Regenesis Remediation Services™ – LNAPL Recovery at an Active Gas Station

Combined Treatment Remedies Reduce Contamination Concentrations at Michigan Service Station

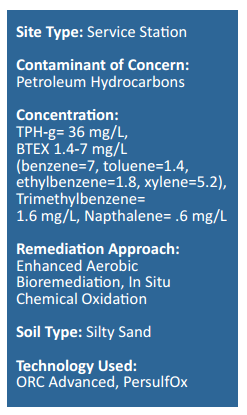

Regenesis Remediation Services (RRS) was contracted to remediate a residual LNAPL and dissolved-phase petroleum plume from historic gasoline and diesel fuel releases at an active service station. RegenOx PetroCleanze™ (PetroCleanze) was chosen as the primary remediation technology to facilitate the recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure.

The design called for three (3) application events using PetroCleanze, with Oxygen Release Compound (ORC®) Advanced applied during the final application event in a down-gradient plume cut- off barrier, to promote the enhanced aerobic biodegradation of dissolved-phase petroleum hydrocarbons. Eight (8) injection/extraction wells and 28 direct-push technology (DPT) injection points were used to apply the remediation reagents in the silty-sand aquifer and smear zone. Vacuum extraction was conducted between PetroCleanze applications to recover residual freephase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring confirmed PetroCleanze was present throughout the targeted source area during each application event.

Prior to the first PetroCleanze application event, no measurable free product was observed at this site since 2006. Less than twenty-four hours after the first PetroCleanze application event, LNAPL up to three inches thick was observed in four of the eight wells. After completing the third application and extraction event, LNAPL was not observed in any wells on site, and BTEX concentrations in groundwater were showing reductions for the first time since the fuel releases first occurred. A total of 2,160 pounds of RegenOx PetroCleanze and 1,120 lbs. of ORC Advanced were injected.

Regenesis Remediation Services™ – LNAPL Recovery & In Situ Chemical Oxidation

Combined Treatment Remedies Reduce Contamination Concentrations at a Former Service Station

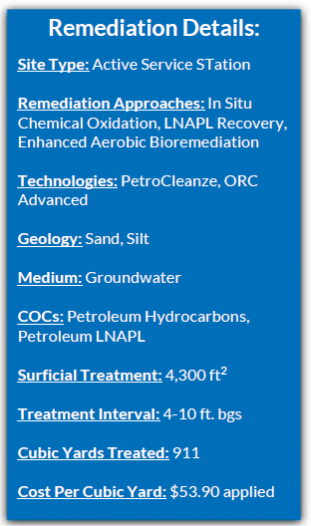

Regenesis Remediation Services (RRS) was contracted to remediate a dissolved-phase and residual LNAPL petroleum hydrocarbon plume resulting from historic petroleum fuel releases at a former service station. RegenOx® PetroCleanze™ (PetroCleanze) was chosen as the primary remediation technology in addition to Oxygen Release Compound (ORC®) Advanced, to facilitate recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure. ORC Advanced was applied during the second PetroCleanze application to promote the enhanced aerobic bioremediation of dissolved phase petroleum hydrocarbons.

Eighteen direct-push injection points were used to apply the reagents in the silty sand aquifer and saturated soil over the course of two application events. Vacuum extraction was conducted after each PetroCleanze application to recover residual free-phase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring during the application events confirmed PetroCleanze was present across the targeted source area. Remediation chemistry was applied via direct-push injection points with a bottom-up approach from 5 to 15 feet below ground surface (bgs). A total of 4,470 pounds (lbs.) of RegenOx PetroCleanze and 720 lbs. of ORC Advanced were injected throughout the course of the two applications.

Regenesis Remediation Services™ – PersulfOx® Treats Petroleum Hydrocarbons

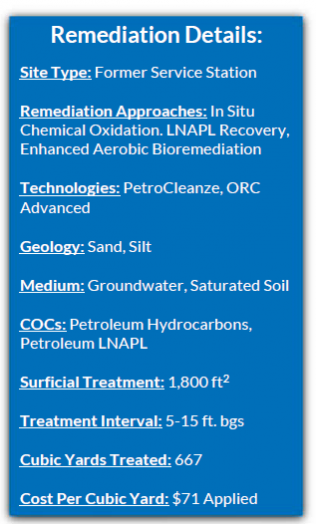

In Situ Chemical Oxidation and Enhanced Aerobic Biodegradation Remediate Underground Storage Tank Site

Regenesis Remediation Services (RRS) was contracted to design and implement an in situ chemical oxidation (ISCO) treatment plan to remediate a diesel gas plume from a former leaking underground storage tank (UST) on a residential farm property. The defined treatment area comprised approximately 5,280 square feet (ft2), and the treatment of the gas plume included three application events using

PersulfOx®, with the final application immediately followed by an application with Oxygen Release Compound Advanced (ORC® Advanced). A total of 5,840.6 pounds of PersulfOx and 2,589 pounds of ORC Advanced were injected during the course of the project.

Utilizing PersulfOx remediation chemistry to distribute throughout the subsurface, 91 direct-push injection technology (DPT) injection points were advanced every 100 ft2 over the course of three application events. ORC-A was applied in 53 discrete DPT injection points approximately every 100 ft2. RRS utilized both expendable points and retractable screen-tip injection tooling to apply the PersulfOx and ORC Advanced at discrete intervals across the vertical treatment interval from 8 to 12 feet and 8 to 16 feet below ground surface (bgs) within the sandy saturated soils. Low pressures and moderate application rates were utilized to apply the remediation chemistry at up to four (4) injection point locations simultaneously. RRS personnel performed real-time reagent distribution diagnostics to optimize the distribution of the material.

Former Service Station Treated on Native American Reservation Land

Combined Remedies Used to Remediate BTEX Contamination

Project Highlights

- Enhanced Aerobic Bioremediation and In Situ Chemical Oxidation used to treat high BTEX levels on-site

- Previous remediation activities included soil excavation but contamination persisted

- One application area located in lot used for beef cattle on reservation land and special approvals were required

- Project was state-funded by Pollution Liability Insurance Agency (PILA) of Washington but regulated by Region 10 EPA resulting in extensive coordination between both agencies

Project Summary

This Wapato, Washington site was a former gas station with historical releases dating back to at least 1995. It is located on a Native American Reservation so the site is regulated through Region 10 of the EPA.

The initial remedial activities consisted of excavation of source area soil but contamination remained. Considering the persistent contamination, the goal of the site was to reduce the remaining concentrations to meet regulatory goals.

Remediation Approach

A combied remedies strategy was devised for this site, including in situ treatment in three separate areas. Two areas were treated with both PersulfOx® and ORC® Advanced.

The third area was an empty lot that was used for ranging beef cattle. The client had concerns about how the treatment might affect the cattle, so only ORC Advanced was applied to this area because it is both insoluable and non-toxic. Because the entire site was located on reservation land it required special approvals by the tribal irrigation office before the injections could occur. A total area of 4,100-square-feet was treated for high levels of BTEX. Monitoring is ongoing.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator

In Situ Chemical Oxidation Treats High TPH Concentrations

Over 114,000 Pounds of PersulfOx® Applied to Illinois Manufacturing Facility

Project Highlights

- High levels of TPH and TCE were detected on-site after a suspected cutting oil/degreasing solvent spill.

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility.

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site.

- Tight treatment deadline met through the use of PersulfOx in 2,204-pound SuperSacks, which were delivered within a few days’ notice.

Project Summary

An Illinois metal fabrication manufacturing facility has been in operation since the early 1900s and is still active today. The use of cutting oils and degreasing solvents lead to high levels of TPH and TCE on-site. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent waterbody. A mechanical oil recovery system was installed and absorbent booms were used to mitigate the oil from reaching the river. ISCO was selected as the remediation approach to address the contamination below the active facility through a series of applications. Additionally, the TCE area was treated with PersulfOx® via injection wells and a soil mixing application.

Remediation Approach

Prior to the start of remediation activities, the primary consultant was removed from the project and a new firm was brought in. The remediation firm placed a tight deadline (a couple of months) to complete the full scope of activities. REGENESIS was able to assist with keeping the project on-deadline through the delivery of 2,204-pound PersulfOx SuperSacks, which were delivered within a few days’ notice. The consultant had a series of injection wells installed inside and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation, and Oxygen Release Compound (ORC®) Advanced Pellets will be used as a long-term oxygen source for enhanced bioremediation of the residual TPH.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

Site Closure Achieved at Colorado Service Station

Benzene Levels Reduced to Below 5 PPB in Clay Soils through Use of ORC® Advanced

Project Highlights

- Benzene concentrations remained on-site despite previous excavation efforts.

- Enhanced aerobic biodegradation using ORC Advanced produced a 99.8% reduction over 12 months.

- Benzene reduced to below detection limits.

- “No Further Action” letter granted in October 2010.

Project Summary

Three underground storage tanks (USTs) were removed at a former tire store as part of corrective measures. Roughly 108 cubic yards of soils were excavated to reduce contamination levels. However, the excavation did not extend below the groundwater interface and residual sorbed contaminant mass remained, resulting in a lingering benzene plume. The client was interested in an in situ approach to reduce the remaining benzene contamination to below the Tier 1 risk based screening level of 5 ppb.

Remediation Approach

A direct-push injection of Oxygen Release Compound Advanced (ORC® Advanced) was chosen to reduce remaining soil and groundwater contamination at the location of the former excavation and well BW-1. Maximum TVPH and benzene concentrations in the prior two years were as high as 2.4 mg/L and 0.48 mg/L, respectively. Due to tighter soils, a 7-footon-center grid pattern with 15 injection points was implemented on-site. ORC Advanced was injected from approximately 6 to 13 feet below ground surface with about 1 foot of the injection interval extending above groundwater in the event of rising water levels. A total of 725 pounds of ORC Advanced was injected for this project.

Despite the relatively tight soils and high potential for contaminant back diffusion, the ORC Advanced treatment resulted in consistent downward trends of benzene contamination. A 96.3% reduction in benzene after only 3 months was observed. By month 12, a 99.8% reduction to below detection limits (The site was granted a no further action letter.)

Technology Description

ORC Advanced® is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

REGENESIS Remediation Services – LNAPL Treated with Combined Remedies

Active Michigan Service Stated Remediated Through Use of PetroCleanze® and ORC® Advanced

RRS was contracted to remediate a residual LNAPL and dissolved phase petroleum plume from historic gasoline and diesel fuel releases at an active service station. PetroCleanze® was chosen as the primary remediation technology to facilitate recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure. ORC® Advanced was also applied with the final PetroCleanze application event and in a downgradient plume cut off barrier to promote the enhanced aerobic bioremediation of the dissolved-phase petroleum hydrocarbons.

Eight injection/extraction wells and 28 direct-push injection points were used to apply the remediation reagents in the silty sand aquifer and smear zone over three application/injection events. Vacuum extraction was conducted between PetroCleanze applications to recover residual free phase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring confirmed PetroCleanze was dispersed across the targeted source area during each application event.

Prior to the first PetroCleanze application event, no measurable free product was observed on this site since 2006. Less than twenty-four hours after the first PetroCleanze application event, LNAPL was observed in four of the eight wells in the source area at quantities up to three inches thick.

Not more than a sheen was observed in any wells on site after the third injection event. A total of 2,160 pounds of PetroCleanze and 1,120 pounds of ORC Advanced were injected.

Regenesis Remediation Services™ – LNAPL Plume Treated at Iowa Service Station

PetroCleanze and ORC Advanced Remediate Historic Petroleum Hydrocarbon Contamination

RRS was contracted to remediate a dissolved phase LNAPL petroleum hydrocarbon plume petroleum fuel releases at a former service station PetroCleanze® was chosen as the primary remediation technology to facilitate recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure. ORC Advanced was also applied with the final PetroCleanze application enhanced aerobic bioremediation of hydrocarbons.

Eighteen direct-push injection points were used to apply the reagents in the silty sand aquifer and application events. Three vacuum extraction conducted after each PetroCleanze application to recover residual free phase petroleum hydrocarbons liberated from the soils.

Reagent distribution monitoring confirmed PetroCleanze was dispersed across the targeted source area during events.

Direct-push injection points were advanced to 15 feet below ground surface where bottom-up injections were performed to 5 feet. A total of 4,470 pounds of PetroCleanze and 720 pounds were injected.

ORC Advanced® Treats Multiple Plumes and High TPH Concentrations

CASE SUMMARY

Past operations at a former U.S. Navy Base in American Samoa had resulted in total petroleum hydrocarbon (TPH) contamination within the subsurface. Currently occupied by an elementary school, the former military base once stored barrels of petroleum-based fuels for military operations. A hydrocarbon sheen was evident following rain events prompting the need for a remedial investigation to determine the extent of contamination within the subsurface. Soil boring samples revealed elevated levels of TPH-diesel, TPH-gasoline, and TPH-motor oil at concentrations exceeding the cleanup standard. Site investigations did not identify any TPH impact to groundwater.

Access to the site and equipment was very limited thus on-site sampling and remediation was conducted only annually when the school was out of session. As a result, a remedial approach was required in which no operations & maintenance would be necessary. In addition, a technology was needed which would not damage on-site structures, successfully treat low permeable soils, and not disrupt the day to day operations of the elementary school. Enhanced bioremediation using ORC Advanced® was chosen since it did not require on-site maintenance and would effectively treat TPH concentrations within a reasonable timeframe.

REMEDIATION APPROACH

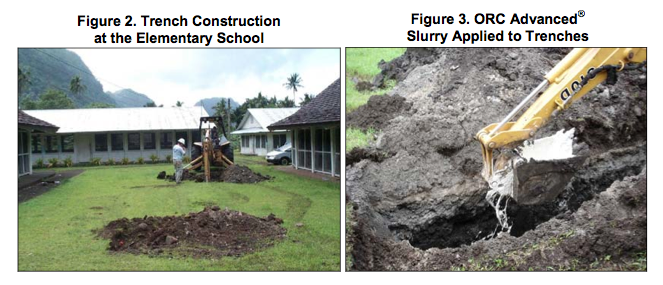

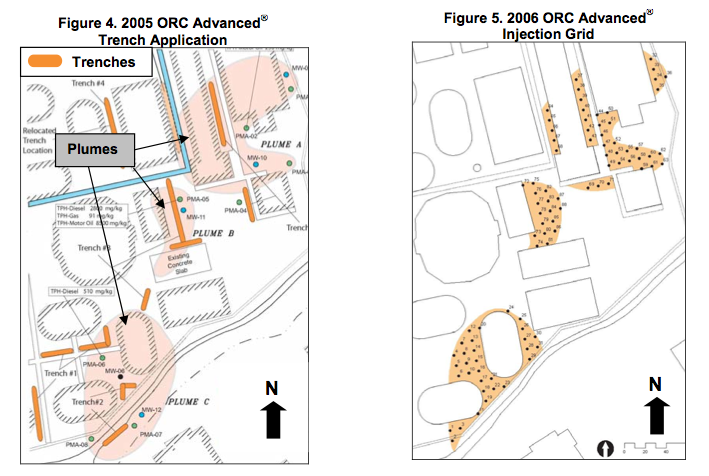

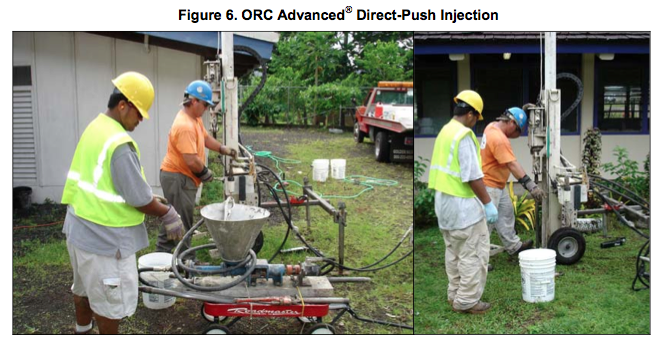

The initial application of ORC Advanced® was applied in 2005 via multiple trenches to address the three identified plumes (Figure 4). ORC Advanced® was mixed with water to form a slurry then placed at the bottom of each trench prior to backfilling (Figure 3). Soil sampling one year later indicated a reduction in TPH levels; however three boring samples remained above the cleanup goal. This was explained by the lack of water available in the subsurface to move the ORC Advanced® radially from the applied trench area. A second application in 2006 was delivered via direct-push injection using approximately 2,000 pounds of ORC Advanced® into a total of 82 injection points (Figure 5 & 6). In 2007, an ORC Advanced® injection application was completed to treat the few remaining hot spots. One last application is scheduled for summer 2008.

RESULTS

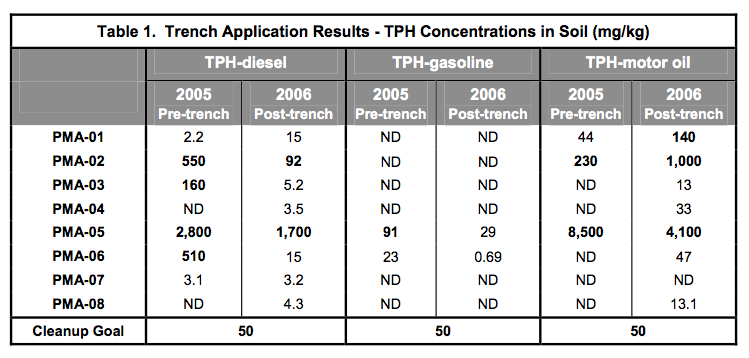

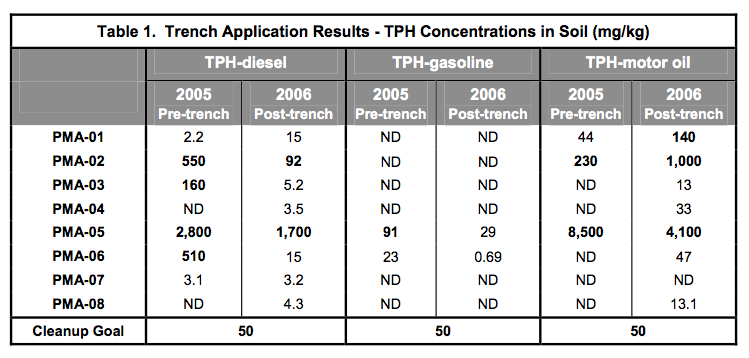

Trench Application

The 2005 trench application was successful in reducing TPH concentrations significantly (Table 1). Within the area of highest concentrations (PMA-05), TPH-diesel was reduced from 2,800 milligrams per kilogram (mg/kg) to 1,700 mg/kg, TPH-motor oil declined by 50% and TPH-gasoline was reduced to below the cleanup goal of 50 mg/kg. Of the eight sampled areas, three remained above the Project Action Level – PMA-01, PMA-02, and PMA-05. Although the trench application was successful in reducing concentrations within the immediate application area, the radius of influence was not great enough to remediate the entire plume. Therefore, a follow up application was designed using direct-push technology.

Direct-Push Application

The direct-push application substantially reduced high concentrations of TPH-diesel and TPH-motor oil (Table 2). Most significant was area PMA-05 where TPH-diesel declined from 1,700 mg/kg to below the cleanup goal and TPH-motor oil was reduced from 4,100 to 120 mg/kg, a 97% reduction. An increase in concentrations was observed as a result of the direct-push technique which mobilized residual contamination from the soil. A direct-push injection was completed in July 2007 to address the remaining concentrations of TPH-diesel and TPH-motor oil. A total of 2,500 pounds of ORC Advanced® were applied using the same design layout as the 2006 application (Figure 5). One last application is planned for summer 2008.

CONCLUSION

To date, one ORC Advanced® trench application and two direct-push injections have been completed. The trench technique was effective within the immediate vicinity of the application. However, in order to achieve a better radius of influence, the direct-push technique was more effective. Additionally, the impact and inconvenience to the site from direct-push was significantly less in comparison to the large trenched areas as shown in Figures 2 and 3.

TPH-motor oil has remained above the cleanup goal as seen in Table 2. This can be explained by the fact that the molecular size of motor oil is more significant compared to diesel and gasoline and, therefore, more time is needed to breakdown the molecule. In addition, as a result of the injection, mobilization of residual contamination from the soil caused an increase in concentrations. The July 2007 application is expected to continue the breakdown of any remaining contamination, including motor oil, towards the cleanup goal. Sampling will again be completed in the summer of 2008 along with one final ORC Advanced® application.

Site Closure via In Situ Aerobic Bioremediation of Petroleum Hydrocarbons

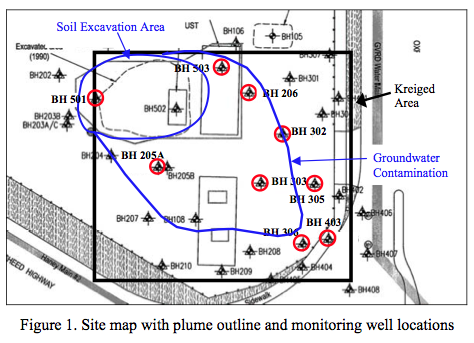

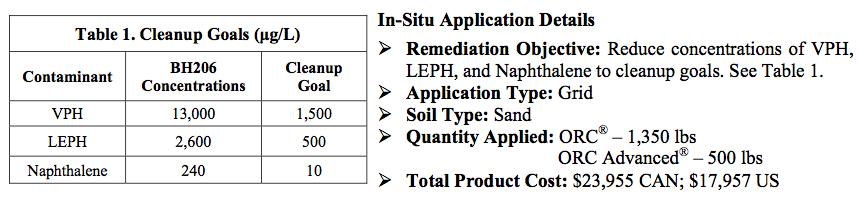

Summary

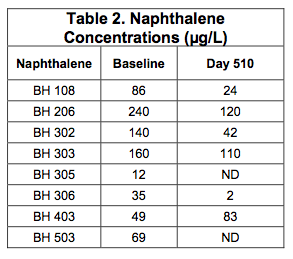

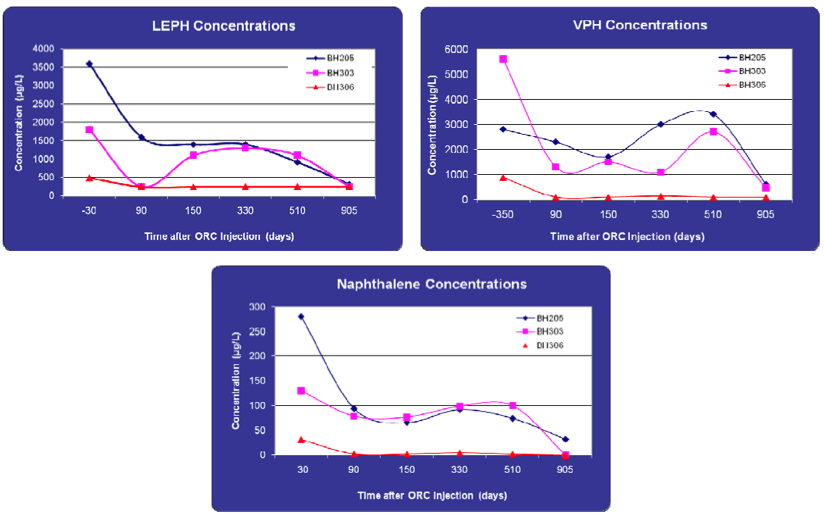

A former fueling facility in Port Coquitlam, BC contained four USTs and accompanying dispensers. The USTs were removed in 1990 after volatile petroleum hydrocarbon (VPH) concentrations were found above regulatory limits. Well BH206 had significant VPH and naphthalene concentrations reaching 13,000 μg/L and 240 μg/L, respectively. In addition, wells BH 303 and BH 205A had concentrations of VPH as high as 5,600 μg/L.

Remediation Approach

Excavation activities removed approximately 1,300 m3 of contaminated soil which were later disposed of at a permitted facility. Following the excavation, a groundwater remediation program was implemented using 1,350 lbs of Oxygen Release Compound (ORC®). An ORC slurry was added to the backfill and injected into the groundwater plume to further reduce VPH concentrations as well as light extractable petroleum hydrocarbons (LEPH). A second application using 500 lbs of ORC Advanced® was applied one year after the ORC application to continue reducing trends of petroleum hydrocarbons.

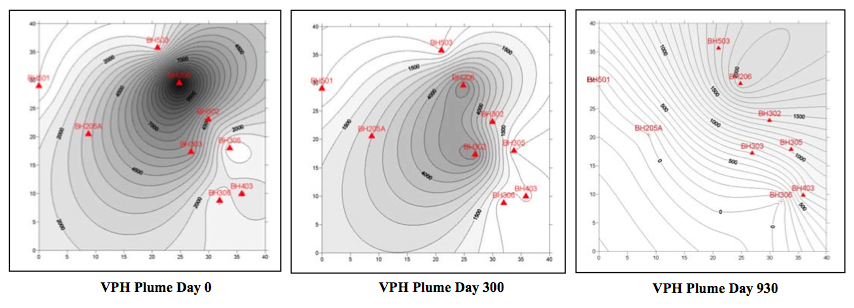

VPH Time Lapse Shots

Results

As shown in the VPH time lapse shots on the front, VPH reduction occurred across the plume. Approximately, one year after injection VPH declined from 13,000 μg/L to 4,300 μg/L in well BH206 and well BH303 showed a decrease of 80%. Downgradient of the source area VPH was reduced below cleanup goals. Prior to injection, a total of 7 wells had LEPH concentrations above the standard (500 μg/L). By day 510, four wells reached concentrations below cleanup goals. Reduction of naphthalene was also seen across the contaminated area (Table 2). Most notable are the 3 wells that reached the cleanup standard 510 days after injection.

Within 3 years of the initial application, all contaminants of concern were reduced to below the cleanup goals. Concentrations of VPH and LEPH were reduced by 1 to 2 orders of magnitude and naphthalene declined from a high of 280 μg/L to 7.9 μg/L. The site achieved closure approximately 5 years after commencing remedial treatment.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español