PersulfOx® ISCO Remediation Reduces BTEX F1 & F2 Concentrations at Alberta Municipal Affairs Site

ISCO Solution Results in Cost Savings and Treatment Area Reduction at Former Service Station

Project Highlights

- In Situ Chemical Oxidation (ISCO) used as a cost-effective alternative to excavation remediation methods

- In Situ treatment using direct push resulted in reduction in treatment area

- ISCO solution met time and budget goals

Project Summary

BTEX contaminated soil was found at an Alberta Municipal Affairs (AMA) site. The former service station located in Central Alberta, Canada had left a petroleum leak creating a smear zone with F1 and F2 concentrations at the source of the plume. Since the AMA site had limited funding and time constraints, a persulfate-based ISCO solution using PersulfOx was recommended to significantly reduce high petroleum concentrations in the soil and groundwater. This site marked the first time the engineering firm working with REGENESIS had employed an ISCO solution, having used excavation remediation methods as their recommended approach in the past. An expedited remediation plan was created and included multiple rounds of PersulfOx injections to treat the site.

Remediation Approach

PersulfOx was applied in seven existing monitoring wells. Working with the engineering firm, using direct-push injection of PersulfOx, REGENESIS strategically focused the application around two of the existing monitoring wells. Due to the saturated soil type and an increased risk for surfacing, precise application-volume monitoring was required. After the first round of two applications was completed, overall contaminant concentrations decreased.

REGENESIS Solution Applied

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

The REGENESIS ISCO plan incorporating direct-push injections of PersulOx significantly reduced the level of BTEX contaminant concentrations following the first round of application. The PersulfOx solution effectively addressed the plume in the saturated smear zone, while meeting the goals of the project, as well as the client’s time and budget constraints.

Former Paint Manufacturing Facility Treated for MIBK, BTEX

RRS Implements Cost-Effective, Turn-Key Remediation in Low-Permeability Soils

Project Highlights

- Soil and groundwater impacted with both BTEX and MIBK.

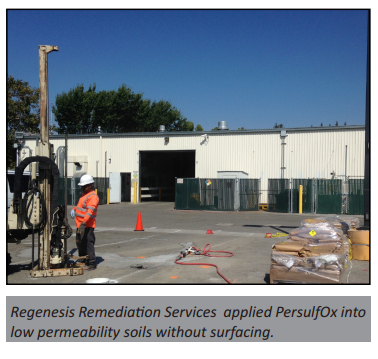

- Low-permeability soil was of a concern to the client, however very little surfacing was witnessed post-injection.

- Regenesis Remediation Services (RRS) finished the project in half the time and nearly half the cost of competing firms.

Project Summary

Site operations at a former paint manufacturing facility in Northern California caused soil and groundwater to be impacted with MIBK and BTEX compounds. The site was under an order for clean-up through the regional water quality board and the treatment was designed to use in situ chemical oxidation (ISCO) to reduce contaminant mass in the source area before transitioning to MNA.

Remediation Approach

Comprised of what the consultant described as “San Francisco Bay Muds” or essentially clay soil with sand stringers, the site had challenging geologic conditions. At first, the client was apprehensive about the ability to inject PersulfOx® into the tight soils without surfacing. However, a turn-key approach was devised during the design of this project, with an emphasis on minimizing product application costs and addressing any possible surfacing issues. A total of 29,644 pounds of PersulfOx was applied by RRS in two applications, through a total of 58 directpush points and 2 injection wells at the site. The product was applied at a 20% solution for a total injection volume of 15,691 gallons.

The injections were completed in half the time and nearly half the cost of what other injection contractor firms proposed. The capabilities of the RRS team, trailer and ability to manifold and inject into four points at one time resulted in significant time and cost savings for the client. Monitoring is ongoing.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solventtype contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

RRS is a dedicated team of scientists and engineers whose primary function is to provide environmental engineering and consulting firms with specialized groundwater and soil remediation planning, design, verification and application services.

In Situ Chemical Oxidation Treats High TPH Concentrations

Over 114,000 Pounds of PersulfOx® Applied to Illinois Manufacturing Facility

Project Highlights

- High levels of TPH and TCE were detected on-site after a suspected cutting oil/degreasing solvent spill.

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility.

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site.

- Tight treatment deadline met through the use of PersulfOx in 2,204-pound SuperSacks, which were delivered within a few days’ notice.

Project Summary

An Illinois metal fabrication manufacturing facility has been in operation since the early 1900s and is still active today. The use of cutting oils and degreasing solvents lead to high levels of TPH and TCE on-site. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent waterbody. A mechanical oil recovery system was installed and absorbent booms were used to mitigate the oil from reaching the river. ISCO was selected as the remediation approach to address the contamination below the active facility through a series of applications. Additionally, the TCE area was treated with PersulfOx® via injection wells and a soil mixing application.

Remediation Approach

Prior to the start of remediation activities, the primary consultant was removed from the project and a new firm was brought in. The remediation firm placed a tight deadline (a couple of months) to complete the full scope of activities. REGENESIS was able to assist with keeping the project on-deadline through the delivery of 2,204-pound PersulfOx SuperSacks, which were delivered within a few days’ notice. The consultant had a series of injection wells installed inside and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation, and Oxygen Release Compound (ORC®) Advanced Pellets will be used as a long-term oxygen source for enhanced bioremediation of the residual TPH.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

Successful Performance-Based Remediation Program at DOD Facility

Former Air National Guard Base in Ohio Treated for High TCE Levels

Project Highlights

- Highly technical design included three different remediation approaches requiring 105 injection points

- 87,000 lbs of PersulfOx successfully applied while not impeding operations at active military site

- Treatment area included injections through an 18-inch-thick concrete tarmac

- State-of-the-art mixing and application equipment allowed for optimal reagent injection in sub-zero temperatures

Project Summary

REGENESIS Remediation Services (RRS) partnered with an environmental consulting firm on a performance-based contract for a Department of Defense site remediation project in Ohio. A TCE plume was detected below the Air National Guard base with concentrations as high as 14,000 ppb. REGENESIS designed the remediation program and performed turn-key application services, including on-site treatment of excavated soils, in situ chemical oxidation through galleries within the subsurface, and injection points across the 16,000-square-foot plume. All operations were accomplished within an active military installation and included injecting through an 18-inch-thick tarmac into a sandy aquifer.

Injections took place during the winter months in below freezing conditions. RRS used heaters around the water supply and utilized their heated trailers to prevent the product and water from freezing. Over the course of two injection events, over 80,000 pounds of PersulfOx® Catalyzed Persulfate was applied to the contaminated area. Three application areas called for different remediation approaches with three horizontal injection galleries below a former excavation, nine injection wells down 27 feet below ground surface and a grid of 105 injection points around a hot spot source area. An additional 7,000 pounds of PersulfOx was applied to the bottom of the excavation site to treat the impacted soil. Application monitoring data collected throughout the field work documented the area of influence impacted by each application point.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

Employing a highly technical remediation strategy, RRS successfully applied PersulfOx to three different areas using targeted remediation approaches resulting in performance-based remediation goals sequentially being met and ensuring a high level of client satisfaction.

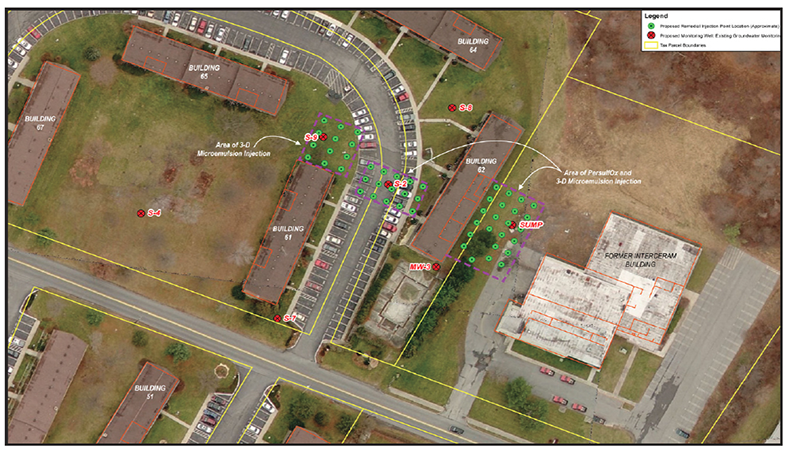

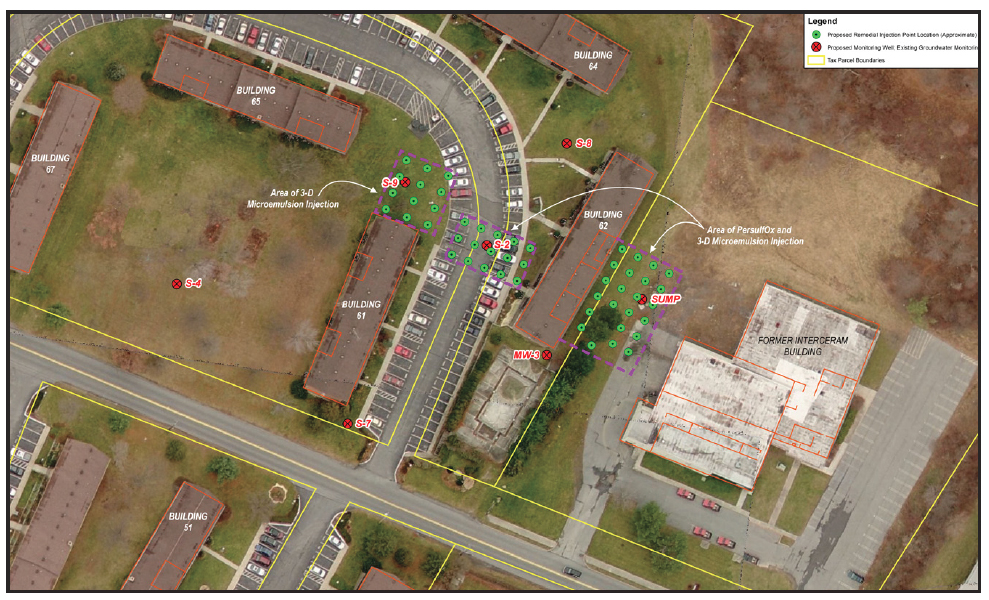

REGENESIS® Achieves MCL Cleanup Goals at New York Manufacturing Facility

cVOC Contamination Successfully Treated Using PersulfOx® and 3-D Microemulsion®

Project Highlights

- 99% reduction of target compounds achieved on-site

- TCE levels reduced from 8,000 ug/L to <5 ug/L to meet site goals

- Integrated remediation approach using PersulfOx® and 3-D Microemulsion® (3DME)

Project Summary

A manufacturing facility in New York was contaminated with high levels of chlorinated solvents. TCE levels were as high as 8,000 ug/L. A combined remedies approach was established to address the migrating plume. The goal of the application design was to reduce cVOCs in the source area, reduce potential for vapor intrusion and address any cVOCs that may migrate into the area downgradient of the manufacturing facility.

An integrated remediation strategy using PersulfOx and 3DME was implemented on-site. Two PersulfOx applications were completed. Results from the In Situ Chemical Oxidation (ISCO) treated area showed >99% reduction of target compounds. A total of 11,600 pounds of PersulfOx was applied on-site. 3DME was applied to enhance anaerobic biodegradation in downgradient locations and within the PersulfOx-treated area. A total of 8,400 pounds of 3DME was applied. While groundwater contamination in the ISCO treated area was reduced to clean-up standards, the goal of the 3DME application was strictly preventative. The client wished to address any potential plume migration from any cVOCs that may be present beneath the building.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Results

The use of PersulfOx safely and effectively reduced TCE levels to regulatory standards providing a 99% reduction of cVOC’s achieved on-site. In addition, the integration of 3DME as a precautionary safety measure addressed the potential for plume migration that was thought to be present.

ISCO/ERD Treat PCE Contamination at Indiana Dry Cleaner

Remediation Plan Addresses Concentrations Below Facility and Downgradient

Project Highlights

- PersulfOx utilized subslab near the source to inhibit vapor issues within the building.

- Combined remediation plan addressed impacts both below the building and downgradient of the facility.

- PCE contamination was nearly depleted and TCE levels below 10 ppb were observed.

- The site is currently being monitored to demonstrate plume stability with approximately 3-4 more monitoring events prior to site closure.

Project Summary

A release of PCE from a former dry cleaning operation in Indianapolis resulted in groundwater contamination below the facility and downgradient. Contamination impacts were also observed in shallow fill below the concrete slab. Along with the groundwater/soil contamination, vapor intrusion was also detected within the facility and adjacent spaces in the strip mall. A combination of enhanced reductive dechlorination (ERD) and in situ chemical oxidation (ISCO) was used for remedial action. Analytical results obtained indicate nearly complete reduction of PCE and less than 10 ppb of TCE in all wells. Currently, elevated VC concentrations in two wells were observed but reductions are expected as the ERD process is completed.

Remediation Approach

PersulfOx® Catalyzed Persulfate was injected below the floor slab of the dry cleaner to inhibit vapor production within the facility and adjacent spaces. 3-D Microemulsion® and Bio-Dechlor INNOCULUM® Plus were injected into the uppermost water-bearing area below the dry cleaner and into two areas downgradient on either side of the building. Supplemental ERD injections were applied in two areas approximately 9 months after the initial injection to address minor sand stringers that were contributing to continued contamination impacts. The supplemental injection resulted in immediate elimination of PCE/TCE and a rapid production of VC. The site is currently being monitored to demonstrate plume stability with approximately 3-4 more monitoring events prior to site closure.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

ISCO/ERD Treat PCE Contamination at Indiana Dry Cleaner

Remediation Plan Addresses Concentrations Below Facility and Downgradient

Project Highlights

- PersulfOx utilized subslab near the source to inhibit vapor issues within the building.

- Combined remediation plan addressed impacts both below the building and downgradient of the facility.

- PCE contamination was nearly depleted and TCE levels below 10 ppb were observed.

- The site is currently being monitored to demonstrate plume stability with approximately 3-4 more monitoring events prior to site closure.

Project Summary

A release of PCE from a former dry cleaning operation in Indianapolis resulted in groundwater contamination below the facility and downgradient. Contamination impacts were also observed in shallow fill below the concrete slab. Along with the groundwater/soil contamination, vapor intrusion was also detected within the facility and adjacent spaces in the strip mall. A combination of enhanced reductive dechlorination (ERD) and in situ chemical oxidation (ISCO) was used for remedial action. Analytical results obtained indicate nearly complete reduction of PCE and less than 10 ppb of TCE in all wells. Per the recent sampling event, VC concentrations have dropped in all wells. Monitoring is ongoing.

Remediation Approach

PersulfOx® Catalyzed Persulfate was injected below the floor slab of the dry cleaner to inhibit vapor production within the facility and adjacent spaces. 3-D Microemulsion® and Bio-Dechlor INNOCULUM® Plus were injected into the uppermost water-bearing area below the dry cleaner and into two areas downgradient on either side of the building. Supplemental ERD injections were applied in two areas approximately 9 months after the initial injection to address minor sand stringers that were contributing to continued contamination impacts. The supplemental injection resulted in immediate elimination of PCE/TCE and a rapid production of VC. The site is currently being monitored to demonstrate plume stability with approximately 3-4 more monitoring events prior to site closure.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Combined Remedies Treatment Results in a $650,000 Cost Savings for End User

Project Highlights

- By implementing this strategy with a clear path to closure, KERAMIDA saved their client approximately $650,000 versus the alternative containment plan. KERAMIDA’s sophisticated and aggressive remedial approach matched the technologies (ISCO, ISCR, ERD) to the technical challenges at the site.

- PCE was virtually eliminated in most other impacted wells, and continued evidence of reductive dechlorination is ongoing.

- Project currently in the monitoring phase to establish plume stability for closure.

Project Summary

A PCE spill from a 55 gallon drum in the late 1980s contaminated a manufacturing site in Indiana. Contaminated soil was excavated in the spill area and a pump and treat interceptor system was installed downgradient of the plume. The system continued to operate intermittently throughout the 1990s. A previous consultant had submitted a remediation work plan proposing the use of a permeable reactive barrier. However, the plan was rejected because the intended goal was remedial closure, not containment. KERAMIDA proposed a combined in-situ chemical oxidation (ISCO)/enhanced reductive dechlorination (ERD) approach focusing on the spill area (source) and the downgradient, on-site plume, with a small injection off-site. The remediation plan was approved and the injection was completed in November 2013. KERAMIDA’s cost to closure is likely to be achieved for less than $500,000 – saving $650,000-800,000 over the life of the project. (The rejected remediation plan from the previous consultant had an estimated cost of $1.3 million with no plan for closure.)

Remediation Approach

The combined remedies treatment included an initial application of PersulfOx® Catalyzed Persulfate in the source area with subsequent applications of 3D Microemulsion® (3DME), BioDechlor INNOCULUM® Plus (BDI-Plus) and Chemical Reducing Solution (CRS®). In addition, 3DME and BDI-Plus were applied in two downgradient areas of the plume. Groundwater monitoring performed in the eight months since injection indicates dramatic reductions in PCE concentrations. Within the source area, an initial PCE concentration of approximately 70,000 ppb was reduced to 278 ppb (with a corresponding increase in cis-1,2-DCE, which is currently being degraded). PCE was virtually eliminated in most other impacted wells and evidence of reductive dechlorination is ongoing.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

CRS is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

In Situ Chemical Oxidation of Chlorinated Solvents Using Persulfox™ At An Industrial Site

Overview:

Chlorinated compounds were discovered in shallow groundwater at a former industrial site in Attleboro, Massachusetts. With total VOC concentrations as high as 85,000 ug/L in groundwater, a rapid and aggressive remediation approach was required. In Situ chemical oxidation (ISCO) using PersulfOxTM – catalyzed persulfate was selected to treat a portion of the impacted area which was approximately 35’ long x 35’ wide x 15’ deep and primarily comprised of sand. Three prescribed injections of ISCO using PersulfOx were performed over a 7- month period.

- PersulfOx is a persulfate based ISCO reagent that promotes rapid and sustained in situ oxidation of a wide-range of organic contaminants.

- This patented technology utilizes a unique catalytic surface on which oxidants and contaminants react in a process known as “surface mediated oxidation.”

- PersulfOx also contains built-in activation which eliminates complex and potentially hazardous chemical addition required to achieve traditional persulfate activation.

- From a health and safety aspect, the use of PersulfOx alone is safer than traditional activation methods such as heat, chelated metals, hydrogen peroxide or base.

- If warranted, PersulfOx can also be activated through traditional means to achieve site remediation goals.

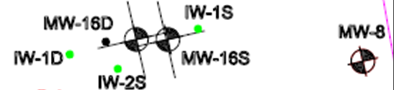

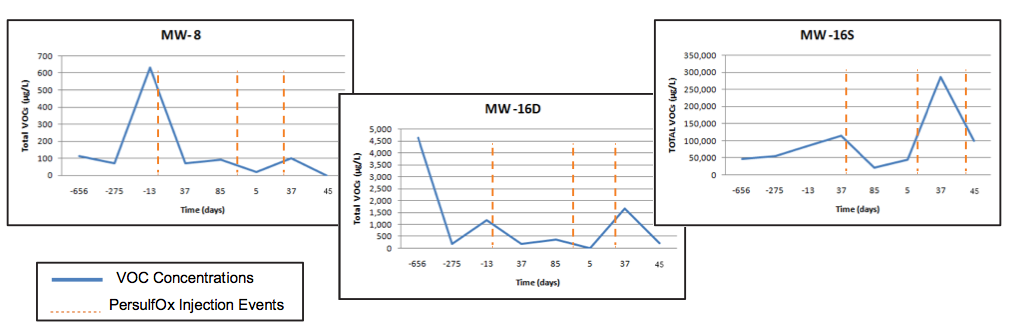

Figure 1. Injection wells and monitoring wells

A 10% solution of PersulfOx in water was mixed and injected into a 10-foot treatment thickness using 3 injection wells within the vicinity of monitoring wells MW-16D, MW-16S and MW-8 (Fig.1).

Results:

After each PersulfOx application, an anticipated increase and subsequent decrease in VOCs (resulting from subsurface disturbance and contaminant desorption) was observed. After the 3 prescribed applications of PersulfOx, 2 of the treatment zone wells, MW-16D and MW-8, measured significant VOC removal, 81% and 99% respectively. Treatment zone well MW-16S (the most highly impacted—starting at 85,000 ug/L) showed a significant increase in VOCs after the first 2 injections (indicative of the liberation of soil bound mass). After the third application of PersulfOx, VOC concentrations in MW-16S were clearly decreasing (see figures below).

Petroleum Hydrocarbon and Chlorinated Solvent Treatment Using PersulfOx™ at a Former Service Station

Overview

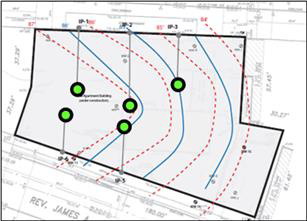

Petroleum hydrocarbons and chlorinated compounds were discovered in groundwater at a former gasoline service station/auto-repair facility. This redevelopment site, located in Bronx County, New York, previously housed an underground storage tank (UST) used for gasoline storage. Following the discovery of groundwater contamination in excess of NYSDEC groundwater protection standards, the UST and soils were removed to bedrock at a depth of 11 feet. Further monitoring revealed toluene and benzene contamination as well as tetrachloroethene (PCE) and trichloroethene (TCE) impacts from parts cleaning associated with the on-site auto-repair shop. Remedial action was required to restore site groundwater and make way for redevelopment and construction of a new building. In Situ chemical oxidation (ISCO) using PersulfOxTM was chosen as the remediation approach.

- PersulfOx is a persulfate based ISCO reagent that promotes rapid and sustained in situ oxidation of a wide-range of organic contaminants.

- This patented technology utilizes a unique catalytic surface on which oxidants and contaminants react in a process known as “surface mediated oxidation.”

- PersulfOx also contains built-in activation which eliminates complex and potentially hazardous chemical addition required to achieve traditional persulfate activation.

- From a health and safety aspect, the use of PersulfOx alone is safer than traditional activation methods such as heat, chelated metals, hydrogen peroxide or base.

- If warranted, PersulfOx can also be activated through traditional means to achieve site remediation goals.

The ISCO treatment system consisted of a series of pipes extending below the basement level of the existing slab for the specific purpose of delivering PersulfOx directly onto the bedrock surface. The pipes terminated into dispersion pits scraped into the bedrock allowing PersulfOx to pool and enter the fractures (Figure 1). The ISCO delivery system design allowed for multiple reagent applications as often as required to complete the remediation process.

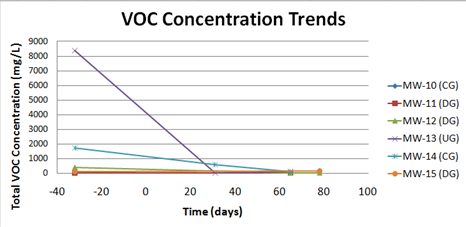

Current trends in the available monitoring well data indicate significant reductions in total VOCs (Figure 2).

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español