Combined Remedies Treatment Results in a $650,000 Cost Savings for End User

Project Highlights

- By implementing this strategy with a clear path to closure, KERAMIDA saved their client approximately $650,000 versus the alternative containment plan. KERAMIDA’s sophisticated and aggressive remedial approach matched the technologies (ISCO, ISCR, ERD) to the technical challenges at the site.

- PCE was virtually eliminated in most other impacted wells, and continued evidence of reductive dechlorination is ongoing.

- Project currently in the monitoring phase to establish plume stability for closure.

Project Summary

A PCE spill from a 55 gallon drum in the late 1980s contaminated a manufacturing site in Indiana. Contaminated soil was excavated in the spill area and a pump and treat interceptor system was installed downgradient of the plume. The system continued to operate intermittently throughout the 1990s. A previous consultant had submitted a remediation work plan proposing the use of a permeable reactive barrier. However, the plan was rejected because the intended goal was remedial closure, not containment. KERAMIDA proposed a combined in-situ chemical oxidation (ISCO)/enhanced reductive dechlorination (ERD) approach focusing on the spill area (source) and the downgradient, on-site plume, with a small injection off-site. The remediation plan was approved and the injection was completed in November 2013. KERAMIDA’s cost to closure is likely to be achieved for less than $500,000 – saving $650,000-800,000 over the life of the project. (The rejected remediation plan from the previous consultant had an estimated cost of $1.3 million with no plan for closure.)

Remediation Approach

The combined remedies treatment included an initial application of PersulfOx® Catalyzed Persulfate in the source area with subsequent applications of 3D Microemulsion® (3DME), BioDechlor INNOCULUM® Plus (BDI-Plus) and Chemical Reducing Solution (CRS®). In addition, 3DME and BDI-Plus were applied in two downgradient areas of the plume. Groundwater monitoring performed in the eight months since injection indicates dramatic reductions in PCE concentrations. Within the source area, an initial PCE concentration of approximately 70,000 ppb was reduced to 278 ppb (with a corresponding increase in cis-1,2-DCE, which is currently being degraded). PCE was virtually eliminated in most other impacted wells and evidence of reductive dechlorination is ongoing.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

CRS is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

In Situ Chemical Oxidation of Chlorinated Solvents Using Persulfox™ At An Industrial Site

Overview:

Chlorinated compounds were discovered in shallow groundwater at a former industrial site in Attleboro, Massachusetts. With total VOC concentrations as high as 85,000 ug/L in groundwater, a rapid and aggressive remediation approach was required. In Situ chemical oxidation (ISCO) using PersulfOxTM – catalyzed persulfate was selected to treat a portion of the impacted area which was approximately 35’ long x 35’ wide x 15’ deep and primarily comprised of sand. Three prescribed injections of ISCO using PersulfOx were performed over a 7- month period.

- PersulfOx is a persulfate based ISCO reagent that promotes rapid and sustained in situ oxidation of a wide-range of organic contaminants.

- This patented technology utilizes a unique catalytic surface on which oxidants and contaminants react in a process known as “surface mediated oxidation.”

- PersulfOx also contains built-in activation which eliminates complex and potentially hazardous chemical addition required to achieve traditional persulfate activation.

- From a health and safety aspect, the use of PersulfOx alone is safer than traditional activation methods such as heat, chelated metals, hydrogen peroxide or base.

- If warranted, PersulfOx can also be activated through traditional means to achieve site remediation goals.

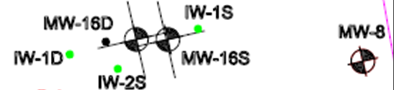

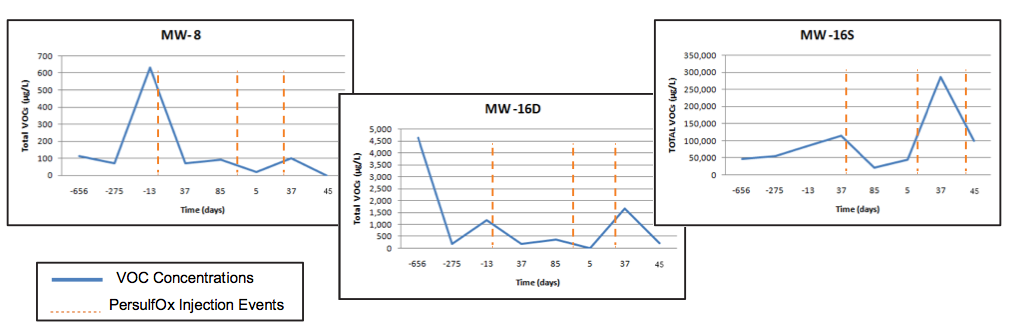

Figure 1. Injection wells and monitoring wells

A 10% solution of PersulfOx in water was mixed and injected into a 10-foot treatment thickness using 3 injection wells within the vicinity of monitoring wells MW-16D, MW-16S and MW-8 (Fig.1).

Results:

After each PersulfOx application, an anticipated increase and subsequent decrease in VOCs (resulting from subsurface disturbance and contaminant desorption) was observed. After the 3 prescribed applications of PersulfOx, 2 of the treatment zone wells, MW-16D and MW-8, measured significant VOC removal, 81% and 99% respectively. Treatment zone well MW-16S (the most highly impacted—starting at 85,000 ug/L) showed a significant increase in VOCs after the first 2 injections (indicative of the liberation of soil bound mass). After the third application of PersulfOx, VOC concentrations in MW-16S were clearly decreasing (see figures below).

Combined Remediation Approach – Dual Phase Vacuum Extraction with In Situ Chemical Oxidation

Introduction

When redevelopment of an old service station was proposed, site investigations revealed a significant petroleum hydrocarbon impact within the soil and groundwater. The subsurface contamination threatened to derail the redevelopment program and a rapid remediation strategy was needed to reduce concentrations to acceptable levels. Geo2 Remediation was contacted to remediate the site in order to allow safe development for luxury residential properties while ensuring no impact to local protected controlled waters.

Figure 1. Successful Site Remediation Leads to Luxury Residence Redevelopment

Project Background

Geo2 Remediation carried out the treatment of a former service station following historic leakage from underground storage tanks (USTs). The tanks had been removed prior to the beginning of the site investigation. Free product was discovered at the surface of the saturated zone and elevated concentrations of total petroleum hydrocarbons (TPH) were observed within the groundwater. Concentrations of TPH as high as 290 mg/L were discovered within the source area.

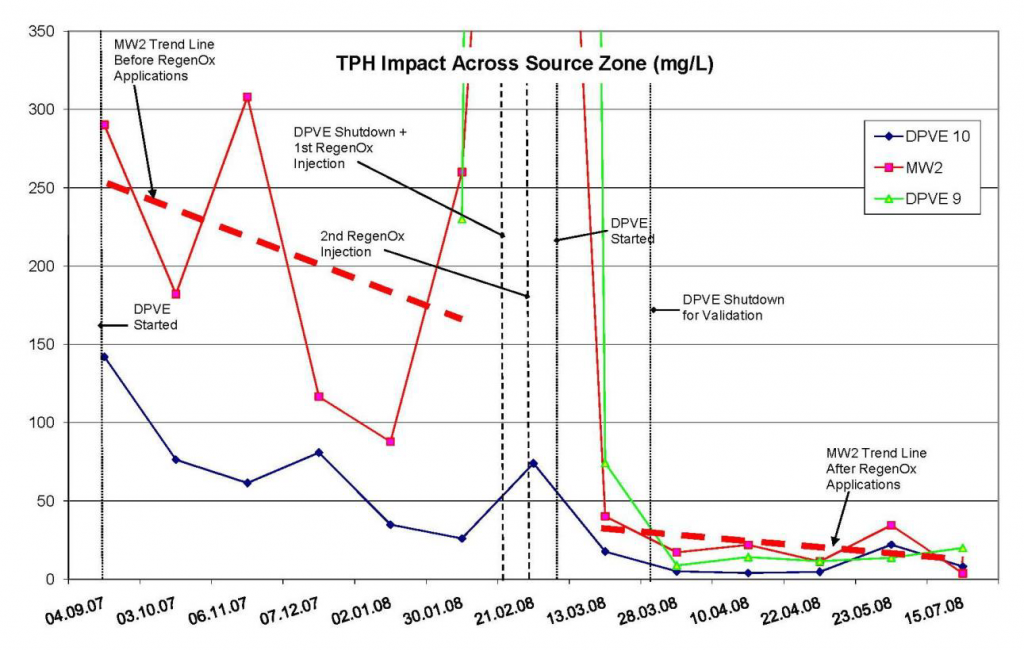

In Situ Physical Remediation

Geo2 Remediation installed a dual phase vacuum extraction (DPVE) system, designed to rapidly remove phase separated product identified on the surface of the groundwater. The DPVE system began treatment in September 2007. Thicknesses of free product up to 50mm, identified around the former tank farm, were removed within 1 month of commencing treatment. Within the groundwater, TPH concentrations were reduced to between 300 mg/L and 150 mg/L over a 5-month monitoring period. In order to increase the efficiency of the DPVE system, Geo2 augmented the physical treatment system with RegenOx to provide a rapid reduction in soil and groundwater concentrations and allow redevelopment to proceed on schedule.

Combined In Situ Physical Remediation and Chemical Oxidation

Geo2 Remediation applied RegenOxTM, a safe and easy to apply proprietary in situ chemical oxidation (ISCO) designed to provide rapid concentration reduction of contaminants without a violent exothermic reaction or other handling difficulties common to ISCO reagents. RegenOx was injected into the subsurface around the dissolved phase impact following DPVE system shutdown using a direct-push injection rig. Two applications were completed within one week of each other using a modest dose of 326 kg RegenOx to achieve sorbed-phase desorption and partial chemical oxidation of the residual hydrocabons. The DPVE system was then restarted to remove the resulting desorbed contamination and partially oxidised hydrocarbon species from the groundwater – this enabled the Reagent requirements to be kept to a minimum (i.e. partial contaminant oxidation rather than full contaminant oxidation) whilst capitalising on the use of the DPVE system already in place. The total cost of the RegenOx application – including all fieldwork – was approximately £ 5,000, the cost of one month’s DPVE operation at the site.

RegenOx® Basics

RegenOx® is a proprietary two-part chemical oxidation product developed and sold by Regenesis for in situ groundwater treatment. It combines the use of a controlled-release percarbonate-based oxygen compound with a proprietary multi-part catalyst to generate surface-mediated free-radical generation and contaminant oxidation (e.g. perhydroxyl radical, hydroxyl radical and superoxide radical), with reactive power comparable to that of Fenton’s reagent but with greatly facilitated handling and subsurface delivery / longevity (up to 30 days). This provides an effective contaminant oxidation reaction without violent exothermic reaction, and can therefore be handled using a wide range of standard field equipment (e.g. direct push injection rigs) or applied directly to excavations. Furthermore, it is alkaline and can therefore be used in calcareous formations in addition to sands and gravels etc.

RegenOx-enhanced Contaminant Desorption

RegenOx has been designed as a bespoke remediation product to provide advantages in usage and application over commodity chemical products used for ISCO (e.g. permanganates, persulphates, peroxides). One of the design features it includes is reduced losses onto the aquifer matrix, commonly known as the matrix Natural Oxidant Demand (NOD). This is achieved by RegenOx through a powerful desorption / surfactant effect of the combined product (principally the catalyst) that draws the contaminant off the soil surface and into solution / onto the catalytic surface where localised free-radical generation occurs leading to focused contaminant destruction. This restricts the oxidant losses onto tightly bound and heavier soil organics such as humics, roots, and other natural or immobile fractions. At the same time, RegenOx is purely inorganic therefore adding no organic surfactant to the system that may prevent a competitive oxygen sink to on-going contaminant biodegradation.

The present project makes use of this product feature to combine in situ chemical oxidation with enhanced physical mass recovery. RegenOx-desorbed contaminant mass and partially oxidised (more soluble) organic species are recovered via groundwater abstraction using the DPVE system, whilst further contamination is destroyed in situ by oxidation.

Results

Upon completing the RegenOx applications, desorption from the highly impacted soils produced a temporary increase in groundwater hydrocarbon concentrations to a maximum of 4,800 mg/L. One week after the second application was completed, the DPVE system was re-started, rapidly reducing the TPH concentrations in the groundwater to an average of 20 mg/L. The improved efficacy of the DPVE system can be seen in Graph 1 where the linear trendline of MW-2 before and after the RegenOx applications shows a conservative 80% reduction in contaminant concentrations within two months – effectively increasing the DPVE efficiency by more than 500% at this stage in its operation. Once the DPVE system was switched off, further monitoring showed that there was no rebound in groundwater hydrocarbon concentrations due to the augmentation process successfully reducing the sorbed TPH concentrations of the soils.

RegenOx Treats #2 Fuel Oil Plume Beneath Residential Home

CASE SUMMARY

Home Heating Oil, New Jersey

A 550-gallon leaking underground storage tank (UST) containing #2 fuel oil was removed from a single family residence in New Jersey (Figure 1). In addition, the surrounding soil was excavated and sampling was performed to determine the extent of the petroleum hydrocarbon plume within soil and groundwater. The plume was delineated at approximately 1,800 ft2 with

concentrations of total petroleum hydrocarbons as high as 40,000 parts per million (ppm) in soil and approximately 40,000 parts per billion (ppb) in groundwater. An estimated 20% of the plume was determined to be located beneath the home itself, eliminating the option for extensive soil excavation. Other remedial strategies such as pump & treat, monitored natural attenuation, and enhanced fluid recovery were ruled out as they did not provide a timely, cost-effective solution.

Figure 1. Residential Site

- Soil Type: Fine to Medium Sands

- Treatment Thickness: 5 to 12 feet bgs

- Free Product: 1” to 3” observed

- Contaminants of Concern:

- TPH – Total Petroleum Hydrocarbons

- TVOC – Total Volatile Organic Carbon

- TSVOC – Total Semi-Volatile Organic Carbon

| Contaminant | Concentration |

| TPH – soil | 40,000 ppm |

| TVOC – gw | 7,900 ppb |

| TSVOC – gw | 40,000 ppb |

REMEDIATION TECHNOLOGY

In Situ chemical oxidation (ISCO) using RegenOxTM was chosen as the most appropriate technology to treat the soil and groundwater plume. In addition, an application of a slow-release oxygen compound, ORC Advanced®, was applied following RegenOx to stimulate aerobic biodegradation of any residual contaminants. RegenOx was applied based on the following:

- Least disruptive to the homeowner

- Successful track record

- Feasible site conditions – sandy soils and a shallow water table paired well with direct-push injection

- Low natural organic carbon in saturated zone

- Safe to use and easy to apply

Ten permanent injection points were installed around the source area, at the edge of the plume and beneath the house in the crawl space as seen in Figure 2. During the installation, free phase product was observed in monitoring wells at approximately 1 to 3 inches. The NJDEP’s Permit-by- Rule prohibited the injection of any remediation technology should free product be present. Once the removal was complete, RegenOx could be applied as designed.

CONTAMINANT PLUME TREATMENT

Free Product Removal

The free product was removed using a mild surfactant and a high powered vacuum extraction truck within the source area. This process also effectively distributed the surfactant across the impacted zone for further desorption of contaminants from the soil matrix. Three free product recovery events were performed which effectively removed all free product from the wells and surrounding areas. TVOC concentrations in groundwater dropped only slightly as a result of the free product removal. However, concentrations of TSVOCs more than doubled in groundwater as a result of desorption from soil.

ISCO Injection for TPH Reduction

The application design included two RegenOx injection events and a third combined RegenOx and ORC Advanced injection for on-going biostimulation to treat residual contaminants. Using temporary and permanent injection points, a total of 6,210 pounds of RegenOx was applied from 5 to 11 feet bgs. The third injection included 650 pounds of ORC Advanced.

Conclusion

No free product, sheen or film was observed after the injections were completed (Figure 5). Levels of dissolved oxygen 30 days following the final application were measured at approximately 10-20 ppm indicating the presence of ORC Advanced in the subsurface.

Within 6 months, significant reductions in petroleum hydrocarbons were observed. TVOCs declined from 7,900 to <50 ppb and TSVOCs were reduced from 40,000 to <150 ppb. Further Action status from the NJDEP. The site is currently seeking No Further Action status from the NJDEP.

Turn-Key PCE Plume Remediation on at Michigan Superfund Site

Former Manufacturing Facility Treated with 437,000 Pounds of PersulfOx® in 18 Days

Project Highlights

- PersulfOx was selected over other persulfate activation methods because of its inherent health and safety benefits and easy-of-use.

- An aggressive application schedule was implemented to satisfy stakeholders – 37,800 lbs (15,500 gallons) of PersulfOx were injected in a single day.

- On-site diagnostics conducted by RRS confirmed PersulfOx distribution throughout the targeted treatment area.

- The project was completed ahead of schedule and on budget.

- The site was left with minimal impact to the PGA Championship Golf Course.

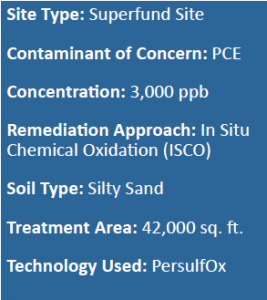

Project Summary

A former manufacturing facility in Western Michigan was redeveloped into an active golf course. The USEPA took over responsibility for cleanup of the chlorinated solvents that remained. Regenesis Remediation Services (RRS) was contracted by a leading consulting fi rm to implement a remediation design to address the chlorinated VOC plume with concentrations as high as 3,000 ppb. PersulfOx was selected over other persulfate activation methods such as hydrogen peroxide or alkaline activate on because the built-in catalyst minimized hazardous materials handling allowing for a safer and easier application. This was especially important because of the treatment areas close proximity to a sensitive receptor (river). Despite persistent freezing temperatures, RRS was able to finish this project ahead of the projected schedule. The RRS team faced a unique challenge on this site as it is a PGA Championship Golf Course which required extreme caution while injecting on the course. Strategic injection point placement, equipment staging, and surface protection via mats were just a few of the techniques implemented by the team

Remediation Approach

The 18-day injection event included 437,000 pounds of PersulfOx which was applied through 129 injection points in a grid pattern 5-30 feet below ground surface. The team used two direct-push injection machines to apply PersulfOx into eight points injection simultaneously.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate componentand generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español