Bedrock Treatment Remediates NJ Manufacturing Facility

Project Highlights

- 3-D Microemulsion injections created 30-foot ROI in fractured bedrock

- TCE concentrations reduced through reductive dechlorination and daughter products reduced to ethene within 12-month study

- Pilot study results allowed for: full-scale design, maximized product ROI, minimized bedrock injection well drilling, and resulted in reduced overall project costs

Project Summary

Previous manufacturing activities impacted a fractured bedrock aquifer with TCE. The plume migrated approximately 600 feet downgradient along fractures at 70-80 feet (shallow) and 105-115 feet (intermediate) below ground surface. Remediation at the site was planned as a phased approach including a source area pilot evaluation of enhanced reductive dechlorination, bioaugmentation, and radius of influence (ROI). A larger source area treatment and property boundary barrier was to be determined based upon the pilot study results.

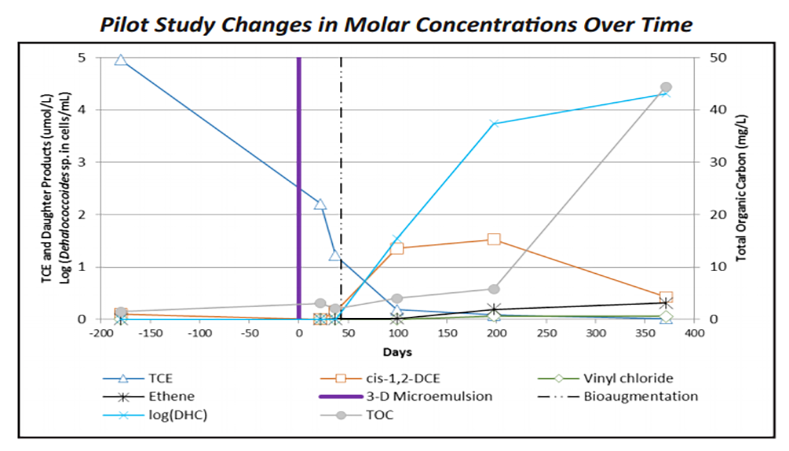

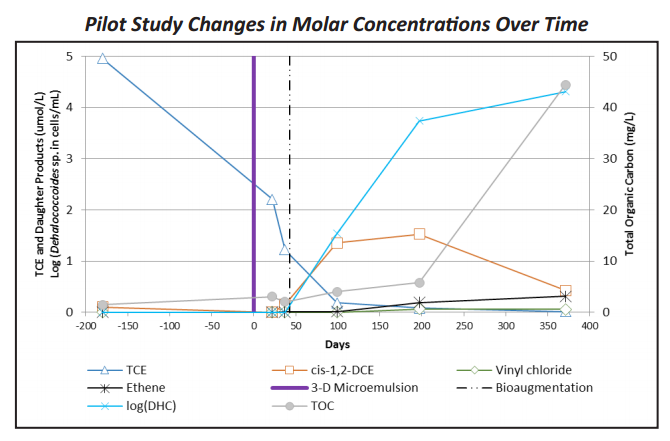

The pilot study found that injection of 3-D Microemulsion was capable of initially influencing a 30-40 feet ROI based on visual (turbidity) and geochemical data. Over a 12-month period, TOC levels remained elevated at concentrations above 10 mg/L at a shallow well 20-feet away. At the two intermediate wells 40-feet away, TOC concentrations increased to >40 mg/L during this period. During this same pilot study period, TCE concentrations decreased, cis-1,2-DCE concentrations increased then attenuated, and VC and ethane concentrations increased. Bioaugmentation, occurring 6 weeks after the 3-D Microemulsion injection resulted in Dehalococcoides sp. populations that increased and sustained at elevated concentrations (104 cells/mL).

Remediation Approach

Injections of 3-D Microemulsion were introduced by packer into 2 injection wells across four 10-foot fracture intervals (60-115 feet bgs). Monitoring was conducted in two shallow bedrock wells at 70-80 feet bgs and two intermediate bedrock wells at 105-115 feet bgs. ROI monitoring was conducted at these four monitoring wells that were located 20 feet, 40 feet, and 55 feet away from the injection wells. Bioaugmentation was performed 6 weeks after 3-D Microemulsion injections. Full-scale treatment is planned, which will include a larger treatment in the source area and a downgradient barrier at the property boundary.

Technology Description

3-D Microemulsion is an engineered electron donor technology that offers a novel 3-stage electron donor release profile pHneutral chemistry, and unique subsurface distribution properties.

Combined Remedies Approach (Dual Phase Extraction, ISCO and ERD) Lead to Rapid Results on a Guaranteed Cost to Closure Project in Indiana

3- D Microemulsion, BDI Plus and RegenOx Reduce cVOC Concentrations

Project Highlights

- Guaranteed cost to closure project.

- ISCO coupled with dual-phase extraction was successful in reducing cVOC concentrations within the core source area.

- Plume-wide ERD injection resulted in meeting remedial goals within 18-20 months.

- Combined remedy approach (ISCO & ERD) accelerated the time to closure allowing project to be completed within budget

Project Summary

A plating plant in Batesville, Indiana was contaminated with chlorinated VOCs. A subsequent investigation identified a plume of TCE extending from the building approximately 250 feet down gradient (off-site and onto private property across a street).

Remediation Approach

The initial remedial approach involved installation and operation of a dual-phase extraction (DPE) system throughout most of the plume area (26 extraction wells), which operated for approximately 1 ½ years. Approximately one year after the DPE system installation, a core area in situ chemical oxidation (ISCO) injection of RegenOx® was performed by KERAMIDA and Regenesis Remediation Services (RRS). ISCO combined with further operation of the DPE system was effective in additional reductions of cVOC concentrations in the groundwater. Upon conclusion of these efforts, the DPE system was shut down to allow for enhanced reductive dechlorination process to take place.

A successful enhanced reductive dechlorination (ERD) pilot test with 3-D Microemulsion® and BDI® Plus was performed around two off-site wells at the leading edge of the plume. Based on the success of this test, an ERD injection was performed in a newly-identified source area with outstanding results in the first six months. Consequently, the DPE system remained shut down and a full-scale ERD injection was performed in the core area of the plume.

Approximately 9 months after the full scale injections, a very small supplemental injection was performed in the off-site area where the pilot study was done and another in an area where no injection was performed. One year after the full-scale ERD injection, cVOC concentrations are below the target cleanup levels in all wells with the exception of two slightly elevated VC concentrations, which are expected to decrease shortly.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

About the Consultant

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

Regenesis Remediation Services™ – TCE Plume Treated with 3-D Microemulsion®

Combined Treatment Remedies Reduce Contamination Concentrations at Wisconsin Manufacturing Facility

Regenesis Remediation Services (RRS) was contracted to design and implement an in situ enhanced reductive dechlorination (ERD) remediation plan for this manufacturing site, impacted by trichloroethylene (TCE). The treatment included the use of 3-D Microemulsion® and Chemical Reducing Solution (CRS®) as controlled-release electron donors, and BDI® Plus to bioaugment the subsurface. The two treatment areas at this former manufacturing facility covered an area of 35,000 square feet (ft2). A total of 19,200 pounds of 3-D Microemulsion, 2,400 lbs. of CRS, and 48 liters of BDI Plus with over 1011 Dehalococcoides (DHC) cells per liter were injected over a period of less than two weeks on site.

Thirty-nine direct-push injection points were advanced between both of the treatment areas. RRS utilized retractable screen tip injection tooling to apply the pH neutral 3-D Microemulsion with CRS and BDI Plus at discrete intervals in the vertical treatment intervals of 5 to 20 feet below ground surface (bgs) and 15 to 30 feet bgs. The RRS trailer and equipment configuration allowed for low pressure application of the remediation chemistry at up to three injection points simultaneously. Remediation chemistry was applied up to 100 feet from the trailer in subfreezing temperatures while RRS personnel monitored flow rates and injection pressures at each application point to optimize distribution and influence of the remediation chemistry.

Regenesis Remediation Services™ – PCE Plume Treated with 3-D Microemulsion®

Enhanced Reductive Dechlorination & Bioaugmentation Used to Remediate Chlorinated Solvents at a Brownfield Site

A real estate developer and their environmental consultant selected RRS to design and implement an in situ enhanced reductive dechlorination (ERD) remediation plan for this Brownfield site originally developed in the 1890s, called Belknap Crossings. The site was impacted by two groundwater plumes averaging 300 ug/L trichloroethylene (TCE). The remediation design included the use of 3-D Microemulsion® as a controlled-release electron donor and bioaugmentation using BDI® Plus. The two TCE plumes at this

former manufacturing facility covered an area of 58,000 square feet (ft2). A total of 26,000 pounds of 3-D Microemulsion and 22 liters of BDI Plus with over 1011 Dehalococcoides (DHC) cells per liter were injected over a period of less than two weeks on site.

Taking advantage of 3-D Microemulsion’s unique subsurface distribution characteristics, direct-push injection points were advanced every 480 ft2. RRS utilized retractable screen-tip injection tooling to apply the pH neutral 3-D Microemulsion with BDI Plus at discrete intervals across the vertical treatment interval from 24 feet below ground surface (bgs) to 34 feet bgs in a bottom-up approach. The RRS trailer and equipment configuration allowed for low pressure application of the remediation chemistry at up to three injection points simultaneously, up to 200 feet from the trailer while monitoring flow rates and injection pressures at each application point.

Regenesis Remediation Services™ – PCE Plume Treated with 3-D Microemulsion®

Combined Treatment Remedies Used to Reductively Dechlorinate Contamination at Former Dry Cleaners Site

Regenesis Remediation Services (RRS) was contracted to design and implement the treatment of groundwater contaminated by residual chlorinated volatile organic compounds (cVOCs) at this former dry cleaner site. The design included the use of 3-D Microemulsion® as a controlledrelease electron donor and bioaugmentation using BDI® Plus. The treatment area covered approximately 600 square feet (ft2), and a total of 800 pounds of 3-D Microemulsion and 18 liters of BDI Plus with over 1011 (Dehalococcoides) DHC cells per liter were injected throughout the treatment area in one day of work.

Taking advantage of 3-D Microemulsion’s unique ability to distribute in the subsurface via micellar movement, twelve direct-push injection points were advanced every 50 ft2. RRS utilized retractable screen-tip injection tooling to apply the pH neutral 3-D Microemulsion with BDI Plus at discrete intervals across the injection vertical treatment interval from 6 to 13 feet below ground surface (bgs). The RRS trailer and equipment configuration allowed for low pressure application of the remediation chemistry while monitoring flow rates, reagent distribution, and injection pressures at each application point.

Regenesis Remediation Services™ – TCE Plume Treated with 3-D Microemulsion®

Enhanced Reductive Dechlorination & Bioaugmentation Used to Remediate Chlorinated Solvents at a Brownfield Site

A real estate developer and their environmental consultant selected RRS to design and implement an in situ enhanced reductive dechlorination (ERD) remediation plan for this Brownfield site originally developed in the 1890s, called Belknap Crossings. The site was impacted by two groundwater plumes averaging 300 ug/L trichloroethylene (TCE). The remediation design included the use of 3-D Microemulsion® as a controlled-release electron donor and

bioaugmentation using BDI® Plus. The two TCE plumes at this former manufacturing facility covered an area of 58,000 square feet (ft2). A total of 26,000 pounds of 3-D Microemulsion and 22 liters of BDI Plus with over 1011 Dehalococcoides (DHC) cells per liter were injected over a period of less than two weeks on site.

Taking advantage of 3-D Microemulsion’s unique subsurface distribution characteristics, direct-push injection points were advanced every 480 ft2. RRS utilized retractable screen-tip injection tooling to apply the pH neutral 3-D Microemulsion with BDI Plus at discrete intervals across the vertical treatment interval from 24 feet below ground surface (bgs) to 34 feet bgs in a bottom-up approach. The RRS trailer and equipment configuration allowed for low pressure application of the remediation chemistry at up to three injection points simultaneously, up to 200 feet from the trailer while monitoring flow rates and injection pressures at each application point.

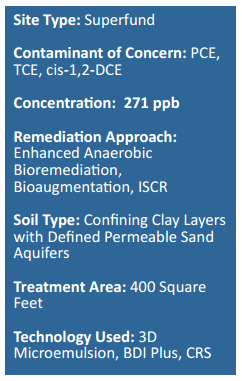

Combined Remedies Treat Chlorinated Solvents at Gulf Coast Superfund Site

Former Industrial Facility and Landfill Pilot Test Shows Rapid Reduction in PCE, TCE and 1,2 DCE

Project Highlights

- Superfund Site once housed an industrial facility and landfill.

- Rapid reduction needed to avoid off-site migration of daughter products.

- Simultaneous application of Enhanced Aerobic Biodegradation, Bioaugmentation and In Situ Chemical Reduction (ISCR).

Project Summary

This former industrial property had a landfill that was used in the mid-1900s for disposal of magnesium dross and refractory brick as well as breakout material from electrolytic chlorine cells. As much as 254,000 cubic feet of material were removed from the landfill although a large chlorinated solvent plume remains both from landfill waste below the water table and from industrial operations on-site. A feasibility study for the site was approved in 2012 which evaluated the use of enhanced reductive dechlorination to treat dissolved chlorinated solvents at the site and to prevent off-site migration past the property boundary and beneath a highway. A pilot test to evaluate at least two different biological amendments was conducted and Regenesis supplied 3D Microemulsion, BDI, and CRS for the evaluation. Three aquifers exist at the site, but the pilot test was performed in the first groundwater bearing unit only.

Remediation Approach

After a review of sulfate concentrations, other natural attenuation data, and cVOC concentrations it was determined that the optimal treatment choice would be to test a combination of an electron donor in the form of 3-D Mircoemulsion®, a bioaugmentation culture called Bio-Dechlor INOCULUM® Plus, and the use of Chemical Reducing Solution® (CRS) to prevent any hydrogen sulfide toxicity and to promote a level of beneficial in situ chemical reduction (ISCR). For the pilot test 10 injections points were used to place 800 pounds of 3-D Microemulsion, 18 liters of BDI Plus and 400 pounds of CRS. The product was injected over a 10-foot interval.

The goal for this project was to attain as rapid reduction as possible for the site specifically to avoid off-site migration of daughter products such as vinyl chloride. Therefore, it was deemed beneficial to inject all three proposed products at once. The product was injected in March 2014 and results at roughly 1 month post injection are extremely promising. PCE has been reduced from 134 ppb to 1.57 ppb, TCE from 271 ppb to 1.77 ppb, and cic-1,2-DCE from 235 ppb to 4.25 ppb. Vinyl Chloride has shown some increase from non-detect to 13 ppb.

However, Dehalococcoides has increased from non-detect to 7 x 10×5 cells/bead and vinyl chloride reduced from nondetect to 9 x 10×4 cells per bead which strongly correlates to the rapid enhanced reductive dechlorination.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory emulsified product.

BDI Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

CRS (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

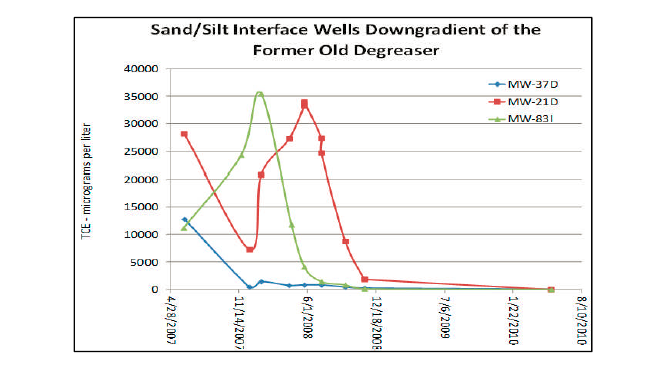

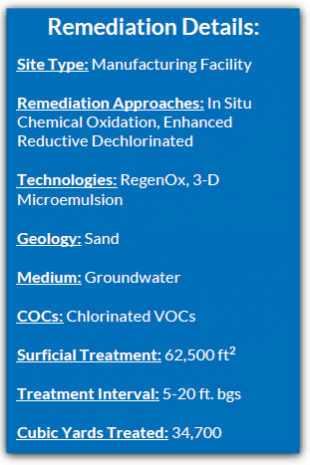

Regenesis Remediation Services™ – TCE Plume Treated with Combined Remedies

Wisconsin Manufacturing Facility Remediated with RegenOx®, 3-D Microemulsion ®

A stainless steel tube manufacturing facility and their environmental consultant, Symbiont, selected Regenesis as a team member to assist in the design and implementation an in situ chemical oxidation and ERD remediation plan. The goal was to reduce trichloroethene (TCE) in source area groundwater over a 1.5 acre site from as high as 110,000ug/L to less than 10,000 ug/L using RegenOx, then transition to ERD. RegenOx® was applied through injection wells over three to five applications from 11/2007 to 6/2008. Five month later, ERD was started using 3-D Microemulsion® in this sandy surficial aquifer.

Combined Remedies Treat Chlorinated Solvents at Gulf Coast Superfund Site

Former Industrial Facility and Landfill Pilot Test Shows Rapid Reduction in PCE, TCE and 1,2 DCE

Project Highlights

- Superfund Site once housed an industrial facility and landfill.

- Rapid reduction needed to avoid off-site migration of daughter products.

- Simultaneous application of Enhanced Aerobic Biodegradation, Bioaugmentation and In Situ Chemical Reduction (ISCR).

Project Summary

This former industrial property had a landfill that was used in the mid-1900s for disposal of magnesium dross and refractory brick as well as breakout material from electrolytic chlorine cells. As much as 254,000 cubic feet of material were removed from the landfill although a large chlorinated solvent plume remains both from landfill waste below the water table and from industrial operations on-site. A feasibility study for the site was approved in 2012 which evaluated the use of enhanced reductive dechlorination to treat dissolved chlorinated solvents at the site and to prevent off-site migration past the property boundary and beneath a highway. A pilot test to evaluate at least two different biological amendments was conducted and Regenesis supplied 3D Microemulsion, BDI, and CRS for the evaluation. Three aquifers exist at the site, but the pilot test was performed in the first groundwater bearing unit only.

Remediation Approach

After a review of sulfate concentrations, other natural attenuation data, and cVOC concentrations it was determined that the optimal treatment choice would be to test a combination of an electron donor in the form of 3-D Mircoemulsion®, a bioaugmentation culture called Bio-Dechlor INOCULUM® Plus, and the use of Chemical Reducing Solution® (CRS) to prevent any hydrogen sulfide toxicity and to promote a level of beneficial in situ chemical reduction (ISCR). For the pilot test 10 injections points were used to place 800 pounds of 3-D Microemulsion, 18 liters of BDI Plus and 400 pounds of CRS. The product was injected over a 10-foot interval.

The goal for this project was to attain as rapid reduction as possible for the site specifically to avoid off-site migration of daughter products such as vinyl chloride. Therefore, it was deemed beneficial to inject all three proposed products at once. The product was injected in March 2014 and results at roughly 1 month post injection are extremely promising. PCE has been reduced from 134 ppb to 1.57 ppb, TCE from 271 ppb to 1.77 ppb, and cic-1,2-DCE from 235 ppb to 4.25 ppb. Vinyl Chloride has shown some increase from non-detect to 13 ppb.

However, Dehalococcoides has increased from non-detect to 7 x 10×5 cells/bead and vinyl chloride reduced from non-detect to 9 x 10×4 cells per bead which strongly correlates to the rapid enhanced reductive dechlorination.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory emulsified product.

BDI Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

CRS (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

Chlorinated Solvent Concentrations Reduced >100x within Six Months

Enhanced Reductive Dechlorination Used to Treat Former Dry Cleaner in South Carolina Coastal Plain

Project Highlights

- Small groundwater recovery system in place to provide hydraulic control.

- Enhanced Reductive Dechlorination (ERD) treatment selected to achieve site closure more quickly.

- High PCE concentrations reduced by more than 100x within 6 months and remain

- Follow-up treatments enhanced initial injection and contributed to continued dechlorination.

Project Summary

The site, located in the Coastal Plain of South Carolina, was impacted from former dry cleaning operations. A small groundwater recovery system had historically been used to provide hydraulic control, but the site owner wanted to move the site toward closure more quickly. Enhanced Reductive Dechlorination (ERD) with 3-D Microemulsion® was selected based on cost, ease-of-use and expected remediation performance. After the initial injection, PCE concentrations decreased by more than 100x within 6 months of application and remain below 5 ug/L two years after the initial injection.

Remediation Approach

The core of the plume was characterized by concentrations of 14-18 mg/L PCE at baseline plus the full suite of chlorinated ethene daughter products. An initial application of 3-D Microemulsion occurred in June 2011 over a 7,750-square-foot area in the surficial aquifer from 3-25 feet below ground surface. The injections were completed using direct-push equipment into temporary borings on 13-20 foot centers. Based on the success of the initial injection, a follow-up injection was completed in September 2013 over a much smaller footprint (2,200 square feet) to fill in treatment gaps near the upgradient edge of the initial treatment area and to supplement the 3-D Microemulsion in the core of the plume. The follow-up treatment has built on the initial treatment and is contributing to continued depletion of the chlorinated solvents.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español