ISCO Treats High Levels of TCE with Planned Enhanced Bio for TPH Treatment

157,000 lbs. of PersulfOx® Applied to Treat Illinois Manufacturing Facility

Project Highlights

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site

- Tight treatment deadline met through supply of 51 PersulfOx SuperSacks, containing 2,204 lbs. each, which were delivered within a few days’ notice

- TPH soil plume has been reduced by >90% (from 6,111 cubic yards to 555 cubic yards)

Project Summary

An operating metal fabrication facility, located in Illinois, caused subsurface impacts from the use of cutting oils and degreasing solvents. This resulted in high levels of TPH and TCE in soil and groundwater. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent river. A mechanical oil recovery system was installed and absorbent booms were used to stop oil from reaching the river. ISCO was selected as the remediation approach to treat the contamination below the active facility. The TCE area was treated with PersulfOx via injection wells and a soil mixing application with an excavator.

Remediation Approach

Prior to the start of remediation activities, a change in the primary consultant was made and a new consultant was brought in. The new consultant imposed a tight deadline of several months to complete the full scope of remediation activities. REGENESIS was able to assist with keeping the project on-deadline through the timely delivery of 51 PersulfOx SuperSacks, containing 2,204 lbs. each. The PersulfOx SuperSacks were delivered within a few days’ notice. The consultant installed a series of injection wells within and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx® through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation and the application of Oxygen Release Compound (ORC®) Advanced Pellets which will supply a long-term oxygen source of oxygen for enhanced bioremediation of the residual TPH. The client is also evaluating the use of PlumeStop to change the FOC value of the soil for a site specific Tier 3 closure level via MNA for an area that had extremely high TPH values >40,000ppm.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

AZ Superfund Site Uses ISCO to Replace Recirculation Wells Leading to Cost Savings of $100,000

Project Highlights

- 95% reduction of BTEX, MTBE and TMBs reported on-site

- Total savings estimated to be $100,000

- In Situ Chemical Oxidation (ISCO) combined remedy design incorporates PersulfOx® to effectively address reduction in contaminants

Project Summary

A former industrial paint facility in Tempe, Arizona was contaminated with high levels of gasoline in the groundwater. Ongoing active remediation using Accelerated Remediation Technology (ART) was applied to treat high levels of BTEX, MTBE and TMB. However, this remediation approach was unsuccessful in reducing contaminants to cleanup target levels due to the limited radius of influence produced by the recirculation well system. REGENESIS was approached to design an ISCO plan using the existing treatment well infrastructure.

Remediation Approach

REGENESIS injected 10,028 pounds of PersulfOx at a 12% solution in two applications. As a result, a 95% reduction of BTEX, MTBE, and TMBs was reported post-application. The overall PersulfOx ISCO injection treatment totaled $40,000 – a small fraction of the previously deployed ART system cost and equal to four months of the ART system’s operational expense.

REGENESIS Solutions Applied

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

The REGENESIS ISCO plan using PersulfOx contributed to the 95% reduction in BTEX, MTBE, and TMBs while providing significant cost savings to the client in the remediation of this Arizona Superfund site. Use of a combined remedy approach offers clients viable options for achieving cleanup target levels and compressed time to closure.

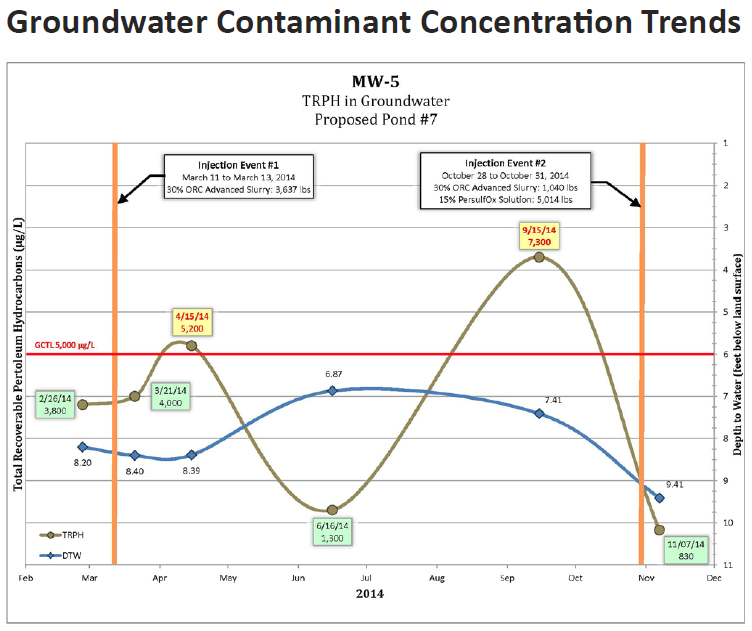

High TPH Concentrations Treated Using PersulfOx® and ORC® Advanced

Future Site of Stormwater Retention Ponds Remediated with ISCO, Enhanced Aerobic Biodegradation

Project Highlights

- Initial treatment with aerobic bioremediation effectively removed 60% of site contamination.

- PersulfOx® and ORC® Advanced were used to treat two remaining hot spot areas.

- Site closure is pending additional groundwater monitoring.

- Contamination concentrations must be reduced to meet stringent groundwater quality standards.

Project Summary

This site is a former commercial facility in the Southeast with high TRPH contaminant impacts to soils and groundwater. The property is currently vacant and the state department of transportation plans to create a stormwater retention pond on site. However, contaminant concentrations in groundwater need to be reduced to meet stringent groundwater quality standards before any construction can begin.

The plume was first treated via enhanced aerobic bioremediation with ORC Advanced, which effectively removed over 60% of the dissolved-phase contamination within 18 months. In two hot spot areas, residual contamination in the smear zone continued to cause impacts to groundwater. A follow-up treatment combining in situ chemical oxidation and enhacned aerobic bioremediation was employed. PersulfOx and ORC Advanced were used to bring this site towards closure by effectively treating these two hot spot areas. Initial sampling results 30 days after treatment showed attainment of groundwater quality standards.

Remediation Approach

ORC Advanced was injected over 60 direct-push locations across two plume areas. A year and a half post-application, two remaining hot spot areas with residual capillary fringe contamination had caused continued issues. PersulfOx and ORC Advanced were used to bring this site towards closure by effectively treating these two hot spot areas.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

PersulfOx® Treats Gasoline Tanker Truck Spill Site

Pilot Study Moved to Full-Scale Application to Remediated Benzene and TPH-G Contamination

Project Highlights

- Pilot study moves to full-scale application after large contamination concentration decrease resulting from in situ chemical oxidation (ISCO).

- High-volume, direct-injection of PersulfOx® ISCO distributes reagent beneath highway.

- ORC Advanced applied to edge of plume to prevent further migration.

- The average reductions of benzene or TPH-G were 83% and 79% respectively.

Project Summary

A gasoline tanker truck rollover occurred in Ringling, Oklahoma resulting in a benzene and TPH-G contamination. A pilot study using PersulfOx ISCO was conducted with up to 98% contamination reduction observed. Upon successful completion of the pilot study, a full-scale application was approved. A series of full-scale ISCO applications commenced to achieve significant knockdown of benzene and TPH-G concentrations at the site.

Remediation Approach

Full-scale PersulfOx injections were focused along a run-off ditch on the east side of the highway where contamination reached the groundwater during the initial spill and also downgradient on the west side of the highway where contamination had migrated.

The intent of injections on the east side of the highway were designed to address source contamination. These injections were also designed to treat the contamination beneath the highway. PersulfOx migrated through the aquifer under the influence of large direct-push injection volumes and a strong underlying groundwater gradient and natural slope of the lower confining bedrock.

Two PersulfOx injections have been completed approximately one month apart while an application of ORC Advanced also was applied in the distal part of the plume to prevent further spreading of BTEX and TPH.

The average reductions of benzene or TPH-G were 83% and 79% respectively. These are encouraging results and indicate beneficial oxidation and mass reduction of fuel hydrocarbon contamination. Ongoing monitoring will determine if additional applications are needed to reach remedial goals.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

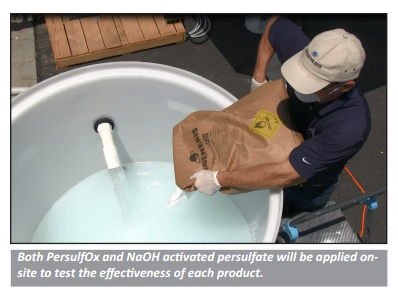

Single PersulfOx® Treatment Reduces MTBE Concentrations by 50 Percent

Project Highlights

- Both PersulfOx and NaOH activated persulfate used on-site to test effectiveness

- Single injection event of PersulfOx resulted in 50% reduction of MTBE

- Backfilled gravel excavation used as a treatment cell for contaminant mass migrating from an inaccessible dispenser canopy toward the property boundary

Project Summary

A gas station in the Washington DC metro area was contaminated with BTEX and MTBE following a release from a dispenser island. High concentrations of MTBE (160 ppm) diffused into the native silty clay and beyond the property boundary. Two persulfate chemistries utilized at the site to evaluate treatment longevity. Persulfate test kits demonstrated that PersulfOx remained active for six months. The PersulfOx® injections were performed within a downgradient former excavation which was backfilled with gravel to intercept the contaminants. The single injection event of PersulfOx resulted in 50% reduction of MTBE. Treatments in the former excavation have also reduced MTBE concentrations at the property boundary.

Remediation Approach

The PersulfOx injection was performed into three injection wells that were located in an excavation that was backfilled with gravel. This gravel backfilled excavation used as a treatment cell for contaminants originating from under the dispenser canopy (upgradient). The goal was to oxidize contaminant mass as it moves through the former excavation toward the property boundary. The native soils consisted of silty clay, which have a low hydraulic conductivity and do not accept injection volumes easily. This approach treats the petroleum bleed-off from the dispenser canopy before it moves downgradient and eventually off-site. The purpose of the project was designed to evaluate performance data where PersulfOx and NaOH activated persulfate were compared for contaminant reduction trends, longevity, and ease of application.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solventtype contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

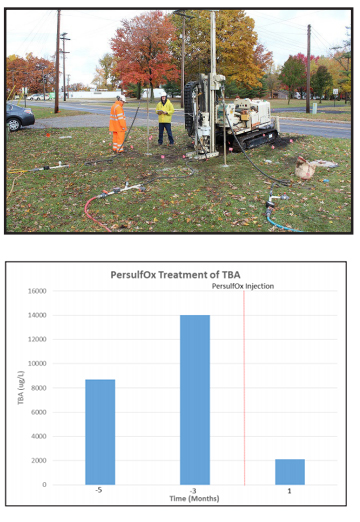

PersulfOx® Rapidly Treats TBA Contamination

Project Summary

Site operations at this manufacturing facility located in New Jersey caused groundwater to be impacted with tert-butyl alcohol (TBA). Previous attempts at site remediation using alkaline activated persulfate had not met performance goals. PersulfOx was subsequently applied in an area of significant TBA contamination resulting in orders of magnitude reductions within just three weeks’ time.

Alkaline Activated Persulfate – Unsuccessful

An initial attempt at remediation using alkaline activated persulfate included a full-scale injection of persulfate and sodium hydroxide (NaOH). This approach was deemed unsuccessful, as sampling after one week showed pH to be below the range required for persulfate activation, leaving significant untreated TBA in site groundwater. Additionally, the large volume of NaOH required for this approach raised concerns of impacting nearby storm sewers.

Remediation Approach

The treatment approach included a grid of six injection points placed 15-feet apart into the sandy aquifer. Each point received >1,800 pounds of PersulfOx across of 5-foot thickness.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant destroying free radicals without the need for the addition of a separate activator.

Results

Following the PersulfOx application, site monitoring indicated a significant reduction in TBA contamination in the target zone. TBA concentrations were reduced from >14,000 ug/L to 2,100 ug/L with a single injection of PersulfOx in only three weeks’ time.

ISCO Treatment Achieves Closure on Arizona Superfund Site

Benzene Contamination Treated to Non-Detect with Single PersulfOx® Application

Project Highlights

- Previous remediation attempts included soil vapor extraction coupled with groundwater pump and treat/air sparging.

- PersulfOx was applied via gravity-feed through existing remediation wells.

- Single application of PersulfOx resulted in benzene reductions of 1,000 ug/L to non-detect.

- Site closure achieved

Project Summary

Persistent benzene contamination at an Arizona Superfund Site kept the state regulatory agency from closing the site. The City of Tucson maintenance yard contained low residual concentrations of benzene around 1,000 ug/L in a single well. An initial remediation approach used soil vapor extraction coupled with groundwater P&T and air sparging, however results did not meet site closure criteria.

When considering alternatives, the State of Arizona wanted to be efficient by using the existing remediation wells. As a result, Regenesis worked with the state to design a PersulfOx application using the existing infrastructure. Regenesis worked with the state to design and assist with the application of PersulfOx® using the existing remediation wells. After one application, benzene contamination levels were non-detect in the offending well and site closure was achieved.

Remediation Approach

The treatment approach was a trial by the State of Arizona to apply PersulfOx via gravity-feed directly into the existing remediation wells to target residual benzene concentrations. By using the existing in situ infrastructure, the cost of the one-time PersulfOx application was less than $15/cubic yard.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Regenesis Remediation Services™ – PersulfOx® Treats Petroleum Hydrocarbons

In Situ Chemical Oxidation and Enhanced Aerobic Biodegradation Remediate Underground Storage Tank Site

Regenesis Remediation Services (RRS) was contracted to design and implement an in situ chemical oxidation (ISCO) treatment plan to remediate a diesel gas plume from a former leaking underground storage tank (UST) on a residential farm property. The defined treatment area comprised approximately 5,280 square feet (ft2), and the treatment of the gas plume included three application events using

PersulfOx®, with the final application immediately followed by an application with Oxygen Release Compound Advanced (ORC® Advanced). A total of 5,840.6 pounds of PersulfOx and 2,589 pounds of ORC Advanced were injected during the course of the project.

Utilizing PersulfOx remediation chemistry to distribute throughout the subsurface, 91 direct-push injection technology (DPT) injection points were advanced every 100 ft2 over the course of three application events. ORC-A was applied in 53 discrete DPT injection points approximately every 100 ft2. RRS utilized both expendable points and retractable screen-tip injection tooling to apply the PersulfOx and ORC Advanced at discrete intervals across the vertical treatment interval from 8 to 12 feet and 8 to 16 feet below ground surface (bgs) within the sandy saturated soils. Low pressures and moderate application rates were utilized to apply the remediation chemistry at up to four (4) injection point locations simultaneously. RRS personnel performed real-time reagent distribution diagnostics to optimize the distribution of the material.

Redeveloped DOD Site Treated with Turn-Key ISCO Remediation

PersulfOx® Applied at Four Locations on Former Air Force Base in Ohio

Project Highlights

- RRS applied PersulfOx in four separate areas of this former air base, including the parking lot of an active business ensuring litlle disturbance to the commercial operation

- RRS was able to redesign the project from the field achieving maximum injection without downtime and cost over-runs

Project Summary

Regenesis Remediation Services (RRS) was contracted to remediate this former DOD facility. Perchlorethene (PCE) levels of 400 ppb were treated with in situ chemical oxidation (ISCO) employing PersulfOx Catalyzed Persulfate technology. The application included two injection events which involved working within an active parking area of an operating business. The original site design included utilizing direct-push injections, but RRS readjusted the plan in the field after product surfacing was observed in one area that was under construction. Despite the redesign, the application was completed ahead of schedule and under budget

Remediation Approach

Two injection events included the application of 50,000 pounds of PersulfOx through 85 injection points per event in a grid design with treatment 18-31 feet below ground surface. RRS had initially designed the project to use only direct-push injection points. But after surfacing was witnessed, RRS redesigned the project to include the installation of five injection wells.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

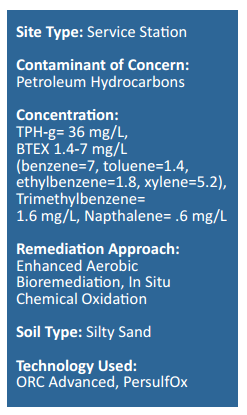

Former Service Station Treated on Native American Reservation Land

Combined Remedies Used to Remediate BTEX Contamination

Project Highlights

- Enhanced Aerobic Bioremediation and In Situ Chemical Oxidation used to treat high BTEX levels on-site

- Previous remediation activities included soil excavation but contamination persisted

- One application area located in lot used for beef cattle on reservation land and special approvals were required

- Project was state-funded by Pollution Liability Insurance Agency (PILA) of Washington but regulated by Region 10 EPA resulting in extensive coordination between both agencies

Project Summary

This Wapato, Washington site was a former gas station with historical releases dating back to at least 1995. It is located on a Native American Reservation so the site is regulated through Region 10 of the EPA.

The initial remedial activities consisted of excavation of source area soil but contamination remained. Considering the persistent contamination, the goal of the site was to reduce the remaining concentrations to meet regulatory goals.

Remediation Approach

A combied remedies strategy was devised for this site, including in situ treatment in three separate areas. Two areas were treated with both PersulfOx® and ORC® Advanced.

The third area was an empty lot that was used for ranging beef cattle. The client had concerns about how the treatment might affect the cattle, so only ORC Advanced was applied to this area because it is both insoluable and non-toxic. Because the entire site was located on reservation land it required special approvals by the tribal irrigation office before the injections could occur. A total area of 4,100-square-feet was treated for high levels of BTEX. Monitoring is ongoing.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español