminants of concern;

- As a result, the size of the excavations in the saturated soils were minimised, saving time and money;

- The use of direct push allowed for adjustment of injection locations when subsurface structures were encountered;

- Direct push treatment was possible even where access was difficult.

Validation of the project is currently ongoing, but interim monitoring shows a reduction in all contaminant concentrations.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español