PersulfOx® Treats Gasoline Tanker Truck Spill Site

Pilot Study Moved to Full-Scale Application to Remediated Benzene and TPH-G Contamination

Project Highlights

- Pilot study moves to full-scale application after large contamination concentration decrease resulting from in situ chemical oxidation (ISCO).

- High-volume, direct-injection of PersulfOx® ISCO distributes reagent beneath highway.

- ORC Advanced applied to edge of plume to prevent further migration.

- The average reductions of benzene or TPH-G were 83% and 79% respectively.

Project Summary

A gasoline tanker truck rollover occurred in Ringling, Oklahoma resulting in a benzene and TPH-G contamination. A pilot study using PersulfOx ISCO was conducted with up to 98% contamination reduction observed. Upon successful completion of the pilot study, a full-scale application was approved. A series of full-scale ISCO applications commenced to achieve significant knockdown of benzene and TPH-G concentrations at the site.

Remediation Approach

Full-scale PersulfOx injections were focused along a run-off ditch on the east side of the highway where contamination reached the groundwater during the initial spill and also downgradient on the west side of the highway where contamination had migrated.

The intent of injections on the east side of the highway were designed to address source contamination. These injections were also designed to treat the contamination beneath the highway. PersulfOx migrated through the aquifer under the influence of large direct-push injection volumes and a strong underlying groundwater gradient and natural slope of the lower confining bedrock.

Two PersulfOx injections have been completed approximately one month apart while an application of ORC Advanced also was applied in the distal part of the plume to prevent further spreading of BTEX and TPH.

The average reductions of benzene or TPH-G were 83% and 79% respectively. These are encouraging results and indicate beneficial oxidation and mass reduction of fuel hydrocarbon contamination. Ongoing monitoring will determine if additional applications are needed to reach remedial goals.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Remediation at Multiple Service Stations using Badger Application System

RegenOx® Applied to Three Long Island Sites Contaminated with High BTEX Levels

Project Highlights

- BTEX levels higher than 20 mg/L observed on-site.

- Badger Injection System allowed for high volume applications of up to 700 gallons per injection point.

- In Situ chemical oxidation (ISCO) using 56,400 pounds of RegenOx® was used at three service station sites.

Project Summary

Several service station sites in Long Island, N.Y. were contaminated with high levels of BTEX. In heavily impacted areas, BTEX levels were higher than 20 mg/L. RegenOx was applied to the sites using the Badger Injection System, which is operated by Environmental Assessment and Remediation (EAR). The Badger injection process is used to deliver large volumes of reagent to targeted treatment zones. The objective is to obtain widespread distribution of reagent. Typical injection volumes are 500 to 700 gallons per injection point.

Remediation Approach

The Long Island sites range in size from 600-square-feet to over 4,000-square-feet.

Injection Amounts:

- Site 1 – 30,000 pounds of RegenOx; 4 Injection Events

- Site 2 – 24,000 pounds of RegenOx; 3 Injection Events

- Site 3 – 2,400 pounds of RegenOx; 2 Injection Events

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled direct oxidation and free-radical reactions. This product maximizes in situ performance through the use of a solid alkaline oxidant (a sodium percarbonate complex) and a multi-part catalyst. These oxidation reactions do not inhibit natural bacterial populations and are compatible with biological treatment methods.

Regulatory Goals Met in 30 Days in Complex Industrial Dry Cleaner Plant Remediation

Project Highlights

- PCE contaminant concentrations met remediation goals within 30 days post-application

- No rebound post-application

- Remediation goals met for site closure submittal

1m 57s reading time

Project Summary

An industrial dry cleaning plant in West Allis, Wisconsin was equipped with multiple underground storage tanks (USTs) which stored the degreasing agent perchloroethylene (PCE). The UST releases date back to 50 years and created a treatment area of approximately 4,500 square feet. An in situ, combined remedies treatment approach was implemented onsite using a range of reagents including PlumeStop®, RegenOx®, Hydrogen Release Compound (HRC®) and BioDechlor INOCULUM Plus (BDI® Plus). This site was planned for future development, consequently the remediation approach was designed to achieve site closure by removing the residual source in the vadose zone and treating the deep groundwater plume.

Remediation Approach

Starting in the residual source area, in situ chemical oxidation (ISCO) was applied via soil mixing down to a depth of 7 ft. below ground surface. The ISCO program using RegenOx was designed to treat a total of 140 tons of PCE-impacted clay soil with initial concentrations measuring 169 mg/kg and a remediation goal of <14 mg/kg. To address the deep groundwater plume with PCE concentrations as high as 13,800 ppb, fast-acting, PlumeStop was applied through a series of deep injection wells approximately 80 to 95 ft. below ground surface. The use of PlumeStop allows remediation practitioners to quickly reduce concentrations over a wide-area with the long-term assurance of biodegradation. HRC and BDI Plus were co-applied with PlumeStop to enhance the biodegradation process.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants and maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

PlumeStop is an innovative in situ remediation technology designed to rapidly reduce contaminant concentrations, stop migrating plumes, eliminate contaminant rebound, achieve stringent clean-up standards, and treat back-diffusing contaminants.

HRC is a controlled release, electron donor material, highly efficient for the production of dissolved hydrogen to fuel anaerobic biodegradation processes in soil and groundwater.

Bio-Dechlor INOCULUM Plus is a species of Dehalococcoides sp. (DHC), enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Results

The ISCO application of RegenOx, and combined approach using HRC, BDI Plus and PlumeStop rapidly reduced contaminant concentrations to achieve the remediation goal in just 30 days post-application. As a result, the client has submitted for site closure. Using an innovative combined remedies approach provides environmental remediation professionals with an effective solution for treating sites that present multiple challenges including hard to treat contaminants, sites with lengthy history of impacted soils, difficult geologies, and time constraints.

Free-Phase Hydrocarbons Significantly Reduced on Historic Spill Site Within Four Months

Project Highlights

- PetroCleanze™ applications combined with High Vacuum Dual-Phase

Extraction (HVDPE) reduced site contaminant mass and totally eliminate

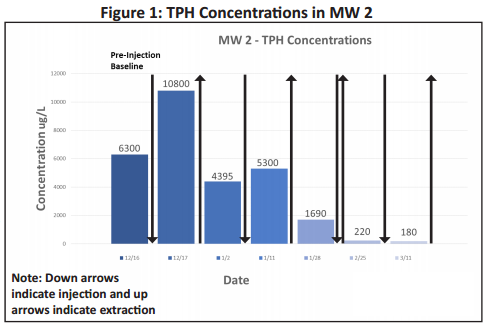

free-phase hydrocarbons within four months - TPH concentrations reduced by over 97% at key monitoring well

Project Summary

A leak from an above ground diesel tank caused groundwater contamination, including free-phase and dissolved hydrocarbons, and significant bound hydrocarbon mass at this manufacturing site. Remediation efforts conducted for nearly a decade included excavation, freephase hydrocarbon recovery, groundwater treatment, bio-venting, high-vacuum dual-phase extraction (HVDPE), and chemical oxidation. However, a free-phase hydrocarbon layer still existed over much of the site as indicated in key monitoring wells.

REGENESIS® recommended the use of PetroCleanze to desorb bound hydrocarbons from the plume area, which was the source of the reoccurring freephase layer. A design was developed that included a regimen of PetroCleanze injections and HVDPE events to desorb and recover the bound hydrcarbons still existing on the site, which would then be recovered by use of the existing HVDPE system.

A total of 107,000 gallons of PetroCleanze was applied through 57 injection points in a grid pattern. Four injection events occurred over the course of four months at depths of 19-27 feet below ground surface. HVDPE was conducted between injection events to recover desorbed hydrocarbon mass.

Technology Description

PetroCleanze is a customized formulation of the widely used RegenOx in situ chemical oxidation technology. The primary function of RegenOx PetroCleanze is to increase the desorption rates of hydrocarbons bound in saturated soil and make them available for more efficient and rapid treatment using a range of enhanced recovery technologies.

Results

Following treatment of the site with PetroCleanze, combined with HVDPE, groundwater hydrocarbon contamination was significantly reduced, as evidenced by a 97% reduction at key monitoring well MW-2 (See Figure 1). The consulting firm leading the project is currently performing quarterly monitoring ahead of petitioning for site closure.

Roadside Fuel Transport Spill Treated with Combined Remediation Approach

Project Highlights

- Combined remediation approach treats contaminants that remained following emergency excavation

- RegenOx® and ORC Advanced® selected to eliminate need for dedicated groundwater treatment infrastructure

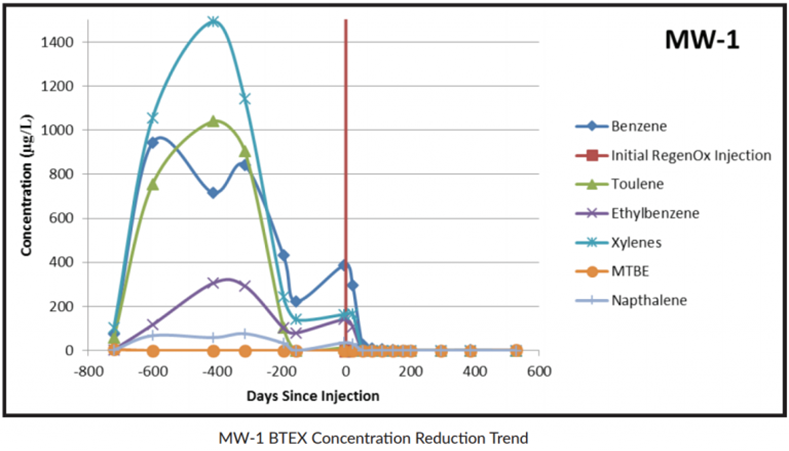

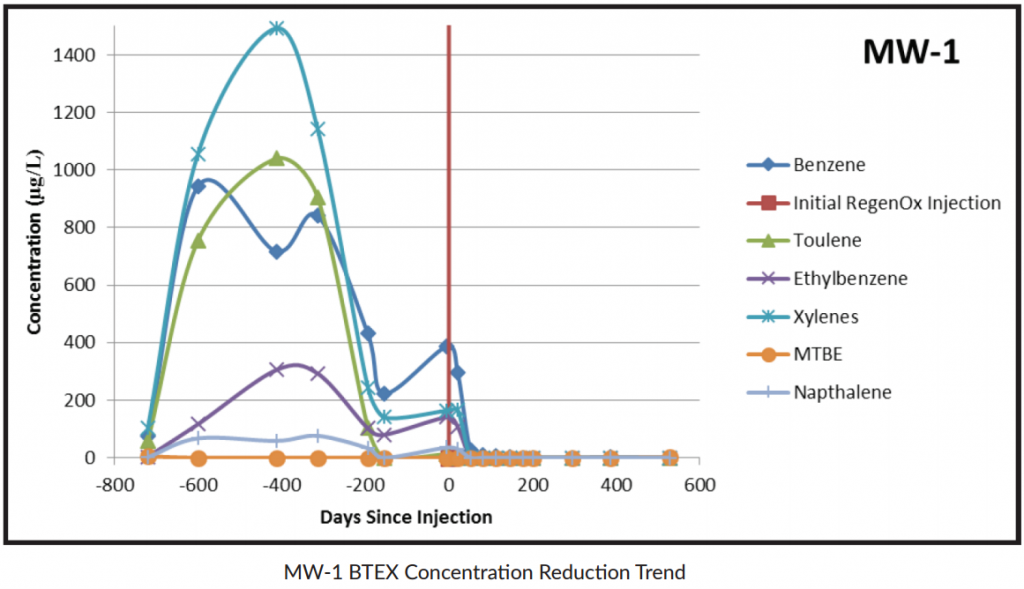

- BTEX levels reduced by 97% to below non-detect levels in the two highest concentration wells

Project Summary

A rural site located in south-central North Carolina required remediation to treat petroleum contamination from an overturned tanker truck. Excavation activities during an emergency response removed much of the contaminant mass, however additional contamination in soil and groundwater remained after the excavation was completed.

In the two highest-concentration wells, total BTEX averaged more than 1,300 μg/L in the four quarterly groundwater monitoring events prior to treatment.

A combined chemical oxidation and aerobic bioremediation treatment was employed to eliminate the need for dedicated groundwater treatment infrastructure at this roadside location to advance the site to regulatory closure.

The products selected were RegenOx, an in situ chemical oxidant, and ORC Advanced, an enhanced aerobic bioremediation product. The treatment covered a 3,900-square-foot area through 30 direct-push injection points in the former spill area.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

Results

Within 18 months of treatment, the site was under natural attenuation monitoring prior to regulatory closure with five of the six wells already below stringent regulatory requirements.

Single PersulfOx® Treatment Reduces MTBE Concentrations by 50 Percent

Project Highlights

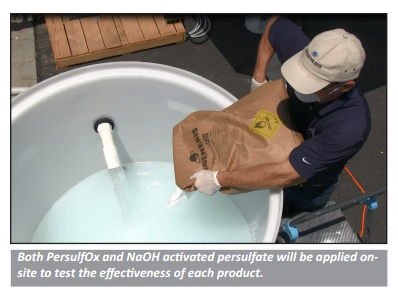

- Both PersulfOx and NaOH activated persulfate used on-site to test effectiveness

- Single injection event of PersulfOx resulted in 50% reduction of MTBE

- Backfilled gravel excavation used as a treatment cell for contaminant mass migrating from an inaccessible dispenser canopy toward the property boundary

Project Summary

A gas station in the Washington DC metro area was contaminated with BTEX and MTBE following a release from a dispenser island. High concentrations of MTBE (160 ppm) diffused into the native silty clay and beyond the property boundary. Two persulfate chemistries utilized at the site to evaluate treatment longevity. Persulfate test kits demonstrated that PersulfOx remained active for six months. The PersulfOx® injections were performed within a downgradient former excavation which was backfilled with gravel to intercept the contaminants. The single injection event of PersulfOx resulted in 50% reduction of MTBE. Treatments in the former excavation have also reduced MTBE concentrations at the property boundary.

Remediation Approach

The PersulfOx injection was performed into three injection wells that were located in an excavation that was backfilled with gravel. This gravel backfilled excavation used as a treatment cell for contaminants originating from under the dispenser canopy (upgradient). The goal was to oxidize contaminant mass as it moves through the former excavation toward the property boundary. The native soils consisted of silty clay, which have a low hydraulic conductivity and do not accept injection volumes easily. This approach treats the petroleum bleed-off from the dispenser canopy before it moves downgradient and eventually off-site. The purpose of the project was designed to evaluate performance data where PersulfOx and NaOH activated persulfate were compared for contaminant reduction trends, longevity, and ease of application.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solventtype contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

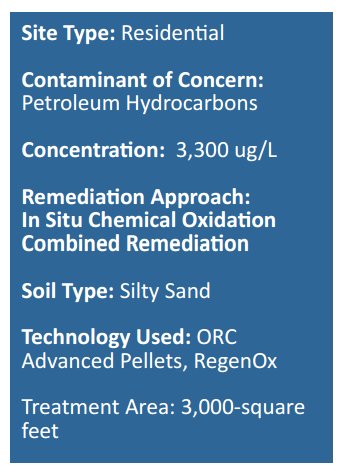

Residential Property Treated for TPHd Concentrations in Groundwater

Project Highlights

- Excavation and remediation injections performed in a tight residential setting with intense local community involvement.

- Treatment included shoring/excavation, soil handling and off-site disposal, in situ chemical oxidation (ISCO), bioremediation and sewer replacement.

- Groundwater sampling post-remediation indicates an overall decrease in TPHd concentrations and monitoring is ongoing.

Project Summary

An underground heating oil storage tank contaminated the groundwater below a residential property in Northern California. The two-story home, located near a downtown beach community, had a 100-gallon heating oil tank that was removed in 1994. Site investigation and groundwater monitoring activities were conducted since the removal, when apparent petroleum hydrocarbon impacts were identified. TPHd concentrations of 3,300 ug/L were detected on-site.

Remediation proved to be difficult considering the location of the residential property. The home was surrounded by other residences on three of its corners, with a bed and breakfast and swimming school located to the northwest of the property. A tight injection approach was required so the neighboring properties were not disturbed.

Remediation Approach

To meet the objective mass reduction of residual TPHd in both soil and groundwater, the remedial approach combined excavation/shoring and removal of TPHd impacted soils. It also included ISCO using RegenOx® and bioremediation using Oxygen Release Compound (ORC Advanced®). Approximately 233 cubic yards of soil were removed. A total of 2,350 pounds of RegenOx Part A and 1,320 pounds of Regenox Part B, along with 716 pounds of ORC Advanced® in slurry form, was injected into the subsurface via 16 direct-push injections.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

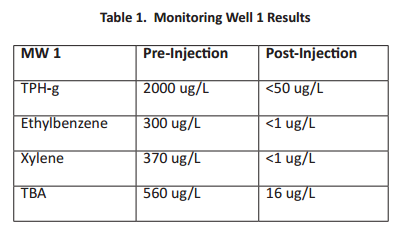

Combined Technologies Treat High TBA Levels

Site Closure Pending at Active California Retail Petroleum Service Station

Project Highlights

- A range of various remediation approaches were applied at the site over a span of 20 years.

- Enhanced Aerobic Biodegradation (EAB) remediation approach replaces soil excavation plan at site.

- Site closure pending.

Project Summary

An active service station in Southern California was contaminated with high levels of TBA and TPH-g. Various active remediation approaches took place on-site for nearly 20 years including excavation of the underground storage tanks and dispensers, soil vapor extraction and groundwater pump and treat. Although the active remediation reduced concentrations at the source, contamination levels remained high. Regenesis became involved with the site in 2011 and after two applications of enhanced aerobic biodegradation using ORC® Advanced and RegenOx®, site closure is pending.

Remediation Approach

In 1995, the underground storage tanks and dispensers were excavated and 257 tons of contaminated soil was removed. From 2003 to 2009, dissolved oxygen injection was applied into seven injection wells and in 2009, over 6,000 gallons of water was extracted from one well. In November 2011, Regenesis became involved in the project and proposed a combined remedies approach.

The remedy implemented at the site from November 2011 through November 2012 included introduction of a controlledrelease molecular oxygen into the subsurface water to promote bio-degradation of the fuel hydrocarbons. The implementation of the remedy was completed in two phases with the initial injection activities being completed in November 2011. A second injection event was completed at the site in November 2012. Approximately a total of 6,000 pounds of ORC Advanced and 480 pounds of RegeneOx were applied on-site.

Contaminant concentrations were analyzed in the most recent monitoring events and compared to pre-injection concentrations. Results for performance monitoring well MW 1 were the most significant as all contaminant concentrations decreased to below regulatory limits (Table 1). Closure has been requested and is currently pending.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Combined Remedies Replace Costly Mechanical Remediation Systems

RegenOx® and ORC® Advanced Treat MTBE/TBA at Five Active California Service Stations

Project Highlights

- In Situ chemical oxidation (ISCO), enhanced aerobic biodegradation replaced costly mechanical remediation systems.

- Underground infrastructure required extra precaution when applying remediation reagents on each site.

- Site closure or review of site closure at all five service stations

Project Summary

Five sites in Orange County, CA were selected for remediation using ISCO and enhanced aerobic biodegradation. All of the selected sites were gasoline service stations that were contaminated with low levels of hydrocarbons methyl tertiary butyl ether (MTBE) and elevated levels of the MTBE biodegradation daughter product tertiary butyl alcohol (TBA). The initial remediation approach consisted of soil vapor extraction, air sparging and dual phase extraction; however, contaminant concentrations remained elevated, impeding regulatory closure.

The decision was made to transition from mechanical-based remediation systems using a combination of ISCO and enhanced aerobic biodegradation to achieve site closure criteria with various regulatory agencies.

Remediation Approach

Initial mass reduction was achieved using mechanical systems, however concentrations remained too high for regulatory closure. The goal was to reduce the remaining levels of petroleum hydrocarbons, MTBE and TBA using RegenOx and ORC Advanced. The service station included up to three direct-push injection applications of the reagents into areas where underground infrastructure was present on each site. RegenOx and ORC Advanced are both highly compatible with subsurface infrastructure so it was more of a challenge from a physical injection vantage. O&M strategy required monitoring of REDOX and microbial shifts. All five sites have been closed or under review for closure under the local regulatory agencies.

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

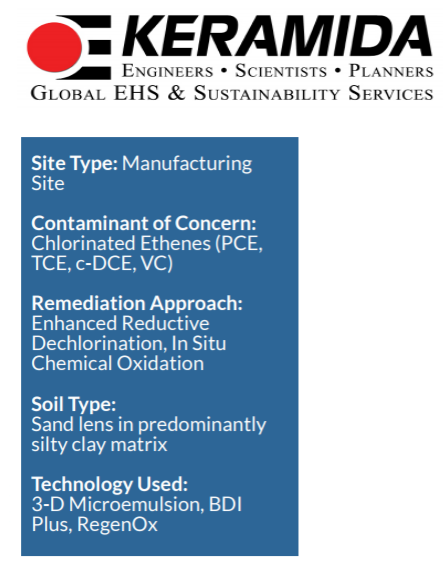

Combined Remedies Approach (Dual Phase Extraction, ISCO and ERD) Lead to Rapid Results on a Guaranteed Cost to Closure Project in Indiana

3- D Microemulsion, BDI Plus and RegenOx Reduce cVOC Concentrations

Project Highlights

- Guaranteed cost to closure project.

- ISCO coupled with dual-phase extraction was successful in reducing cVOC concentrations within the core source area.

- Plume-wide ERD injection resulted in meeting remedial goals within 18-20 months.

- Combined remedy approach (ISCO & ERD) accelerated the time to closure allowing project to be completed within budget

Project Summary

A plating plant in Batesville, Indiana was contaminated with chlorinated VOCs. A subsequent investigation identified a plume of TCE extending from the building approximately 250 feet down gradient (off-site and onto private property across a street).

Remediation Approach

The initial remedial approach involved installation and operation of a dual-phase extraction (DPE) system throughout most of the plume area (26 extraction wells), which operated for approximately 1 ½ years. Approximately one year after the DPE system installation, a core area in situ chemical oxidation (ISCO) injection of RegenOx® was performed by KERAMIDA and Regenesis Remediation Services (RRS). ISCO combined with further operation of the DPE system was effective in additional reductions of cVOC concentrations in the groundwater. Upon conclusion of these efforts, the DPE system was shut down to allow for enhanced reductive dechlorination process to take place.

A successful enhanced reductive dechlorination (ERD) pilot test with 3-D Microemulsion® and BDI® Plus was performed around two off-site wells at the leading edge of the plume. Based on the success of this test, an ERD injection was performed in a newly-identified source area with outstanding results in the first six months. Consequently, the DPE system remained shut down and a full-scale ERD injection was performed in the core area of the plume.

Approximately 9 months after the full scale injections, a very small supplemental injection was performed in the off-site area where the pilot study was done and another in an area where no injection was performed. One year after the full-scale ERD injection, cVOC concentrations are below the target cleanup levels in all wells with the exception of two slightly elevated VC concentrations, which are expected to decrease shortly.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

About the Consultant

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español