AZ Superfund Site Uses ISCO to Replace Recirculation Wells Leading to Cost Savings of $100,000

Project Highlights

- 95% reduction of BTEX, MTBE and TMBs reported on-site

- Total savings estimated to be $100,000

- In Situ Chemical Oxidation (ISCO) combined remedy design incorporates PersulfOx® to effectively address reduction in contaminants

Project Summary

A former industrial paint facility in Tempe, Arizona was contaminated with high levels of gasoline in the groundwater. Ongoing active remediation using Accelerated Remediation Technology (ART) was applied to treat high levels of BTEX, MTBE and TMB. However, this remediation approach was unsuccessful in reducing contaminants to cleanup target levels due to the limited radius of influence produced by the recirculation well system. REGENESIS was approached to design an ISCO plan using the existing treatment well infrastructure.

Remediation Approach

REGENESIS injected 10,028 pounds of PersulfOx at a 12% solution in two applications. As a result, a 95% reduction of BTEX, MTBE, and TMBs was reported post-application. The overall PersulfOx ISCO injection treatment totaled $40,000 – a small fraction of the previously deployed ART system cost and equal to four months of the ART system’s operational expense.

REGENESIS Solutions Applied

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

The REGENESIS ISCO plan using PersulfOx contributed to the 95% reduction in BTEX, MTBE, and TMBs while providing significant cost savings to the client in the remediation of this Arizona Superfund site. Use of a combined remedy approach offers clients viable options for achieving cleanup target levels and compressed time to closure.

Safe and Simple Excavation Application Provides Long-Term Treatment

Summary

During the demolition and redevelopment of a former petrol filling station, an underground storage tank was removed. The tank had been used for the storage of diesel and had leaked into the surrounding soils and groundwater. The impacted soils were excavated and removed to a waste management facility. The groundwater within the excavation was impacted with dissolved phase hydrocarbons and required further treatment.

Regenesis provided the remediation contractor with a remedial design for the application of ORC Advanced Pellets to treat the residual contamination within the groundwater in and around the open excavation.

Treatment

ORC Advanced Pellets were applied into the groundwater, in the base of the excavation. This was completed by placing them in an excavator bucket and spreading evenly across the area. By using the pelletised version of ORC Advanced, there was no need for mixing or application using pumps and the potential for dust creation was minimised.

The pellets take only minutes to apply and yet provide a controlled release of oxygen into the groundwater for a period of 9-12 months from a single application. The ORC Advanced stimulates the growth of an aerobic biomass which accelerates the biological degradation of dissolved phase hydrocarbon contamination.

What’s Special?

- The use of ORC Advanced Pellets meant that the contractor could backfill the excavation and continue the build programme with minimal disruption.

- The remediation then continued in situ with no need for physical plant taking up valuable space or requiring maintenance.

- ORC Advanced Pellets provide an effective long-term treatment of residual dissolved phase contamination though a very easy, safe and rapid application process.

Product Description

ORC Advanced Pellets (ORC-A Pellets) are a pelletised version of REGENESIS’ widely-used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletised, dry application material minimises airborne dust while eliminating the need for specialised equipment and spray water required for powder-slurry applications. ORC Advanced Pellets are approximately 3-10 mm in size.

High TPH Concentrations Treated Using PersulfOx® and ORC® Advanced

Future Site of Stormwater Retention Ponds Remediated with ISCO, Enhanced Aerobic Biodegradation

Project Highlights

- Initial treatment with aerobic bioremediation effectively removed 60% of site contamination.

- PersulfOx® and ORC® Advanced were used to treat two remaining hot spot areas.

- Site closure is pending additional groundwater monitoring.

- Contamination concentrations must be reduced to meet stringent groundwater quality standards.

Project Summary

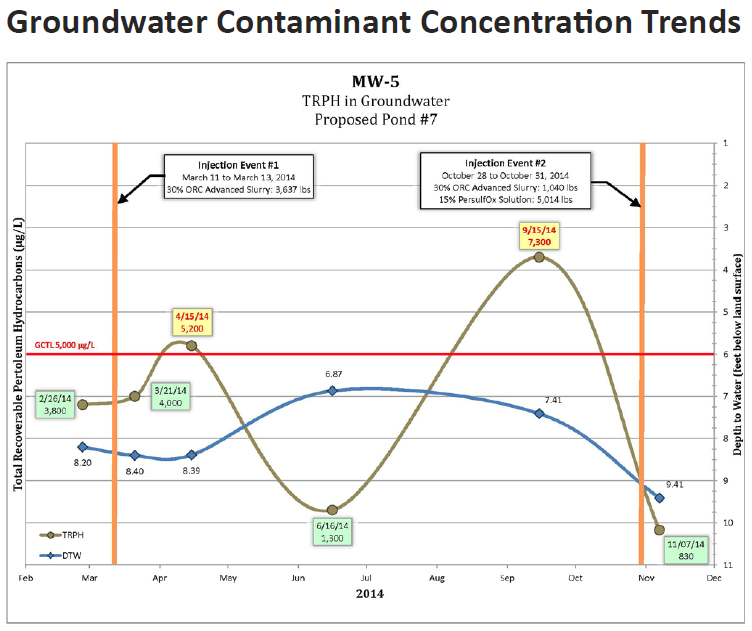

This site is a former commercial facility in the Southeast with high TRPH contaminant impacts to soils and groundwater. The property is currently vacant and the state department of transportation plans to create a stormwater retention pond on site. However, contaminant concentrations in groundwater need to be reduced to meet stringent groundwater quality standards before any construction can begin.

The plume was first treated via enhanced aerobic bioremediation with ORC Advanced, which effectively removed over 60% of the dissolved-phase contamination within 18 months. In two hot spot areas, residual contamination in the smear zone continued to cause impacts to groundwater. A follow-up treatment combining in situ chemical oxidation and enhacned aerobic bioremediation was employed. PersulfOx and ORC Advanced were used to bring this site towards closure by effectively treating these two hot spot areas. Initial sampling results 30 days after treatment showed attainment of groundwater quality standards.

Remediation Approach

ORC Advanced was injected over 60 direct-push locations across two plume areas. A year and a half post-application, two remaining hot spot areas with residual capillary fringe contamination had caused continued issues. PersulfOx and ORC Advanced were used to bring this site towards closure by effectively treating these two hot spot areas.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

RegenOx® Excavation Application Treats Groundwater Contamination

80% TPH Concentration Reduction at California DoD Facility

Project Highlights

- Source removal and RegenOx® ISCO application reduce contamination levels to clean-up standards

- Horizontal piping network installed as contingency plan for additional remediation

- 80% reduction in groundwater concentrations observed

Project Summary

The project site is a former Department of Defense (DoD) fuel dispenser facility in Northern California where past corrective measures included AST/UST removal, soils excavation and groundwater monitoring. Sample results indicated continued elevated concentration levels of TPH-G, TPH-D and TPH-mo within a defined area near the former USTs. The treatment approach included additional excavation and in situ chemical oxidation (ISCO) application via RegenOx mixed into saturated zone. Quarterly sampling indicated an 80% reduction in groundwater concentration levels post treatment; which met the corrective action cleanup levels for TPH.

Remediation Approach

The selected contractor excavated, managed and disposed of impacted soils to depths of nine feet over the two defined treatment areas. RegenOx Part A (oxidizer) and Part B (silica gel activator solution) were placed in the saturated zone and mixed in with the excavator bucket to 3 feet below the excavation bottom. Prior to backfill and compaction, a horizontal piping network was installed to serve as a contingency plan in the event that any additional in situ and/or bioremediation remediation was required. Regenesis assisted the client with the horizontal piping network design which was incorporated into the bid specifications. This site area has been submitted for closure and with continued quarterly monitoring.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Acetone and Petroleum Hydrocarbons Treated at Active Industrial Facility

Combined ISCO/Bioremediation Treatment Approach Reduces Contamination Levels

Project Highlights

- Acetone concentrations pre-remedation were as high as 54,000 μg/L

- Site access agreement required that existing site operations could not be interrupted for construction

- Site water was not allowed to be used therefore all water had to be trucked in and a separate water permit to access city water from fire hydrants was required

Project Summary

A former industrial facility in northern California operated as a gas manufacturing plant from the early 1900s until it was decommissioned in 2001 and sold. The property is currently leased by a bottled water distribution facility.

At this facility, acetone was used extensively in acetylene manufacturing. The acetone was stored on-site in underground storage tanks (UST) but no evidence of leaking acetone USTs was found.

However, high concentrations of acetone – a pre-remediation maximum of 54,000 micrograms per liter (μg/L) were found in one area of the site. Other dissolved chemicals of concern (COC) include gasoline and gasoline-range petroleum hydrocarbons from former USTs such as benzene, toluene, ethylbenzene and xylenes (BTEX).

The extent of contamination in the early 1990s extended to large portions of the site. A pump and treat system was used on-site in 2005, however contamination persisted. Contamination approximately 12 feet below ground surface was detected within the soil. A remediation plan using both ORC® Advanced and RegenOx® was used to treat the remaining contamination.

The site access agreement for this project required that existing site operations could not be interrupted for construction. In order to minimize disturbance to tenants and work within these constraints, all drilling field work was performed on weekends. Site water was not allowed to be used therefore all water had to be trucked in and a separate water permit to access city water from fire hydrants was required. In addition, multiple drill rigs and support vehicles operated within a small area, increasing logistical and safety concerns.

Remediation Approach

A mixture of 6,500 pounds of RegenOx and 3,000 pounds of ORC Advanced was injected at 45 locations using multiple direct-push drill rigs. The injection points were designed in a grid pattern with a nominal 15-foot spacing between injection points, but more densely placed in the area of highest contaminant concentration. Benzene concentrations in groundwater have stabilized at about 10 μg/L and acetone concentrations have stabilized at about 1,600 μg/L. Post-treatment monitoring results show that all the COCs in the treatment area have consistently remained below health-based cleanup levels since the treatment was applied.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Open Excavation Treatment at Former NJ Service Station

RegenOx® and ORC® Advanced Pellets Remediate Petroleum Hydrocarbon Contamination

Project Highlights

- Former service station contaminated with BTEX levels measuring 11 ppm in groundwater and soil impacts removed through excavation

- Combined remedy to treat the open excavation with both in situ chemical oxidation and enhanced aerobic bioremediation technologies

- RegenOx and ORC Advanced Pellets technologies are compatible/non-corrosive with underground infrastructure and utilities infrastructure in the subsurface

Project Summary

A former service station in New Jersey was contaminated with high levels of BTEX (measuring 11 ppm in groundwater pre-treatment). Due to significant amounts of contaminated soil mass remaining at the former service station, an excavation was proposed by the environmental consultant. RegenOx and ORC Advanced Pellets were applied to the open excavation to chemically oxidize remaining saturated impacts and to promote enhanced aerobic biodegradation of petroleum hydrocarbons in the dissolved phase. Both of these technologies utilize alkaline chemistry (pH > 8), which is non-corrosive to nearby public utilities and the underground infrastructure at the service station.

Remediation Approach

RegenOx and ORC Advanced were co-applied into an open excavation at the former service station site. The excavation extended approximately four feet into the saturated zone. Because the excavation was limited by physical constraints, RegenOx, a chemical oxidant, was applied to the base of the excavation to oxidize and desorb residual petroleum mass from the soil. ORC Advanced Pellets were co-applied to provide a slow release of oxygen (up to 12 months longevity) that promotes enhanced aerobic biodegradation of petroleum hydrocarbons. In total, 2,000 pounds of RegenOx and 882 pounds of ORC Advanced Pellets were co-applied to the 2,600 square foot excavation area.

Technology Description

The advanced formulation of the Oxygen Release Compound (ORC Advanced) is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration. The pelletized form of ORC Advanced were designed to improve safety and handling for excavation applications.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled direct oxidation and free-radical reactions. This product maximizes in situ performance through the use of a solid alkaline oxidant (a sodium percarbonate complex) and a multi-part catalyst. These oxidation reactions do not inhibit natural bacterial populations and are compatible with biological treatment methods.

Combined Remedies Treat BTEX Contamination on Government Property

Ontario, Canada Site Remediated with ORC® Advanced and RegenOx®

Project Highlights

- In Situ Chemical Oxidation (ISCO) and Enhanced Biodegradation used post-excavation to treat residual contamination.

- Extensive site mapping conducted with membrane interface probe (MIP) to detect distinct zones of higher mass contamination.

- 95% reductions seen in dissolved phase petroleum hydrocarbon contamination.

Project Summary

A large public works property in Ontario, Canada was contaminated with TPH. Approximately 5,000 gallons of fuel was released into the subsurface primarily due to fuel theft that had taken place on-site. Due to significant volumes of free-product, an excavation occurred followed by skimming activities from 2005-2010. Through extensive site evaluation, it was determined that there was a need for further mass reduction using ISCO.. RegenOx® ISCO was selected for use in the heavily and moderately impacted areas. Enhanced aerobic biodegradation using ORC® Advanced was selected for use in the dissolved-phase areas downgradient from the source. Overall, 96% reductions were seen in dissolved phase petroleum hydrocarbon concentrations.

Remediation Approach

Membrane interface probe (MIP) data was collected and proved to be integral for the remediation design and implementation. Distinct zones with high mass were present on-site and detected through the probe. RegenOx and ORC Advanced were applied via direct-push injections. Approximately 150,000 pounds of RegenOx and 45,000 pounds of ORC Advanced were applied over several injections. Higher concentrations of RegenOx were applied into the vertical zones of higher contamination to improve overall product performance.

Technology Description

Advanced Formula Oxygen Release Compound is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

PersulfOx® Treats Gasoline Tanker Truck Spill Site

Pilot Study Moved to Full-Scale Application to Remediated Benzene and TPH-G Contamination

Project Highlights

- Pilot study moves to full-scale application after large contamination concentration decrease resulting from in situ chemical oxidation (ISCO).

- High-volume, direct-injection of PersulfOx® ISCO distributes reagent beneath highway.

- ORC Advanced applied to edge of plume to prevent further migration.

- The average reductions of benzene or TPH-G were 83% and 79% respectively.

Project Summary

A gasoline tanker truck rollover occurred in Ringling, Oklahoma resulting in a benzene and TPH-G contamination. A pilot study using PersulfOx ISCO was conducted with up to 98% contamination reduction observed. Upon successful completion of the pilot study, a full-scale application was approved. A series of full-scale ISCO applications commenced to achieve significant knockdown of benzene and TPH-G concentrations at the site.

Remediation Approach

Full-scale PersulfOx injections were focused along a run-off ditch on the east side of the highway where contamination reached the groundwater during the initial spill and also downgradient on the west side of the highway where contamination had migrated.

The intent of injections on the east side of the highway were designed to address source contamination. These injections were also designed to treat the contamination beneath the highway. PersulfOx migrated through the aquifer under the influence of large direct-push injection volumes and a strong underlying groundwater gradient and natural slope of the lower confining bedrock.

Two PersulfOx injections have been completed approximately one month apart while an application of ORC Advanced also was applied in the distal part of the plume to prevent further spreading of BTEX and TPH.

The average reductions of benzene or TPH-G were 83% and 79% respectively. These are encouraging results and indicate beneficial oxidation and mass reduction of fuel hydrocarbon contamination. Ongoing monitoring will determine if additional applications are needed to reach remedial goals.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Remediation at Multiple Service Stations using Badger Application System

RegenOx® Applied to Three Long Island Sites Contaminated with High BTEX Levels

Project Highlights

- BTEX levels higher than 20 mg/L observed on-site.

- Badger Injection System allowed for high volume applications of up to 700 gallons per injection point.

- In Situ chemical oxidation (ISCO) using 56,400 pounds of RegenOx® was used at three service station sites.

Project Summary

Several service station sites in Long Island, N.Y. were contaminated with high levels of BTEX. In heavily impacted areas, BTEX levels were higher than 20 mg/L. RegenOx was applied to the sites using the Badger Injection System, which is operated by Environmental Assessment and Remediation (EAR). The Badger injection process is used to deliver large volumes of reagent to targeted treatment zones. The objective is to obtain widespread distribution of reagent. Typical injection volumes are 500 to 700 gallons per injection point.

Remediation Approach

The Long Island sites range in size from 600-square-feet to over 4,000-square-feet.

Injection Amounts:

- Site 1 – 30,000 pounds of RegenOx; 4 Injection Events

- Site 2 – 24,000 pounds of RegenOx; 3 Injection Events

- Site 3 – 2,400 pounds of RegenOx; 2 Injection Events

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled direct oxidation and free-radical reactions. This product maximizes in situ performance through the use of a solid alkaline oxidant (a sodium percarbonate complex) and a multi-part catalyst. These oxidation reactions do not inhibit natural bacterial populations and are compatible with biological treatment methods.

Free-Phase Hydrocarbons Significantly Reduced on Historic Spill Site Within Four Months

Project Highlights

- PetroCleanze™ applications combined with High Vacuum Dual-Phase

Extraction (HVDPE) reduced site contaminant mass and totally eliminate

free-phase hydrocarbons within four months - TPH concentrations reduced by over 97% at key monitoring well

Project Summary

A leak from an above ground diesel tank caused groundwater contamination, including free-phase and dissolved hydrocarbons, and significant bound hydrocarbon mass at this manufacturing site. Remediation efforts conducted for nearly a decade included excavation, freephase hydrocarbon recovery, groundwater treatment, bio-venting, high-vacuum dual-phase extraction (HVDPE), and chemical oxidation. However, a free-phase hydrocarbon layer still existed over much of the site as indicated in key monitoring wells.

REGENESIS® recommended the use of PetroCleanze to desorb bound hydrocarbons from the plume area, which was the source of the reoccurring freephase layer. A design was developed that included a regimen of PetroCleanze injections and HVDPE events to desorb and recover the bound hydrcarbons still existing on the site, which would then be recovered by use of the existing HVDPE system.

A total of 107,000 gallons of PetroCleanze was applied through 57 injection points in a grid pattern. Four injection events occurred over the course of four months at depths of 19-27 feet below ground surface. HVDPE was conducted between injection events to recover desorbed hydrocarbon mass.

Technology Description

PetroCleanze is a customized formulation of the widely used RegenOx in situ chemical oxidation technology. The primary function of RegenOx PetroCleanze is to increase the desorption rates of hydrocarbons bound in saturated soil and make them available for more efficient and rapid treatment using a range of enhanced recovery technologies.

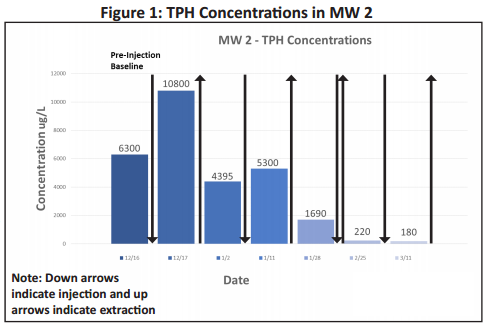

Results

Following treatment of the site with PetroCleanze, combined with HVDPE, groundwater hydrocarbon contamination was significantly reduced, as evidenced by a 97% reduction at key monitoring well MW-2 (See Figure 1). The consulting firm leading the project is currently performing quarterly monitoring ahead of petitioning for site closure.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español