Combined Remedies Treatment Results in a $650,000 Cost Savings for End User

Project Highlights

- By implementing this strategy with a clear path to closure, KERAMIDA saved their client approximately $650,000 versus the alternative containment plan. KERAMIDA’s sophisticated and aggressive remedial approach matched the technologies (ISCO, ISCR, ERD) to the technical challenges at the site.

- PCE was virtually eliminated in most other impacted wells, and continued evidence of reductive dechlorination is ongoing.

- Project currently in the monitoring phase to establish plume stability for closure.

Project Summary

A PCE spill from a 55 gallon drum in the late 1980s contaminated a manufacturing site in Indiana. Contaminated soil was excavated in the spill area and a pump and treat interceptor system was installed downgradient of the plume. The system continued to operate intermittently throughout the 1990s. A previous consultant had submitted a remediation work plan proposing the use of a permeable reactive barrier. However, the plan was rejected because the intended goal was remedial closure, not containment. KERAMIDA proposed a combined in-situ chemical oxidation (ISCO)/enhanced reductive dechlorination (ERD) approach focusing on the spill area (source) and the downgradient, on-site plume, with a small injection off-site. The remediation plan was approved and the injection was completed in November 2013. KERAMIDA’s cost to closure is likely to be achieved for less than $500,000 – saving $650,000-800,000 over the life of the project. (The rejected remediation plan from the previous consultant had an estimated cost of $1.3 million with no plan for closure.)

Remediation Approach

The combined remedies treatment included an initial application of PersulfOx® Catalyzed Persulfate in the source area with subsequent applications of 3D Microemulsion® (3DME), BioDechlor INNOCULUM® Plus (BDI-Plus) and Chemical Reducing Solution (CRS®). In addition, 3DME and BDI-Plus were applied in two downgradient areas of the plume. Groundwater monitoring performed in the eight months since injection indicates dramatic reductions in PCE concentrations. Within the source area, an initial PCE concentration of approximately 70,000 ppb was reduced to 278 ppb (with a corresponding increase in cis-1,2-DCE, which is currently being degraded). PCE was virtually eliminated in most other impacted wells and evidence of reductive dechlorination is ongoing.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

CRS is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

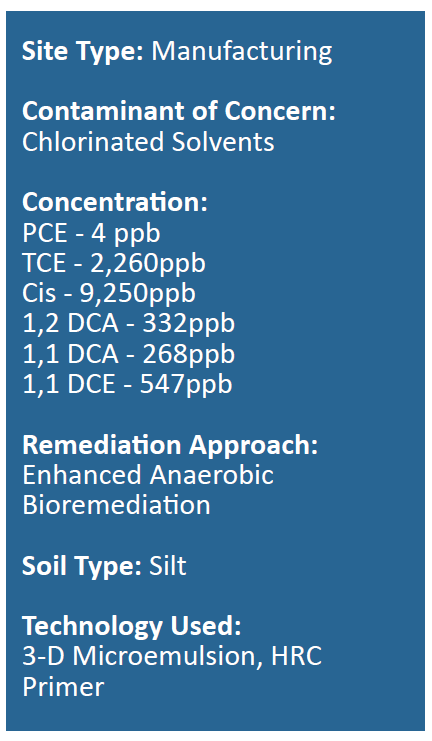

Historic California Site Treated with 3-D® Microemulsion and HRC® Primer

Project Highlights

- Site was open for over 20 years with the Central Coast Regional Board

- Immediate results showed a TCE decrease from 2,260 ppb to 12 ppb

- Site is currently under review for closure

- Cost per cubic yard was under $10 per cubic yard complete turn-key

Project Summary

This California site has been open with the Central Coast Regional Board for over 20 years with groundwater VOC concentrations thousands of times higher than the MCL. The site also had limited metal concentrations above MCL. A remediation plan was created to treat the groundwater plume using enhanced anaerobic bioremediation via Hydrogen Release Compound (HRC®) Primer and 3-D Microemulsion®. Immediate results showed a decrease in TCE concentrations from 2,260 ppb to 12 ppb.

Remediation Approach

Seven separate designs were developed to treat the 60,450-square-foot area. Several water bearing zones were treated throughout the site. Initial concerns for treatment included the possibility of a buildup of methane in the soil gas. However, because 3-D Microemulsion is a controlled-release, high-volume electron donor, no methane issues were observed. Cost for the product and application was less than $10 per cubic yard and the site is currently under review for closure.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

HRC Primer is a less viscous version of the standard Hydrogen Release Compound (HRC) product. It is a thinner, water-like compound that is typically injected into an aquifer where it releases lactic acid at a rate faster than standard HRC (several weeks), but at a slower, more controlled rate than dispersing aqueous simple sugar solutions or straight lactic acid (several days).

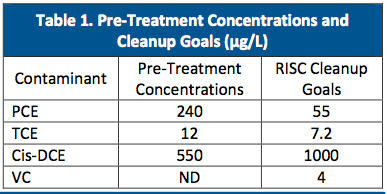

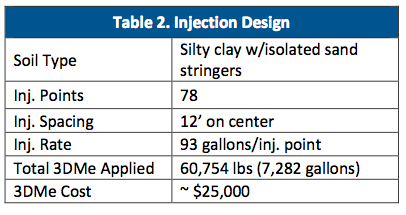

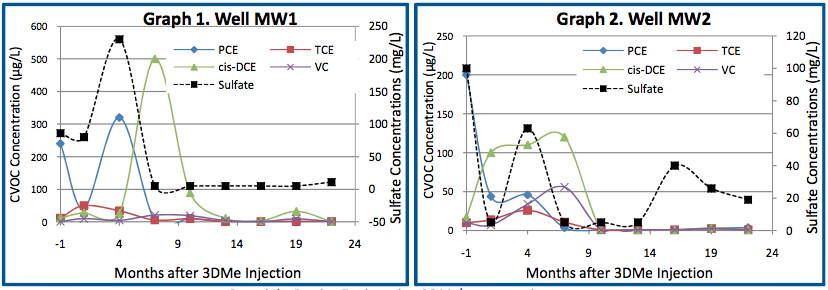

Long-Term Chlorinated Solvent Treatment using a Controlled-Release Microemulsion

PROJECT SUMMARY

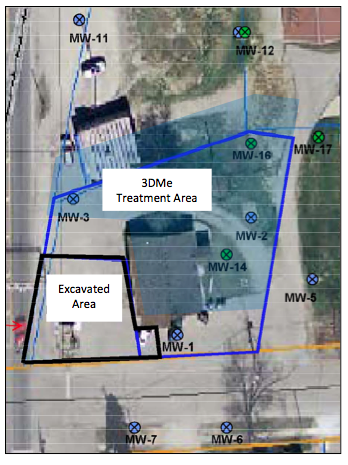

- Dry cleaning operations resulted in a chlorinated solvent plume with concentrations as high as 700 micrograms per liter (μg/L) in chlorinated solvents

- Typical Midwestern geology: Silty clay with intermittent sand stringers underlain by a clay till confining layer

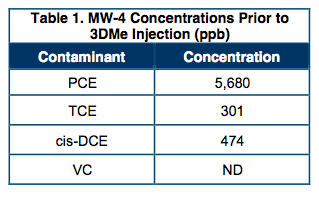

- Contaminants of concern within the silty clay aquifer included tetrachloroethene (PCE) and trichloroethene (TCE) (see Table 1)

- High sulfate environment (~100 mg/L) – potential inhibitor for successful remediation

- Cleanup goals were based on the Industrial Risk Integrated System of Closure (RISC) levels

- Enhanced anaerobic bioremediation of chlorinated solvents in groundwater using 3-D Microemulsion (3DMe)®

- $195,000 (Costs include 3DMe® material, injection, field oversight, 2 yrs post injection monitoring, project management and report writing)

RESULTS

- The 3DMe application overcame high sulfate levels and resulted in a reducing environment lasting almost 2 years

- Sampling at 22 months post-3DMe indicated sustained low levels of ORP (-136mV) and DO (1.3mg/L)

- Reduction of chlorinated solvents by 83% to 98% in all impacted wells

- Site is pending closure from regulatory agency

ELECTRON DONOR INFLUENCE

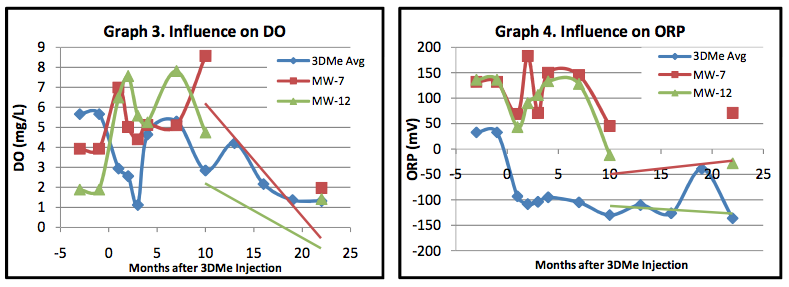

Analytical parameters including oxidation-reduction potential (ORP), dissolved oxygen (DO) and total organic acids (TOAs) were monitored to verify the influence of the electron donor post-injection. The monitoring wells likely influenced by 3DMe (MW1-3, MW5, MW14-17) were analyzed on average and compared to background wells MW7 and MW12.

Within the 3DMe influence area:

- On average, ORP reduced to -100mV and DO levels declined to ~2mg/L (Graphs 3 and 4)

- Concentrations of TOAs were detected at >1,000 mg/L during the first 10 months of

monitoring

3-D Microemulsion® Enhances Reductive Dechlorination and Reduces PCE and TCE Concentrations to Non-Detect

CASE SUMMARY

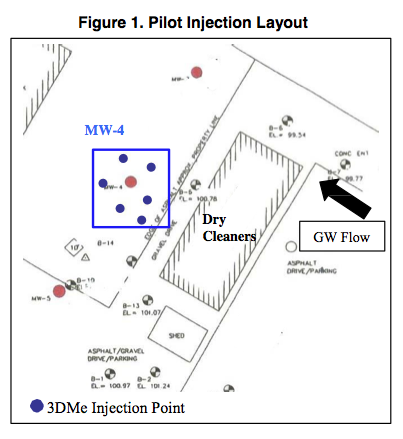

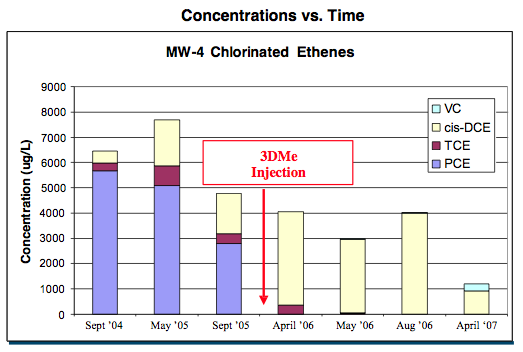

Operations at a dry cleaning facility in Illinois resulted in elevated levels of chlorinated ethenes in the subsurface. Downgradient of the contaminant source (in Well MW-4), the total chlorinated compound concentration was greater than 6,400 parts per billion (ppb), the main contaminant being tetrachloroethene (PCE). A pilot test using Hydrogen Release Compound (HRC®) was initially designed and deployed to produce conditions favorable for the reduction of contaminants. Well MW-4 was the designated sampling point to observe the contaminant reduction. The HRC pilot application was mis-applied over a 20 foot vertical interval instead of the recommended and planned 10 foot interval, resulting in under-dosing of HRC and only moderate treatment performance. A second application was performed 18 months later using the correct dosing of 3-D Microemulsion (3DMe)®.

REMEDIATION APPROACH

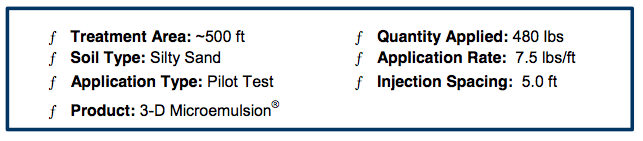

3-DMicroemulsion is a completely new molecule with staged hydrogen release capabilities and is applied as a microemulsion for enhanced distribution. The 3-D Microemulsion was directly injected at 6 locations surrounding the targeted monitoring well MW-4 (Figure 1). It was injected at a rate of 120 pounds per injection point and at 10 to 20 feet below ground surface (at the correct 10 foot interval). The injection points were spaced approximately 7 feet from one another.

RESULTS

Although HRC was applied and under-dosed in September 2004, moderate increases in the reductive dechlorination process were observed near Well MW-4. The moderate effect resulted in a 50 percent decrease in PCE concentrations. As expected some daughter products were also produced.

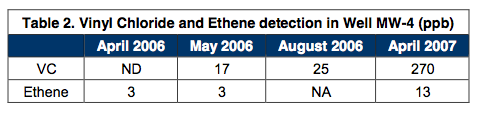

Within 30 days of the 3DMe application, PCE was reduced from 5,680 ppb to non-detect followed by a similar reduction in TCE. A reduction of 77 percent was observed in cis-DCE between August 2006 and April 2007. Slight increases in vinyl chloride (VC) and ethene indicated that complete dechlorination was occurring with no stalling effect (Table 2).

CONCLUSION

Biostimulation using 3-D Microemulsion was successful in treating the target contaminants as a result of the proper dosing/emplacement of the material and overall product performance. In MW-4, PCE and TCE were reduced to non-detect while total chlorinated compounds were reduced by more than 70 percent.

3-D Microemulsion® Bio-Barrier Rapidly Treats Cis-DCE and Vinyl Chloride Contamination and Maintains Reductive Dechlorination Over a 1,200-Day Period

CASE SUMMARY

Cis-1,2-dichloroethene (cis-DCE) and vinyl chloride (VC) were migrating off-site at this commercial facility. A pilot test of enhanced anaerobic bioremediation was performed to determine if a bio-barrier using 3-D Microemulsion, a form of HRC Advanced®, could effectively reduce the cis-DCE and VC contamination before it moved off-site. The remediation design included the subsurface injection of 3-D Microemulsion upgradient of contaminated well MW-9.

TECHNOLOGY DESCRIPTION

Reductive dechlorination is a process used to degrade certain contaminants in groundwater (e.g., cis-DCE and VC) to ethene. 3-D Microemulsion is a highly effective agent to facilitate this process. 3-D Microemulsion is composed of free lactic acid, controlled-release lactic acid (polylactate), and certain fatty acid components esterified to a carbon backbone molecule of glycerin. When injected into contaminated soil and groundwater, 3DMe produces a sequential, staged release of its electron donor components. The immediately available free lactic acid is fermented rapidly while the controlled-release lactic acid is metabolized at a more gradual rate. The fatty acids are converted to hydrogen over a mid- to long-range timeline giving 3DMe an exceptionally long electron donor release profile. This staged fermentation provides an immediate, mid-term, and very long-term controlled release supply of hydrogen (electron donor) to fuel the reductive dechlorination process.

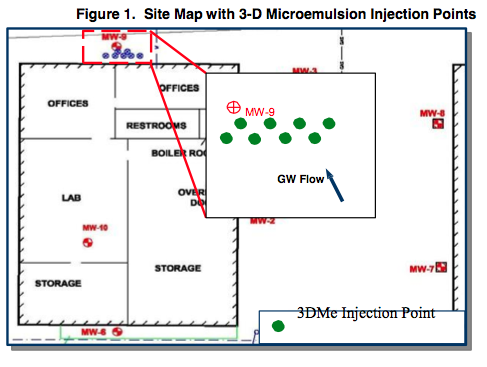

REMEDIATION APPROACH

The objective at the site was to demonstrate the ability of 3-D Microemulsion to prevent the off-site migration of cis-DCE and VC by contaminant reduction. The reduction was to be achieved by the introduction of 3DMe into the subsurface through 8 injection points spaced 5 feet apart (Figure 1).

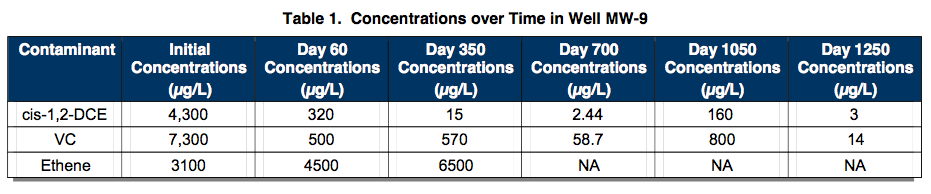

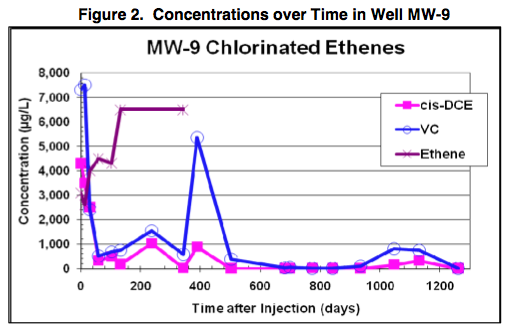

RESULTS

Within 60 days of the application of 3-D Microemulsion, concentrations of the target contaminants were significantly reduced (Table 1 and Figure 2). Over the 1,200-day monitoring period, cis-DCE was reduced by a magnitude of 3 from 4,300 to 3 micrograms per liter (μg/L). VC was reduced by 2 orders of magnitude from 7,300 to 24 μg/L, interrupted briefly by an anomalous spike likely to be laboratory error. As a result of this process, ethene concentrations increased by 102 percent, from 3,100 to 6,500 μg/L, after 130 days (a clear indication of complete dechlorination). Elevated levels of ethene were maintained for more than 300 days until ethene monitoring ended at Day 350 (Figure 2)

CONCLUSION

Overall, the results of this pilot test clearly show that when using 3-D Microemulsion, chlorinated ethene degradation via enhanced reductive dechlorination can be achieved both rapidly (60 days after injection) and successfully maintained over the long term.

Enhanced Reductive Dechlorination of Chlorinated Solvents in Groundwater Enables Development of Contaminated Site

A former dry cleaning site was scheduled for redevelopment into residential properties. Site investigations revealed that past laundry operations had resulted in chlorinated solvent contamination within the groundwater. Concentrations of tetrachloroethene (PCE) were increasing with little to no measureable daughter products being observed, indicating a lack of reductive dechlorination occurring in the subsurface. ENVIRON UK Ltd. completed a Detailed Quantitative Risk Assessment (DQRA) for the contaminants of concern on the site and liaised with the regulatory authorities in order to agree on site specific target levels (SSTL) for the remediation project. Anaerobic biostimulation using an electron donor was chosen to biologically reduce chlorinated solvent concentrations. The majority of contamination was delineated around wells BHR1, BHR2, BH3, and BH4. Within the most impacted well, BH4, the total chlorinated solvent contamination had reached approximately 4,000 micrograms per litre (μg/L).

3-D Microemulsion (3DMe®) Application

3-D Microemulsion (3DMe), supplied by Regenesis Ltd., uses a 3-stage donor release profile allowing for the immediate, mid-range and long-term release of hydrogen into the groundwater. The hydrogen is used to increase the mass and activity of indigenous microorganisms performing reductive dechlorination. 3DMe was mixed with water to form a microemulsion for injection. Approximately 1,250 kg (2,750 lbs) of 3DMe was mixed with water at a ratio of 20 parts water to 1 part 3DMe and injected using the grid design shown in Figure 1.

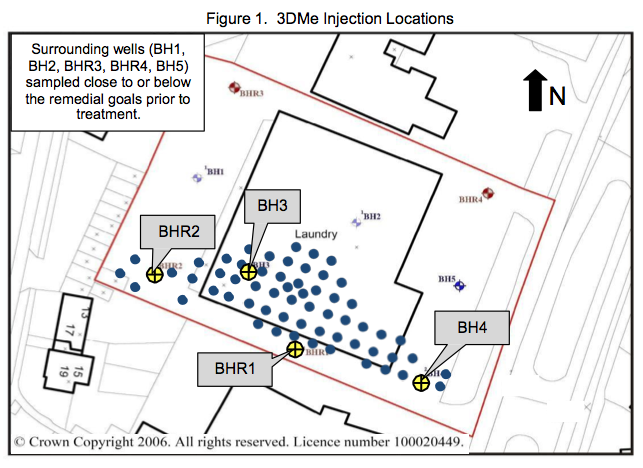

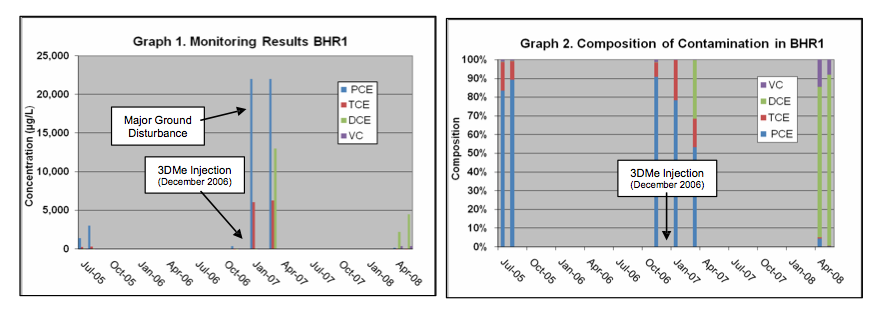

BHR1 – Southern Plume Boundary

PCE in well BHR1 (Graph 1) reached concentrations of up to 3,000 μg/L prior to treatment. Approximately one month after the 3DMe injection and following the removal of a concrete slab and excavation works, an increase in PCE and trichloroethene (TCE) concentrations was observed, peaking at 22,000μg/L and 6,300μg/L, respectively. This was attributed to an influx of chlorinated solvents caused by a physical disturbance and a rain event which mobilised contamination from the capillary fringe zone. Despite these peaks, PCE and TCE concentrations declined significantly to approximately 20 μg/L at 17 months post-injection. Concentrations of DCE increased to a peak of 13,000 μg/L as PCE and TCE were dechlorinated, followed by a decline to below 5,000 μg/L. Vinyl chloride (VC) was also detected at approximately 400 μg/L. The total chlorinated solvent mass was reduced by over 80% in 17 months.

The chlorinated solvent contamination in BHR1 comprised of 90% PCE prior to the application (Graph 2) with little evidence of significant reductive dechlorination occuring. Following the injection of 3DMe, concentrations of PCE and TCE declined to non-detect with the sequential appearance and degradation of daughter products indicating the decline in contaminant concentrations was due to enhanced reductive dechlorination.

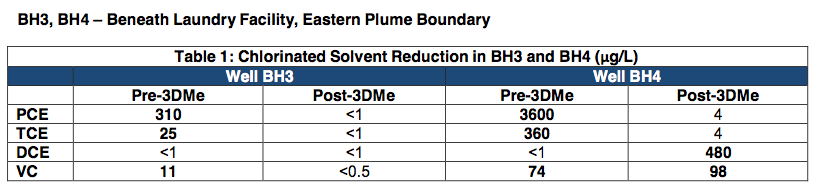

BH3, BH4 – Beneath Laundry Facility, Eastern Plume Boundary

Prior to the 3DMe application, concentrations of parent products PCE and TCE were stable indicating a low rate of dechlorination was occurring. Within three months of the 3DMe injection, concentrations of PCE and TCE were reduced to near non-detect levels while DCE and VC concentrations sequentially increased. At ten months post- injections, all contaminants of concern in well BH3 had reached non-detect levels and continued reduction was observed in well BH4. It is anticipated that the long-term release profile of 3DMe will maintain an anaerobic environment for further reduction in this area.

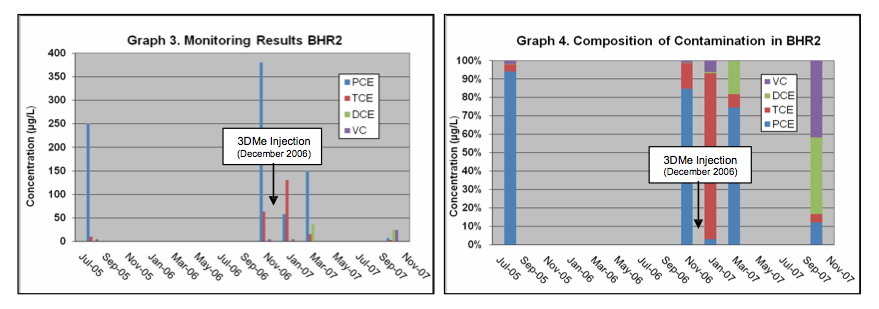

BHR2 – Western Plume Boundary

Well BHR2 (Graph 3) contained almost 400 μg/L total chlorinated solvents prior to the 3DMe injection. Within one month of the application, PCE was reduced to 4 μg/L while TCE concentrations initially rose to approximately 130 μg/L and then declined to approximately 15 μg/L. The reductive dechlorination sequence continued as DCE increased to 35 μg/L then declined. Concentrations of VC remained reduced. An analogous spike in PCE concentration was observed similar to that observed in well BHR1 following the concrete slab removal. It is notable that the spike comprised the parent product PCE whilst daughter product trends were not notably affected. This would be consistent with an influx of fresh contamination following the disturbance, while on-going degradation of the original contamination proceeded. Following this peak, concentrations of total chlorinated solvents declined to below 60 μg/L at 22 months post-injection.

Before the application of 3DMe, the chlorinated solvent contamination in BHR2 comprised of up to 95% PCE (Graph 4). Following the injection of 3DMe, the PCE concentration reduced by 98% and the TCE declined by 95% within 22 months. As seen in well BHR1, the sequential appearance and degradation of daughter products was observed indicating that enhanced reductive dechlorination was occurring.

CONCLUSION

Prior to remediation work commencing, concentrations of PCE in the groundwater were increasing presumably due to ongoing desorption from impacted soils and infiltration of the capillary fringe zone. Minor concentrations of TCE and DCE indicated a lack of reductive dechlorination was occurring and enhanced anaerobic biostimulation was needed in order to reach the SSTLs. Within one month of the 3DMe application, strong evidence of reductive dechlorination was observed as PCE and TCE declined by more than 96% to non-detect levels and breakdown products DCE and VC increased, then declined.

Chlorinated solvent concentrations throughout the plume were reduced towards the cleanup goals within ten months of the 3DMe application, representing a total contaminant mass reduction of more than 80%, despite influx of additional contamination. Further reduction is expected as 3DMe continues to enhance the reductive dechlorination process allowing for continued treatment of the remaining chlorinated solvents. Redevelopment of the site has since been completed with the appropriate regulatory authority sign off in place. The remediation was achieved through a single injection event costing less than £30,000 for 3DMe and application fieldwork combined.

Successful Treatment of Chlorinated Solvents using 3‐D Microemulsion (3DMe®) allows for Housing Redevelopment

BACKGROUND

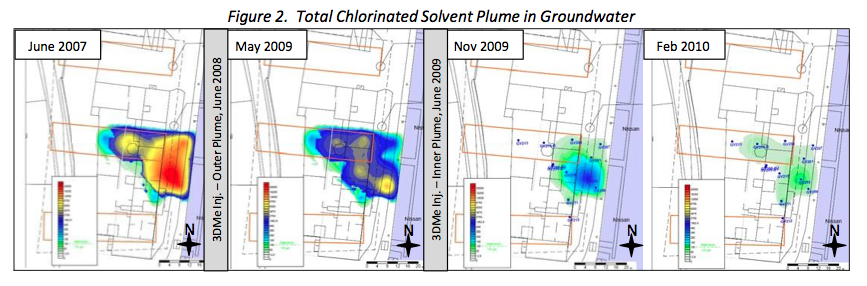

Groundwater remediation was required at a former industrial site in order to allow for the completion of a large housing development project consisting of 330 apartments along the shore of a river (Figure 1). Membrane Interface Probe (MIP)1 data was used to delineate both the vertical and lateral extent of cis‐1,2‐ dichloroethene (DCE) and vinyl chloride (VC) contamination at the site. To enhance anaerobic bioremediation and bring the site to closure, 3‐D Microemulsion (3DMe®) was used to treat DCE and VC to the cleanup goals. Chlorinated solvent treatment was successful, achieving a 98 – 99% reduction in DCE and VC concentrations within 20 months (Figure 2). The site was granted closure and redevelopment was approved by the regulatory agency.

REMEDIATION HIGHLIGHTS

- Rate of dechlorination increased from 50% to nearly 100% as a result of the 3DMe injection

- Concentrations of DCE and VC reduced to below the cleanup goals

- Significant ethene production from the breakdown of DCE and VC

- Site closure achieved

- The success of the project was both supported and validated by the use of MIP data.

GROUNDWATER REMEDIAL STRATEGY

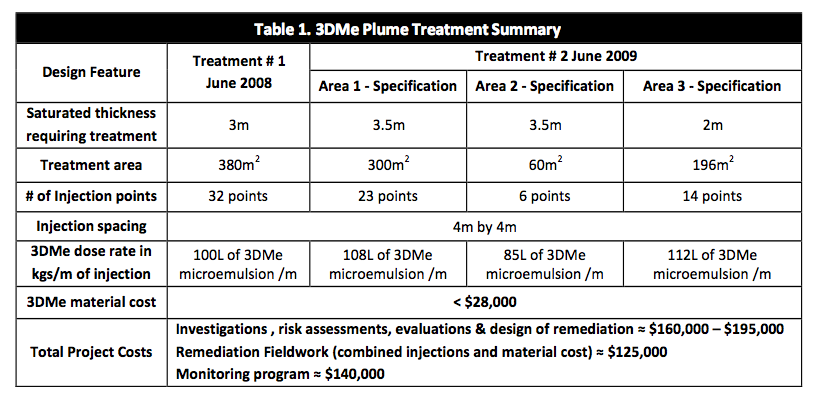

The remedial objective was to reduce concentrations of DCE and VC contamination in the groundwater to below the cleanup goal of 100μg/L. The maximum concentrations of DCE and VC were sampled at 19,000 μg/L and 12,000 μg/L, respectively. The 3DMe application was undertaken in two stages to allow for demolition works on‐site. Phase one (June 2008) included the injection of 3DMe into the eastern and western portions of the plume. Phase two (June 2009) included the injection of 3DMe in the previously inaccessible central plume area. Details of the injection are given in Table 1.

RESULTS

The degree of dechlorination was calculated to determine the progress of reductive dechlorination on‐site. Over the course of the treatment, a significant increase in full reductive dechlorination was observed as concentrations of DCE and VC were broken down to ethene. The degree of dechlorination increased from approximately 50% to nearly 100% within the treatment area.

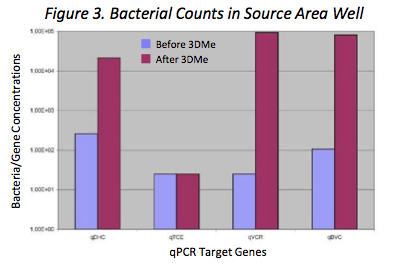

Quantification of microbial populations pre‐ and post‐3DMe application, clearly demonstrated that the microbial populations had increased (Figure 3) and were supported by the controlled supply of hydrogen from 3DMe to the treatment area. This was complimented by a corresponding increase in the degradation rate after the treatment was undertaken.

Compound Specific Isotope Analysis (CSIA) was undertaken as a final line of evidence. Transformation of organic compounds by biological processes can cause significant shifts in the ratios of 13C to 12C (δ13C) in both the reactants and products of the reaction. This occurs as a result of slower degradation kinetics associated with the heavier isotope 13C in comparison to 12C. As a result, molecules with the lighter isotopes tend to be transformed more rapidly, resulting in isotopic fractionation between 13C in the residual reactant and 12C in the initial product. For example, isotopic fractionation was reported for both DCE (‐9.1 to +5.2‰) and VC (‐22.0 to +27‰) between May 2008 and February 2010. This is evidence that the reduction in chlorinated solvent concentrations was not the result of abiotic processes such as physical dilution and dispersion, as isotope fractionation typically only occurs due to biological degradation of the chlorinated solvents.

CONCLUSION

Within two months of the 3DMe application, the rate of reductive dechlorination increased substantially. This was evidenced by:

- Sequential production and degradation of daughter compounds

- Significant increase in ethene concentrations post‐3DMe injection

- An increase in biomass and activity of microorganisms performing reductive dechlorination

- Isotopic fractionation between the parent and daughter compounds resulting from degradation

- An overall reduction in chlorinated compound concentrations in the groundwater

Contaminant levels throughout the plume were reduced to below the cleanup goals within 20 months of the 3DMe application and regulatory acceptance for redevelopment of the site was secured.

Combined Technologies Replace Pump and Treat System

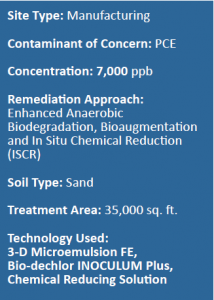

Manufacturing Facility Remediated Using Bioremediation, Bioaugmentation and ISCR

Project Highlights

- Combined technologies of bioremediation and ISCR were used to treat the PCE

- The remediation design replaced a costly legacy pump and treat system

- More than $200,000 per year saved by shuting down pump and treat system

- RRS’ injection strategy allows for the coapplication of BDI Plus, 3D-Microemulsion and CRS during the same mobilization event

Project Summary

Historic activities at an active manufacturing facility contaminated a sand aquifer with chlorinated solvents (primarily perchloroethene, PCE). Previous remediation activities included an extensive pump and treat system as well as other in situ activities. The cost of operating the pump and treat system was such that the client looked for a more cost-eff ective remediation approach. Regenesis Remediation Services (RRS) combined bioremediation/in situ chemical reduction (ISCR) approach proved to be cost-effective as a replacement technology for the pump and treat system, saving the client more than $200,000 per year. This remediation solution was installed both inside and outside of the manufacturing facility during winter in sub-zero temperatures.

Remediation Approach

Four treatment rows of a total 48 injection points were used to apply the product with a treatment area of 5-30 feet below ground surface.

The following in situ remediation technologies were used:

- 19,300 pounds of 3-D Microemulsion FE®

- 48 liters of Bio-Dechlor INOCULUM Plus®

- 2,400 pounds of Chemical Reducing Solution (CRS®)

Technology Description

3-D Microemulsion FE is an engineered electron donor material that off ers a novel 3-stage electron donor release profi le, pH neutral chemistry and is delivered on-site as a factory-emulsifi ed product. When injected into the subsurface, this stimulates bioremediation of the pollutant by the process of biologically enhanced reductive dechlorination. Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing a high density of Dehalococcoides sp. (DHC). This microbial consortium, when added to the subsurface augments the naturally occurring population of microbes that carry out the desired reductive dechlorination process. CRS (Chemical Reducing Solution) is a soluble iron substrate designed to easily distribute to an aquifer and stimulate that serves to stimulate the abiotic in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español