Challenging Fast-Moving, High Concentration Chlorinated Solvent Plume Effectively Treated

Case study highlights

A permeable reactive barrier installed using advanced colloidal technologies demonstrates pilot test’s effectiveness treating a fast-moving, high-concentration chlorinated solvent plume in groundwater:

-

Within a month of the application, the highest concentrations were reduced by 98 percent.

-

PlumeStop and S-MicroZVI co-injected barrier treats CVOCs for >3 years in high-mass-flux aquifer

-

Additional site design testing used passive flux samplers to better understand contaminant mass flux

Hamp, Mathews & Associates, Inc. (HMA), working on behalf of EGLE, collaborated with REGENESIS to develop a remedial approach to address the contaminant plume. Following data review and modeling, a sorption-ERD approach was selected for implementation in a field-scale test, using the following technologies applied in an in situ permeable reactive barrier (PRB).

In this sorption-ERD approach, PlumeStop® slows the speed of contaminants (i.e., mass flux) entering a barrier, increasing the time available for the added amendments to fully reduce these contaminants into non-toxic end products such as ethene, ethane, carbon dioxide, and chloride before they leave the PRB. In combination, these remedialtechnologies create a highly reactive zone of biogeochemical reduction that can address plumes with high contaminant mass flux.

Sustainable and Low-Cost PFAS Source Treatment

Pilot Studies incorporating SourceStop horizontal barrier treatments demonstrate reduction of leaching

This case study reviews the in situ treatment of PFAS source zones at firefighting training areas on two aviation sites where PFAS-containing AFFF was historically discharged. Pilot tests at both sites demonstrated PFAS soil leachate concentrations has been reduced by >99% following the source zone treatments.

The PFAS source treatments applied site-specific amendment blends of SourceStop, a new concentrated form of colloidal activated carbon, in conjunction with powdered activated carbon. SourceStop is a micron scale aqueous carbon suspension emplaced as a horizontal PFAS barrier at the base of the target treatment zones to improve remediation effectiveness dramatically. In controlled laboratory studies, SourceStop has been proven to prevent PFAS leaching with >10x more effectiveness than powdered activated carbon alone.

Case study highlights:

- In situ PFAS source treatments using SourceStop® immediately halt PFAS plume development and prevent impacts to downgradient receptors

- SourceStop approach is a sustainable remediation alternative compared to other mechanical and physical PFAS treatment methods

- Enhanced attenuation removes unacceptable PFAS exposure risk at a low cost

6m 33s reading time

PFAS Eliminated for 3.5 Years and Counting

This case study reviews a pilot test to remove PFAS risk via an in situ colloidal activated carbon barrier at Camp Grayling in Crawford County, Michigan, a large year-round military training center operated by the Michigan Army National Guard (MIARNG).

Colloidal activated carbon was selected because of the expected rapid reductions of PFAS by removal from the dissolved mobile phase, as well as its expected lower total project costs when compared to operating a mechanical system over a similar time. The MIARNG decided to conduct a PlumeStop pilot test to determine if this treatment would meet their site goals prior to a possible full-scale application. The goals for this pilot project were to utilize an approach that could both protect the Grayling community from exposure and cost-effectively expand to a full-scale application.

This case study features the following:

- Results 3.5 years post-application show PFAS and PCE reduced to non-detect

- New, innovative approach using an in situ colloidal activated carbon barrier to eliminate PFAS exposure pathway and protect the community

- Collaborative effort amongst various State of Michigan and military departments

- Economical and effective pilot study design

8m 59s reading time

Advanced Remedial Technologies Restore Neighborhood

Former Michigan Industrial Site Treated Using Combined Remedy Approach

This case study reviews a former plating facility in southwest Michigan that had released chlorinated volatile organic compounds (cVOCs) into shallow groundwater, resulting in a ¼-mile long contaminant plume. In response, the Michigan Department of Environmental Quality (MDEQ) and the environmental firm, DLZ, implemented a combined remedy which included mitigating vapor intrusion in the residential basements and treating the groundwater plume with a novel, multi-phase in situ bioremediation approach.

- Application of combined REGENESIS technologies to biodegrade contaminants, prevent further plume migration, and protect occupants from the threat of vapor intrusion.

- Reduction of the total cVOC plume extent by 95% and reduced mass by 99.8%.

- Positive results indicating the degradation process is ongoing and processing.

8m 54s reading time

Manufacturing Site Gets Closure using In Situ Desorption with Vacuum Enhanced Recovery for Petroleum Hydrocarbons

Project Highlights

- VOC levels show a 99% decrease in soil and 66% decrease in groundwater contamination

- Unique desorption reagent and enhanced recovery process approved for use by Michigan DEQ

- Site closure granted for two petroleum releases within same general area

Project Summary

Two separate UST petroleum releases were identified within the same general area of the manufacturing site with one being more recent and the other an older historic release. Following soil hydro-excavation activities which were limited by a building footprint, residual VOC contamination was identified at concentrations of 770,820 μg/kg in soil and 12,387 μg/L in groundwater. In Situ remediation using PetroCleanze® , an enhanced desorption/ extraction technology was planned for use to treat the remaining high levels of VOCs. Petro- Cleanze is optimized to desorb bound hydrocarbon mass and drive it from the soil matrix into the aqueous phase. Once pollutants are moved into the dissolved phase, its ability to chemically oxidize portions of the contamination coupled with enhanced recovery (physical extraction) effectively reduces contaminant concentrations.

Remediation Approach

A total of four initial PetroCleanze injection/extraction events took place in two treatment areas close to where the UST was once located. Each injection used a total of 1,320 lbs. of PetroCleanze and 925 lbs. of RegenOx Part A; the material was applied as a 5% solution (2000 gallons) through eight direct-push injection points. The vertical treatment interval ranged between 5 feet to 15 feet below ground surface. Following each injection, a vacuum enhanced recovery event was performed approximately two weeks later. The two week period was critical as it allowed PetroCleanze time to react and free up the bound hydrocarbon mass. Approximately 2,000 gallons of petroleum impacted water was removed during each extraction event and disposed of at a licensed disposal facility. Correlating soil samples in key treatment areas indicated that concentrations were reduced up to 99% with the exception of one area which required an additional injection event. Based on the site conditions, subsurface obstructions limited the influence of the PetroCleanze to this area. Therefore, a fifth injection event was conducted immediately surrounding the residual area in which the soil contamination remained to directly address the soil contamination. Correlating soil samples following the additional injection event indicated the concentrations were reduced up to 90%. Six months after treatment, groundwater VOC levels in EW-2 were reduced from 12,000 μg/L to 4000 μg/L marking a 66% reduction in the treatment zone. Within the same well, following each injection/extraction event, TPH data reported concentrations consistently decreasing from 20,000 μg/L to 10,000 μg/L to 5,900 μg/L. In 2014, as a result of the significant reductions in both soil and groundwater contamination, Michigan DEQ approved restricted UST closure for the two petroleum releases with no further action required.

Technology Description

PetroCleanze is a customized formulation of the widely used RegenOx in situ chemical oxidation technology. The primary function of PetroCleanze is to increase the desorption rates of hydrocarbons bound in saturated soil and make them available for more efficient and rapid treatment using a range of enhanced recovery technologies.

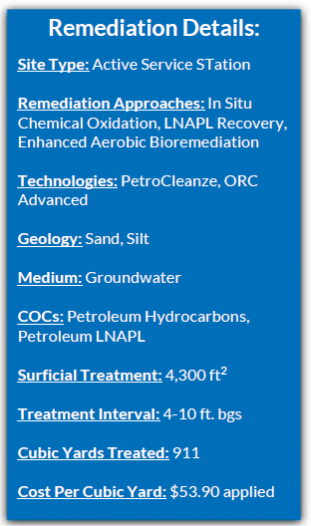

Regenesis Remediation Services™ – LNAPL Recovery at an Active Gas Station

Combined Treatment Remedies Reduce Contamination Concentrations at Michigan Service Station

Regenesis Remediation Services (RRS) was contracted to remediate a residual LNAPL and dissolved-phase petroleum plume from historic gasoline and diesel fuel releases at an active service station. RegenOx PetroCleanze™ (PetroCleanze) was chosen as the primary remediation technology to facilitate the recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure.

The design called for three (3) application events using PetroCleanze, with Oxygen Release Compound (ORC®) Advanced applied during the final application event in a down-gradient plume cut- off barrier, to promote the enhanced aerobic biodegradation of dissolved-phase petroleum hydrocarbons. Eight (8) injection/extraction wells and 28 direct-push technology (DPT) injection points were used to apply the remediation reagents in the silty-sand aquifer and smear zone. Vacuum extraction was conducted between PetroCleanze applications to recover residual freephase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring confirmed PetroCleanze was present throughout the targeted source area during each application event.

Prior to the first PetroCleanze application event, no measurable free product was observed at this site since 2006. Less than twenty-four hours after the first PetroCleanze application event, LNAPL up to three inches thick was observed in four of the eight wells. After completing the third application and extraction event, LNAPL was not observed in any wells on site, and BTEX concentrations in groundwater were showing reductions for the first time since the fuel releases first occurred. A total of 2,160 pounds of RegenOx PetroCleanze and 1,120 lbs. of ORC Advanced were injected.

Regenesis Remediation Services™ – LNAPL Recovery & In Situ Chemical Oxidation

Combined Treatment Remedies Reduce Contamination Concentrations at a Former Service Station

Regenesis Remediation Services (RRS) was contracted to remediate a dissolved-phase and residual LNAPL petroleum hydrocarbon plume resulting from historic petroleum fuel releases at a former service station. RegenOx® PetroCleanze™ (PetroCleanze) was chosen as the primary remediation technology in addition to Oxygen Release Compound (ORC®) Advanced, to facilitate recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure. ORC Advanced was applied during the second PetroCleanze application to promote the enhanced aerobic bioremediation of dissolved phase petroleum hydrocarbons.

Eighteen direct-push injection points were used to apply the reagents in the silty sand aquifer and saturated soil over the course of two application events. Vacuum extraction was conducted after each PetroCleanze application to recover residual free-phase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring during the application events confirmed PetroCleanze was present across the targeted source area. Remediation chemistry was applied via direct-push injection points with a bottom-up approach from 5 to 15 feet below ground surface (bgs). A total of 4,470 pounds (lbs.) of RegenOx PetroCleanze and 720 lbs. of ORC Advanced were injected throughout the course of the two applications.

Regenesis Remediation Services™ – LNAPL Recovery with RegenOx®

Remediation of Residual LNAPL and a Dissolved-Phase Plume at a Former Gasoline Service Station

Regenesis Remediation Services (RRS) was contracted to remediate a residual LNAPL and dissolved phase petroleum plume from a historic fuel release at this former gasoline service station. RegenOx PetroCleanze™ (PetroCleanze) was chosen as the primary remediation technology to facilitate recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure.

Twenty-six (26) direct-push injection points were used during each of the four (4) application events to apply the remediation chemistry in the sandysilt aquifer and smear zone soils. Vacuum extraction was conducted after each PetroCleanze application to recover residual free-phase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring confirmed PetroCleanze was present across the targeted source area during each application event. Direct-push injection points were advanced using a bottom-up approach between 25 and 20 feet below ground surface (bgs). The injection interval focused on the highest concentrations of contaminants identified in the upper saturated soils and smear zone soils. A total of 13,230 pounds of PetroCleanze were injected via DPT injection points over the course of the project with low pressures and moderate flow rates.

REGENESIS Remediation Services – LNAPL Treated with Combined Remedies

Active Michigan Service Stated Remediated Through Use of PetroCleanze® and ORC® Advanced

RRS was contracted to remediate a residual LNAPL and dissolved phase petroleum plume from historic gasoline and diesel fuel releases at an active service station. PetroCleanze® was chosen as the primary remediation technology to facilitate recovery of residual LNAPL and chemically oxidize contaminants without negatively impacting sensitive infrastructure. ORC® Advanced was also applied with the final PetroCleanze application event and in a downgradient plume cut off barrier to promote the enhanced aerobic bioremediation of the dissolved-phase petroleum hydrocarbons.

Eight injection/extraction wells and 28 direct-push injection points were used to apply the remediation reagents in the silty sand aquifer and smear zone over three application/injection events. Vacuum extraction was conducted between PetroCleanze applications to recover residual free phase petroleum hydrocarbons liberated from the soils. Reagent distribution monitoring confirmed PetroCleanze was dispersed across the targeted source area during each application event.

Prior to the first PetroCleanze application event, no measurable free product was observed on this site since 2006. Less than twenty-four hours after the first PetroCleanze application event, LNAPL was observed in four of the eight wells in the source area at quantities up to three inches thick.

Not more than a sheen was observed in any wells on site after the third injection event. A total of 2,160 pounds of PetroCleanze and 1,120 pounds of ORC Advanced were injected.

Replacement of P&T with ORC Advanced® Reduces Cost to Closure

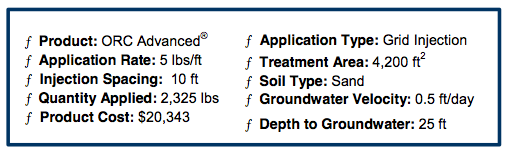

CASE SUMMARY

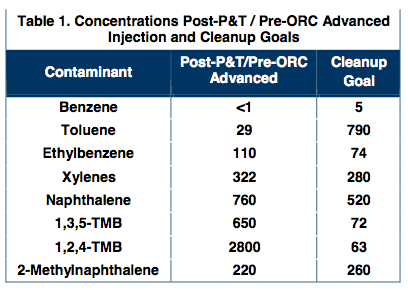

Two leaking underground storage tanks (USTs) resulted in soil and groundwater contamination at a service station in Michigan. Naphthalene, trimethylbenzene (TMB) and benzene, toluene, ethylbenzene, and xylenes (BTEX) contamination were discovered in the subsurface prompting the need for remedial cleanup. Michigan DEQ began remediation via UST removal and soil excavation. A total of 4,000 cubic yards of contaminated soil was removed. A pump and treat (P&T) system was installed and operated for 8 years through November 2003. The system removed 1,575 pounds of BTEX and significantly lowered contaminant concentrations. However, the P&T system reached asymptotic conditions and would not be effective in achieving site closure goals. Regulators began looking into new ways of accelerating the remediation process and reducing the overall cost of cleanup. Enhanced aerobic bioremediation using ORC Advanced® was deployed to replace the P&T system and degrade the remaining contamination.

REMEDIATION APPROACH

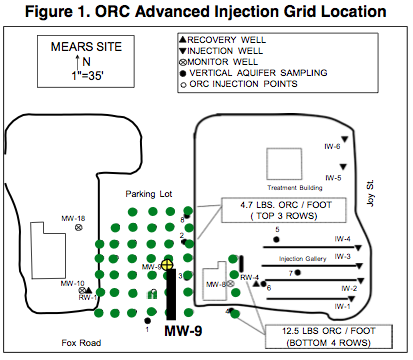

The remediation objective was to continue the reduction of petroleum hydrocarbons in the subsurface and reduce the cost to closure. Three months after the P&T was shutdown an ORC Advanced application took place. The ORC Advanced injection included 43 injection points in a grid design within the contaminated area surrounding well MW-9 (Figure 1).

RESULTS

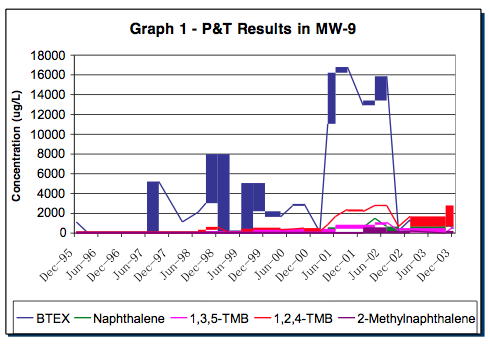

Pump & Treat Results

An increase in rainfall during certain parts of the remedial period contributed to some of the increases observed in Graph 1. During wet periods, an increase in concentrations resulted from the mobilization of contaminants within the capillary fringe smear zone. An infiltration gallery was installed to flush the contamination into the dissolved-phase where it was available for P&T removal.

Prior to shutdown in November 2003, O&M costs were increasing and low-level dissolved- phase concentrations were still elevated indicating the system was not effective at reaching the required low cleanup levels.

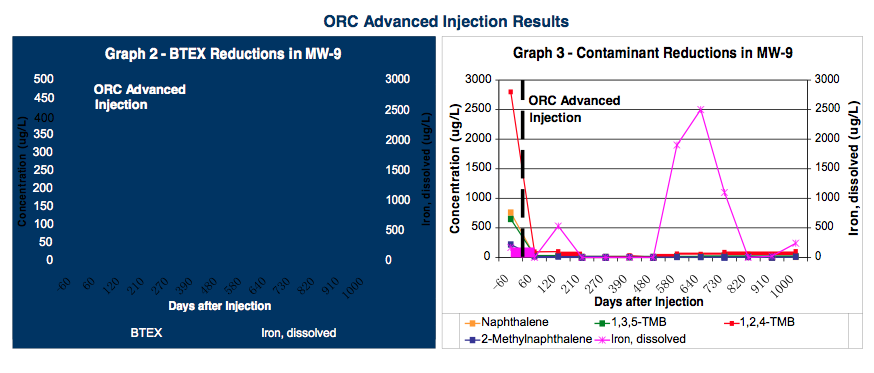

ORC Advanced Injection Results

ORC Advanced Injection Results

Within 60 days of the ORC Advanced application, low-level concentrations were significantly reduced below post-P&T levels. Reduction continued throughout the monitoring period and a 99% mass reduction was achieved approximately 13 months after the initial injection. In well MW-9, concentrations in all contaminants were reduced to below the cleanup goals.

The ORC Advanced application eliminated increasing O&M costs of an aging P&T system and allowed the site to be closed years ahead of projections.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español