In Situ Chemical Oxidation Treats High TPH Concentrations

Over 114,000 Pounds of PersulfOx® Applied to Illinois Manufacturing Facility

Project Highlights

- High levels of TPH and TCE were detected on-site after a suspected cutting oil/degreasing solvent spill.

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility.

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site.

- Tight treatment deadline met through the use of PersulfOx in 2,204-pound SuperSacks, which were delivered within a few days’ notice.

Project Summary

An Illinois metal fabrication manufacturing facility has been in operation since the early 1900s and is still active today. The use of cutting oils and degreasing solvents lead to high levels of TPH and TCE on-site. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent waterbody. A mechanical oil recovery system was installed and absorbent booms were used to mitigate the oil from reaching the river. ISCO was selected as the remediation approach to address the contamination below the active facility through a series of applications. Additionally, the TCE area was treated with PersulfOx® via injection wells and a soil mixing application.

Remediation Approach

Prior to the start of remediation activities, the primary consultant was removed from the project and a new firm was brought in. The remediation firm placed a tight deadline (a couple of months) to complete the full scope of activities. REGENESIS was able to assist with keeping the project on-deadline through the delivery of 2,204-pound PersulfOx SuperSacks, which were delivered within a few days’ notice. The consultant had a series of injection wells installed inside and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation, and Oxygen Release Compound (ORC®) Advanced Pellets will be used as a long-term oxygen source for enhanced bioremediation of the residual TPH.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

Regenesis Remediation Services™ – TCE Plume Treated with Combined Remedies

Wisconsin Manufacturing Facility Remediated with RegenOx®, 3-D Microemulsion ®

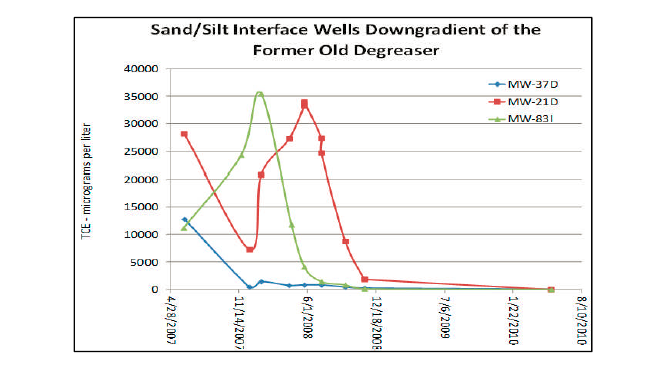

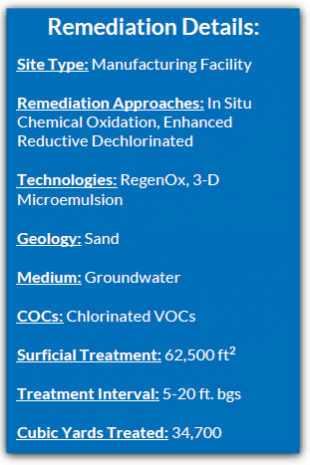

A stainless steel tube manufacturing facility and their environmental consultant, Symbiont, selected Regenesis as a team member to assist in the design and implementation an in situ chemical oxidation and ERD remediation plan. The goal was to reduce trichloroethene (TCE) in source area groundwater over a 1.5 acre site from as high as 110,000ug/L to less than 10,000 ug/L using RegenOx, then transition to ERD. RegenOx® was applied through injection wells over three to five applications from 11/2007 to 6/2008. Five month later, ERD was started using 3-D Microemulsion® in this sandy surficial aquifer.

Successful Performance-Based Remediation Program at DOD Facility

Former Air National Guard Base in Ohio Treated for High TCE Levels

Project Highlights

- Highly technical design included three different remediation approaches requiring 105 injection points

- 87,000 lbs of PersulfOx successfully applied while not impeding operations at active military site

- Treatment area included injections through an 18-inch-thick concrete tarmac

- State-of-the-art mixing and application equipment allowed for optimal reagent injection in sub-zero temperatures

Project Summary

REGENESIS Remediation Services (RRS) partnered with an environmental consulting firm on a performance-based contract for a Department of Defense site remediation project in Ohio. A TCE plume was detected below the Air National Guard base with concentrations as high as 14,000 ppb. REGENESIS designed the remediation program and performed turn-key application services, including on-site treatment of excavated soils, in situ chemical oxidation through galleries within the subsurface, and injection points across the 16,000-square-foot plume. All operations were accomplished within an active military installation and included injecting through an 18-inch-thick tarmac into a sandy aquifer.

Injections took place during the winter months in below freezing conditions. RRS used heaters around the water supply and utilized their heated trailers to prevent the product and water from freezing. Over the course of two injection events, over 80,000 pounds of PersulfOx® Catalyzed Persulfate was applied to the contaminated area. Three application areas called for different remediation approaches with three horizontal injection galleries below a former excavation, nine injection wells down 27 feet below ground surface and a grid of 105 injection points around a hot spot source area. An additional 7,000 pounds of PersulfOx was applied to the bottom of the excavation site to treat the impacted soil. Application monitoring data collected throughout the field work documented the area of influence impacted by each application point.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

Employing a highly technical remediation strategy, RRS successfully applied PersulfOx to three different areas using targeted remediation approaches resulting in performance-based remediation goals sequentially being met and ensuring a high level of client satisfaction.

Combined Remedies Treat Chlorinated Solvents at Gulf Coast Superfund Site

Former Industrial Facility and Landfill Pilot Test Shows Rapid Reduction in PCE, TCE and 1,2 DCE

Project Highlights

- Superfund Site once housed an industrial facility and landfill.

- Rapid reduction needed to avoid off-site migration of daughter products.

- Simultaneous application of Enhanced Aerobic Biodegradation, Bioaugmentation and In Situ Chemical Reduction (ISCR).

Project Summary

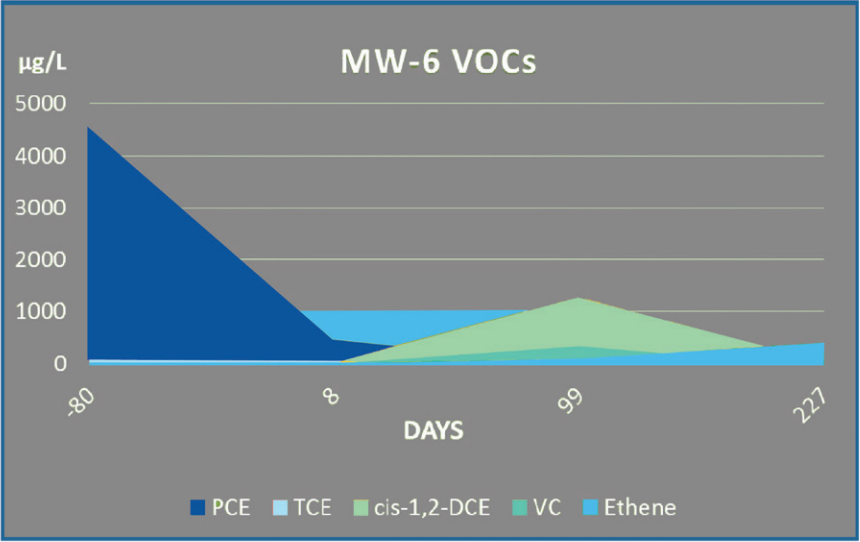

This former industrial property had a landfill that was used in the mid-1900s for disposal of magnesium dross and refractory brick as well as breakout material from electrolytic chlorine cells. As much as 254,000 cubic feet of material were removed from the landfill although a large chlorinated solvent plume remains both from landfill waste below the water table and from industrial operations on-site. A feasibility study for the site was approved in 2012 which evaluated the use of enhanced reductive dechlorination to treat dissolved chlorinated solvents at the site and to prevent off-site migration past the property boundary and beneath a highway. A pilot test to evaluate at least two different biological amendments was conducted and Regenesis supplied 3D Microemulsion, BDI, and CRS for the evaluation. Three aquifers exist at the site, but the pilot test was performed in the first groundwater bearing unit only.

Remediation Approach

After a review of sulfate concentrations, other natural attenuation data, and cVOC concentrations it was determined that the optimal treatment choice would be to test a combination of an electron donor in the form of 3-D Mircoemulsion®, a bioaugmentation culture called Bio-Dechlor INOCULUM® Plus, and the use of Chemical Reducing Solution® (CRS) to prevent any hydrogen sulfide toxicity and to promote a level of beneficial in situ chemical reduction (ISCR). For the pilot test 10 injections points were used to place 800 pounds of 3-D Microemulsion, 18 liters of BDI Plus and 400 pounds of CRS. The product was injected over a 10-foot interval.

The goal for this project was to attain as rapid reduction as possible for the site specifically to avoid off-site migration of daughter products such as vinyl chloride. Therefore, it was deemed beneficial to inject all three proposed products at once. The product was injected in March 2014 and results at roughly 1 month post injection are extremely promising. PCE has been reduced from 134 ppb to 1.57 ppb, TCE from 271 ppb to 1.77 ppb, and cic-1,2-DCE from 235 ppb to 4.25 ppb. Vinyl Chloride has shown some increase from non-detect to 13 ppb.

However, Dehalococcoides has increased from non-detect to 7 x 10×5 cells/bead and vinyl chloride reduced from non-detect to 9 x 10×4 cells per bead which strongly correlates to the rapid enhanced reductive dechlorination.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory emulsified product.

BDI Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

CRS (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

Chlorinated Solvent Concentrations Reduced >100x within Six Months

Enhanced Reductive Dechlorination Used to Treat Former Dry Cleaner in South Carolina Coastal Plain

Project Highlights

- Small groundwater recovery system in place to provide hydraulic control.

- Enhanced Reductive Dechlorination (ERD) treatment selected to achieve site closure more quickly.

- High PCE concentrations reduced by more than 100x within 6 months and remain

- Follow-up treatments enhanced initial injection and contributed to continued dechlorination.

Project Summary

The site, located in the Coastal Plain of South Carolina, was impacted from former dry cleaning operations. A small groundwater recovery system had historically been used to provide hydraulic control, but the site owner wanted to move the site toward closure more quickly. Enhanced Reductive Dechlorination (ERD) with 3-D Microemulsion® was selected based on cost, ease-of-use and expected remediation performance. After the initial injection, PCE concentrations decreased by more than 100x within 6 months of application and remain below 5 ug/L two years after the initial injection.

Remediation Approach

The core of the plume was characterized by concentrations of 14-18 mg/L PCE at baseline plus the full suite of chlorinated ethene daughter products. An initial application of 3-D Microemulsion occurred in June 2011 over a 7,750-square-foot area in the surficial aquifer from 3-25 feet below ground surface. The injections were completed using direct-push equipment into temporary borings on 13-20 foot centers. Based on the success of the initial injection, a follow-up injection was completed in September 2013 over a much smaller footprint (2,200 square feet) to fill in treatment gaps near the upgradient edge of the initial treatment area and to supplement the 3-D Microemulsion in the core of the plume. The follow-up treatment has built on the initial treatment and is contributing to continued depletion of the chlorinated solvents.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Chlorinated Solvents in Soil, Gas, and Groundwater Remediated at Former Manufacturing Facility

No Further Action” Status Achieved at Ohio Brownfields Site

Project Highlights

- Integrated Site Remediation coupling enhanced reductive dechlorination (ERD) and vapor mitigation was implemented to address the immediate risk of vapor intrusion and the long-term risk of identified CVOCs in groundwater.

- Combined remedy approach allowed site to be redeveloped as an apartment complex roughly 6 months following the groundwater treatment.

- “No Further Action” status and covenant not to sue letter was granted in 2013.

- Cost for groundwater water treatment was approximately $10 per cubic yard (product and application) and vapor intrusion mitigation was $3.34 per square foot with no long term O&M required.

Project Summary

The site, a former industrial magnet manufacturing facility in Ohio, received a $2.34 million Clean Ohio Revitalization Fund grant through the Ohio Department of Development in 2011. Site investigation activities identified chlorinated VOCs in groundwater and vapors above the state regulatory limits. Using a combined approach of ERD with vapor mitigation addressed the immediate risk of vapor intrusion and the long-term risk of groundwater impacts. By implementing this strategy, the site was allowed to be redeveloped as an apartment complex roughly 6 months following the groundwater treatment. “No Further Action” status and covenant not to sue letter was granted in 2013. The site currently operates as a residential apartment complex.

Remediation Approach

In the Spring of 2012, ERD using 3-D Microemulsion® and Bio-Dechlor INOCULUM® Plus was implemented within the defined 24,000-square-foot treatment area via direct-push injection. In Fall 2012, the Geo-Seal™ vapor barrier system was installed below a 15,522-square-foot apartment complex raised at the site. The cost for groundwater treatment was approximately $10/cy (product and application) and Geo-Seal was $3.34/sf (product and installation).

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Geo-Seal is a composite system that creates the ideal blend between constructability and chemical resistance by using both high density polyethylene (HDPE) and spray applied asphalt latex.

Active Manufacturing Facility Remediated to Compliance Levels

Extensive Chlorinated Solvents Contamination Treated with Combined Remedies

Project Highlights

- Active manufacturing and low permeability soil caused application limitations.

- Combined use of 3-D Microemulsion®, Hydrogen Release Compound® (HRC) and Chemical Reducing Solution® (CRS) were used for the remediation approach.

- Significant reductions were observed in TCE, DCE and VC post-application.

- Site closure is pending regulatory approval.

Project Summary

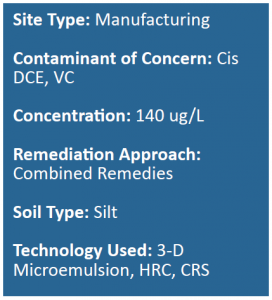

The site, located in Southern New Hampshire, was contaminated with chlorinated solvents in soils, groundwater and surface water beneath and adjacent to a former industrial facility. After investigations to characterize the extent of contamination beneath and adjacent to the industrial facility caused by spills and aggravated by leaks in a storm drain underlying the building, a remedial action was designed and implemented. HRC applications were completed February 2008 and March 2011 to reduce cVOC levels in groundwater. The site had limitations that included reduced access because of active manufacturing inside the building and soil had reduced permeability. Significant reductions were observed in TCE, DCE and VC after the application. However, two wells remained above standards for DCE and VC with the assumption that HRC was not adequately distributed in that area. An application of 3-D Microemulsion® and CRS® was completed in May 2013. Significant reductions of DCE and VC were observed and levels were rapidly brought into compliance.

Remediation Approach

HRC was applied to stimulate the biodegradation of chlorinated solvents. Permanent re-injection points were installed in a grid layout so as to make it easy for re-application without additional construction or drilling activities. Surface water contamination was caused by contaminated groundwater leaking into the storm drain with discharge to the headwaters of a small stream downgradient of the facility. The contamination was addressed by air sparging within the drain pipe near the discharge point but before water discharged to the stream. The discovery of soil contamination causing low level groundwater contamination was addressed by excavating the soil source and disposing the soil off-site.

In the first three years after HRC injection, ¾ of the site was remediated at three source locations. One source area beneath the building exhibited persistent groundwater contamination. The remaining contamination appears to have been caused by poor HRC distribution resulting from underground cement blocks and low permeability soils. 3-D Microemulsion and CRS were injected at two locations surrounding where hot spots of 1,2-DCE and VC persisted at high levels. Recent measurements show significant reductions in the groundwater contamination indicating successful bio-stimulation of chlorinated solvent degraders in the hot spot areas.

Currently the site is under a Groundwater Management Permit which establishes a Groundwater Management Zone with eleven monitoring wells and one surface water monitoring point. Recent monitoring results show dramatic decreases in groundwater concentrations at the location of contamination persistence, and site closure is now projected to occur in the near future.

Technology Description

3-D Microemulsion factory emulsified is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory–emulsified product.

HRC is a controlled release, electron donor material, that when hydrated is specifically designed to produce a controlled release of lactic acid. The newly available lactic acid is critical for the production of hydrogen to fuel anaerobic biodegradation processes in soil and groundwater.

CRS (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

PCE Treated at Active Dry Cleaner in Less Than 200 Days

Project Receives “No Further Action” Letter Following Combined Application of 3-D Microemulsion® and BDI® Plus

Project Highlights

- Enhanced reductive dechlorination used to treat PCE contamination under an active dry cleaning facility

- Total cVOC concentrations reduced by three orders of magnitude in less than 200 days

- Total cVOC concentrations were below remediation goal

Project Summary

Groundwater below a Missouri dry cleaning facility was contaminated from a cleaning solvent spill, resulting in PCE concentrations >4,000 μg/L. An enhanced reductive dechlorination approach was developed that integrated biodegradation and bioaugmentation via application of a controlled-release electron donor and a microbial consortium of dechlorinating bacteria.

REGENESIS® Remediation Services (RRS) was contracted to co-apply 3-D Microemulsion® and Bio-Dechlor Inoculum® Plus to the affected groundwater. The products were applied to the affected groundwater underneath the building via direct-push injections.

Technology Description

3-D Microemulsion factory emulsified is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Results

Following treatment, total cVOC were reduced by 99.9%. Concentrations were reduced by three orders of magnitude from a baseline concentration of >4,000 μg/L to <10 μg/L in less than 200 days.

Furthermore, monitoring data indicated complete dechlorination with no remaining daughter products above the remediation goals. As a result of the rapid and complete reduction of chlorinated solvents, the project received a “No Further Action” letter (NFA) through the Missouri Department of Natural Resources.

| Download the PDF |

Project Receives “No Further Action” Letter Following Combined Application of 3-D Microemulsion® and BDI® Plus

Project Highlights

- Enhanced reductive dechlorination used to treat PCE contamination under an active dry cleaning facility

- Total cVOC concentrations reduced by three orders of magnitude in less than 200 days

- Total cVOC concentrations were below remediation goals

Project Summary

Groundwater below a Missouri dry cleaning facility was contaminated from a cleaning solvent spill, resulting in PCE concentrations >4,000 μg/L. An enhanced reductive dechlorination approach was developed that integrated biodegradation and bioaugmentation via application of a controlled-release electron donor and a microbial consortium of dechlorinating bacteria.

REGENESIS® Remediation Services (RRS) was contracted to co-apply 3-D Microemulsion® and Bio-Dechlor Inoculum® Plus to the affected groundwater. The products were applied to the affected groundwater underneath the building via direct-push injections.

Technology Description

3-D Microemulsion factory emulsified is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Results

Following treatment, total cVOC were reduced by 99.9%. Concentrations were reduced by three orders of magnitude from a baseline concentration of >4,000 μg/L to <10 μg/L in less than 200 days.

Furthermore, monitoring data indicated complete dechlorination with no remaining daughter products above the remediation goals. As a result of the rapid and complete reduction of chlorinated solvents, the project received a “No Further Action” letter (NFA) through the Missouri Department of Natural Resources.

Combined Remedies Used at Historic Illinois Chemical Company

cVOCs in Bedrock Treated at Active Manufacturing Facility

Project Highlights

- Regenesis Remediation Services (RRS) used combined technologies to work toward the shutdown of a pump and treat (P&T) system.

- Previous Enhanced Reductive Dechlorination (ERD) technology applications did not achieve COC reductions.

- Advanced ERD, Bioaugmentation and ISCR remedies were combined and applied into weathered bedrock.

- The project required RRS to be PICS certified. PICS is a contractor prequalification services used many large E&C and fortune 500 companies.

Project Summary

The site is home to an active chemical manufacturing facility with historic spills of cVOCs. Within the contamination impact zones, a groundwater P&T system is being used to mitigate off-site migration of cVOCs in the groundwater. The consultant was seeking ways to turn off the P&T system by treating the plume in-situ. They had previously used an ERD technology without fully achieving primary COC reductions. RRS designed and implemented a pilot study for the site.

Remediation Approach

The pilot study was designed to test Regenesis’ combined remedy approach which incorporated ERD using 3-D Microemulsion, Bioaugmentation with BDI Plus and ISCR with CRS. RRS applied the integrated technologies through direct-push borings. The 2,500-square-foot treatment zone included 10-foot vertical injections into silty sand and clay over weathered dolomite bedrock.

Technology Description

- 3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory–emulsified product.

- HRC Primer is a less viscous version of the standard Hydrogen Release Compound (HRC) product. It is a thinner, water-like compound that is typically injected into an aquifer where it releases lactic acid at a rate faster than standard HRC (several weeks), but at a slower, more controlled rate than dispersing aqueous simple sugar solutions or straight lactic acid (several days).

- Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

- CRS® (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

Combined Remedies Used at Former Chemical Company in Illinois, USA

cVOCs in Bedrock Treated at Active Manufacturing Facility

Project Highlights

- Regenesis Remediation Services (RRS) used combined technologies to work toward the shutdown of a pump and treat (P&T) system.

- Previous Enhanced Reductive Dechlorination (ERD) technology applications did not achieve COC reductions.

- Advanced ERD, Bioaugmentation and ISCR remedies were combined and applied into weathered bedrock.

- The project required RRS to be PICS certified. PICS is a contractor prequalification services used many large E&C and fortune 500 companies.

Project Summary

The site is home to an active chemical manufacturing facility with historic spills of cVOCs. Within the contamination impact zones, a groundwater P&T system is being used to mitigate off-site migration of cVOCs in the groundwater. The consultant was seeking ways to turn off the P&T system by treating the plume in-situ. They had previously used an ERD technology without fully achieving primary COC reductions. RRS designed and implemented a pilot study for the site.

Remediation Approach

The pilot study was designed to test Regenesis’ combined remedy approach which incorporated ERD using 3-D Microemulsion, Bioaugmentation with BDI Plus and ISCR with CRS. RRS applied the integrated technologies through direct-push borings. The 2,500-square-foot treatment zone included 10-foot vertical injections into silty sand and clay over weathered dolomite bedrock.

Technology Description

- 3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory–emulsified product.

- HRC Primer is a less viscous version of the standard Hydrogen Release Compound (HRC) product. It is a thinner, water-like compound that is typically injected into an aquifer where it releases lactic acid at a rate faster than standard HRC (several weeks), but at a slower, more controlled rate than dispersing aqueous simple sugar solutions or straight lactic acid (several days).

- Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

- CRS® (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español