High Concentrations of Chlorinated Solvents Reduced to Non-Detect Allowing for Site Closure

The subject site has been used for the manufacture of industrial switchgear assemblies and warehousing since the 1970s. A subsurface investigation revealed a highly localized plume near WS10 with significant groundwater concentrations of trichloroethene (TCE) at 260 parts per million (ppm) along with its breakdown product cis-1,2- dichloroethene (cDCE). A site specific target level (SSTL) was established for TCE (1.0 ppm) and remedial action began with an in situ injection of Hydrogen Release Compound (HRC®). The product was chosen over other remedial strategies since the application would not disrupt on-site operations and did not require long-term maintenance.

Remediation Approach

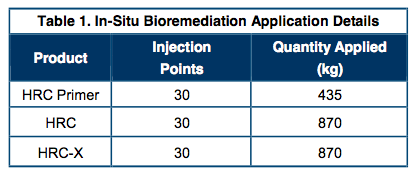

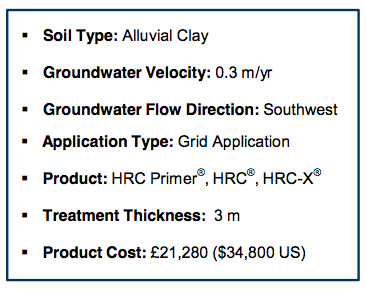

The remediation objective was to reduce concentrations of TCE to below the SSTL of 1.0 ppm. A combined approach using HRC Primer®, HRC and extended release, HRC-X®, was applied using a grid injection layout (Figure 1). HRC Primer was initially injected to quickly establish reducing conditions within the aquifer. The injection of HRC would sustain anaerobic conditions over the next 18 months while the addition of HRC-X would continue releasing hydrogen for approximately 5 years. Two new wells were installed to monitor the progress of remediation – BH1 and BH2. Well BH1 replaced future monitoring in WS10 while BH2 was installed downgradient. Sampling of both wells indicated a hot spot at BH1 and no elevated level of contamination in BH2.

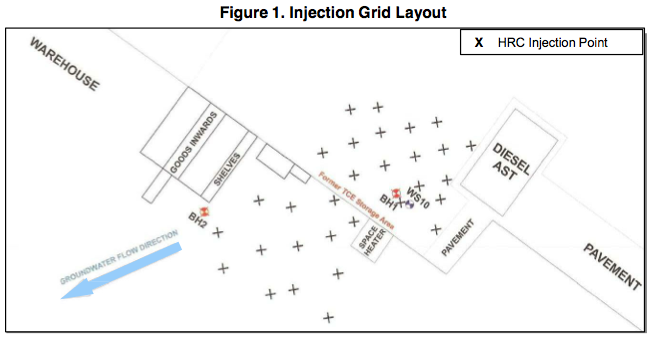

Monitoring results immediately following the HRC injection (November 2005) revealed TCE was present at BH1 but not at BH2 indicating no migration off-site was likely to occur. Breakdown products 1,1-dichloroethene (1,1-DCE), trans-1,2- dichloroethene (tDCE), and cDCE were present for the first time demonstrating a reductive dechlorination process had been established as a result of the HRC application. By January 2006, trace concentrations of vinyl chloride (VC) were detected for the first time indicating that complete dechlorination was occurring in the subsurface.

In September 2006, sampling results indicated TCE levels were below the SSTL of 1.0 ppm (Graph 1). Breakdown products continued to be detected however all were on a reducing trend.

CONCLUSION

Within 10 months, total chlorinated compounds in Well WS10/BH1 were reduced from 198 to 4.3 ppm, a 98% reduction. The TCE remedial goal was reached using one combined application of HRC Primer, HRC and HRC-X. The consultant and environmental agency agreed that the remaining chlorinated solvents would continue to reduce and no further action was needed. A request for site closure was granted in November 2006.

PCE and TCE Remediation at a Dry Cleaning Facility

SITE SUMMARY

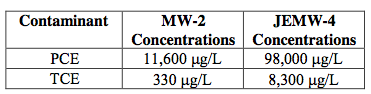

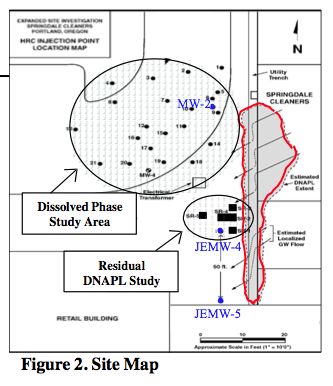

A focused Site Investigation was completed for a dry cleaner site in Portland, OR. Results showed contamination levels of PCE as high as 120,000 ug/L in groundwater and 320,000 ug/L in soil. It is believed that the source of the contamination was a leaking sewer line beneath the facility. The high concentrations suggested the presence of Dense Non-Aqueous Phase Liquid (DNAPL) and a remedial technology was needed to address the distinctive contaminant concentrations. The HRC® application at this site is significant since it was the first time HRC-X® was injected, along with HRC, to treat VOCs. The extended life expectancy of HRC-X, 2 times-3 times that of HRC, made for a feasible option to reduce the high concentration of PCE. A pilot study was implemented using HRC to target the area near wells MW-1, MW-2, and MW-4 while HRC-X was injected near JEMW-4, the projected area of DNAPL.

REMEDIATION APPROACH

- Remediation Objective: Pilot Study to prove HRC applicability at the site.

- Application Type: Grid (Direct-Push Injection) for both applications

- Product: HRC and HRC-X

- Quantity Applied: 1,920 lb of HRC and 1,680 lb of HRC-X

- Application Rate: HRC – 6 lb/ft; HRC-X – 9 lb/ft

- Injection Spacing: Variable distances, see site map

- Product Cost: $11,520 HRC; $11,760 HRC-X

SITE CHARACTERISTICS

General

- Name: Springdale Cleaners

- Location: Portland, OR

- Industry: Dry Cleaning

Hydrogeology

- Treatment Area: 9,100 ft2

- Soil Type: silty clay and silty sand

- Groundwater Velocity: 0.68 ft/day

- Groundwater Flow Direction: Southwest

- Depth to Groundwater: Variable

RESULTS

CONCLUSION

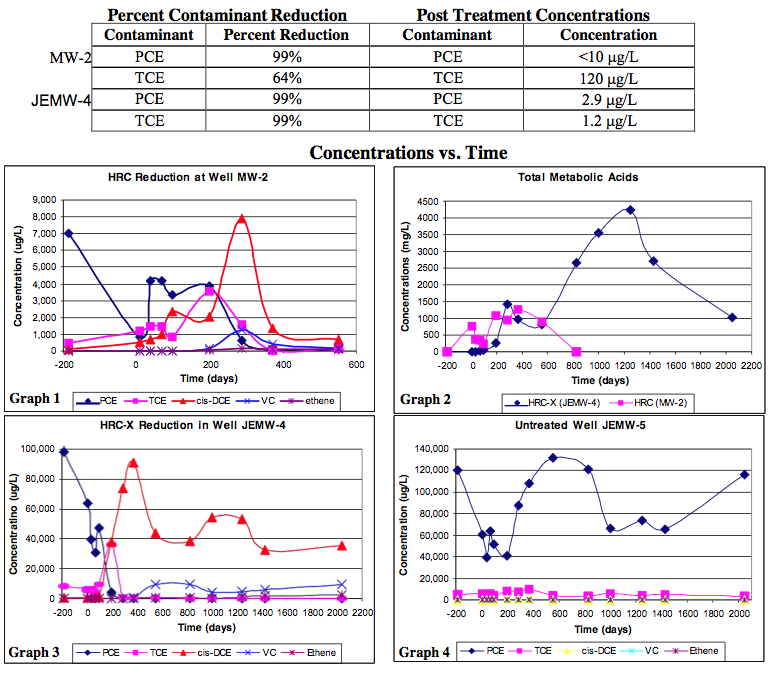

HRC performance in MW-2 produced sustained degradation of PCE and TCE as well as their breakdown products over roughly a two year period (Graph 1). HRC metabolic acids peaked around 1300 mg/L after a year then tapered off over time (Graph 2). HRC-X performance in JEMW-4 and JEMW-5 indicates unprecedented performance in terms of contaminant reduction and total metabolic acid production and longevity. JEMW-4 shows significant reductions in high concentrations of 100,000 ug/L PCE to near non-detect (ND) levels in approximately 300 days (Graph 3). PCE levels continue to remain at very low levels for greater than 5 years after HRC-X application. TCE was also reduced significantly from 90,000 ug/L to approximately 35,000 ug/L in close to 4 years. Daughter products such as cis-DCE and VC have been produced as a result of the parent product breakdown and are eventually expected to dissipate. Metabolic acids remain high (1000 mg/L) as a result of the HRC-X application. HRC-X continues to reduce high concentration PCE and daughter products TCE, cis-DCE, and VC more than 5 years after injection.

Rapid Reduction of Petroleum Hydrocarbons using ORC Advanced® allows for Redevelopment of Site

Summary

Remedial works at the Former Lama Petroleum site were undertaken in late 2008 as part of the ongoing redevelopment of the Fresh Wharf Estate in Barking UK. The site was to be developed for light industrial use, however, historical oil mixing handling and storage activities performed on the site had resulted in TPH and PAH contamination in the groundwater.

Site investigation works suggested the presence of an approximately 1,000m2 source area in thenorthwestern portion of the site, as well as a downgradient plume area, estimated to be in the region of 6,000m2 extending towards the Handtrough Creek. Phase separated hydrocarbons were detected in the source area where the former above ground storage tanks had been located prior to decommissioning circa 2003. In the downgradient plume area, the maximum dissolved phase TPH concentration was 1,100μg/L (Monitoring Well BH102) and located adjacent to Handtrough Creek.

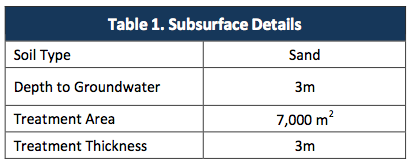

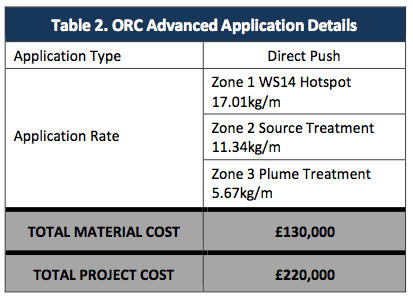

Remedial Strategy

The remedial objective was to reduce dissolved phase concentrations of Total TPH and PAH in groundwater to the agreed remedial target level of 110μg/L, within 12 months of treatment. A trigger level for further remediation was set at 200μg/L, equating to an 80% contaminant concentration reduction within 42 weeks post treatment. If the trigger TPH concentration was not achieved within 42 weeks after treatment, further options would be undertaken.

The original assessment of remedial options identified that a combination of Pump and Treat (P&T) to target free product in the source area and ORC Advanced® treatment in the groundwater plume would represent the most time‐efficient and cost‐effective remedial solution for the site. However, trial pits advanced in the source area during site clearance works

determined that free product was not present in the groundwater, but was present in discrete bands within the unsaturated made ground. Following this observation, excavation to remove the most impacted soils in the source area was determined to be the most suitable approach and P&T was discarded as an option.

Soil removal works were undertaken at the site in October 2008. ORC Advanced treatment in both the source and plume areas was undertaken in October and November 2008. ORC Advanced was applied using three direct push injection rigs and a separate mixing and pumping unit. The rods were driven to 6mBGL and the ORC Advanced was applied over the impacted saturated zone as the rods were slowly withdrawn to 3mBGL. The application included a total of 813 injection points over 19 drilling days. The dose rates were varied to match the different contaminant concentrations and conditions encountered across the site (Tables 1 & 2). Vibro‐piling works were completed across the site at the same time as the ORC Advanced was being applied and were unimpeded by the direct push equipment.

Results

Following the injection of ORC Advanced, a slight increase in the dissolved phase contaminant concentrations was observed due to the site disturbance from injection and piling works. Both TPH and PAH concentrations then rapidly decreased to below the site specific remedial target values and remained low over the monitoring programme. A 99% reduction in the groundwater concentrations of TPH and PAH was achieved with no rebound. Monitoring results are presented below for well BH102, which was located on the southern site boundary, adjacent to Handtrough Creek.

Conclusion

Following the application of ORC Advanced, TPH and PAH concentrations were rapidly reduced and maintained below the site specific target values without contaminant rebound. The works were completed safely and efficiently and did not hinder the ongoing construction works occurring simultaneously at the site. The low final contaminant concentrations and the lack of rebound resulted in regulatory acceptance of the remediation and development works were completed.

Replacement of P&T with ORC Advanced® Reduces Cost to Closure

CASE SUMMARY

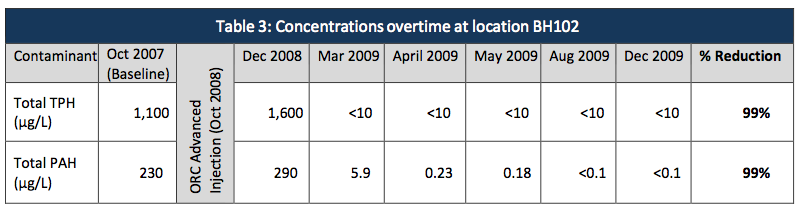

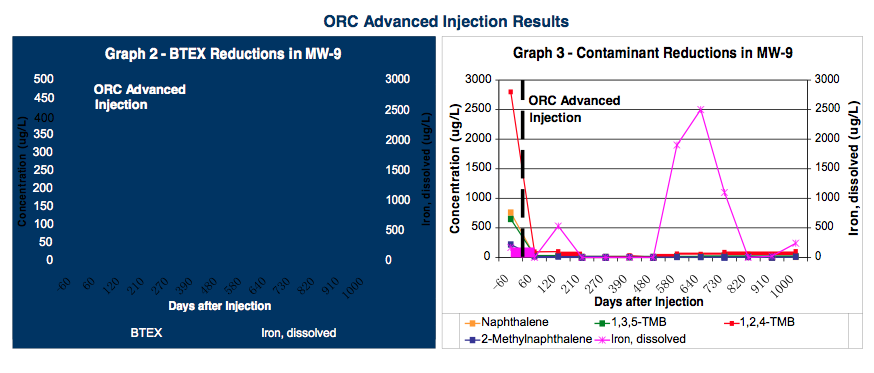

Two leaking underground storage tanks (USTs) resulted in soil and groundwater contamination at a service station in Michigan. Naphthalene, trimethylbenzene (TMB) and benzene, toluene, ethylbenzene, and xylenes (BTEX) contamination were discovered in the subsurface prompting the need for remedial cleanup. Michigan DEQ began remediation via UST removal and soil excavation. A total of 4,000 cubic yards of contaminated soil was removed. A pump and treat (P&T) system was installed and operated for 8 years through November 2003. The system removed 1,575 pounds of BTEX and significantly lowered contaminant concentrations. However, the P&T system reached asymptotic conditions and would not be effective in achieving site closure goals. Regulators began looking into new ways of accelerating the remediation process and reducing the overall cost of cleanup. Enhanced aerobic bioremediation using ORC Advanced® was deployed to replace the P&T system and degrade the remaining contamination.

REMEDIATION APPROACH

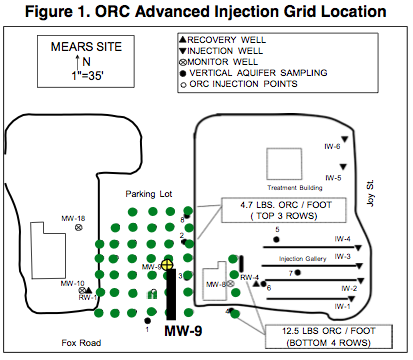

The remediation objective was to continue the reduction of petroleum hydrocarbons in the subsurface and reduce the cost to closure. Three months after the P&T was shutdown an ORC Advanced application took place. The ORC Advanced injection included 43 injection points in a grid design within the contaminated area surrounding well MW-9 (Figure 1).

RESULTS

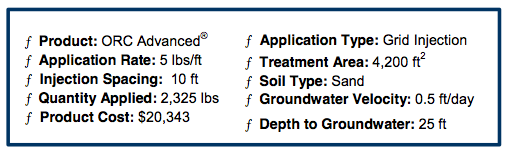

Pump & Treat Results

An increase in rainfall during certain parts of the remedial period contributed to some of the increases observed in Graph 1. During wet periods, an increase in concentrations resulted from the mobilization of contaminants within the capillary fringe smear zone. An infiltration gallery was installed to flush the contamination into the dissolved-phase where it was available for P&T removal.

Prior to shutdown in November 2003, O&M costs were increasing and low-level dissolved- phase concentrations were still elevated indicating the system was not effective at reaching the required low cleanup levels.

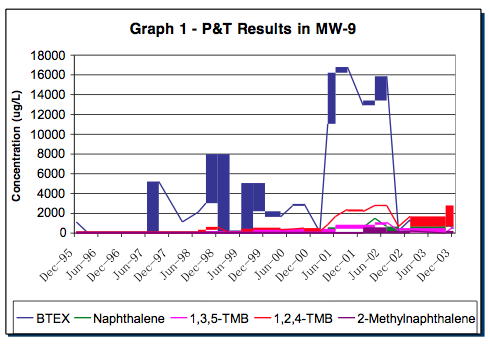

ORC Advanced Injection Results

ORC Advanced Injection Results

Within 60 days of the ORC Advanced application, low-level concentrations were significantly reduced below post-P&T levels. Reduction continued throughout the monitoring period and a 99% mass reduction was achieved approximately 13 months after the initial injection. In well MW-9, concentrations in all contaminants were reduced to below the cleanup goals.

The ORC Advanced application eliminated increasing O&M costs of an aging P&T system and allowed the site to be closed years ahead of projections.

High Benzene Concentrations Reduced Using ORC Advanced

SITE SUMMARY

Elevated levels of petroleum hydrocarbons were discovered near the former dispenser island at a former service station in Sheboygan, WI. In hopes of reducing concentrations, soil excavation activities took place in June 2003. A total of 500 tons of hydrocarbon-impacted soils were removed and transported to a landfill for disposal. However, residual contamination continued to affect the groundwater after the excavation. By March 2004, benzene and ethylbenzene had risen to 2,500 ug/L and 1,300 ug/L, respectively. In Situ bioremediation using ORC Advanced was chosen to reduce BTEX, naphthalene, and trimethylbenzenes. In the northwest corner of the site, the location of the former UST basin, a total of 480 pounds of ORC Advanced was injected. In the southeast corner, the area of highest contamination, a total of 2,370 pounds of ORC Advanced was injected.

REMEDIATION APPROACH

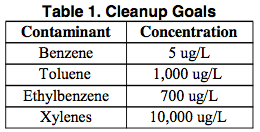

- Remediation Objective: Reduce concentrations of Benzene to cleanup goals at the entire site. See Table 1.

- Application Type: Grid

- Product: ORC Advanced

- Quantity Applied: 2,850 lbs

- Application Rate: NW Corner–4 lbs/ft; SE Corner-11.9 lbs/ft

- Injection Spacing: 10 ft

- Product Cost: $24,225

SITE CHARACTERISTICS

- Name: Former Marathon Unit #3697

- Location: Sheboygan, WI

- Industry: Service Station

- Contaminants of Concern:

Hydrogeology

- Treatment Area: NW Corner 1,200 ft2; SE Corner 1,800 ft2

- Soil Type: Silty sand lenses in clay matrix

- Groundwater Flow Direction: Southeast

- Depth to Groundwater: 12-15 ft

RESULTS

CONCLUSION

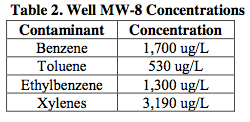

Groundwater sampling results after excavation activities show an increasing trend of contamination. On average, concentrations continued to increase up until the ORC Advanced application due to residual contamination. Concentrations peaked before ORC Advanced injection followed by a significant reduction across the plume. In well MW-5, benzene spiked to 160 ug/L while naphthalene rose to 170 ug/L and in well MW-4 BTEX, naphthalene and trimethylbenzenes all increased. Significant decreases of all contaminants were seen shortly after ORC Advanced injection. In well MW-8 total BTEX was reduced from 6,720 ug/L to 168.8 ug/L, a 97% reduction. Naphthalene concentrations were above the MCL of 20 ug/L in wells MW-1, MW-4, MW-5. ORC Advanced reduced concentrations to non-detect in wells MW-4 and MW-5, leaving 38 ug/L in well MW-1. Monitoring is on-going as concentrations continue to decrease towards MCLs.

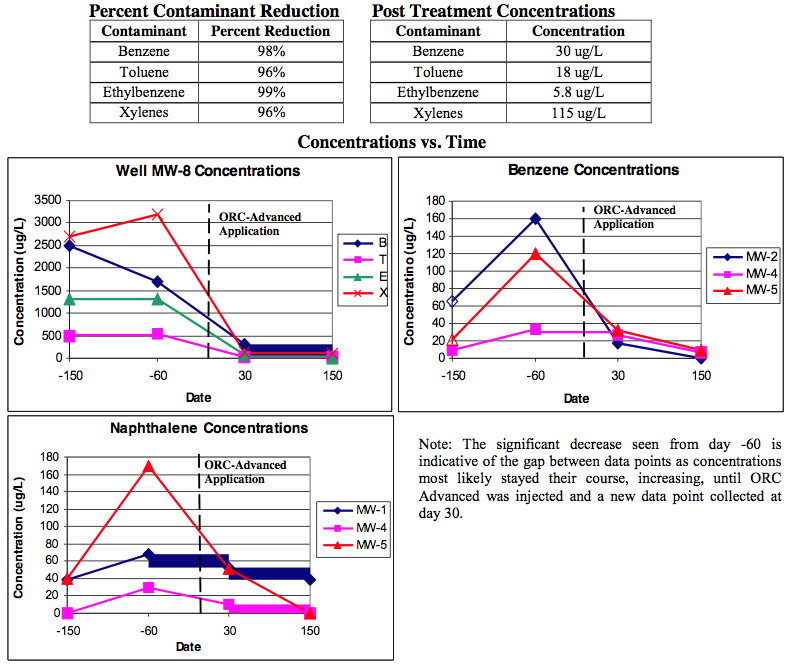

Surgical Site Closure – 30 Sites in Indiana Receive Closure using ORC

CASE SUMMARY

Surgical Site Closure

The “Surgical Site Closure” strategy was developed by Mr. Steve Sittler, an employee of KERAMIDA in Indianapolis, Indiana. The method is an innovative remedial strategy designed to intelligently integrate natural attenuation, risk-based cleanup goals and focused source removal/treatment to cost-effectively remediate contaminated areas. This approach is best applied at sites where released materials are amenable to biodegradation and where long-term, natural attenuation-type strategies are not suitable for reasons of property transfer or potential off-site liability. This strategy was performed at 30 sites in Indiana for a major oil company.

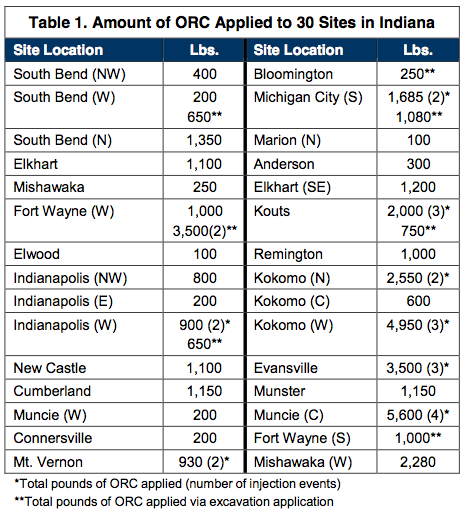

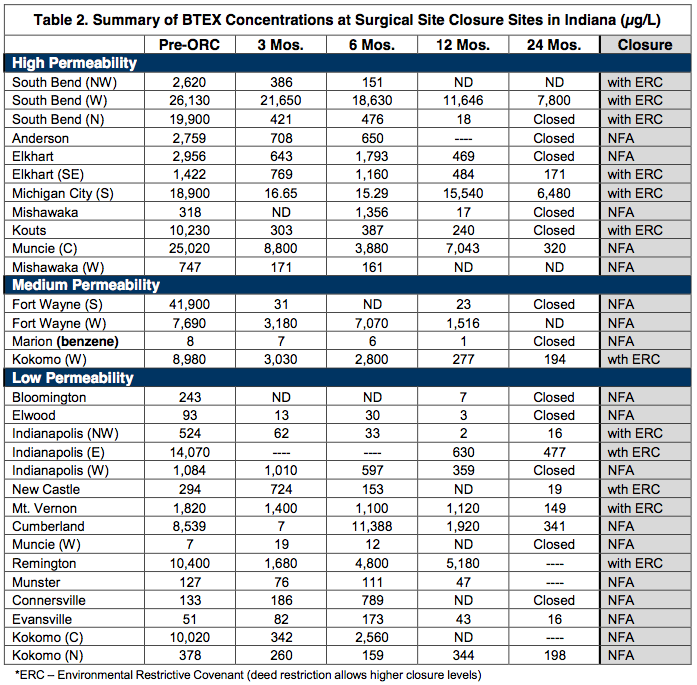

Service Stations/Bulk Storage Terminals – Indiana

From 1998-2008, a total of 30 service station/bulk storage terminal sites were targeted for Surgical Site Closure in Indiana. The subsurface matrix consisted of unconsolidated sediments ranging from low-permeability silty clays with sand stringers to sand and gravel formations. The contaminants of concern were primarily gasoline and diesel fuel. A combination of source removal via excavation coupled with enhanced in situ bioremediation using Oxygen Release Compound (ORC®) was performed at most sites.

REMEDIATION APPROACH

The remediation approach included focused soil excavation of the source area and/or ORC direct-push injection. At some sites ORC was applied to the base of the excavation prior to backfilling. Shortly afterwards, a direct-push injection of ORC was completed over the remainder of the plume. The amount of ORC needed at each site location was determined using various site characteristics including contaminant concentration, seepage velocity, and treatment area.

The majority of the sites were successfully treated using only one injection of ORC; however, a handful of sites received multiple applications. Most of these sites indicated that high levels of BTEX were present prior to treatment (>1,000ppb to <50,000ppb) and required additional applications to sustain aerobic bioremediation.

ABOUT THE CONSULTANT

![]() KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

CONCLUSION

The Surgical Site Closure method was successful in reaching site closure at 30 petroleum-impacted sites over a nine-year period. The average time to reach site closure was ~3 years and the average cost to implement the remedial strategy was ~$70,000. Cost analyses indicated that a traditional remediation approach would have ranged from at least $100,000 to potentially $1 million. Actual implementation costs for the Surgical Site Closure approach ranged from approximately $25,000 to $75,000 plus monitoring costs.

Successful Pilot Test Results in Full-Scale Treatment of Large BTEX Plume

CASE SUMMARY

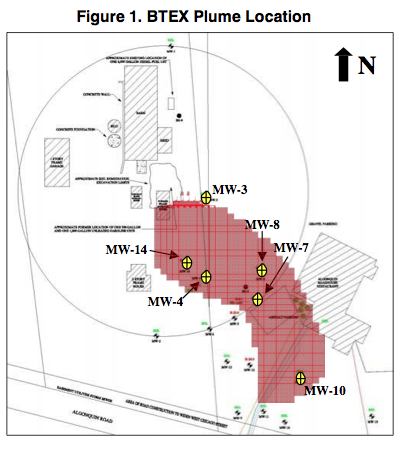

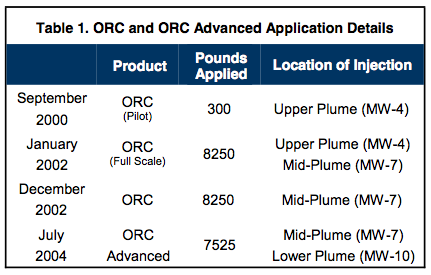

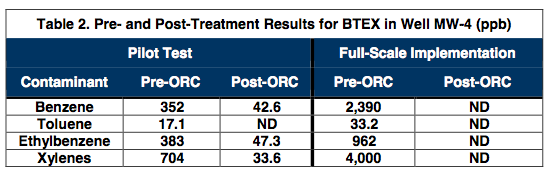

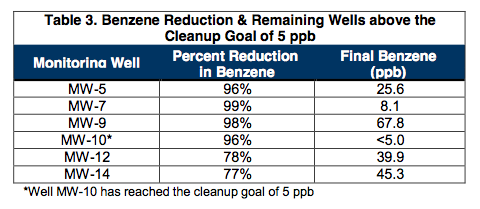

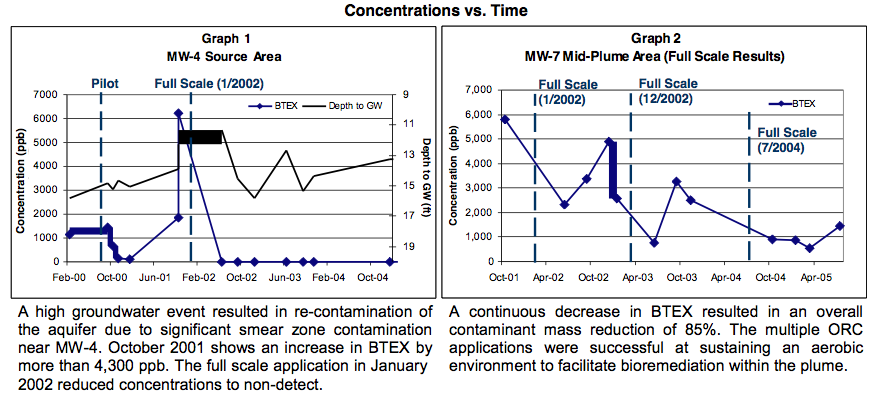

Refueling Station – Algonquin, IL

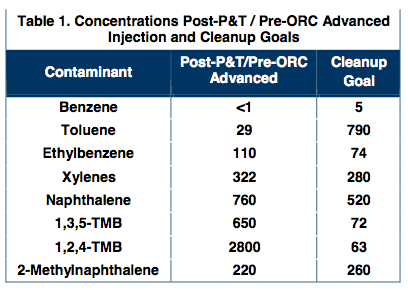

Leaking underground storage tanks at a refueling station resulted in a benzene, toluene, ethylbenzene and xylene (BTEX) plume in the underlying sand/gravel aquifer. The plume covered 1-acre and extended 390 feet downgradient from the source area, with a total BTEX concentration exceeding 24,000 parts per billion (ppb). In an effort to mitigate the source, 795 cubic yards of contaminated soil was excavated; however, further groundwater monitoring revealed that BTEX concentrations still exceeded the Illinois EPA cleanup levels. To address the remaining contamination and reduce concentrations to the state cleanup goal, a remediation plan was implemented using Oxygen Release Compound (ORC®) and ORC Advanced®.

REMEDIATION APPROACH

The remediation objective was to reduce petroleum hydrocarbon contamination, mainly benzene, to the state cleanup goal. A pilot test was performed using ORC to observe the effectiveness of reducing BTEX concentrations. Successful reduction was achieved within 4 months and a full-scale application was implemented. The full-scale application was focused near the source area as well as within the mid-plume area (near MW-7 & MW-8). Two applications followed within the mid- and lower plume areas to continue BTEX reduction.

- Application Type: Grid & Barrier Application

- Soil Type: Clay above Sand/Gravel

- Groundwater Velocity: 0.25 ft/day

- Treatment Area: 43,500 ft2

- Injection Spacing: 10–20 feet

- Product Cost: $171,600

Five of the ten contaminated monitoring wells achieved the remedial objective for benzene as well as all other contaminants following the ORC and ORC Advanced injection. Benzene reduction for those wells that have not yet achieved the cleanup goal are listed in Table 3. Overall, a benzene mass reduction of over 95% was achieved. It is expected that the remaining contaminant concentrations will reach cleanup goals as monitoring continues.

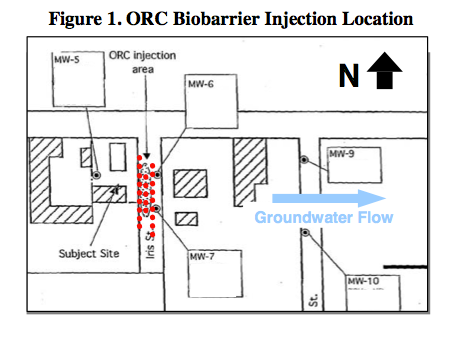

Site Closure Sought after using ORC® Biobarrier to Enhance Aerobic Biodegradation of MTBE and TPHg

CASE SUMMARY

Former Service Station – Bishop, CA

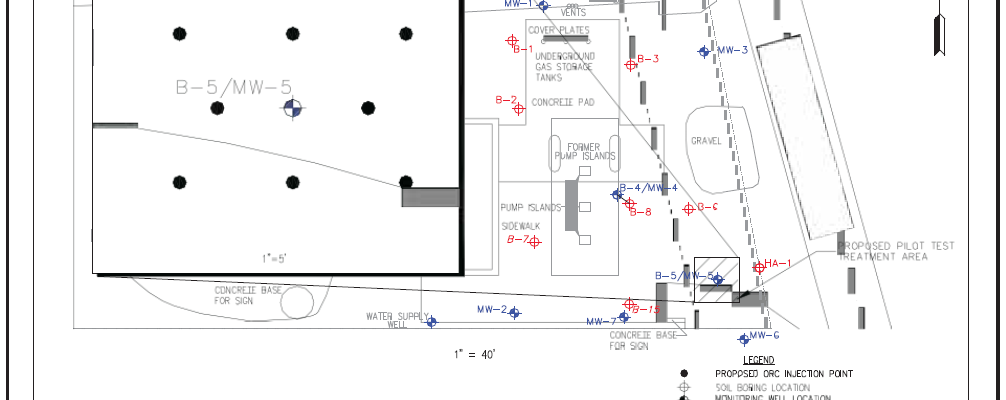

Extensive methyl tertiary-butyl ether (MTBE) and total petroleum hydrocarbons as gasoline (TPHg) contamination was discovered within the subsurface as a result of leaking underground storage tanks (USTs) at a former service station. Following the removal of the leaking USTs, a total of 1,192 cubic yards of gasoline- impacted soil in the source area was excavated and transported off-site for treatment. Monitoring following the excavation activities revealed residual source contamination found in the capillary fringe immediately downgradient near Wells MW-6 and MW-7. Concentrations in Well MW-6 exceeded 7 parts per million (ppm) MTBE and approximately 11 ppm TPHg. Efforts to further delineate the plume revealed petroleum contamination extending 1,700 feet downgradient from the source. Early efforts were made to treat the downgradient plume utilizing an air sparging/vapor extraction system placed 800 feet downgradient from the site of the original release. This approach proved to be effective as MTBE and TPHg were reduced to non-detect levels downgradient from where it was installed. However, the source area continued to reveal MTBE and TPHg concentrations above the cleanup goals enforced by the California Regional Water Quality Board. To treat the source area and bring the site to closure, an enhanced bioremediation barrier (biobarrier) was designed and implemented using Oxygen Release Compound (ORC®).

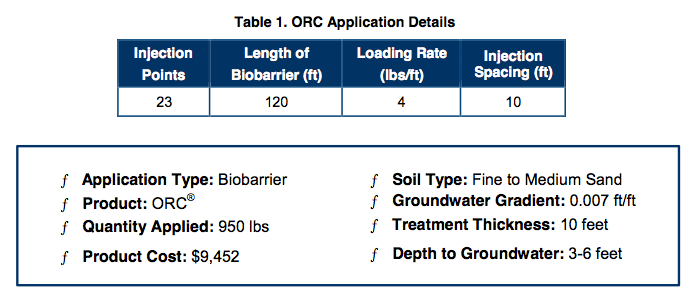

REMEDIATION APPROACH

To address the source area, a total of 950 pounds of ORC was mixed with water to form a slurry and injected via direct-push technology. The 3 row ORC biobarrier was applied immediately downgradient from the release area (Figure 1). Wells MW-6 and MW-7 were monitored to observe the effectiveness of ORC.

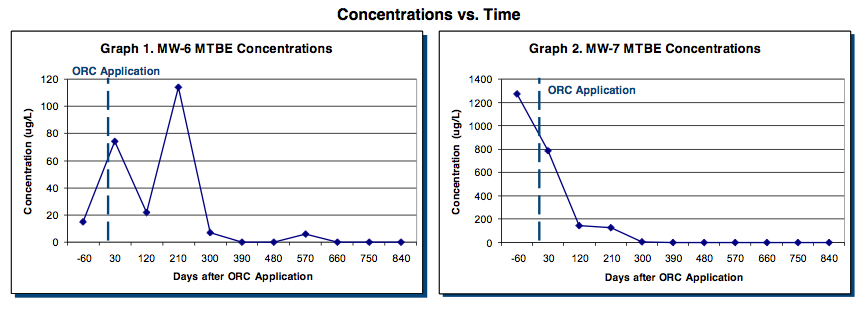

RESULTS

The post-ORC injection monitoring results show an effective reduction of MTBE and TPHg within one year. Well MW-6 indicates two MTBE concentration spikes likely caused by residual contamination from the soil entering into the groundwater (Graph 1). However, an MTBE reduction of 94% occurred between day 210 and 300 and concentrations reached non-detect shortly afterwards. TPHg concentrations declined by 70% within the first 30 days and continued on a downward trend, reaching non-detect levels approximately one year after the application.

In Well MW-7, reduction occurred immediately after injection with an MTBE decrease of 88% by day 120 (Graph 2). Concentrations reached non-detect less than a year after the ORC application. TPHg levels declined similarly to MTBE and reached non-detect in less than one year.

The effective treatment of MTBE and TPHg using ORC resulted in non-detect levels of both contaminants and has allowed the consultant to seek site closure status from the regulatory agency.

In Situ Aerobic Bioremediation vs. AS/SVE Cost Comparison at UST Site

REGENESIS® Demonstrates Effective Cost-Savings Using ORC®

Project Highlights

- An in situ aerobic bioremediation pilot test demonstrates a cost-effective treatment option vs. traditional Air Sparge and Soil Vapor Extraction (AS/SVE) system

- Within one month, benzene concentrations were reduced from baseline concentrations of 200 ug/L to non-detect (>5 ug/L)

- Approach using ORC® resulted in a $79K savings vs. traditional mechanical treatment option

Project Summary

The site of a former gas station with leaking underground storage tanks (LUSTs) was chosen for a pilot test to demonstrate the effectiveness of ORC® in treating the existing benzene (BTEX) and MTBE concentrations. In addition to the pilot test, a cost-comparison was also prepared to illustrate the potential for cost-savings associated with the use of a passive, innovative technology like ORC vs. a traditional AS/SVE remediation system.

For the pilot test a 20 ft. x 20 ft. area, with the highest concentrations of BTEX and MTBE, was treated with 180 lbs of ORC. BTEX concentrations within this area varied from 200 ug/L to 2100 ug/L from low and high groundwater elevation, respectively. ORC was injected into 10 points from 8-14 ft bgs to ensure ample coverage of the sand layer and some of the smear zone.

Technology Description

Oxygen Release Compound (ORC) is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater or saturated soils.

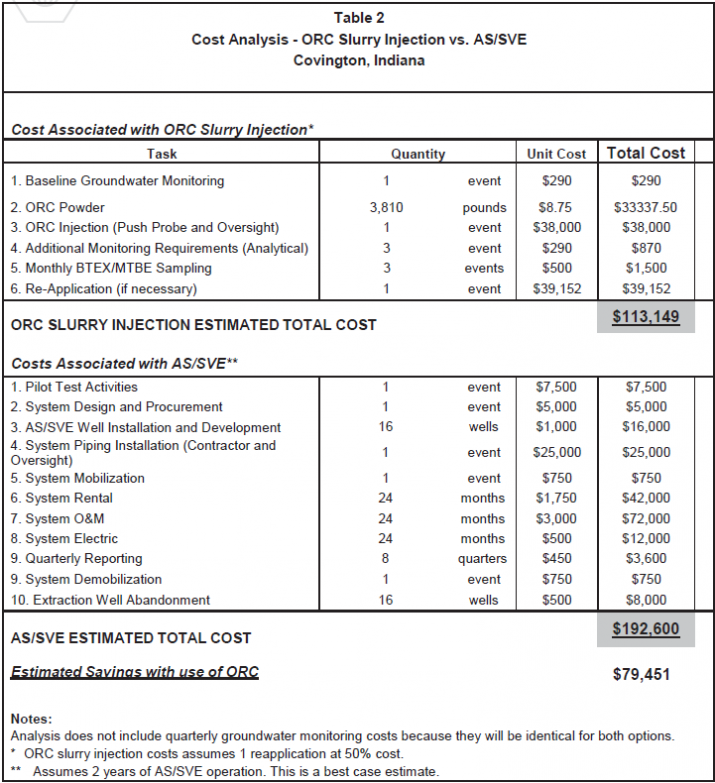

Cost Comparison Analysis

A cost comparison analysis was prepared by the consultant for the Indiana Department of Environmental Management (IDEM) to show a comprehensive cost savings using ORC versus the AS/SVE system for full-scale treatment of benzene and MTBE. This cost comparison is illustrated in Table 2 and includes the initial full-scale ORC application costs as well as a second application at 50% of the initial application cost. This second application is shown as an “insurance policy” in the event that more ORC is needed to complete the remediation. The AS/SVE costs are reflective of the design, installation, and operation of such a system for two years. Based on the analysis, the use of ORC represents ~59% of the cost of the AS/SVE option or a potential savings of $79,451. If a second insurance application is avoided, then the savings are $79,451 (initial saving) plus $39,1529 (cost for re-application) equaling $118,603.

Results

Within one month, benzene concentrations in the low groundwater elevation were reduced from baseline concentrations of 200 ug/L to non-detect (<5 ug/L). Dissolved oxygen content also increased dramatically from <0.5 ppm (baseline) to >20 ppm post application. A successful full-scale application was designed using 4,000 pounds of ORC, which will save the client >$79K versus a traditional AS/SVE system.

PCP Bioremediation at Eastern Virginia DoD Wood Dip Tank Site

Site Summary

This site is the location of a former Department of Defense dip tank with associated storage racks that has been used to treat wood with a mixture of pentochlorophenol (PCP), diesel fuel and kerosene. The dip tank was dismantled in 1982 and the area was paved with asphalt and converted to a storage area. Subsequent soil and groundwater sampling indicated that PCP was present in both media, with soil concentrations greater than USEPA Region III Risk-Based Contaminant Levels and groundwater concentrations greater than USEPA Maximum Contaminant Levels (MCLs). In 1999, a soil excavation took place at the site removing all the soil above the water table with a PCP concentration greater than 16 mg/kg and the removal of one to three feet of soil below the water table. In 2000, a treatability study was conducted to evaluate the in-situ aerobic bioremediation) of PCP in the groundwater using Oxygen Release Compound (ORC®).

Remediation Approach

- Remediation Objective: Determine the efficacy of using ORC for the reduction of PCP concentrations in groundwater.

- Application Type: Grid (direct-push injection)

- Product: ORC

- Quantity Applied: 1,400 lbs

- Application Rate:

- Upper Aquifer: 6.3 lb/ft

- Lower Aquifer: 3.0 lb/ft

- Product Cost: $14,000

Site Characteristics

General

- Name: DOD Wood Dip Tank Site

- Location: Eastern, VA

- Industry: Wood Treatment

- Contaminants of Concern:

Hydrogeology

- Treatment Area: 5,000 ft2

- Soil Type: Fine to medium sands

- Groundwater Velocity: 0.3 ft/day

- Groundwater Flow Direction: Southwest

- Depth to Groundwater: 5.3 ft

Results

Conclusion

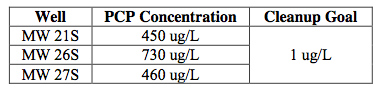

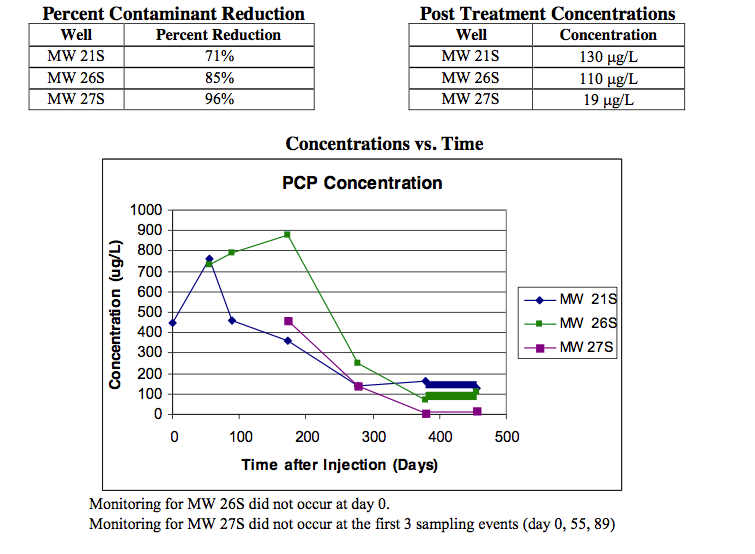

The treatability study performed at the site validated the prediction that ORC-facilitated bioremediation could successfully degrade existing PCP concentrations. After 250 days of observation, sampling of the source well, MW-27S, indicated the successful degradation of PCP by 95.9%. Other wells further from the source also responded well to ORC treatment. Data for each well begins at different time periods following the treatment date because some wells were added after treatment occurred, specifically MW-26S and MW27S. Due to the likely remediation that took place before concentrations were monitored, it is hypothesized that initial concentrations and overall contaminant reduction in MW-26S and MW-27S were higher than existing data indicates. Therefore, it is assumed that the ORC treatment could have performed even better than data indicates.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español