Non-Detect Achieved at Florida Spill Site

This case study reviews a multi-use convenience store site in Panama City Beach, Florida, USA, impacted by contamination from a leaking underground storage tank (UST). PetroFix® Remediation Fluid, a micro-scale carbon suspension with soluble electron acceptors, was applied to reach target goals within 60 days.

PetroFix is successful in high concentration source areas because it provides a permanent, in situ sorptive and biologically permeable reactive barrier (PRB).

Advanced Environmental Technologies, LLC (AET) chose this technology because it offered a cost-effective solution that would quickly address the groundwater concentrations.

This case study features the following:

- Unlike other approaches applied onsite, PetroFix met targets within 60 days and has remained below this target level for a year

- PetroFix was able to degrade the petroleum contaminants within a fast-moving, 150-yard plume

- Due to the successful pilot test results, Advanced Environmental Technologies, LLC (AET) has applied for a full-scale application through the FDEP

PetroFix Successfully Treats Residential Fuel Oil Leak

This case study reviews a residential site in the US, where the groundwater was contaminated with 200 gallons of home heating fuel oil. PetroFix Remediation Fluid reduced the heating oil constituents to below detectable limits, resulting in successful regulatory closure.Read More

PetroFix and ORC Advanced Application into Excavation

This case study reviews a former retail petroleum (petrol station) site in the US, where Antea Group developed an excavation plan including an in situ remediation phase using PetroFix® and ORC Advanced® pellets to address contaminant levels following the excavation and removal of contaminated soil.

This marks the first site where the remediation plan employs applying a mixture of both PetroFix and ORC Advanced pellets at the base of the excavation, along with spray-applying PetroFix to the sides of an excavation pit. Antea Group was tasked with the remediation of the site. Working with the REGENESIS team, Antea Group specified the application of PetroFix in conjunction with the excavation due to the product’s ability to sorb and biodegrade petroleum hydrocarbons.

This case study features the following:

- Success at this site can shape and improve the treatment of other similar sites.

- PetroFix technology allowed Antea Group to design a remediation strategy that was fast, affordable, and highly effective.

Combined approach to remediate chlorinated solvents in Cambridge, UK

In Situ Chemical Reduction (ISCR), Enhanced Reductive Dechlorination (ERD) and bioaugmentation used on active construction site to allow redevelopment to be completed

Summary

This site is currently undergoing redevelopment from a former industrial estate and trade park, into a business park. The underlying groundwater is impacted with chlorinated solvents from an adjacent industrial site. REGENESIS provided an in situ approach that could provide full reductive dechlorination of the contamination from a single injection, allowing redevelopment to occur during the remediation period.

This site is currently undergoing redevelopment from a former industrial estate and trade park, into a business park. The underlying groundwater is impacted with chlorinated solvents from an adjacent industrial site. REGENESIS provided an in situ approach that could provide full reductive dechlorination of the contamination from a single injection, allowing redevelopment to occur during the remediation period.

1m reading time

Application

It was decided that a combination of In Situ Chemical Reduction (ISCR) using Chemical Reducing Solution (CRS) and Enhanced Reductive Dechlorination (ERD) using 3-D Microemulsion (3DME) as well as bioaugmentation with Bio-Dechlor Inoculum Plus (BDI+) would be applied at this site. This combined approach was designed to provide rapid contaminant degradation, minimised daughter product creation and long term treatment from the single injection. The treatment used seven direct push injection points to accurately target the contamination in a heterogeneous gravels, sands and clay.

What’s Special?

- The ISCR, bioaugmentation and biostimulation approach was used to optimise the remedial approach by combining:

- Wide radii of influence to minimise the number of injection points required

- Rapid onset of ERD

- Minimisation of daughter product creation

- Long-term treatment from a single application

- The application took only one day, with remediation occurring in situ, allowing the site development to continue unimpeded.

In Situ pilot remediation of gasworks impacted groundwater, Stockholm, Sweden

Introduction

In the north-east of Central Stockholm, a historical industrial site was earmarked for redevelopment. Part of the site comprised a former gasworks, where historical operations have caused a complex mix of contaminants to impact the surrounding soil, groundwater and shoreline sediments.

The large site is due to be redeveloped in a series of parcels including a road, industrial park, residential homes and schools. Remediation is required to ensure the human health risk is removed as part of the restoration of the site. The impacted groundwater also represents an environmental risk and requires treatment. Risk assessments were used to determine that remediation was required to a depth of 20m BGL. The geology of the site is heterogeneous, comprising a shallow made ground, a clay layer and underlying coarse sands.

The sands are highly impacted with a range of gas works contamination included creosote NAPLs and high levels of benzene. The saturated clays are also impacted with dissolved phase contamination. Due to contaminants, concentrations and superficial geologies, a range of remedial methods would be required to ensure the most appropriate was used in each scenario. Therefore, RGS Nordic engaged REGENESIS to design a series of pilot tests utilising several in-situ methods. The results from these trials would then be used to shape the full-scale remediation strategy for the entire gasworks site area.

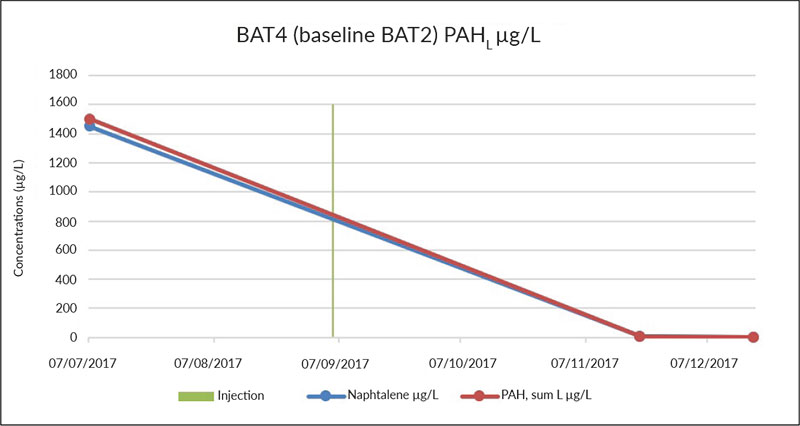

Combined In Situ Remediation Approach and Planning

REGENESIS proposed a pilot-scale combined remediation approach comprising:

- Enhanced desorption using PetroCleanze to target high concentrations of soil-bound contaminants of concern (COC’s) in the sands,

- In Situ Chemical Oxidation (ISCO) using both RegenOx and PersulfOx to target medium to high dissolved phase and soil-bound PAHs in the sandy soil, and

- Enhanced aerobic degradation using ORC-Advanced to target the low dissolved phase benzene and naphthalene concentrations in the clay.

Results

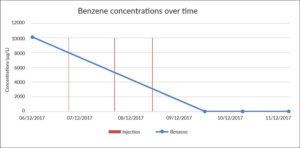

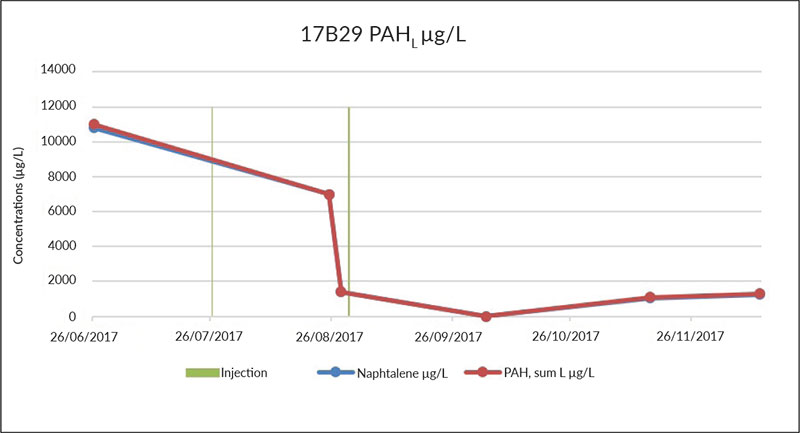

Groundwater samples were collected 3-4 months after the application of REGENESIS remediation products, see graphs 1 to 3. The results are displayed below:

Enhanced Desorption using PetroCleanze

>95% reduction in dissolved phase benzene was achieved with the addition of PetroCleanze. The treatment for PAHs was found to be less effective, primarily due to the low baseline PAH concentrations which were below the optimum treatment concentration range for PetroCleanze.

ISCO using RegenOx and PersulfOx

>90% reduction in dissolved phase benzene and PAHs was observed using PersulfOx. In the RegenOx trial, dissolved benzene concentrations were found to decrease by 80%, while PAH levels increased slightly, potentially due to large volumes of desorbed COCs being released into groundwater post-treatment.

Enhanced Aerobic Biodegradation using ORC-Advanced

A sustained reduction in Naphthalene and benzene (despite suspected influx into the test area) was achieved using ORC-Advanced in the saturated clay.

Conclusion

- A wide range of contaminant concentrations were treated effectively using a combined in-situ remediation approach.

- Substantial reductions in COC concentrations were achieved despite the challenging geological setting.

- The results from the pilot tests show that all areas of the gasworks site can be successfully remediated in-situ using REGENESIS remediation products, providing significant cost savings when compared with conventional techniques

Innovative In Situ Application of PetroCleanze Uses Horizontal Wells

This case study reviews an innovative remediation design at a site that is using two horizontal wells which will administer a total of four injection events, with enhanced fluid recovery (EFR) events being performed before and after each injection. BTEX contamination and free-phase product from a petroleum release was discovered in the groundwater at an active gas station in Colorado. After previous remediation attempts from prior consultants, CGRS, Inc., Paragon Consulting Group, Inc., the Colorado Division of Oil and Public Safety (OPS), and REGENESIS® collaborated to create a design that would successfully remediate the persistent groundwater contamination and free-phase product.

This case study features the following:

- Innovative design and creative solution using horizontal wells to apply PetroCleanze and minimize daylighting

- The horizontal well system allows for the active gas station to continue to conduct business without disruptions

- Staying open during remediation efforts saved gas station owners an estimated $8,000 per day

- PetroCleanze was successfully applied despite the challenging lithology and shallow bedrock

Treatment of site impacted with high levels of petroleum hydrocarbons, Cambridge, UK

Achieving remediation objectives on a busy construction site

Summary

REGENESIS was tasked with the remediation of a former vehicle repair garage impacted with high levels of petroleum hydrocarbons, including some Light Non Aqueous Phase Liquid (LNAPL). Construction of new student accommodation facilities had already commenced on the site when the contamination was discovered. Rapid remediation was needed due to the requirement to complete the construction in time for the start of the new academic year.

The remediation objectives were betterment of the environment through a reduction in LNAPL levels and dissolved phase TPH concentrations. This was to be achieved amongst significant access limitations on the building site and without impacting the construction schedule.

Treatment

Recoverable LNAPL was removed through skimming via wells drilled at the site boundary. RegenOx was then used to chemically oxidise the residual sheen of free product in the wells. An application of ORC-Advanced was also used to provide a controlled release of dissolved oxygen and enhanced aerobic biological degradation of a proportion of the residual dissolved phase contamination.

Recoverable LNAPL was removed through skimming via wells drilled at the site boundary. RegenOx was then used to chemically oxidise the residual sheen of free product in the wells. An application of ORC-Advanced was also used to provide a controlled release of dissolved oxygen and enhanced aerobic biological degradation of a proportion of the residual dissolved phase contamination.

Following a successful pilot comprising injection of RegenOx into 3 fixed wells: 2 full scale injection campaigns were completed comprising injection of RegenOx and ORC-Advanced into a grid of 19 wells located by the site boundary.

What’s Special?

-

Full-scale injection of RegenOx and ORC-Advanced was completed despite considerable access limitations due to construction works.

-

Remediation objectives were rapidly achieved.

-

The works were completed without impacted the construction project programme, during the latter stages of the site redevelopment.

In Situ treatment of toluene in groundwater, Helsingborg, Sweden

Working with multiple stakeholders to complete chemical oxidation and enhanced aerobic bioremediation works

Summary

Multiple historic leakages from stored chemicals on an industrial site led to hydrocarbon contamination of the underlying groundwater, predominantly with toluene. Multiple site investigations indicated that the plume had migrated beyond the site boundary and into land owned by the neighbouring harbour authorities. An initial treatment comprised a pump and treat system which had successfully recovered 14m3 of toluene. However, the contaminant concentrations exceeded the legal limits for less sensitive or industrial land use (Swedish MKM values). Therefore, additional remediation phases were required to address the residual dissolved phase. An in situ remedial approach was chosen, using RegenOx and ORC Advanced.

Treatment

Access for the injection works was limited to two areas: one on the original industrial site, and the other in the harbour downgradient. Both areas comprised operation industrial facilities and were separated by a public road and a railway line associated with the harbour.

Initial pilot trials were completed to assess which treatment options would be most effective for the site. The results demonstrated that RegenOx was the most suitable oxidant to address the elevated sorbed-phase and high concentrations of dissolved phase contamination. In the full-scale works, RegenOx was combined with ORC Advanced. ORC Advanced provides a constant supply of dissolved oxygen to enhance aerobic biodegradation, in order to further reduce dissolved phase contaminant concentrations below the target criteria.

What’s Special?

- Pilot trials were used to determine the best remediation options for full-scale works.

- Engagement with multiple stakeholders to complete remediation of a toluene plume extending over several site boundaries.

- In Situ injection works were completed on two separate industrial facilities without disturbance to their operations.

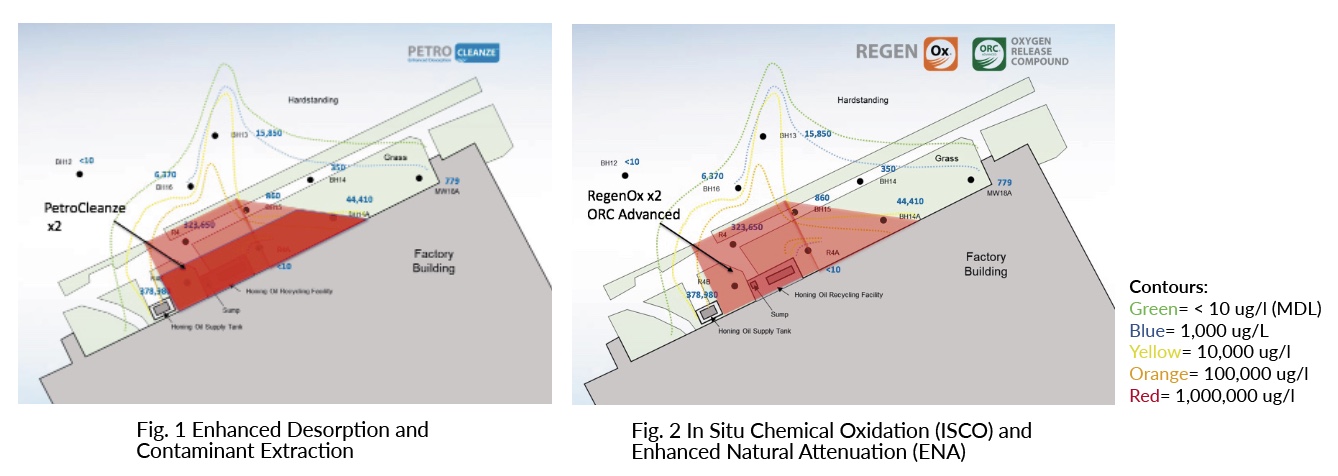

Integrated in situ remediation of honing oil in a chalk aquifer, UK

Summary

At an active factory, the spillage of ‘honing oil’, a heavy oil used as a lubricant in metal machining, occurred in the oil recovery plant on the side of the main building. The oil infiltrated the vadose zone and entered the groundwater via fractures in the weathered chalk under the site. This resulted in high levels of dissolved phase contamination and some Light Non Aqueous Phase Liquid (LNAPL) on the ground. The contamination posed a potential offsite liability for the site owner and so it was determined that active remediation should be voluntarily completed.

Treatment

REGENESIS employed a sequential remedial approach:

Enhanced vacuum extraction of the LNAPL

- To avoid the installation of a pump and treat system on the busy site, 3 mobilisations of a vacuum tanker was used to provide total fluids removal.

- Recovery was enhanced through multiple injections of PetroCleanze, an inorganic, oxidative surfactant.

- This temporarily promoted rapid desorption of the heavy oils adsorbed to the bedrock within the ‘smear zone’.

- By desorbing this contaminant mass, the vacuum extraction was able to remove more mass, shortening the remedial programme.

- This depleted the contaminant mass on the soils, reducing the potential ‘rebound’ due to desorption.

In Situ Chemical Oxidation (ISCO)

- ISCO was completed at the downgradient edge of the treatment area to target high levels of dissolved phase contamination and prevent egress of any contamination mobilized during the PetroCleanze treatment.

- This was completed using RegenOx, which is alkaline and suitable for use in calcareous formations.

- ISCO was also used across the treatment area following the last enhanced vacuum extraction event, in order to target the residual high levels of dissolved phase contamination prior to bioremediation.

Enhanced Aerobic Biological Degradation

- ORC Advanced was injected with the RegenOx in order to create highly aerobic conditions, increasing the biomass of microbes that would aerobically degrade the residual dissolved phase contamination.

- This single application provides a controlled release of oxygen into the groundwater for up to 12 months.

- This treatment targeted the dissolved phase contamination in the mobile groundwater in the chalk fractures and also provided prevention of rebound due to back-diffusion from the contamination located in the primary porosity of the chalk matrix.

Results

The treatment produced a rapid reduction in the contaminant mass on the site. All LNAPL was removed from the groundwater. Dissolved phase concentrations were reduced by 98% through the combination of treatment processes, see graph 3. The contaminant concentrations remained low and rebound was avoided through the depletion of adsorbed mass and contamination within the immobile porosity.

Conclusion

- Enhanced vacuum extraction avoided the installation of abstraction equipment onsite and reduced the treatment programme.

- A combination of approaches targeted each contaminant phase in order to provide the most efficient technique for each level of contamination, from LNAPL to low dissolved phase.

- A rapid and dramatic reduction in the contaminant concentrations was achieved.

- Low concentrations were maintained through the targeting of sources of rebound via desorption and back-diffusion.

PlumeStop® and ORC Advanced® Applications Achieve Successful Results in 24 Hours

4m 35s reading time

Project Highlights

- Successful rapid reduction of petroleum hydrocarbon contaminant concentrations in soil and groundwater completed within approximately 24 hours.

- In Situ injection application of PlumeStop® Liquid Activated Carbon and ORC Advanced technologies assist REGENESIS strategic partner in bringing closure to facility identified as Leaking Underground Storage Tank (LUST) site

- Petroleum hydrocarbon concentrations (PHCs) in groundwater and soil reduced below Washington Department of Ecology’s (Ecology) Model Toxics Control Act (MTCA)

Project Summary

An active gasoline station in Bothell, Washington was listed as a hazardous Leaking Underground Storage Tank (LUST) site by the State of Washington Department of Ecology (Ecology) after two subsurface investigations detected petroleum hydrocarbon-impacted soil and groundwater. Entering into the state’s Voluntary Cleanup Program (VCP) in 2001, the site continuously failed to meet regulatory requirements defined in the Model Toxics Control Act (MTCA), despite years of cleanup efforts using a soil vapor extraction (SVE) system and an air sparge (AS) system to remove contaminant concentrations from beneath the site. Charged with remediation, Antea Group partnered with REGENESIS to implement a solution, which included in situ injection applications using PlumeStop and ORC Advanced technologies.

Technology Applied

PlumeStop – an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation. PlumeStop is composed of very fine particles of activated carbon (1-2µm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and expediting permanent contaminant biodegradation.

ORC Advanced (ORC-A) – an engineered, oxygen-release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils that, upon contact with groundwater, produces a controlled-release of molecular oxygen (17% by weight) for periods of up to 12 months in a single application, accelerating aerobic biodegradation processes up to 100 times faster than natural degradation rates.

Background

Despite the installation of three groundwater monitoring wells (MW-1 through MW-3) in 2002 and five additional monitoring wells (MW-4 through MW-8) in 2003, concentrations of total petroleum hydrocarbons in TPH-g and BTEX in the western portion of the site exceeded the Model Toxics Control Act (MTCA) Method A cleanup levels. In 2004, a soil vapor extraction (SVE) system and an air-sparge (AS) system were installed and by 2005 an estimated 2,076 pounds of total volatile hydrocarbons (TVH) were extracted, with concentrations falling below MTCA Method A cleanup levels for two consecutive quarters. Laboratory analysis of groundwater samples collected during the following two quarters, however, indicated that hydrocarbon compounds in groundwater had increased in several monitoring wells.

Challenge

The AS system was restarted in October, 2005 and operated on an approximate 2-week-on and 2-week-off cycle through February, 2009, when it was shut down based on non-detectable hydrocarbon concentrations in all but one groundwater monitoring well, MW-3. As a remediation strategy to address TPH-g and benzene impacts that remained in well MW-3, sulfate injection was proposed. However, due to high sulfate concentrations observed in the down-gradient monitoring well, MW-9, the sulfate injections were suspended in November of 2012 and evaluations of other chemical injection methods were proposed.

REGENESIS Remediation Services (RRS) recommended PlumeStop injection and completed two soil borings for design verification testing in November, 2015. Soils on-site were primarily sand and gravel, with two, 4-6” clayey silt layers—one at approximately five feet and the other at 10.5 feet below ground surface (bgs). Based on field screening with photoionization (PID), contamination appeared to be concentrated at the 8-9 feet depth interval, a point at which soil increasingly hardens. With results of a laboratory analysis, RRS modified the design, adjusting the vertical treatment interval from 5-12 feet below ground surface to 7-11 feet, with the concentrations and quantities of PlumeStop and ORC-A remaining unchanged.

Solution

REGENESIS Remediation Services (RRS) injected approximately 200 gallons of PlumeStop 6,000 ppm solution into on-site wells IW-1 and SVE-1 December, 2015. Using strategically placed point locations to rapidly reduce contaminant concentrations, Direct Push Technology (DPT) was employed to advance injection points throughout the treatment zone at each respective injection point location. The following day, the solution was increased to 12,000 ppm, for a total of 835 gallons of PlumeStop solution (as applied with water) injected within the targeted treatment interval to deliver the full volume of remediation chemistry and complete the application on schedule.

A total of nine (9) PlumeStop DPT injection points were cleared to 5 feet below ground surface pre-injection, and during the course of the injection seven (7) point locations were advanced to a depth of 11 feet below ground surface and retracted to a depth of 7 feet below ground surface using 1.50 inch outer diameter (O.D) Geoprobe® injection rods with retractable screen tooling.

Additionally, 120 pounds of ORC-A were applied at approximately 30% solution (w/w) in cleared boreholes via a backfilling method, which involved drilling to the target depth, retracting the rods and pouring the ORC-A slurry down open boreholes to approximately 5 feet below ground surface in order to properly abandon points.

Results

During the course of the injection and at the end of the application, increases in groundwater levels were observed in monitoring wells MW-3 and MW-9 in the treatment area. Additionally, increases in ORP (oxidation reduction potential) were observed in MW-2, MW-3, MW-6, MW-7, MW-8, and MW-9. Increases in dissolved oxygen were also noted post-injection in MW-2, MW-3, MW-6, MW-7, MW-8, and MW-9.

The successful and rapid reduction of petroleum hydrocarbon contaminant concentrations in soil and groundwater was achieved within approximately 24 hours, despite difficulty injecting the material via direct-push injection points. With field modifications, RRS was able to not only mitigate surfacing issues by switching to injection via injection well application but also observe the desired distribution of the remediation chemistry in the subsurface.

In the same way the State of Washington Department of Ecology continues to take steps and implement tools that will streamline the cleanup process even further, REGENESIS recognizes the critical need for cost-effective, sustainable and environmentally sound remediation solutions. Whether pioneering new in situ technologies in the lab or rolling up its sleeves in the field to ensure a successful project outcome, REGENESIS remains committed to advancing the remediation industry for the benefit of its partners as well as for the future of the world at large.

How PlumeStop® Brings Sites to Permanent Closure

PlumeStop rapidly removes contaminants from groundwater and stimulates their permanent degradation. This exciting, turn-key solution offers several key benefits for addressing brownfield site treatment, including:

- Rapid reduction of dissolved-phase plumes

- Distribution of widely under low injection pressures

- Achievement of stringent groundwater clean-up standards

- Providing a long-term means of addressing matrix back–diffusion

- Elimination of excessive time and end-point uncertainty associated with groundwater remediation

PlumeStop is composed of very fine particles of activated carbon (1-2µm), suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix, binding to the aquifer matrix, rapidly removing contaminants from groundwater, and expediting permanent contaminant biodegradation. This unique remediation technology accomplishes treatment with the use of highly dispersible, fast-acting, sorption-based technology which captures and concentrates dissolved-phase contaminants within its matrix-like structure. When contaminants are sorbed onto the regenerative matrix, biodegradation processes achieve complete remediation at an accelerated rate, leading to successful site treatment.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español