Chlorinated Solvent Remediation via ISCO at Former Industrial Site in Barcelona, Spain

Due to the target area extending under the footprint of the proposed building and the short build programme, a grid of horizontal injection pipes was installed in the subsurface prior to construction commencing. The grid was then linked to a remote injection location, so that when the new building was constructed, injection was simultaneously completed underneath it. The intention of the remediation was to achieve a rapid and significant reduction of the contaminant concentrations in the groundwater. PersulfOx was selected as the preferred ISCO agent due to its efficiency and capability of moving through the vadose zone into the groundwater, guaranteeing a good distribution.Read More

In Situ Remediation at an Active Manufacturing Facility in Northern Italy

Historic leakages at an active manufacturing facility in Northern Italy resulted in the underlying groundwater becoming impacted with hexavalent chromium (Cr(VI)) contamination of up to 2,000 μg/L, and chlorinated solvents (CHC) concentrations of up to 10,000 μg/L. 3-D Microemulsion® (3DMe) and Metals Remediation Compound (MRC®) were selected to remediate the site because of:Read More

Pilot Test of ISCO Soils Treatment in Industrial Area, Italy

At a former oil refinery in Italy, leaks from several large Aboveground Storage Tanks (ASTs) had caused the soil to become impacted with fuel. Concentrations of up to 3,000 mg/kg of petroleum hydrocarbons were measured in the unsaturated soil within the immediate vicinity of the ASTs. Read More

Treatment of a Widespread Plume Beneath a Metropolitan Area, Italy

A widespread plume of chlorinated solvents has been monitored for more than a decade underneath a metropolitan area in Italy. The chlorinated solvent concentrations are low (100 μg/l) but persistent, with no effective natural attenuation occurring. This plume had previously been considered as practically untreatable, due to the low concentration, location and size.Read More

Combined PlumeStop® and ORC-Advanced® Treatment Remediates Low Level Benzene Contamination

Project Highlights

- Persistent benzene contamination reduced from 530 μg/L to 4 μg/L

- Target Medium Specific Concentration (MSC) achieved within one quarter of treatment

- Application of PlumeStop® and ORC Advanced® successfully completed by REGENESIS® Remediation Services (RRS) within three days allowing for the project

1m 38s reading time

Project Summary

Operation activities at the site of an active gas station resulted in contamination of the groundwater with low levels of benzene. The concentration of benzene fluctuated, reaching 530 μg/L before remediation efforts were undertaken. REGENESIS designed a remediation plan to address the persistent low levels of benzene that combined the application of PlumeStop and ORC Advanced for in situ sorption and enhanced aerobic biodegradation.

The sorbent properties of PlumeStop make it possible to successfully treat low contaminant levels by creating local areas of high contaminant concentration that can then be colonized by contaminant-degrading bacteria. This co-localization of the contaminants and bacteria on the PlumeStop surface greatly improves the contact between the two components, thereby enhancing the speed and efficiency of the degradative reactions. Addition of ORC-Advanced further supports aerobic biodegradation by providing a long-lasting oxygen source.

RRS injected PlumeStop and ORC Advanced into 12 points around MW-6R (Fig. 1) that showed elevated benzene levels. A total of 1,200 lb of PlumeStop were first injected via direct push technology followed by injections of 240 lb of ORC Advanced into the same 12 holes. Treatment of the site was completed over the course of two days without any complications.

Technology Description

PlumeStop Liquid Activated Carbon (LAC) is an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation.

ORC Advanced is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

Results

In the first quarterly sampling event after the remediation chemistries were applied, benzene levels had dropped from the pre-application level of 530 μg/L to below the Medium Specific Concentration (MSC) of 5 μg/L set by the Pennsylvania Department of Environmental Protection. Furthermore, groundwater quality parameters in MW-6R indicated good distribution of the remediation chemistry through the subsurface and the establishment of optimum parameters for continued aerobic biodegradation.

Innovative Application of PersulfOx Addresses BTEX Contamination at Former Gas Station Site

Project Highlights

- Innovative remediation plan designed by IRSL to address hydrocarbon plume using PersulfOx® addresses migrating plume

- Cleanup criteria on site was reached with only two injections of PersulfOx

- Direct Push Technology using PersulfOx counters any back diffusion

Project Summary

An active gasoline station in southwestern Ontario exhibited a hydrocarbon plume, which was migrating off site toward commercial buildings, presenting liability concerns for developers. Previous remediation efforts using other oxidants, including base-activated persulphate, did not result in significant reductions, and rebound was a problem, including pH buffering. InSitu Remediation Services, Ltd. (IRSL) was the consulting firm hired to perform the remediation work.

Led by Rick McGregor, IRSL designed an approach that included REGENESIS’® PerfulfOx to address the concentrations in the plume including BTEX ~ 25 mg/L, F1 ~29 mg/L, and F2 ~ 1.5 mg/L. The geology was silty sand with sand lens and a unconfined aquifer. The client’s cleanup goals were F1 0.75 mg/L and F2 0.15 mg/L. Two injections of PersulfOx using Direct Push Technology (DPT) were applied, targeting the sand lens and providing enough mass to allow for diffusion of PersulfOx into the silty sand to counter back diffusion.

Technology Description

PersulfOX and PersulfOX SP promote the rapid and sustained in situ oxidation of a wide-range of organic contaminants. As an advanced in situ chemical oxidation (ISCO) reagent, it destroys organic contaminants found in groundwater and soil through abiotic chemical oxidation reactions.

This turn-key, all-in-one product with a built-in catalyst activates the sodium persulfate component and generates contaminant-destroying free radicals without the costly and potentially hazardous addition of a separate activator. The patented catalyst enhances the oxidative destruction of both petroleum hydrocarbons and chlorinated contaminants in the subsurface.

With the purchase and proper use of PersulfOx Catalyzed Persulfate, clients gain the benefits of the latest advancements in persulfate technology for environmental remediation. PersulfOx SP was formulated for use on projects specifying the use of persulfate and a separate chemical activation process such as alkaline activation, hydrogen peroxide activation, or iron activation. It can also be used as a follow-on treatment to REGENESIS’ PersulfOx Catalyzed Persulfate technology.

Results

Following the two injections of PersulfOx using direct push technology, cleanup criteria was reached quickly, resulting in two-plus years of sublevel monitoring.

About InSitu Remediation Services

One of Canada’s most experienced remediation companies, InSitu Remediation Services Ltd. (IRSL) has designed, implemented, and maintained soil and groundwater remediation programs in diverse geological environments in North, Central, and South America, Europe and the Middle East. The company offers remediation support services and specializes in ensuring the most efficient use of technical and financial resources, managing shortened remedial time-frames, and mitigating unnecessary technical and financial risk.

Rick McGregor, B.Sc. Geology, M.Sc. Hydrogeology, M.B.A., is president of InSitu Remediation Services Ltd. A respected environmental professional with over a quarter century in environmental assessment and remediation, he has designed and implemented remediation programs across the globe.

Enhanced Reductive Dechlorination in a Fast Flowing Aerobic Aquifer

Introduction

Enhanced Reductive Dechlorination (ERD) through biostimulation and redox manipulation is a well-established treatment method for chlorinated solvent contamination in groundwater. However, it is sometimes considered inappropriate where natural conditions are not already conducive to anaerobic attenuation, such as highly aerobic aquifers or fast-flowing groundwater. The use of microbial assays or PCR testing can potentially reinforce this view, when baseline sampling shows little or no evidence of the presence of dehalorespirators or active reductive dechlorination. However, ERD can be achieved in these situations through the creation and maintenance of the ideal redox conditions, coupled with a long term supply of terminal electron donors. Regenesis has successfully remediated many sites via ERD, where initial conditions appear unpromising, using Hydrogen Release Compound (HRC) and 3-D Microemulsion (3DMe) substrate technologies. This case study exemplifies this approach and presents data from a site where treatment is ongoing.

Fig. 1 Metal fabrication works

The Site

The groundwater under an active metal fabrication works in eastern France was impacted with tetrachloroethylene (also known as perchloroethylene (PCE)) following historic leaks and spillages at the facility. The underlying aquifer comprised a highly permeable sandy formation, which allowed a high groundwater seepage velocity of greater than 300 m/year. This had resulted in an extensive dissolved phase plume forming on the site. The contamination extended over 260 m, with concentrations of up to 1,300 μg/L and no obvious source, although multiple areas were suspected. The contamination also extended from the top of the groundwater at 3 m BGL to approximately 10 – 13 m BGL (chlorinated solvents, having a high specific gravity and a low viscosity, tend to move downwards through the water column). The groundwater in ux was also highly aerobic, hence very little natural biological attenuation of the PCE was occurring.

The main risk from the PCE plume was due to its migration beyond the site boundary into a nearby fishing lake. Where the contaminant concentrations could actually be measured in the lake water (32 μg/L PCE). The contamination also potentially posed a human health risk to site.

Fig. 2 Impacted nearby fishing lake

Remediation Strategy

Studio Maffezzoli and Regenesis designed, and Ortec implemented, a safe, economical and cost effective in situ ERD strategy, which was new to this part of France.

Although no site specific target values were set for the project, the intention of the remediation strategy is to prevent offsite migration of the plume, thereby mitigating the impact to the fishing lake and secondary, and to reduce the risk to human health onsite.

There are several potential spill locations at the site and as the high seepage velocity has created a large plume with low concentrations, it has proved difficult to accurately delineate the source areas. The buildings and activity on the site have also made access for site investigation, difficult in some areas. Therefore, a staged remedial strategy has been adopted, with a series of barriers used to treat as much of the plume as can be accessed in an economical manner. As monitoring continues, it may be the case that more recalcitrant areas may be observed, which will help to give better resolution on the source locations. Further site investigation during the validation period can also then be used to determine if a second locally tailored dose may then be completed in these areas.

The remedial approach was also intended to minimise the disturbance to this busy, active facility. It was therefore decided to use 3D Microemulsion (3DMe) as this stimulates ERD from a single application for up to 5 years (although it may be expected to be slightly less in a fast flowing site such as this), minimises the number of injection locations and avoids the use of any physical abstraction equipment at the site.

Fig. 3 The buildings and activity on the site made access difficult in some areas

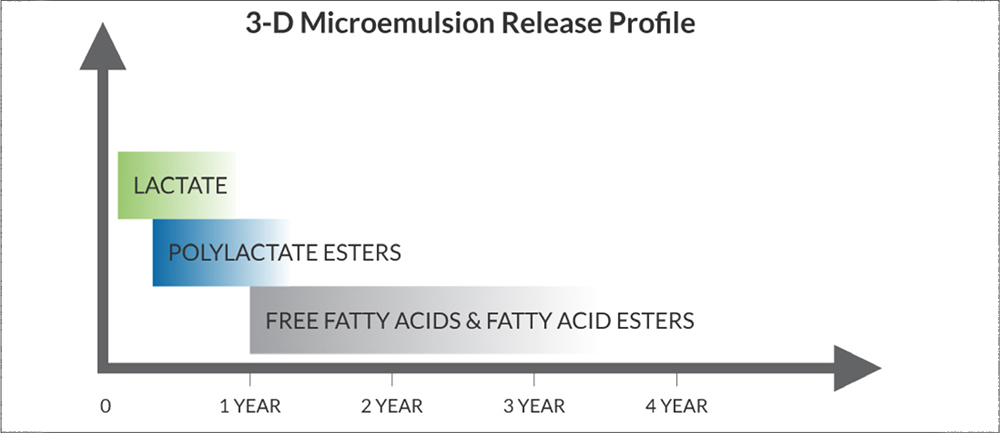

Fig. 4 3DMe Electron Donor Release Profile

3DMe provides three stages of electron donor release from a single concentrate of specially designed polar molecules. When mixed with water on site, 3DMe forms a high-volume microemulsion, without the requirement of emulsifiers. Upon injection into the groundwater, 3DMe initially moves out into the formation and adsorbs to the soil particles. As the molecule is designed to be appropriately soluble, it then gradually dissolves back into the groundwater, where it ferments to drive ERD, but also reaches its critical micelle concentration (300 ppm), reforms as a microemulsion and moves further out from the injection point.

This process repeats to ‘self-distribute’ the 3DMe over large distances within the subsurface, without it washing away. This mechanism allowed for wider injection spacing which reduced the number of injection locations. This then allowed both the cost and disruption to the site to be minimised. The ability of 3DMe to coat the subsurface without being washed away, whilst still being soluble enough to provide an effective terminal electron donor concentration in the groundwater, made it ideal for this fast flowing site.

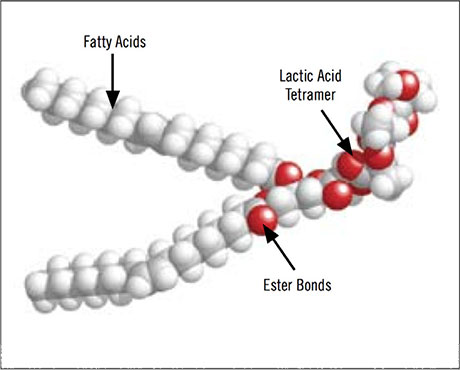

Fig. 5 3DMe Molecular Structure

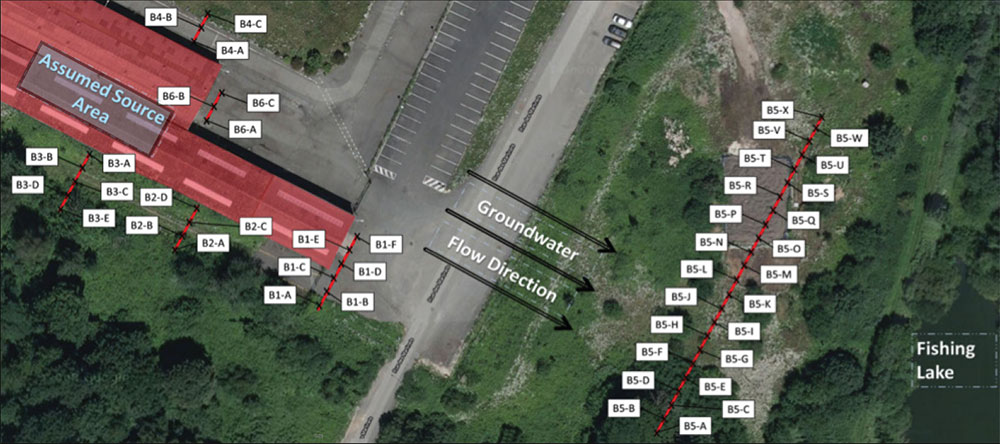

Fig. 6 Treatment zones (‘barrier’) locations

The first phase of the treatment was applied in March 2012. 3DMe was applied in six ‘barriers’ installed perpendicular to the flow of the groundwater. Each injection involved driving a direct push injection rod into the subsurface and applying the requisite dose across the vertical target zone. The injections were then repeated in a row across the width of the plume. The 3DMe then self-distributes from these locations to create a wide radii of influence (ROI), which interlock, creating an anaerobic treatment zone in which reductive dechlorinating bacteria can flourish.

As the groundwater flows through the treatment zones (or ‘barriers’, see Fig. 6), the dehalogenators biologically degrade the dissolved contamination through reductive dechlorination, enhanced through the creation and maintenance of ideal redox conditions and a continual supply of dissolved hydrogen. A barrier approach was chosen to minimize costs whilst still ensuring treatment of the entire plume, through migration of contamination between barriers into the next treatment zone downgradient. In order to remediate a plume of 12,000 m2 to a depth of 13 m BGL, the treatment comprised a single injection into 45 points, spaced 4 m apart within 6 barriers. The works took only 15 days to complete, with in situ treatment expected to last several years.

Results

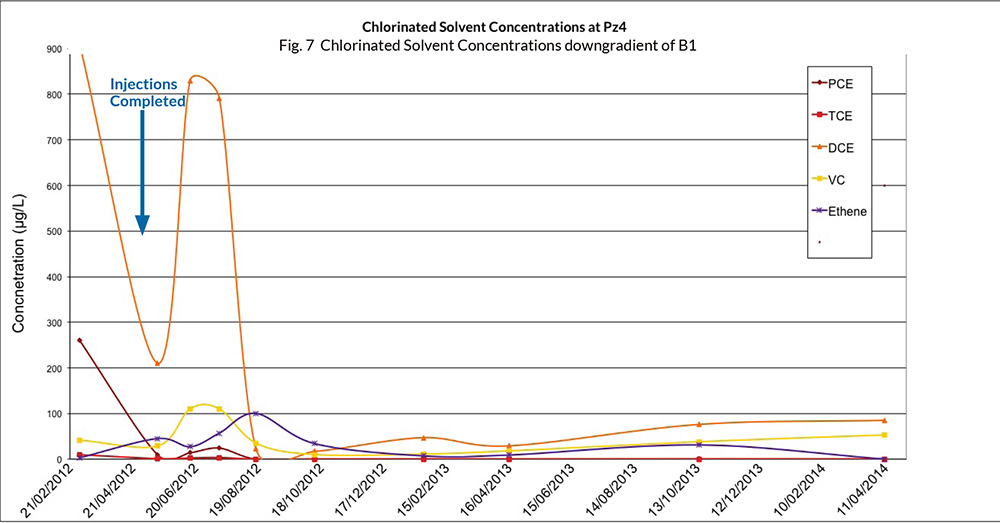

Following the application, a rapid reduction in PCE concentrations was seen in all wells downgradient of the barriers across the site. In Fig. 7, it can be seen that concentrations of PCE are non-detect after only 5 months. The application resulted in the sequential production and breakdown of daughter products and an increase in ethene production showing that full reductive dechlorination is being achieved.

Ongoing low levels of DCE and VC downgradient of the barrier show that there is a small residual in ux of PCE/TCE into the barrier, which is being fully dechlorinated. Ortec are completing further SI in order to locate the source and target further treatment.

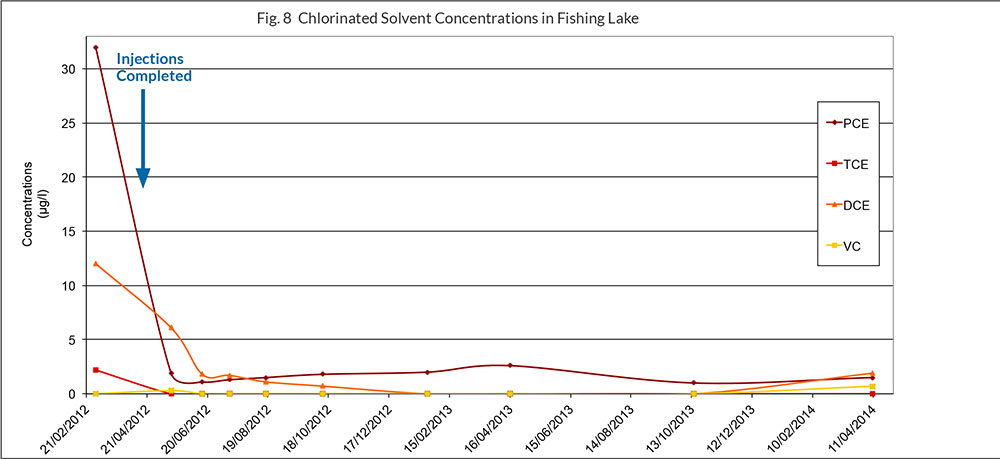

In Fig 8, it can be seen that the PCE concentrations in the fishing lake were rapidly reduced after the application and have remained low ever since. The breakdown products have also reduced to almost non-detect and remain at a very low level. With the onsite barriers remediating the contamination before it reaches the lake, the residual concentrations in the lake water may be expected to attenuate over time.

Conclusions

24 months after treatment, the concentration of PCE onsite has been dramatically reduced on the site and within the fishing lake, without the build- up of daughter products. In the monitoring locations downgradient of the onsite barriers, parent compound concentrations have been reduced to non detect, preventing any further contaminant egress from the site. With only 15 days of onsite works, two years of remediation has so far been achieved, overcoming challenging aquifer conditions to successfully create and maintain ERD treatment.

Further intrusive investigation has recently started to locate any residual source areas on the site, which can then be accurately targeted. In the meantime, the 3DMe product applied on the site will continue to remain active for many months/years to come, continuing to degrade any contaminant in ux and protect both the offsite environment and site personnel.

Large-scale In Situ Enhanced Reductive Dechlorination of a 6 Hectare Site

Treatment of chlorinated solvents at a complex 6ha site with sensitive receptor. The on-site activities were successfully completed in only 6 months. Remediation will occur over several years, with no further site attendance or operational costs beyond validation sampling.Read More

Ohio Brownfield Site Receives “No Further Action” Status within One Year of Implementation

Project Highlights

- Combined remedy approach allowed for immediate redevelopment within same year of implementation.

- Efficiencies resulted in vapor intrusion mitigation cost of $3.34 per sq. ft., with no long term operation and maintenance required.

- Cost for groundwater treatment approximately $10 per cubic yard (product + application).

1m 25s reading time

Project Summary

A former industrial magnet manufacturing facility in Ohio received a $2.34 million Clean Ohio Revitalization Fund (CORF) grant through the Ohio Department of Development in 2011. Site investigation activities identified chlorinated VOC’s in groundwater and vapors above the state standards, requiring remediation. Enhanced Reductive Dechlorination, using 3D Micro-Emulsion®, and BDI-Plus® were implemented within the defined 24,000 sq. ft. treatment area via direct push injection.

This work was conducted in the Spring of 2012. In the Fall of 2012, the Geo-Seal Vapor barrier system was installed below a 15,522 sq. ft. apartment complex raised at the site. Utilizing a combined approach of enhanced reductive dechlorination with vapor mitigation addressed the immediate risk of vapor intrusion, in addition to the long term risk of groundwater impacts. By implementing this strategy, the site was allowed to be redeveloped as an apartment complex roughly 6 months following the groundwater treatment. The cost for groundwater treatment was approximately $10/cy (product + application) and Geo-Seal® was $3.34/sq. ft. (product + installation).

Technology Description

BDI Plus is an enriched, natural microbial consortium containing species of Dehalococcoides sp. (DHC) which are capable of completely dechlorinating contaminants during in situ anaerobic bioremediation processes.

3-D Microemulsion is a wide-area distribution, staged release, electron donor emulsion for the optimized enhanced anaerobic biodegradation of chlorinated compounds.

Geo-Seal is a composite system that creates the ideal blend between constructability and chemical resistance by using both high density polyethylene (HDPE) and spray-applied asphalt latex.

Results

Housing developers face many considerations, including approvals for land excavation and required building permits. By implementing a combined remedy approach, consisting of enhanced reductive dechlorination with vapor mitigation, this site was able to qualify for NFA status in less than a year, allowing the developer to begin new construction without further delay.

Successful Bioremediation at a Former Air Force Base Fire Training Area

Project Highlights

- Air Force Base contaminated with high levels of carbon tetrachloride due to on-site firefighting training

- 97% reduction in contaminant within three months

- Carbon tetrachloride reduced to below detection limits

1m 20s reading time

Project Summary

Training exercises at Texas Air Force Base resulted in an impact to soil and groundwater by trichloroethylene (TCE) and carbon tetrachloride. A monitored natural attenuation study conducted indicated that chlorinated solvents at the plume would naturally decline to acceptable levels after 30 years of monitoring.

After over 14 years of monitoring, contaminant reductions were not proceeding as quickly as predicted and additional remediation was advised. It was determined that limited anaerobic activity was present and biostimulation was a viable option. A pilot test was conducted on-site.

The objective of the test was to determine the feasibility of injection into the shallow, discontinuous groundwater unit. The pilot test was also designed to determine if the residual TCE and carbon tetrachloride could be biodegraded through enhanced bioremediation and reduced to below 5 ppb (the Texas Risk Reduction Program limit). Follow-up injections were applied downgradient of the source area and also in a barrier configuration several hundred feet dowgradient of the source were implemented about 6 months after the pilot test.

Technology Description

3-D Microemulsion® is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory-emulsified product.

Results

The combination of the pilot test and full-scale application resulted in a 97.8% reduction in carbon tetrachloride 8 months post-injection, with chloroform, methylene chloride, and chloromethane remediation daughter products on a downward trend. High TCE concentrations were effectively treated as well with TCE peaking after injections to 126 ppb within a 3-month period to 0.2 ppb.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español