PlumeStop Eliminates PFAS for 8 Years

This case study reviews the first known full-scale in situ PFAS treatment worldwide completed in 2016 at a manufacturing and former firefighting training site in Ontario, Canada, where aqueous film-forming foams (AFFF) were used.

A single application of PlumeStop resulted in a significant reduction of contaminant concentrations to below standards for 8+ years since the injection.

Case Study Highlights

- PlumeStop application reduces PFAS to non-detect within 3 months, maintaining for 8+ years thus far

- Remediation company IRSL collects critical treatment zone information to ensure successful application

- Sampling confirms PlumeStop fully distributed through the treatment zone

- Third-party modeling indicates that PlumeStop will halt PFAS migration out of the treatment zone for more than 60 years

Proven, Rapid, and Cost-Effective Petroleum Spill Treatment

The case studies included in this multi-site review include sites where one of Canada’s largest and most experienced environmental remediation services companies InSitu Remediation Services Ltd. (IRSL) effectively used PetroFix in achieving site closures across Canada. IRSL relies on the technology as an effective, low-cost, and more sustainable remedial solution. As one of the first to apply PetroFix in the field, IRSL has deployed the PetroFix technology to remediate a large number of TPH-contaminated properties, with land use ranging from gasoline stations and commercial properties to residential homes and a national park lodge. PetroFix has quickly eliminated TPH impacts in groundwater at these sites and prevented contaminant movement away from impacted properties, thus eliminating potential human exposure to TPH and protecting pristine, ecologically sensitive surface waters.

Case study highlights:

- Nine sites IRSL treated with PetroFix have already achieved closure, most within one year after a single injection event

- PetroFix chosen at UNESCO World Heritage site due to sensitivity of a pristine water body at the site, offering a less disruptive approach to address TPH

- Site remedies have led to significant cost savings for IRSL’s clients and demonstrated PetroFix as a viable means for treating TPH-contaminated sites in Canada

Significant Reduction in VOCs Achieved at Rail Site

This case study reviews a contaminated rail site in Canada that had released chlorinated solvents in groundwater. WSP conducted a pilot test at the site to assess the applicability of a brand-new technology that optimizes delivery of amendments using hydrocolloids. The pilot test would determine the applicability of a passive treatment barrier using PlumeStop and AquaZVI. A combined remedy approach was chosen because it optimizes the use of colloidal activated carbon and zero valent iron, allowing for the highest treatment efficiency at the lowest possible cost. After conducting the pilot test, data for samples collected within the treatment barrier indicated significant contaminant concentration decreases in groundwater and saturated soil.

This case study reviews a contaminated rail site in Canada that had released chlorinated solvents in groundwater. WSP conducted a pilot test at the site to assess the applicability of a brand-new technology that optimizes delivery of amendments using hydrocolloids. The pilot test would determine the applicability of a passive treatment barrier using PlumeStop and AquaZVI. A combined remedy approach was chosen because it optimizes the use of colloidal activated carbon and zero valent iron, allowing for the highest treatment efficiency at the lowest possible cost. After conducting the pilot test, data for samples collected within the treatment barrier indicated significant contaminant concentration decreases in groundwater and saturated soil.

This case study features the following:

- First application of PlumeStop® and AquaZVI™ globally

- Despite wintery weather conditions at the Rail Site in Northern Quebec, the amendment delivery and distribution was successful

- Over 95% decrease in dissolved and saturated soil VOC concentrations

- Thorough data analysis including ISMs and CSIA confirmed definite contaminant degradation

6m 9s reading time

PHCs at Former Farming Site Successfully Remediated Using PersulfOx®

Project Highlights

- Introduction of PersulfOx® resulted in reduction of PHCs in fractured bedrock, meeting site remediation goals

- High sulphate concentrations in groundwater resulted from the application of PersulfOx which is assisting natural attenuation of any residual petroleum hydrocarbons

Project Summary

A former farming facility located in Calgary, Alberta contained three above ground storage tanks (ASTs) and two pump islands. Environmental assessments related to the planned urban redevelopment of the former farming facility revealed contamination of the soil and groundwater beneath the site with petroleum hydrocarbons (PHCs) due to release(s) from the former ASTs. During a remedial excavation, PHC impacts above the applicable vapor inhalation guidelines were identified within the fractured bedrock. Given the nature and depth of the bedrock, the remedial excavation was no longer feasible. Therefore, PersulfOx, a proprietary chemical oxidant chemical, was utilized for in situ treatment of soil and groundwater within the excavation to reduce the remaining PHC concentrations below the commercial vapor inhalation guidelines.

Based on the subsurface investigations and monitoring activities prior and subsequent to the chemical application, it was determined that PersulfOx was effective in remediation of PHC impacts within the fractured bedrock in an open excavation, within a short period of time and under the low groundwater temperatures. Following treatment with PersulfOx, reduction or the absence in PHC concentrations has been observed in soil or groundwater samples and all post-remediation concentrations have remained below the vapor inhalation pathway guidelines for commercial use. However, high sulphate concentrations were identified as a result of this chemical application which over the long term would assist in the natural attenuation of any residual petroleum hydrocarbons.

Technology Description

PersulfOx is a chemical oxidant that rapidly reduces the mass of the contaminants. This chemical consists of 90% of sodium persulfate and 10% catalyst powder. PersulfOx is very effective in rapid oxidation of petroleum hydrocarbons in both soil and groundwater.

Results

Reduction of PHC concentrations by oxidation using PersulfOx facilitated the urban development of the former farming facility. The high sulphate concentrations are expected to attenuate to background concentrations with time as sulphate is an electron acceptor in the natural attenuation process of petroleum hydrocarbons.

Remediation Plan Completed in Two Days at Former Service Station. No Further Action Received Following Successful PlumeStop® Application

Remediation of BTEX and PHC in the Greater Toronto Area Using PlumeStop

Project Highlights

- Regulatory standards met following single injection of PlumeStop

- Remedial injection event completed in two days with the first clean samples obtained within three weeks post-injection

- Effective design and approach led to time and cost savings for the client

1m 41s reading time

Project Summary

A former gasoline retail station located in Whitby, Ontario, was the site of BTEX and PHC contaminants requiring remediation. Excavation, as well as pump and treat approaches, had been used to address contaminant levels, but groundwater remained impacted by BTEX and PHC F1 and F2 above regulatory standards. While the contractors were able to remove the majority of impacts, they were not able to remediate the site to the applicable regulatory standards.

The client hired INSITU Remediation Services LTD (IRSL), an environmental firm specializing in in situ remediation technologies, to reduce the levels and reach required standards safely and effectively following a tendered contract issued to a total of five contractors. IRSL was chosen based on their innovative approach and lower total cost. Using a proprietary design, IRSL injected PlumeStop Liquid Activated Carbon™, to remediate residual BTEX and PHC F1 and F2 groundwater impacts.

Technology Description

PlumeStop is an innovative in situ remediation technology designed to rapidly reduce contaminant concentrations, stop migrating plumes, eliminate contaminant rebound, achieve stringent cleanup standards and treat back-diffusing contaminants. PlumeStop provides a unique colloidal biomatrix platform which rapidly sorbs contaminants out of the dissolved-phase. Once contaminants are concentrated within the PlumeStop biomatrix, they can be completely biodegraded in place using compatible REGENESIS bioremediation products.

Results

The remedial program was completed in two days with the first clean samples obtained within three weeks post-injection. The BTEX and PHC plumes were treated to below the regulatory standards. Sampling has been performed over four quarters and the site has been deemed remediated.

About the Client

One of Canada’s most experienced remediation companies, INSITU Remediation Services Ltd. (IRSL) has designed, implemented, and maintained soil and groundwater remediation programs in diverse geological environments in North, Central, and South America, Europe and the Middle East.

Remediation of PHCs and VOCs at a Former Dry Cleaner Site Using RegenOx®, ORC Advanced®, and ORC® Filter Socks

Former Dry Cleaning Site Redeveloped to Serve as New Home to Non-Profit Serving Homeless in Chilliwack B.C. Area

Project Highlights

- Introduction of RegenOx® and ORC Advanced® following in situ treatment using PulseOx1 resulted in the reduction in the initial concentrations of PHCs and dry cleaning chemicals in a sand and gravel aquifer, meeting site remediation goals

- Upon completion of remedial efforts, the project was awarded three British Columbia Ministry Environment instruments

Project Summary

A building occupied by a former dry cleaning business (1960s) located in Chilliwack, British Columbia was acquired by Ruth & Naomi’s Mission, (www.ranmission.ca) a non-profit organization serving Chilliwack. Environmental investigations to support the redevelopment of the former dry cleaner building revealed contamination of the soil and groundwater beneath the site and the offsite alley with petroleum hydrocarbons (PHCs) and dry cleaning related chemicals. Since the remedial excavation onto the offsite alley was not considered to be practical, RegenOx, along with ORC Advanced, was utilized for the in situ treatment of soil and groundwater within the excavation to reduce the remaining PHC and dry cleaning chemical concentrations.

Following treatment with RegenOx, reduction in the concentrations of PHC and dry cleaning related compounds were observed in soil and groundwater samples. RegenOx was additionally injected within the alley to treat the offsite plume. As a result, all post-remediation concentrations are below the applicable commercial land use standards. Additionally, ORC socks were applied to assist natural attenuation of any residual contaminants in groundwater. The successful investigation and remedial effort received three British Columbia Ministry of Environment instruments and now safely serves as a resource center and shelter.

Concentrations

- Volatile Petroleum Hydrocarbons VPH (up to 3,400mg/kg)

- EPH10-19 (8,200 mg/kg)

- Ethylbenzene (33mg/kg)

- Total Xylenes (160 mg/kg)

- Perchloroethylene (7μg/g)

- Trichloroethylene (2.8 mg/kg)

- VPHw (110mg/L)

- LEPH (5.6 mg/L)

- Ethylbenzene (2.14 mg/L)

- Toluene (2.7mg/L)

- Naphthalene (410μg/L)

- Perchloroethylene (2.76 mg/L)

- Xylenes (6.78mg/L)

- Vinyl Chloride (349 μg/L)

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

ORC Filter Sock is a permeable filter sock containing calcium oxy-hydroxide based chemical which produces a controlled release of molecular oxygen (17% by weight) when hydrated.

Results

PHC and dry cleaning compounds were reduced in concentrations to groundwater standards following the application of RegenOx and ORC Advanced, facilitating the redevelopment of the former dry cleaning business to house the not-for-profit homeless shelter, Ruth and Naomi’s Mission, serving the Chilliwack, B.C. community. Upon completion of investigation and remedial efforts, the project was awarded three British Columbia Ministry Environment instruments. Up to 200+ homeless are served dinner daily by this organization which provides both shelter and recovery programs to men and women, assisting them in their reintegration into the community and work place.

1 PulseOx is a registered trademark of APT Water, Inc.

Innovative Application of PersulfOx Addresses BTEX Contamination at Former Gas Station Site

Project Highlights

- Innovative remediation plan designed by IRSL to address hydrocarbon plume using PersulfOx® addresses migrating plume

- Cleanup criteria on site was reached with only two injections of PersulfOx

- Direct Push Technology using PersulfOx counters any back diffusion

Project Summary

An active gasoline station in southwestern Ontario exhibited a hydrocarbon plume, which was migrating off site toward commercial buildings, presenting liability concerns for developers. Previous remediation efforts using other oxidants, including base-activated persulphate, did not result in significant reductions, and rebound was a problem, including pH buffering. InSitu Remediation Services, Ltd. (IRSL) was the consulting firm hired to perform the remediation work.

Led by Rick McGregor, IRSL designed an approach that included REGENESIS’® PerfulfOx to address the concentrations in the plume including BTEX ~ 25 mg/L, F1 ~29 mg/L, and F2 ~ 1.5 mg/L. The geology was silty sand with sand lens and a unconfined aquifer. The client’s cleanup goals were F1 0.75 mg/L and F2 0.15 mg/L. Two injections of PersulfOx using Direct Push Technology (DPT) were applied, targeting the sand lens and providing enough mass to allow for diffusion of PersulfOx into the silty sand to counter back diffusion.

Technology Description

PersulfOX and PersulfOX SP promote the rapid and sustained in situ oxidation of a wide-range of organic contaminants. As an advanced in situ chemical oxidation (ISCO) reagent, it destroys organic contaminants found in groundwater and soil through abiotic chemical oxidation reactions.

This turn-key, all-in-one product with a built-in catalyst activates the sodium persulfate component and generates contaminant-destroying free radicals without the costly and potentially hazardous addition of a separate activator. The patented catalyst enhances the oxidative destruction of both petroleum hydrocarbons and chlorinated contaminants in the subsurface.

With the purchase and proper use of PersulfOx Catalyzed Persulfate, clients gain the benefits of the latest advancements in persulfate technology for environmental remediation. PersulfOx SP was formulated for use on projects specifying the use of persulfate and a separate chemical activation process such as alkaline activation, hydrogen peroxide activation, or iron activation. It can also be used as a follow-on treatment to REGENESIS’ PersulfOx Catalyzed Persulfate technology.

Results

Following the two injections of PersulfOx using direct push technology, cleanup criteria was reached quickly, resulting in two-plus years of sublevel monitoring.

About InSitu Remediation Services

One of Canada’s most experienced remediation companies, InSitu Remediation Services Ltd. (IRSL) has designed, implemented, and maintained soil and groundwater remediation programs in diverse geological environments in North, Central, and South America, Europe and the Middle East. The company offers remediation support services and specializes in ensuring the most efficient use of technical and financial resources, managing shortened remedial time-frames, and mitigating unnecessary technical and financial risk.

Rick McGregor, B.Sc. Geology, M.Sc. Hydrogeology, M.B.A., is president of InSitu Remediation Services Ltd. A respected environmental professional with over a quarter century in environmental assessment and remediation, he has designed and implemented remediation programs across the globe.

Combined Remedies Treat BTEX Contamination on Government Property

Ontario, Canada Site Remediated with ORC® Advanced and RegenOx®

Project Highlights

- In Situ Chemical Oxidation (ISCO) and Enhanced Biodegradation used post-excavation to treat residual contamination.

- Extensive site mapping conducted with membrane interface probe (MIP) to detect distinct zones of higher mass contamination.

- 95% reductions seen in dissolved phase petroleum hydrocarbon contamination.

Project Summary

A large public works property in Ontario, Canada was contaminated with TPH. Approximately 5,000 gallons of fuel was released into the subsurface primarily due to fuel theft that had taken place on-site. Due to significant volumes of free-product, an excavation occurred followed by skimming activities from 2005-2010. Through extensive site evaluation, it was determined that there was a need for further mass reduction using ISCO.. RegenOx® ISCO was selected for use in the heavily and moderately impacted areas. Enhanced aerobic biodegradation using ORC® Advanced was selected for use in the dissolved-phase areas downgradient from the source. Overall, 96% reductions were seen in dissolved phase petroleum hydrocarbon concentrations.

Remediation Approach

Membrane interface probe (MIP) data was collected and proved to be integral for the remediation design and implementation. Distinct zones with high mass were present on-site and detected through the probe. RegenOx and ORC Advanced were applied via direct-push injections. Approximately 150,000 pounds of RegenOx and 45,000 pounds of ORC Advanced were applied over several injections. Higher concentrations of RegenOx were applied into the vertical zones of higher contamination to improve overall product performance.

Technology Description

Advanced Formula Oxygen Release Compound is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

PersulfOx® ISCO Remediation Reduces BTEX F1 & F2 Concentrations at Alberta Municipal Affairs Site

ISCO Solution Results in Cost Savings and Treatment Area Reduction at Former Service Station

Project Highlights

- In Situ Chemical Oxidation (ISCO) used as a cost-effective alternative to excavation remediation methods

- In Situ treatment using direct push resulted in reduction in treatment area

- ISCO solution met time and budget goals

Project Summary

BTEX contaminated soil was found at an Alberta Municipal Affairs (AMA) site. The former service station located in Central Alberta, Canada had left a petroleum leak creating a smear zone with F1 and F2 concentrations at the source of the plume. Since the AMA site had limited funding and time constraints, a persulfate-based ISCO solution using PersulfOx was recommended to significantly reduce high petroleum concentrations in the soil and groundwater. This site marked the first time the engineering firm working with REGENESIS had employed an ISCO solution, having used excavation remediation methods as their recommended approach in the past. An expedited remediation plan was created and included multiple rounds of PersulfOx injections to treat the site.

Remediation Approach

PersulfOx was applied in seven existing monitoring wells. Working with the engineering firm, using direct-push injection of PersulfOx, REGENESIS strategically focused the application around two of the existing monitoring wells. Due to the saturated soil type and an increased risk for surfacing, precise application-volume monitoring was required. After the first round of two applications was completed, overall contaminant concentrations decreased.

REGENESIS Solution Applied

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

The REGENESIS ISCO plan incorporating direct-push injections of PersulOx significantly reduced the level of BTEX contaminant concentrations following the first round of application. The PersulfOx solution effectively addressed the plume in the saturated smear zone, while meeting the goals of the project, as well as the client’s time and budget constraints.

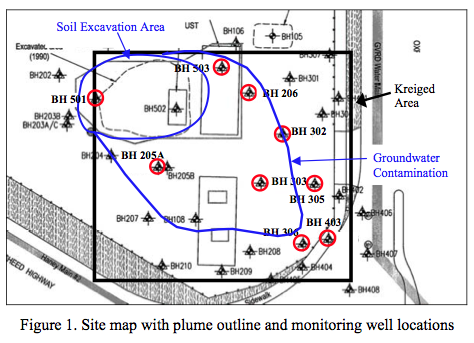

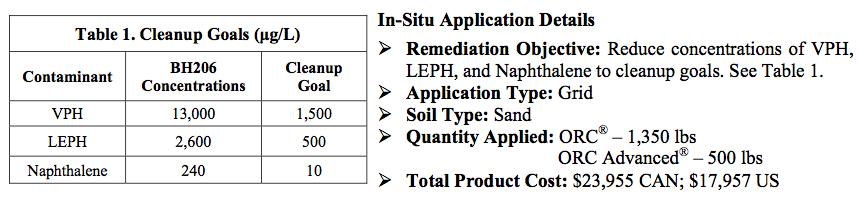

Site Closure via In Situ Aerobic Bioremediation of Petroleum Hydrocarbons

Summary

A former fueling facility in Port Coquitlam, BC contained four USTs and accompanying dispensers. The USTs were removed in 1990 after volatile petroleum hydrocarbon (VPH) concentrations were found above regulatory limits. Well BH206 had significant VPH and naphthalene concentrations reaching 13,000 μg/L and 240 μg/L, respectively. In addition, wells BH 303 and BH 205A had concentrations of VPH as high as 5,600 μg/L.

Remediation Approach

Excavation activities removed approximately 1,300 m3 of contaminated soil which were later disposed of at a permitted facility. Following the excavation, a groundwater remediation program was implemented using 1,350 lbs of Oxygen Release Compound (ORC®). An ORC slurry was added to the backfill and injected into the groundwater plume to further reduce VPH concentrations as well as light extractable petroleum hydrocarbons (LEPH). A second application using 500 lbs of ORC Advanced® was applied one year after the ORC application to continue reducing trends of petroleum hydrocarbons.

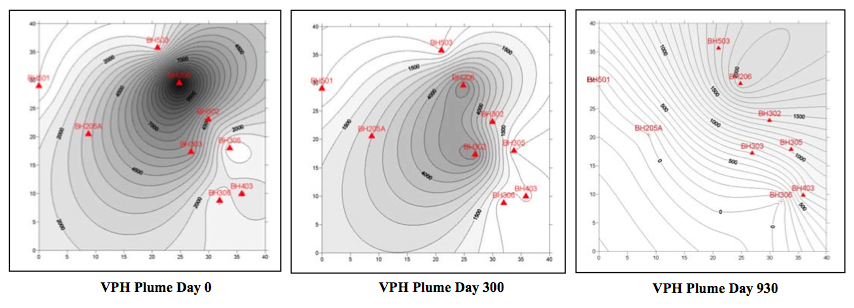

VPH Time Lapse Shots

Results

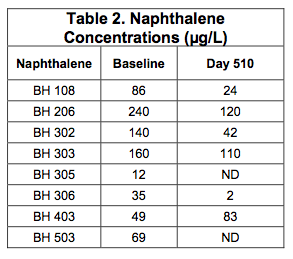

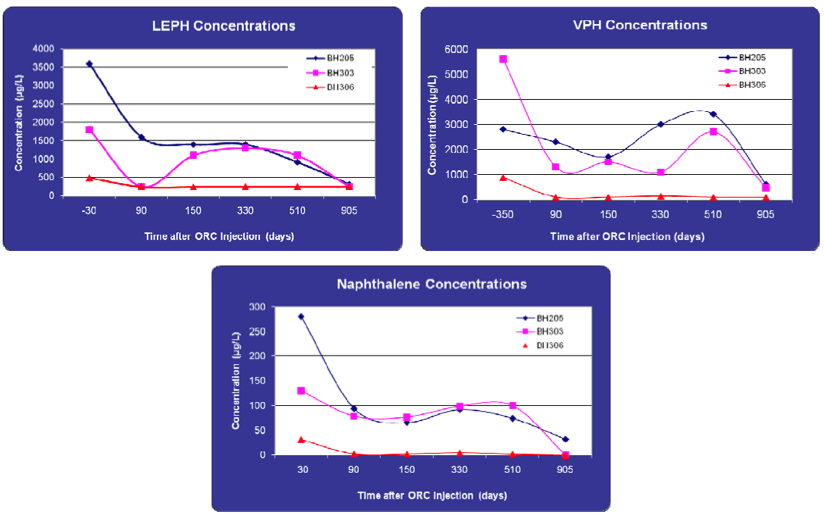

As shown in the VPH time lapse shots on the front, VPH reduction occurred across the plume. Approximately, one year after injection VPH declined from 13,000 μg/L to 4,300 μg/L in well BH206 and well BH303 showed a decrease of 80%. Downgradient of the source area VPH was reduced below cleanup goals. Prior to injection, a total of 7 wells had LEPH concentrations above the standard (500 μg/L). By day 510, four wells reached concentrations below cleanup goals. Reduction of naphthalene was also seen across the contaminated area (Table 2). Most notable are the 3 wells that reached the cleanup standard 510 days after injection.

Within 3 years of the initial application, all contaminants of concern were reduced to below the cleanup goals. Concentrations of VPH and LEPH were reduced by 1 to 2 orders of magnitude and naphthalene declined from a high of 280 μg/L to 7.9 μg/L. The site achieved closure approximately 5 years after commencing remedial treatment.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español