PersulfOx® Rapidly Treats TBA Contamination

Project Summary

Site operations at this manufacturing facility located in New Jersey caused groundwater to be impacted with tert-butyl alcohol (TBA). Previous attempts at site remediation using alkaline activated persulfate had not met performance goals. PersulfOx was subsequently applied in an area of significant TBA contamination resulting in orders of magnitude reductions within just three weeks’ time.

Alkaline Activated Persulfate – Unsuccessful

An initial attempt at remediation using alkaline activated persulfate included a full-scale injection of persulfate and sodium hydroxide (NaOH). This approach was deemed unsuccessful, as sampling after one week showed pH to be below the range required for persulfate activation, leaving significant untreated TBA in site groundwater. Additionally, the large volume of NaOH required for this approach raised concerns of impacting nearby storm sewers.

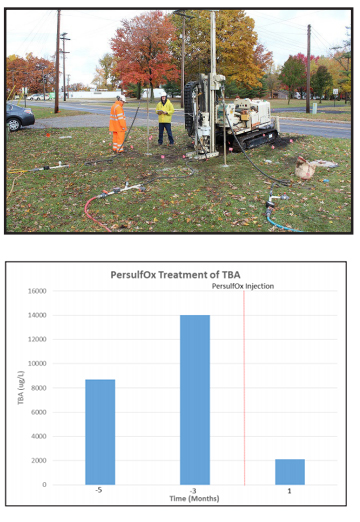

Remediation Approach

The treatment approach included a grid of six injection points placed 15-feet apart into the sandy aquifer. Each point received >1,800 pounds of PersulfOx across of 5-foot thickness.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant destroying free radicals without the need for the addition of a separate activator.

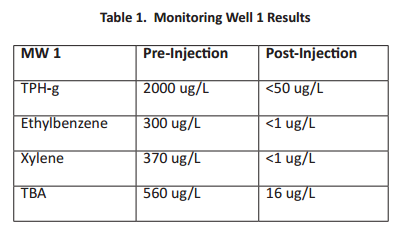

Results

Following the PersulfOx application, site monitoring indicated a significant reduction in TBA contamination in the target zone. TBA concentrations were reduced from >14,000 ug/L to 2,100 ug/L with a single injection of PersulfOx in only three weeks’ time.

Combined Technologies Treat High TBA Levels

Site Closure Pending at Active California Retail Petroleum Service Station

Project Highlights

- A range of various remediation approaches were applied at the site over a span of 20 years.

- Enhanced Aerobic Biodegradation (EAB) remediation approach replaces soil excavation plan at site.

- Site closure pending.

Project Summary

An active service station in Southern California was contaminated with high levels of TBA and TPH-g. Various active remediation approaches took place on-site for nearly 20 years including excavation of the underground storage tanks and dispensers, soil vapor extraction and groundwater pump and treat. Although the active remediation reduced concentrations at the source, contamination levels remained high. Regenesis became involved with the site in 2011 and after two applications of enhanced aerobic biodegradation using ORC® Advanced and RegenOx®, site closure is pending.

Remediation Approach

In 1995, the underground storage tanks and dispensers were excavated and 257 tons of contaminated soil was removed. From 2003 to 2009, dissolved oxygen injection was applied into seven injection wells and in 2009, over 6,000 gallons of water was extracted from one well. In November 2011, Regenesis became involved in the project and proposed a combined remedies approach.

The remedy implemented at the site from November 2011 through November 2012 included introduction of a controlledrelease molecular oxygen into the subsurface water to promote bio-degradation of the fuel hydrocarbons. The implementation of the remedy was completed in two phases with the initial injection activities being completed in November 2011. A second injection event was completed at the site in November 2012. Approximately a total of 6,000 pounds of ORC Advanced and 480 pounds of RegeneOx were applied on-site.

Contaminant concentrations were analyzed in the most recent monitoring events and compared to pre-injection concentrations. Results for performance monitoring well MW 1 were the most significant as all contaminant concentrations decreased to below regulatory limits (Table 1). Closure has been requested and is currently pending.

Technology Description

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Combined Remedies Replace Costly Mechanical Remediation Systems

RegenOx® and ORC® Advanced Treat MTBE/TBA at Five Active California Service Stations

Project Highlights

- In Situ chemical oxidation (ISCO), enhanced aerobic biodegradation replaced costly mechanical remediation systems.

- Underground infrastructure required extra precaution when applying remediation reagents on each site.

- Site closure or review of site closure at all five service stations

Project Summary

Five sites in Orange County, CA were selected for remediation using ISCO and enhanced aerobic biodegradation. All of the selected sites were gasoline service stations that were contaminated with low levels of hydrocarbons methyl tertiary butyl ether (MTBE) and elevated levels of the MTBE biodegradation daughter product tertiary butyl alcohol (TBA). The initial remediation approach consisted of soil vapor extraction, air sparging and dual phase extraction; however, contaminant concentrations remained elevated, impeding regulatory closure.

The decision was made to transition from mechanical-based remediation systems using a combination of ISCO and enhanced aerobic biodegradation to achieve site closure criteria with various regulatory agencies.

Remediation Approach

Initial mass reduction was achieved using mechanical systems, however concentrations remained too high for regulatory closure. The goal was to reduce the remaining levels of petroleum hydrocarbons, MTBE and TBA using RegenOx and ORC Advanced. The service station included up to three direct-push injection applications of the reagents into areas where underground infrastructure was present on each site. RegenOx and ORC Advanced are both highly compatible with subsurface infrastructure so it was more of a challenge from a physical injection vantage. O&M strategy required monitoring of REDOX and microbial shifts. All five sites have been closed or under review for closure under the local regulatory agencies.

Advanced Formula Oxygen Release Compound (ORC Advanced®) is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

$1 Million Dollar Savings for Insurance Funded Remediation Project through Use of In Situ Chemical Oxidation and Enhanced Reductive Dechlorination

Combined Remedies Treat PCE Contamination at Active Dry Cleaner

Project Highlights

- Combined Remedies Approach (ISCO & ERD) implemented in unison near and below active dry cleaning facility.

- Sustained reduction of contaminants below clean-up levels observed 20 months after initial application.

- ISCO & ERD approach approximately $1,000,000 less expensive than proposed dual-phase extraction system option.

Project Summary

An active dry cleaner site located within a multi-use commercial development strip mall was impacted with high levels of PCE vapors. A subsequent investigation revealed groundwater impacts below the building and outside the building in a former filter storage area.

The original remediation plan involved a dual-phase extraction system with an estimated cost of approximately $1.3 million. An alternative approach consisting of in situ chemical oxidation (ISCO) coupled with enhanced reductive dechlorination (ERD) was proposed by KERAMIDA and ultimately selected by the funding source. To date, the ISCO/ERD approach has cost less than $200,000, including 2 years of monitoring and multiple indoor air/sub-slab vapor sampling events. $50,000 – $75,000 in additional remediation/monitoring is anticipated to achieve closure, resulting in an estimated total savings of $1,000,000 for this project being funded by insurance companies.

Remediation Approach

KERAMIDA developed a remediation work plan consisting of an ISCO injection into the permeable fill material directly beneath the floor of the dry cleaning space (Source Area), combined with a plume-wide ERD injection.

Injection points for both RegenOx® and 3-D Microemulsion® were installed inside the dry cleaner because there was insufficient clearance for the drilling equipment. The remainder of the ERD injection points outside the building were advanced using direct push technologies.

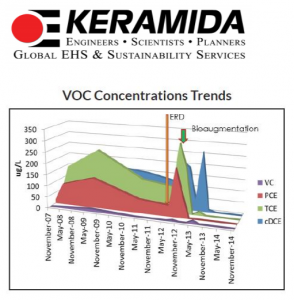

After approximately six months of post-injection monitoring, the data suggested insufficient bacteria were present to promote accelerated reductive dechloriation. Consequently, the bioaugmentation substrate BDI Plus was applied within the ERD treatment area. Graph to the right shows results from key well within this area.

As indicated above, the bioaugmentation substrate rapidly reduced the daughter products generated as a result of the initial electron donor injection. Two years of groundwater monitoring has been performed since the initial injection and CVOC concentrations in all of the wells, except one source-area well, are below the onsite remedial standard (groundwater migration to indoor airscreening level). In addition, two downgradient wells just outside the treatment area have slightly elevated TCE and VC concentrations.

A small supplemental injection is currently planned for the source area (to further reduce the VC concentration to below the screening level) and around the two off-site wells to reduce the minor cVOC concentrations to below residential levels so that deed restrictions are not required.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

After approximately six months of post-injection monitoring, the data suggested insufficient bacteria were present to promote accelerated reductive dechloriation. Consequently, the bioaugmentation substrate BDI Plus was applied within the ERD treatment area. Graph to the right shows results from key well within this area.

As indicated above, the bioaugmentation substrate rapidly reduced the daughter products generated as a result of the initial electron donor injection. Two years of groundwater monitoring has been performed since the initial injection and CVOC concentrations in all of the wells, except one source-area well, are below the onsite remedial standard (groundwater migration to indoor airscreening level). In addition, two downgradient wells just outside the treatment area have slightly elevated TCE and VC concentrations.

A small supplemental injection is currently planned for the source area (to further reduce the VC concentration to below the screening level) and around the two off-site wells to reduce the minor cVOC concentrations to below residential levels so that deed restrictions are not required.

About the Consultant

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

Combined Remedies Approach (Dual Phase Extraction, ISCO and ERD) Lead to Rapid Results on a Guaranteed Cost to Closure Project in Indiana

3- D Microemulsion, BDI Plus and RegenOx Reduce cVOC Concentrations

Project Highlights

- Guaranteed cost to closure project.

- ISCO coupled with dual-phase extraction was successful in reducing cVOC concentrations within the core source area.

- Plume-wide ERD injection resulted in meeting remedial goals within 18-20 months.

- Combined remedy approach (ISCO & ERD) accelerated the time to closure allowing project to be completed within budget

Project Summary

A plating plant in Batesville, Indiana was contaminated with chlorinated VOCs. A subsequent investigation identified a plume of TCE extending from the building approximately 250 feet down gradient (off-site and onto private property across a street).

Remediation Approach

The initial remedial approach involved installation and operation of a dual-phase extraction (DPE) system throughout most of the plume area (26 extraction wells), which operated for approximately 1 ½ years. Approximately one year after the DPE system installation, a core area in situ chemical oxidation (ISCO) injection of RegenOx® was performed by KERAMIDA and Regenesis Remediation Services (RRS). ISCO combined with further operation of the DPE system was effective in additional reductions of cVOC concentrations in the groundwater. Upon conclusion of these efforts, the DPE system was shut down to allow for enhanced reductive dechlorination process to take place.

A successful enhanced reductive dechlorination (ERD) pilot test with 3-D Microemulsion® and BDI® Plus was performed around two off-site wells at the leading edge of the plume. Based on the success of this test, an ERD injection was performed in a newly-identified source area with outstanding results in the first six months. Consequently, the DPE system remained shut down and a full-scale ERD injection was performed in the core area of the plume.

Approximately 9 months after the full scale injections, a very small supplemental injection was performed in the off-site area where the pilot study was done and another in an area where no injection was performed. One year after the full-scale ERD injection, cVOC concentrations are below the target cleanup levels in all wells with the exception of two slightly elevated VC concentrations, which are expected to decrease shortly.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

About the Consultant

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

ISCO Treatment Achieves Closure on Arizona Superfund Site

Benzene Contamination Treated to Non-Detect with Single PersulfOx® Application

Project Highlights

- Previous remediation attempts included soil vapor extraction coupled with groundwater pump and treat/air sparging.

- PersulfOx was applied via gravity-feed through existing remediation wells.

- Single application of PersulfOx resulted in benzene reductions of 1,000 ug/L to non-detect.

- Site closure achieved

Project Summary

Persistent benzene contamination at an Arizona Superfund Site kept the state regulatory agency from closing the site. The City of Tucson maintenance yard contained low residual concentrations of benzene around 1,000 ug/L in a single well. An initial remediation approach used soil vapor extraction coupled with groundwater P&T and air sparging, however results did not meet site closure criteria.

When considering alternatives, the State of Arizona wanted to be efficient by using the existing remediation wells. As a result, Regenesis worked with the state to design a PersulfOx application using the existing infrastructure. Regenesis worked with the state to design and assist with the application of PersulfOx® using the existing remediation wells. After one application, benzene contamination levels were non-detect in the offending well and site closure was achieved.

Remediation Approach

The treatment approach was a trial by the State of Arizona to apply PersulfOx via gravity-feed directly into the existing remediation wells to target residual benzene concentrations. By using the existing in situ infrastructure, the cost of the one-time PersulfOx application was less than $15/cubic yard.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

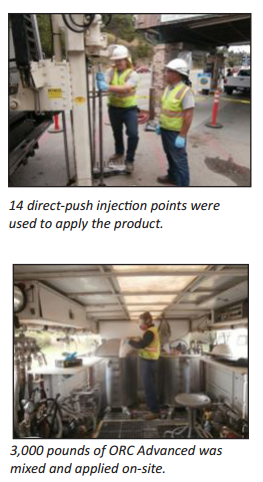

Dissolved-Phase Petroleum Hydrocarbons in Clay Treated with Enhanced Aerobic Biodegradation Using ORC® Advanced

Site Closure Pending Post-Treatment at California Retail Store Location

Project Highlights

- Dual-phase extraction had been used on-site, however BTEX contamination concentrations remained high.

- Enhanced aerobic biodegradation using ORC Advanced applied via directinjection into clay soils.

- Post-ORC Advanced Application, BTEX groundwater concentrations below 10 ug/L.

Site closure pending.

Project Summary

The Cambria General Store in Central California had a history of petroleum hydrocarbon contamination. Dual-phase extraction had been used in the past to treat the site and a total of 130 pounds of petroleum hydrocarbons were removed. However, contamination levels remained above regulatory levels. Contaminant concentrations included: benzene at 310 ppb, toluene at 8,000 ug/L, ethylbenzene at 2,700 ug/L and xyelene at 12,000 ug/L. THPg levels were measured as high as 14,000 ug/L on-site. The site was successfully treated with ORC Advanced which reduced BTEX groundwater concentrations below 10 ug/L. Site closure is pending.

Remediation Approach

ORC Advanced was used to treat the residual dissolved-phase groundwater to California’s low threat groundwater levels. It was applied to two areas within a 1,200-square-foot treatment area. A total of 14 injection points were used to apply a total of 3,000 pounds of ORC Advanced with injection spacing of 7.5 feet on center.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration. This newly available source of oxygen is available for aerobic microorganisms to metabolize along with the unwanted petroleum hydrocarbons.

Regenesis Remediation Services™ – TCE-Impacted Soil Treated with RegenOx®

In Situ Chemical Oxidation Significantly Reduces Contamination Concentrations at Former Manufacturing Facility Site

Regenesis Remediation Services (RRS) was contracted to design and perform in situ chemical oxidation (ISCO) via soil mixing to remediate trichloroethylene (TCE) impacted soils at a former manufacturing site in Hamilton, Ohio. RegenOx® was selected as the primary remediation technology based on site conditions, and the treatment area focused on soilbound TCE contamination averaging 86 mg/kg in the sandy-silt to clay-rich unsaturated soils. The remediation objective was to reduce TCE levels in the soil to below the maximum concentration for Toxicity Characteristic Leaching Procedure (TCLP) of 0.5 mg/L, to allow for subsequent off-site disposal.

The impacted soils were treated in-place by a hydraulic excavator with a specialized mixing attachment. RegenOx was evenly dispersed throughout the contaminated soil, then thoroughly mixed using the excavator attachment. Once mixing was complete, the soils were hydrated with a RegenOx solution, to maximize oxidant loading to achieve aggressive remediation goals. As a result of the soil mixing procedures, a 99% reduction in soil concentrations was achieved. RRS remediated approximately 670 cubic yards of TCE-impacted soil on this real estate redevelopment project. Soil mixing was performed primarily from 4 feet to 8 feet below ground surface (bgs) over an area of approximately 4,500 square feet. Construction activities were able to proceed on schedule due to RRS’s well managed application and proper use of the RegenOx chemistry.

Regenesis Remediation Services™ – TCE Impacted Soil Treated with RegenOx®

Soil Mixing Using In Situ Chemical Oxidation Reduces Contamination Concentrations at Former Manufacturing Facility

Regenesis Remediation Services (RRS) was asked to design and implement a pilot test as well as a full scale design for a soil mixing project using in situ chemical oxidation (ISCO) technology. The specific goal of the remediation plan was to reduce trichloroethylene (TCE) levels to less than .5 ppm, to meet standards for off-site removal as non-hazardous waste. The design included the use of RegenOx® Part A and B as an oxidant in a pug mill system. The TCE at this former manufacturing facility was present from two (2) feet below ground surface (bgs) down to eleven feet bgs in certain areas.

A total of 27,950 pounds of RegenOx Part A and 7,260 lbs of RegenOx Part B were applied over 39 discrete treatment cells during the course of the remediation project. Using an excavator, the top two feet of soil was removed and stored separately, after which the contaminated soil could be excavated and treated with RegenOx Part A and B in a pug mill system. Using RegenOx as an oxidizer, TCE on site was remediated using oxidation to dechlorinate TCE to dichloroethene (DCE), vinyl chloride (VC), and finally to ethene, a benign end product. Two years later, soil samples came back clean and the soil could be trucked off site as non-hazardous waste.

Regenesis Remediation Services™ – PCE Treated with RegenOx®

Soil Mixing Using In Situ Chemical Oxidation Reduces Contamination Concentrations at Former Dry Cleaning Facility

Regenesis Remediation Services (RRS) was hired for this large-scale soil mixing project to treat tetrachloroethylene (PCE) in shallow surface soils. The application used in situ chemical oxidation (ISCO) technology to oxidize residual chlorinated solvents at this former dry cleaner site. The goal was to reduce chlorinated volatile organic compounds (cVOCs), particularly PCE, from >20 ppm to less than 5 ppb. The design of the project was divided into a grid with twelve sections, each 25 feet (ft.) by 21.5 ft., and 5 ft. deep.

Using RegenOx® remediation chemistry and an excavator to complete the soil mixing, the impacted soils were removed by an excavator and a proportional amount of RegenOx was evenly dispersed throughout the excavated soil, then thoroughly mixed using the excavator.

Once mixing was complete, the soils were placed back into the treatment cell while being hydrated with a RegenOx solution made up of RegenOx, water and hydrogen peroxide. By optimizing the contact between the soil, contaminants, and RegenOx, powerful desorption effects strip PCE off of the soil matrix and onto the RegenOx catalytic surface. This catalytic surface contributes to localized free-radical generation, leading to focused and efficient contaminant destruction via soil mixing. After eight days of the completion of the project, 98-100% reductions were achieved in the twelve sections of the grid.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español