Combined approach to remediate chlorinated solvents in Cambridge, UK

In Situ Chemical Reduction (ISCR), Enhanced Reductive Dechlorination (ERD) and bioaugmentation used on active construction site to allow redevelopment to be completed

Summary

This site is currently undergoing redevelopment from a former industrial estate and trade park, into a business park. The underlying groundwater is impacted with chlorinated solvents from an adjacent industrial site. REGENESIS provided an in situ approach that could provide full reductive dechlorination of the contamination from a single injection, allowing redevelopment to occur during the remediation period.

This site is currently undergoing redevelopment from a former industrial estate and trade park, into a business park. The underlying groundwater is impacted with chlorinated solvents from an adjacent industrial site. REGENESIS provided an in situ approach that could provide full reductive dechlorination of the contamination from a single injection, allowing redevelopment to occur during the remediation period.

1m reading time

Application

It was decided that a combination of In Situ Chemical Reduction (ISCR) using Chemical Reducing Solution (CRS) and Enhanced Reductive Dechlorination (ERD) using 3-D Microemulsion (3DME) as well as bioaugmentation with Bio-Dechlor Inoculum Plus (BDI+) would be applied at this site. This combined approach was designed to provide rapid contaminant degradation, minimised daughter product creation and long term treatment from the single injection. The treatment used seven direct push injection points to accurately target the contamination in a heterogeneous gravels, sands and clay.

What’s Special?

- The ISCR, bioaugmentation and biostimulation approach was used to optimise the remedial approach by combining:

- Wide radii of influence to minimise the number of injection points required

- Rapid onset of ERD

- Minimisation of daughter product creation

- Long-term treatment from a single application

- The application took only one day, with remediation occurring in situ, allowing the site development to continue unimpeded.

In Situ Treatment of Chrome(VI) Plume in Fast Flowing Aquifer, NW Italy

Summary

A former chemical manufacturing plant in northwest Italy was due for demolition to allow redevelopment into residential properties. Site investigations showed elevated concentrations of Cr(VI) in the groundwater, which were above the stringent National Standards of 5μg/L, requiring remedial works to be completed. The groundwater under the site is aerobic and fast-flowing, causing the contaminant plume to migrate beyond the site boundary. It was decided that an in situ approach was required to remediate the Cr(VI) prior to sale of the site.

A former chemical manufacturing plant in northwest Italy was due for demolition to allow redevelopment into residential properties. Site investigations showed elevated concentrations of Cr(VI) in the groundwater, which were above the stringent National Standards of 5μg/L, requiring remedial works to be completed. The groundwater under the site is aerobic and fast-flowing, causing the contaminant plume to migrate beyond the site boundary. It was decided that an in situ approach was required to remediate the Cr(VI) prior to sale of the site.

3m 28s reading time

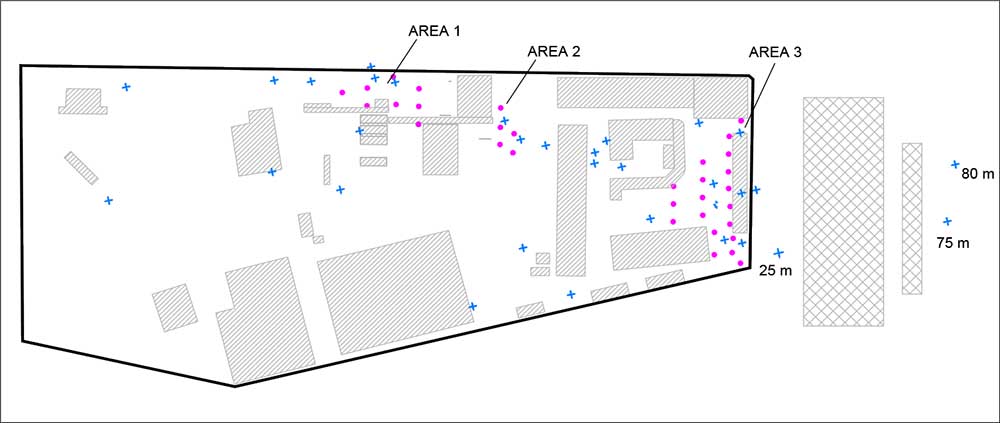

Site plan showing treatment areas, injection wells (pink) and monitoring well (blue) locations

Remedial Approach

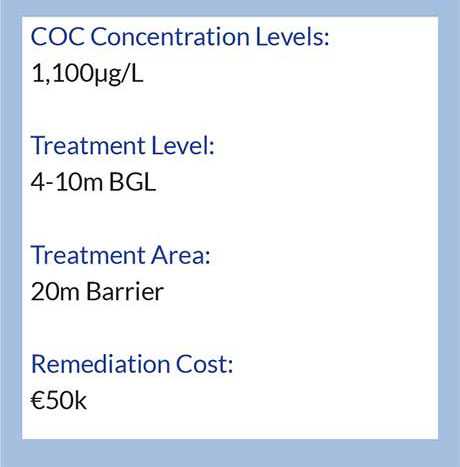

Two areas within the plume were identified as being above the site remediation target of 100μg/L. These were targeted with an injection of 3D Microemulsion (3DMe) and MRC in order to reduce the soluble Cr(VI) to non-toxic solid Cr(III) and stabilise it within the aquifer matrix.

The dose of MRC was tailored to match the vertical distribution of the contamination in order to provide the most accurate and cost effective treatment. 3DMe relies upon micellar transportation following injection in order to provide a wide radius of influence from each injection location. This was important on this deep site, in order to minimize the number of injection points required on the site.

Fixed injection points were installed and a single application of the reagents was completed. The injectable substrates were combined at a central mixing location and then pumped into several injection points simultaneously. The process was repeated until the all of the target areas were treated.

Reagent mixing and injection into fixed wells

3-D Microemulsion (3DMe)®

3DMe provides an immediate, mid-range and long-term, controlled release supply of hydrogen (electron donor) to rapidly create and then sustain anaerobic conditions. This will reduce the Cr(VI) to Cr(III), which will then settle out as a solid. Reversion to natural conditions following the 3DMe treatment (in perhaps five years or more) will not cause this process to reverse.

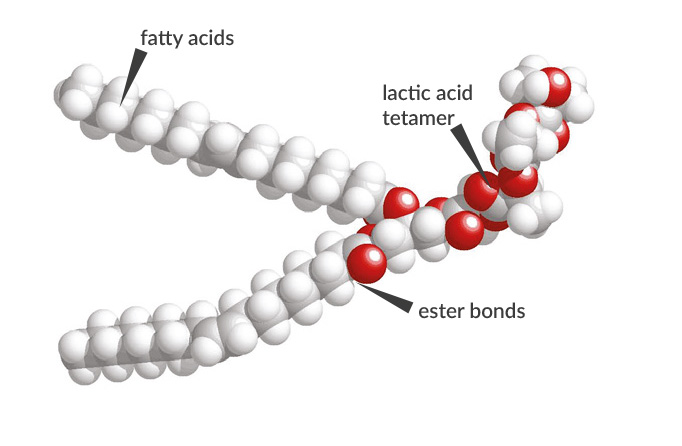

3DMe is also designed to distribute over very wide areas from each injection point. This is achieved through the molecule having hydrophilic and oliophilic properties hence upon mixing with water, 3DMe forms a microemulsion made of tiny micelles, which propagate through and coat the aquifer. This micelles are also able to transport MRC molecules within them, creating a wide and effective treatment zone, which is then sustained for many years.

Metals Remediation Compound (MRC)®

MRC is a controlled release remediation product designed specifically for the treatment of hexavalent chromium (Cr(VI)) in groundwater. MRC’s active compound is an ester of cysteine (a sulfur-containing amino acid) on a carbon backbone molecule of glycerol and sorbitol. A cysteine-based product such as MRC is well suited for in situ Cr(VI) immobilisation, since it has a strong affinity for metal contaminants and does not alter the properties of the subsurface. The active compound in MRC (sorbitol hexacysteinate) is embedded in a polylactate matrix that provides a carbon source and electron donor for subsurface bacteria. This combination of materials makes MRC a viscous but injectable material that slowly releases the cysteine ester to a contaminated aquifer via hydrolysis by water or enzymatic action by microbes. MRC’s slow release property allows for a longevity of 12 to 18 months in an aquifer, allowing for an effective approach to metals immobilisation.

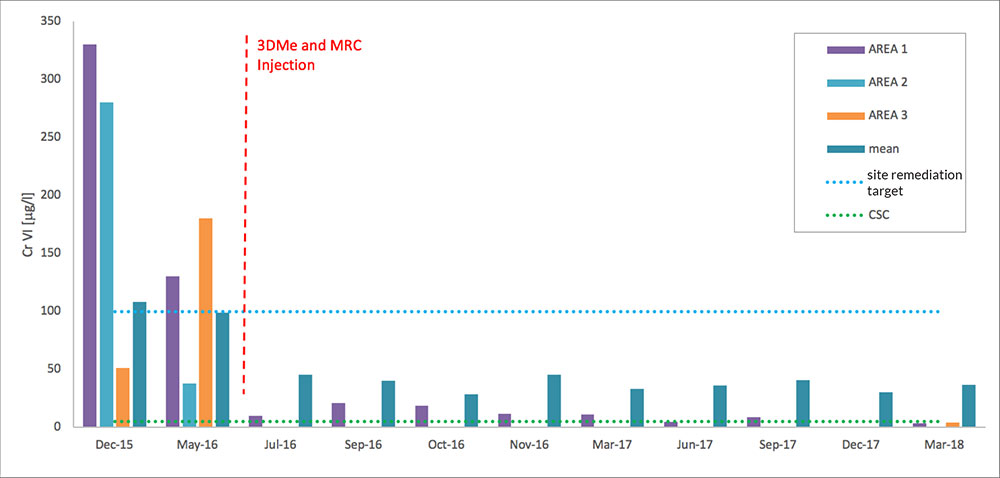

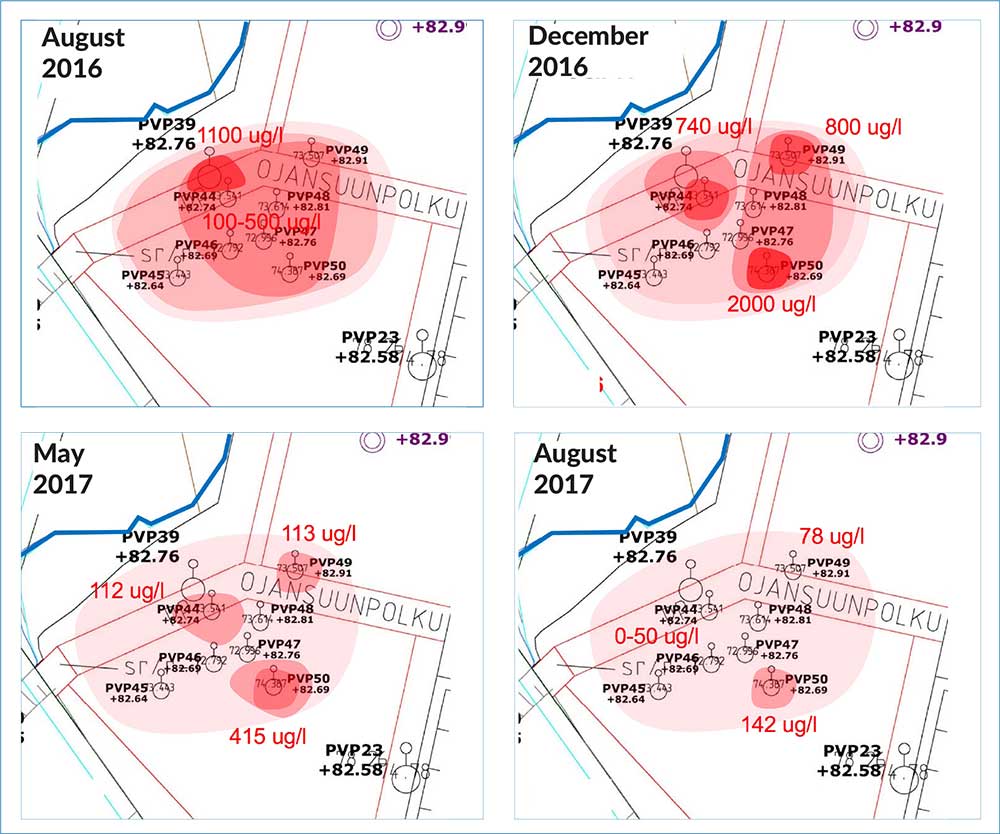

Chromium VI concentrations in groundwater before and after treatment.

Area 1 and 2 need to reach the site remediation target, Area 3 needs to reach CSC

Results

Validation monitoring shows very good substrate distribution at all but one out of thirteen monitoring points. The reduction of the Oxidation- Reduction Potential (ORP) and dissolved oxygen with the simultaneous increase of the Total Organic Carbon (TOC), as well as an increase in iron and manganese, clearly showed the desired trend. The analytical results showed a rapid and significant reduction of CrVI targeting values often below the 5 μg/l limit, with a removal efficiency of 90% on average.

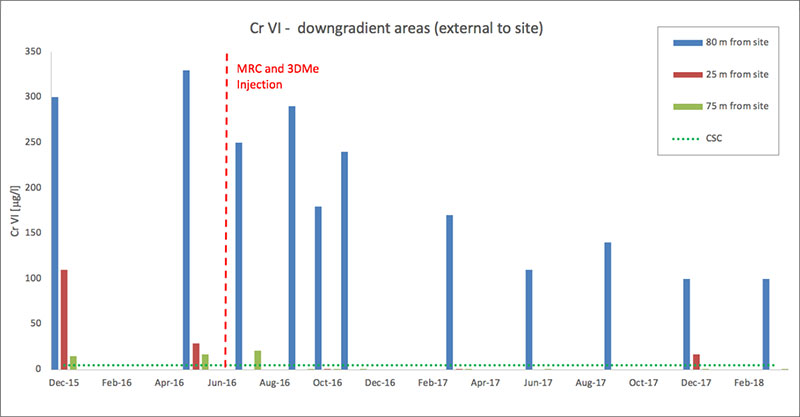

Downgradient Chromium VI concentrations at 25m (red), 75m (green) and 80m (blue) from the site

What’s Special?

- The ability of 3DMe to self-distribute over a wide radius of influence from each injection point allowed the injection grid to be widely spaced. This minimised the number of application wells, which, given the depth of the treatment, greatly reduced the remedial costs.

- Treatment of Cr(VI) was very rapid and sustained despite the aquifer being very aerobic and fast flowing.

- Even though the aquifer was very fast-flowing, the products have not suffered from wash-out and continue to successfully treat the target areas over an extended period of time.

- The seasonal variation in groundwater level at the site has the potential to mobilise contaminants into the groundwater during periods of high precipitation. The longevity of the reagents allows this contaminant influx to be addressed and avoid rebound.

- The injection technology selected saved money by avoiding the use of clustered-wells. The injection rate was high, saving time on site.

- The results of the remediation can be seen over 20m downgradient, through a significant reduction of Cr(VI) in offsite monitoring wells, providing rapid benefit to the environment on and off the site.

Successful 12-Month Pilot Trial of Enhanced Reductive Dechlorination

With RGS Nordic and Nordic Envicon

Introduction

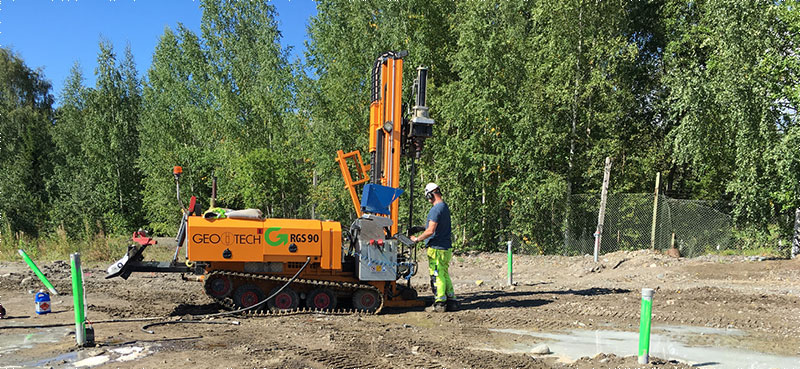

![]() REGENESIS were approached by RGS Nordic and Nordic Envicon to form part of a specialist team to design a remedial scheme for a former aerospace factory in Finland.

REGENESIS were approached by RGS Nordic and Nordic Envicon to form part of a specialist team to design a remedial scheme for a former aerospace factory in Finland.

An area of over 100,000m2 is impacted by a chlorinated solvent plume in the groundwater, comprising predominantly cis-1,2-dichloroethylene (DCE) contamination. The first phase of these works comprised a pilot trial, to demonstrate the applicability and efficacy of the suggested treatment method ahead of full-scale deployment.

An area of over 100,000m2 is impacted by a chlorinated solvent plume in the groundwater, comprising predominantly cis-1,2-dichloroethylene (DCE) contamination. The first phase of these works comprised a pilot trial, to demonstrate the applicability and efficacy of the suggested treatment method ahead of full-scale deployment.

Download the PDF 2m 21s reading time

Remediation Approach

The site had many challenges that needed to be overcome in order to deliver a cost-effective scheme of works:

- Complex heterogeneous formation, comprising sands, gravels, silts and crystalline bedrock;

- Extremely large plume (>100,000m2 of which 60,000m2 requires treatment);

- Conflicting seasonal groundwater flow directions;

- Full-scale works will be required to deliver a fully remediated site within two years.

After completing an in-situ remediation option appraisal the team agreed that the full-scale strategy should comprise a series of ‘barriers’ (treatment zones through which groundwater would continue to flow, but in which the contamination would be degraded) perpendicular to groundwater flow.

This configuration would minimize the number of injection points, reducing application costs, without compromising treatment efficiency. The electron donor which was suggested was 3-D Microemulsion® (3DMe).

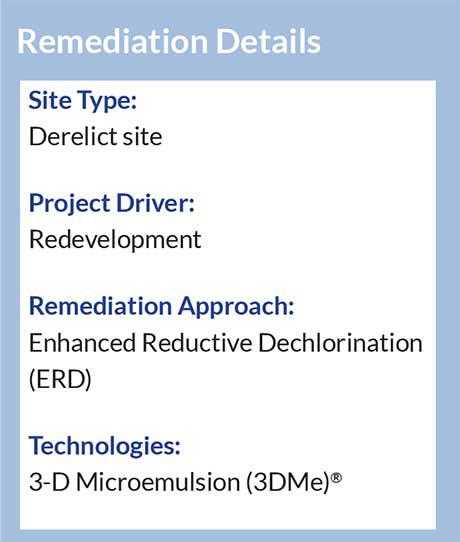

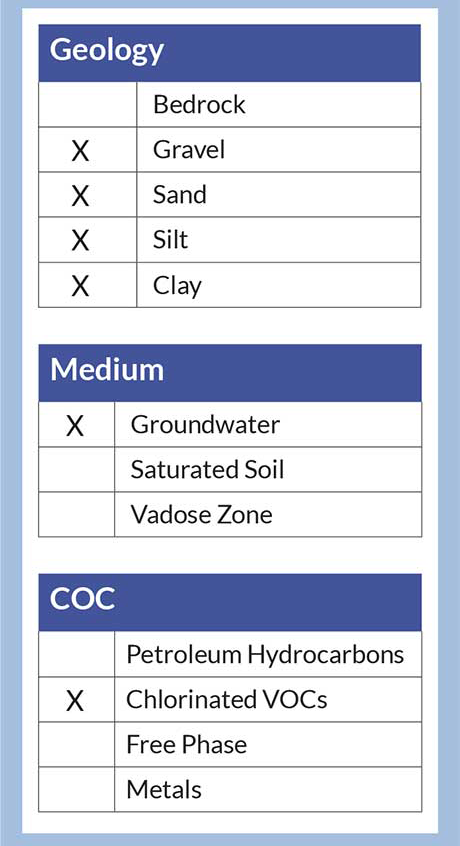

Fig. 1 – The molecular structure of 3-D Microemulsion

Fig. 2 – The 3 Stage Release profile of 3DMe

3DMe provides three stages of electron donor release from a single concentrate of specially designed polar molecules. When mixed with water on site, 3DMe forms a high-volume microemulsion, without the requirement of emulsifiers.

Upon injection into the groundwater, 3DMe initially moves out into the formation and adsorbs to the soil particles. As the molecule is designed to be appropriately soluble, it then gradually dissolves back into the groundwater, where it ferments to drive enhanced reductive dechlorination (ERD), but also reaches its critical micelle concentration (300 ppm), reforms as a microemulsion and moves further out from the injection point.

This process repeats to ‘self-distribute’ the 3DMe over large distances within the subsurface, without it washing away. This mechanism allows for wider injection spacing which reduced the number of injection locations.

Fig. 3 – 3DMe micelle representation

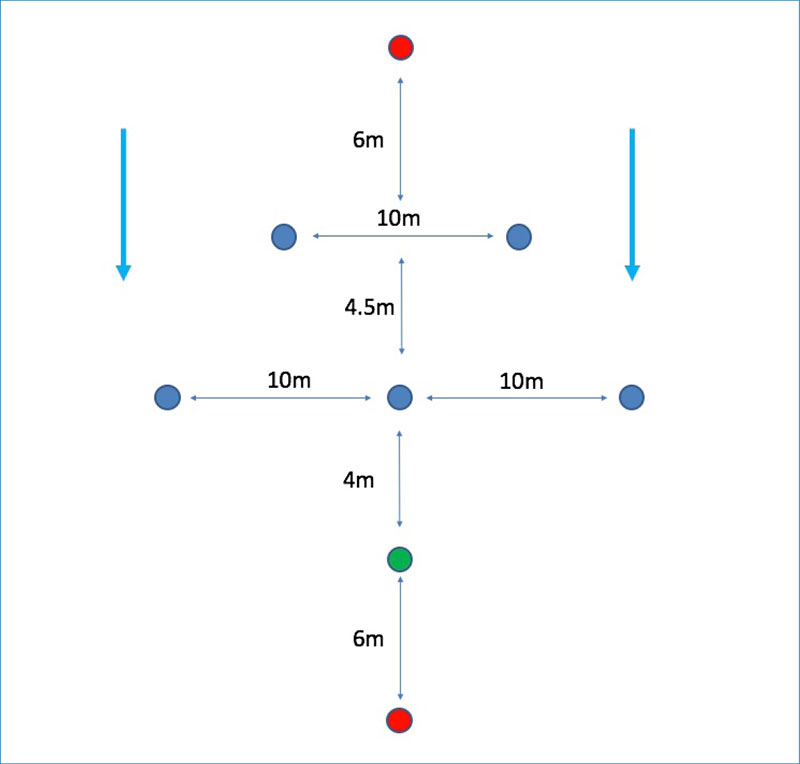

Fig. 4 – Injection configuration

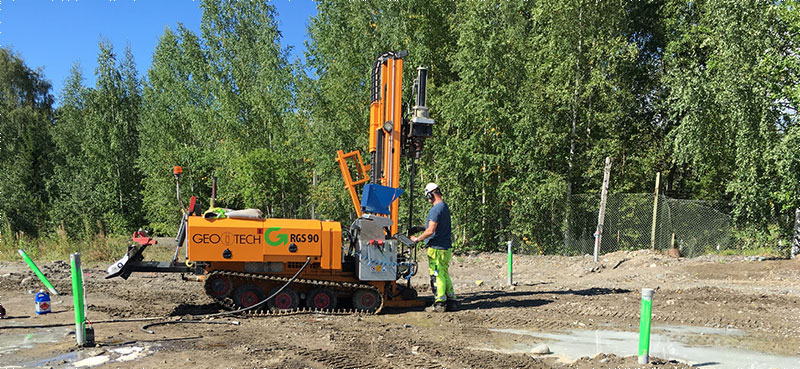

Pilot Trial Application

Prior to a full-scale application being completed, it was determined that a pilot test should be completed. The intention was to determine how well the heterogeneous formation would accept the application, verify the injection spacing and confirm the efficacy of the treatment. A 20m wide barrier was installed perpendicular to groundwater flow. This consists of 5 injection points, forming two rows with 10m spacing within the rows and 4.5m in between rows (see fig. 4) This created an effective injection spacing of 5m perpendicular to groundwater flow.

Direct push injection was used, with the requisite dose of 3DMe injected at each location from 4m BGL (groundwater level) to 10m BGL (top of the competent bedrock).

Fig. 5 – Injection works on site

Fig. 6 – Injection works on site

Results

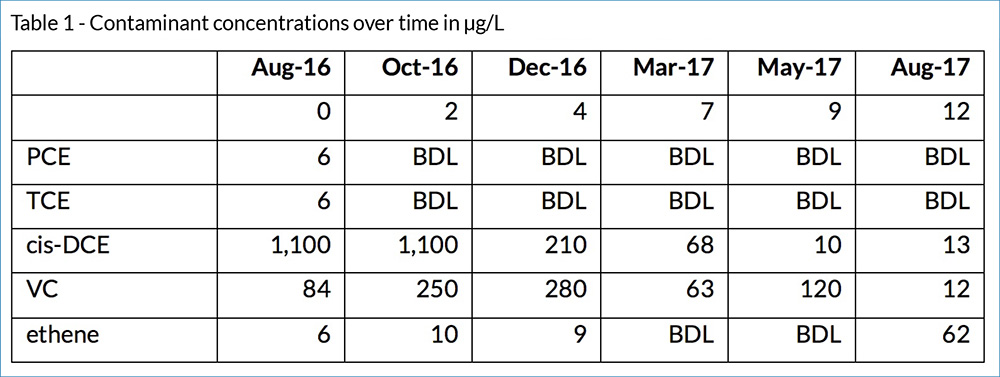

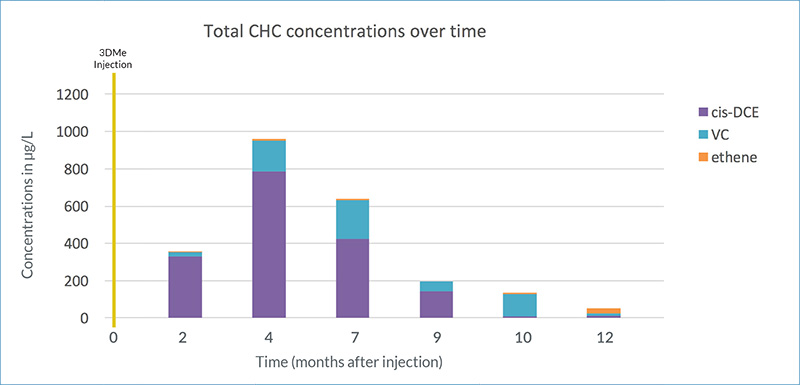

Validation was completed over 12 months following application. During this period the small amounts of PCE and TCE were reduced in the groundwater to below detection limit. The main cis-1,2-DCE contamination was reduced by 99% to 13μg/L, well below the remedial target of 500μg/L. Sequential production and degradation of daughter products showed that full reductive dechlorination was achieved, with vinyl chloride (VC) concentrations peaking at 280μg/L, but then quickly decreasing to 12μg/L by the end of the validation period. Full reductive dechlorination was also evidenced by the production of ethene throughout the treatment.

Fig. 7 – Contaminant concentrations plots in target area over time

Fig. 8 – Total CHC concentrations over time

Conclusion

- The pilot trial demonstrated the ability to apply 3DMe on a wide grid in a heterogeneous formation.

- The treatment successfully reduced the contaminant of concern by 98%, well below the remedial target values.

- Full reductive dechlorination of the contaminant was achieved.

- The pilot trial allows for the full scale treatment to be accurately designed and programmed.

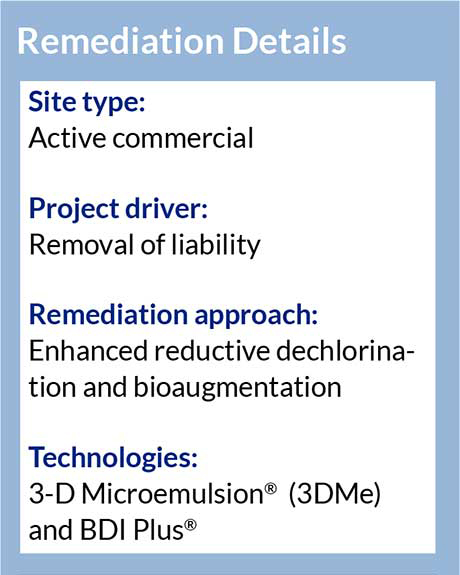

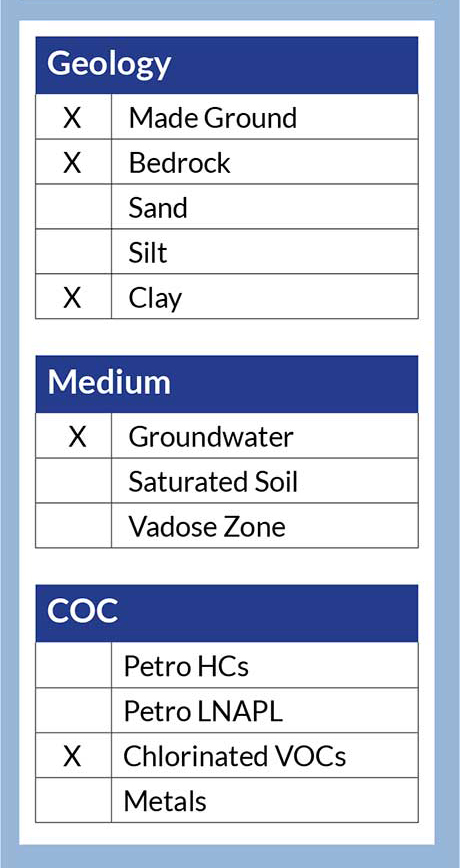

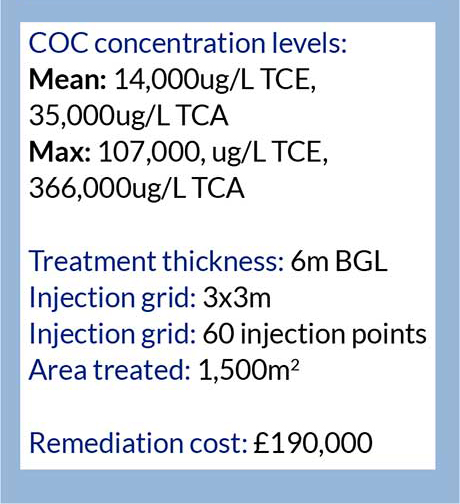

Treatment of mixed chlorinated ethenes and ethanes at an active site, UK

Introduction

REGENESIS was approached to offer an in situ remedial solution to address high levels of mixed chlorinated solvent (TCA and TCE) contamination of the groundwater at a site in northeast Scotland. At the time, an ongoing DPVE system was operating, but was unable to achieve the remediation goal of a 75% reduction in chlorinated solvent mass. Furthermore, a supplementary MIP investigation showed that there was more contamination at depth (>6m) which the DVPE system was not able to reach.

Download pdf2m 42s reading time

Fig. 1 REGENESIS Remediation Services applying 3DMe and BDI Plus on site

Fig. 1 REGENESIS Remediation Services applying 3DMe and BDI Plus on site

The initial design was based on treatment between 3 – 9m BGL of the aquifer across a 1,200m2 using 3DME and BDI with the preferred method of application being direct push injection. However, during the MIP investigation progression of the rods deeper than 6mBGL was found to be difficult. This raised concerns that (1) direct push injection would not be able to reach 9m BGL and (2) injection of the required dose of 3DMe may not be possible. REGENESIS were therefore asked to undertake a pilot study over a limited area to demonstrate that the works were possible. This was completed successfully and also showed excellent dose response and demonstrated to the site owners that the works (which were completed at night) would not have a deleterious effect on their operations.

Full Scale Application

The pilot trial was conducted over two days (see figure 1) during which the direct push injection rig had no problems getting the injection rod to the required depth of 9m BGL (unlike the MIP). Furthermore, the required volume of 3DMe was accepted by the aquifer with minimal daylighting/surfacing.

Following the MIP and pilot, the fullscale design was tailored to provide the most cost effective approach for the site. 60 direct push injection points were completed over 10 nights, with no disturbance to the site operations.

The direct push injection points were centred on BH 11, a pre-existing well, to ensure we had good baseline data. Both BH11 and the surrounding wells were monitored over 8 months to assess the effect and distribution of 3DMe.

Results

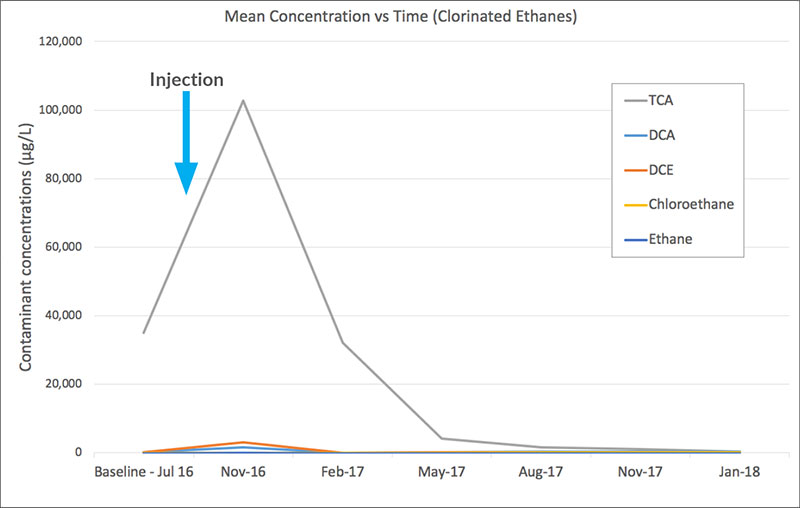

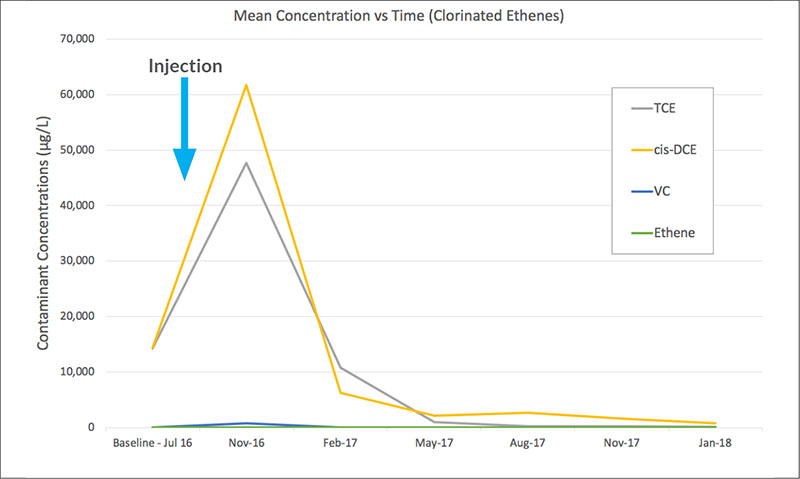

Following the injection works, quarterly validation monitoring was completed. Post injection monitoring showed no inhibition of parent compound degradation due to the mixed halogenated compound plume. 98% and 99% reduction in mean concentration of TCA and TCE respectively.

Full reductive dechlorination was achieved with no build up in daughter products (see fig 2 and 3). The validation curves suggest that both biotic and abiotic degradation occurred.

Fig. 2 Mean concentrations of Chlorinated Ethanes over time

Fig. 3 Mean concentrations of Chlorinated Ethenes over time

Abiotic degradation occurred through the production of reduced iron species by the production of low redox conditions created by the 3DMe.

What’s Special

- A limited pilot study was used to prove the practicality and efficacy of the proposed approach. This area did not require further injection, so added little extra cost to the remediation of the site.

- Bioaugmentation using BDI+ avoided any inhibition of either chlorinated ethenes and ethanes by ensuring that the microbial consortia contained viable counts of dehalogenating bacteria specialising in either contaminant group.

- Very high levels of contamination, suggestive of DNAPL, were reduced to very low concentrations within 18 months.

- No build up of degradation products occurred, showing full reductive dechlorination was achieved and sustained.

- No disturbance of the onsite operations occurred during the limited injection time onsite, with the remediation occurring under the site as it continued to function normally.

- Remediation goals were achieved.

Fig. 4 REGENESIS’s team onsite

Advanced Remedial Technologies Restore Neighborhood

Former Michigan Industrial Site Treated Using Combined Remedy Approach

This case study reviews a former plating facility in southwest Michigan that had released chlorinated volatile organic compounds (cVOCs) into shallow groundwater, resulting in a ¼-mile long contaminant plume. In response, the Michigan Department of Environmental Quality (MDEQ) and the environmental firm, DLZ, implemented a combined remedy which included mitigating vapor intrusion in the residential basements and treating the groundwater plume with a novel, multi-phase in situ bioremediation approach.

- Application of combined REGENESIS technologies to biodegrade contaminants, prevent further plume migration, and protect occupants from the threat of vapor intrusion.

- Reduction of the total cVOC plume extent by 95% and reduced mass by 99.8%.

- Positive results indicating the degradation process is ongoing and processing.

8m 54s reading time

In Situ Treatment of Dichloroethene and Vinyl Chloride in Brussels, Belgium

Integrated remediation allows for redevelopment of historic industrial site. Read the case study.Read More

Site Goals Achieved Within Two Months

A Former Santa Barbara Manufacturing Facility Treated Using a Combined Remedy Approach

This case study reviews a contaminated manufacturing site in Santa Barbara, California. A former manufacturing operation had left PCE and TCE contaminant levels above regulatory limits with previous remediation approaches attempted without complete success. Applying a combined remedy approach, Haro Environmental chose to focus on incorporating a design to rapidly reduce contaminant concentrations for sustained treatment, and reduce the potential for further downgradient migration of the PCE and TCE contaminants.

This case study reviews a contaminated manufacturing site in Santa Barbara, California. A former manufacturing operation had left PCE and TCE contaminant levels above regulatory limits with previous remediation approaches attempted without complete success. Applying a combined remedy approach, Haro Environmental chose to focus on incorporating a design to rapidly reduce contaminant concentrations for sustained treatment, and reduce the potential for further downgradient migration of the PCE and TCE contaminants.

This case study features the following:

- This site has been an active case since 2007. REGENESIS was able to eliminate the contaminant quickly and effectively using a combined remedy approach.

- After conducting a pre-field remediation test, the injection interval was reduced from 12 feet to 9 feet with a bottom-up approach, reducing the project costs by 30%.

- The combination of PlumeStop, HRC and BDI+ successfully eliminated the contaminants and created conditions for sustained treatment at the site.

5m 22s reading time

In-Situ Bioremediation at a French Airport in Southwest France

Successful standalone treatment of a large plume with difficult site conditions. With a longevity of minimum 4 – 5 years, 3DMe was selected to remediate the site from a single application. This removed the need for further application on this busy factory site.

and allowed the contamination within the overlying clay layer to be addressed, avoiding a rebound due to back-diffusion.Read More

Remediation of Chlorinated Hydrocarbons at Manufacturing Facility, UK

AECOM successfully applied a phased treatment train solution for chlorinated solvents under an operational manufacturing facility. After an initial Dual Phase Extraction (DPE) phase, REGENESIS and AECOM devised a remedial design based on the updated Conceptual Site Model including In Situ Chemical Oxidation (ISCO) using RegenOx®, and Enhanced Reductive Dechlorination (ERD) using HRC®, to treat the residual contamination in groundwater.

Read More

Treatment of a Diverse Range of Contaminants, Emilia Romagna, Italy

Treatment of a very low permeability geology with mixed contaminants at varying concentrations, using multiple application methods and a range of different REGENESIS products.Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español