DNAPL to Non-Detect: 6 Orders of magnitude reduction of chlorinated solvents

Combined in situ sorption and biological degradation leads to site closure of large manufacturing site in Northern Italy

Chlorinated solvents were used for many years at a former manufacturing facility in Northern Italy. This resulted in contamination of the groundwater underlying a large proportion of this 60,000 m2 site. Groundwater concentrations of up to 155,000 μg/L TCE meant there was a suspected presence of Dense Non Aqueous Phase Liquid (DNAPL) on parts of the site. The contamination posed an unacceptable risk to both on- and off-site receptors and it was determined that active remediation was required on a large proportion of the site.

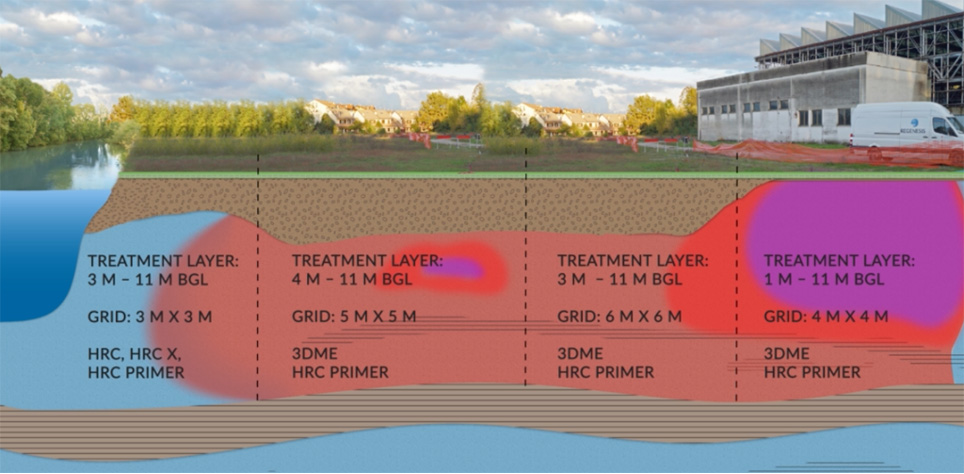

Remediation Strategy:

REGENESIS created a strategy comprising Enhanced Reductive Dechlorination (ERD) tailored to contaminant concentrations and local geology, across the entire impacted area. This strategy was coupled with an injectable Permeable Reactive Barrier (i-PRB) at the site boundaries. This in situ remediation approach proved to be successful, leading the site to closure after having reached stably very stringent concentrations (VC<0.5 μg/l; TCE<1.5 μg/l) and obtaining up to 6 orders of magnitude reduction in concentrations.

Suite of REGENESIS products applied for ERD: 3-D Microemulsion®, HRC®, HRC-X®, HRC Primer®.

Injectable Permeable Reactive Barrier : PlumeStop®Liquid Activated Carbon™ (CAC)

6m 30s reading time

PlumeStop and S-MicroZVI Application Paves The Way For Redevelopment

Case study highlights

This case study reviews a contaminated chlorinated solvent site in northern California, USA, where advanced design verification testing and predictive modeling methods were used to guide a remarkably successful in-situ remediation effort:

-

Highly successful remediation solution using colloidal technologies: PlumeStop and S-MicroZVI

-

Complete reduction of PCE, TCE and daughter products in the treatment areas

-

Flux-based predictive modeling used to optimise remediation to meet two-year timeline

-

Remedial objectives achieved allowed redevelopment of the property

Over 8 Million Cubic Feet of Groundwater Treated In 13 Days

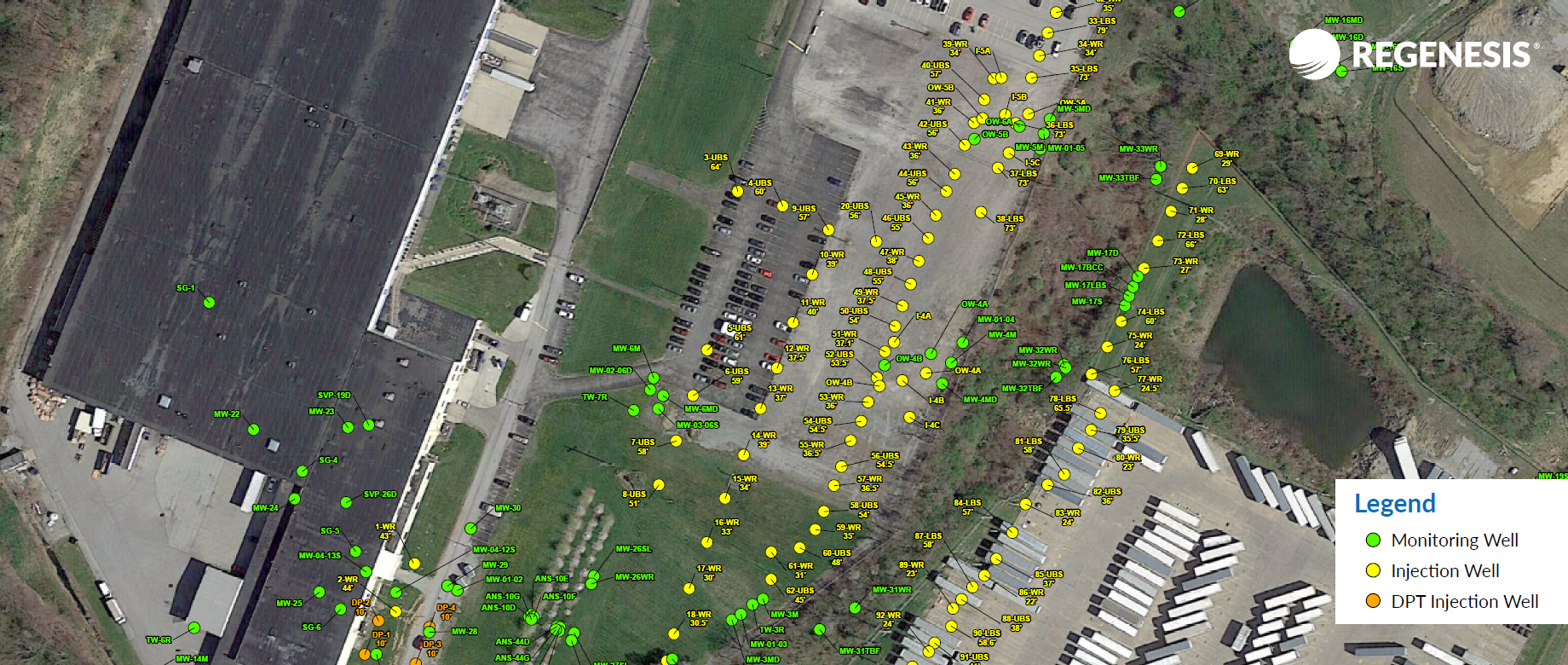

This case study reviews the site of a large-scale enhanced reductive dechlorination (ERD) treatment of chlorinated volatile organic compounds (CVOCs) applied in a fractured bedrock aquifer at a voluntary remediation site in Pennsylvania. REGENESIS Remediation Services (RRS) began the application in May 2020 and completed it in less than 13 days, averaging nearly 7,000 gallons of fluid volume injected per day at this active facility. In total, more than 260,000 combined pounds of 3-D Microemulsion, Chemical Reducing Solution (CRS) and Bio-Dechlor INOCULUM Plus (BDI Plus) were injected for ERD treatment of the CVOCs. The extensive injection well network and large injection volume required RRS to develop an innovative injection process and containment design. Two 21,000-gallon frac tanks were delivered to the site to hold deoxygenated water used for mixing and to chase product injections. Mixing for the main high-flow system was performed in two large polyethylene tanks that were constantly recirculated to ensure a homogenous mixture.

Case study highlights:

- 8 million cubic feet of CVOC impacted groundwater treated

- 88,000 gallons of ERD remedial amendments applied in less than 13 days using novel, innovative tooling and application approach

- The project was completed more than 40% faster than originally scheduled.

7m 30s reading time

Remediation of chlorinated solvents under a commercial development, Belgium

Summary:

In Belgium, the former Ubell metal-working factory, which had stood abandoned since the 1990’s, was chosen by Spaque to be redevelopment for commercial use. Significant amounts of chlorinated solvents had been observed in the groundwater, both widespread and with high concentrations in the source area. Reductive dechlorination was seen to be occurring naturally, but was stalling at cis-1,2 DCE due to a carbon-limited system. REGENESIS designed a remediation approach that would use a slow release electron donor to enhance and maintain full and effective reductive dechlorination (Enhanced Reductive Dechlorination (ERD)) of the target contamination.

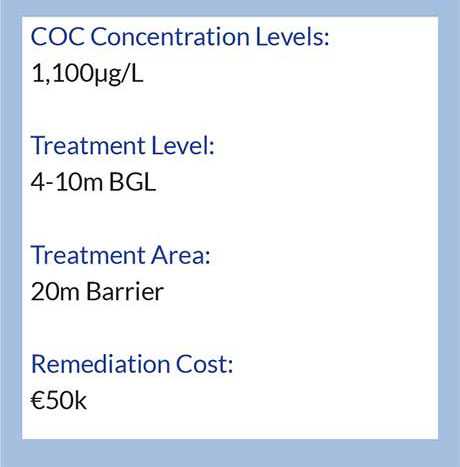

Case study highlights:

- How a single application of 3DME resulted in the full reductive dechlorination of a large plume of chlorinated solvents

- How this simple and inexpensive treatment allowed the redevelopment of a highly impacted brownfield site, while allowing construction and economic use to go ahead unimpeded by the remediation occurred beneath the ground

4m 38s reading time

In situ treatment of MNT, DNT and TNT at former explosives factory

in situ remediation solution for groundwater contamination relating a former explosives factory, now redevelopment site. Goal: mass reduction of dissolved phase propellant contamination, a co-mingled TNT, DNT, MNT plume.Read More

Treatment of Cr(VI) and CHC Groundwater Contamination under a Residential Development

In situ remediation of hexavalent chromium (VI) and chlorinated solvents using combined anaerobic biodegradation and immobilisation in Northampton, UK

Background

On the site of a former chrome plating works, construction and inhabitation had begun on a new residential development. Hexavalent chromium (Cr(VI)) and some chlorinated hydrocarbon compounds (CHCs) had been discovered in the groundwater beneath the development. It was determined by the environmental consultant that the Cr(VI) was driving a risk on the site. The housebuilder required rapid achievement of site targets in order to continue the development of the site.

Case Study Highlights

- REGENESIS provided an accurate and pragmatic design approach for the busy residential construction site

- Full-scale remediation was completed comprising a of a series of rows, totalling 78 injection points, to fit in between the residential properties and services

- A mixed plume of CHCs and Cr(VI) was treated concurrently using a combination of complementary substrates

- The works were completed rapidly with minimal disruption to the construction project and existing residents

- The use of barriers, targeting hotspots and pathways provided a cost-effective and efficient treatment of the plume

- Remediation Cost and Result Graph included

2m 40s reading time

Remediation Products Applied

A combination of ERD and in situ immobilisation using 3-D Microemulsion (3DME) and Metals Remediation Compound (MRC) has been used to primarily to treat the Cr(VI) contamination.

Combined approach to remediate chlorinated solvents in Cambridge, UK

In Situ Chemical Reduction (ISCR), Enhanced Reductive Dechlorination (ERD) and bioaugmentation used on active construction site to allow redevelopment to be completed

Summary

This site is currently undergoing redevelopment from a former industrial estate and trade park, into a business park. The underlying groundwater is impacted with chlorinated solvents from an adjacent industrial site. REGENESIS provided an in situ approach that could provide full reductive dechlorination of the contamination from a single injection, allowing redevelopment to occur during the remediation period.

This site is currently undergoing redevelopment from a former industrial estate and trade park, into a business park. The underlying groundwater is impacted with chlorinated solvents from an adjacent industrial site. REGENESIS provided an in situ approach that could provide full reductive dechlorination of the contamination from a single injection, allowing redevelopment to occur during the remediation period.

1m reading time

Application

It was decided that a combination of In Situ Chemical Reduction (ISCR) using Chemical Reducing Solution (CRS) and Enhanced Reductive Dechlorination (ERD) using 3-D Microemulsion (3DME) as well as bioaugmentation with Bio-Dechlor Inoculum Plus (BDI+) would be applied at this site. This combined approach was designed to provide rapid contaminant degradation, minimised daughter product creation and long term treatment from the single injection. The treatment used seven direct push injection points to accurately target the contamination in a heterogeneous gravels, sands and clay.

What’s Special?

- The ISCR, bioaugmentation and biostimulation approach was used to optimise the remedial approach by combining:

- Wide radii of influence to minimise the number of injection points required

- Rapid onset of ERD

- Minimisation of daughter product creation

- Long-term treatment from a single application

- The application took only one day, with remediation occurring in situ, allowing the site development to continue unimpeded.

Former Taxi Maintenance Site Successfully Treated with Enhance d Anaerobic Biodegradation and Bioaugmentation

Project Highlights

- Combined introduction of HRC® hydrogen release compounds and BDI Plus® bioaugmentation cultures resulted in reduction in chlorinated solvent concentrations, meeting site goals

- Successful remediation permitted redevelopment of the site into an elementary school

Project Summary

A former taxi maintenence facility located in Los Angeles, California was used as a garage and maintenance facility containing seven underground storage tanks (USTs), four hydraulic hoists, an elevator, a clarifier, and a spray paint booth. Environmental assessment related to the planned redevelopment of the garage and nearby commercial properties and residences revealed contamination of the soil and groundwater beneath the site with trichloroethene (TCE) and 1,2-dichloroethene (1,2-DCE) due to release from the former USTs and paint shop areas.

Under the jurisdiction of the California Department of Toxic Substance Control, an enhanced anaerobic biodegradation approach in conjunction with bioaugmentation was developed to remediate the chlorinated solvent contamination. This approach combined the introduction of the dechlorinating microcosm BDI Plus® with the application of supporting hydrogen release compounds 3-D Microemulsion® and HRC Primer®. Following treatment of the site, reduction in TCE and 1,2-DCE concentrations have been observed after four quarters of postremediation monitoring. Microbial data supports the benefits of the bioaugmentation effort by showing a steep increase in dehalococcoides populations, which increased by nearly four orders of magnitude. In addition, all geochemical parameters are in range for a reductive state.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel three-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory-emulsified product.

HRC Primer is derivative of the standard Hydrogen Release Compound product and is designed to provide a controlled but fast release of hydrogen to assist in initiating anaerobic biodegradation.

Bio-Dechlor INOCULUM Plus (BDI Plus) is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Results

Reduction of TCE and 1,2-DCE concentrations by enhanced anaerobic biodegradation and bioaugmentation facilitated the redevelopment of a former taxi garage and maintenance facility. Following a reduction in contaminant concentrations, the site was redeveloped to an elementary school.

45s reading time

In Situ Treatment of Chrome(VI) Plume in Fast Flowing Aquifer, NW Italy

Summary

A former chemical manufacturing plant in northwest Italy was due for demolition to allow redevelopment into residential properties. Site investigations showed elevated concentrations of Cr(VI) in the groundwater, which were above the stringent National Standards of 5μg/L, requiring remedial works to be completed. The groundwater under the site is aerobic and fast-flowing, causing the contaminant plume to migrate beyond the site boundary. It was decided that an in situ approach was required to remediate the Cr(VI) prior to sale of the site.

A former chemical manufacturing plant in northwest Italy was due for demolition to allow redevelopment into residential properties. Site investigations showed elevated concentrations of Cr(VI) in the groundwater, which were above the stringent National Standards of 5μg/L, requiring remedial works to be completed. The groundwater under the site is aerobic and fast-flowing, causing the contaminant plume to migrate beyond the site boundary. It was decided that an in situ approach was required to remediate the Cr(VI) prior to sale of the site.

3m 28s reading time

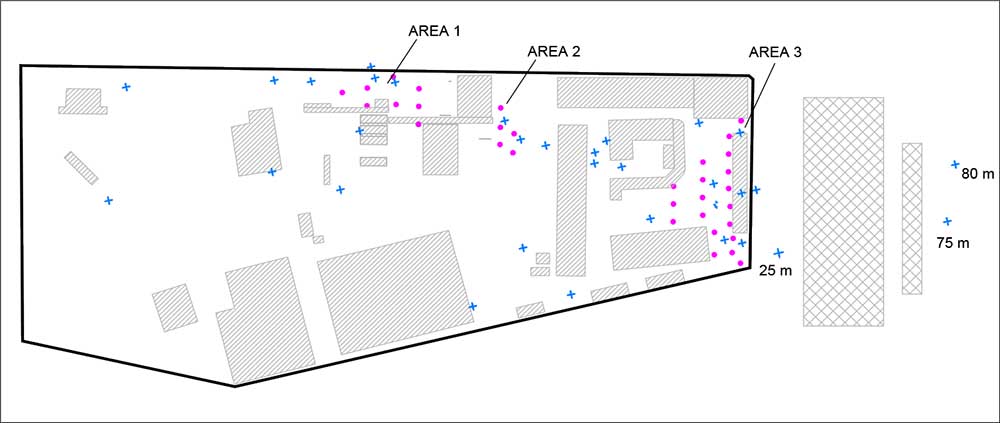

Site plan showing treatment areas, injection wells (pink) and monitoring well (blue) locations

Remedial Approach

Two areas within the plume were identified as being above the site remediation target of 100μg/L. These were targeted with an injection of 3D Microemulsion (3DMe) and MRC in order to reduce the soluble Cr(VI) to non-toxic solid Cr(III) and stabilise it within the aquifer matrix.

The dose of MRC was tailored to match the vertical distribution of the contamination in order to provide the most accurate and cost effective treatment. 3DMe relies upon micellar transportation following injection in order to provide a wide radius of influence from each injection location. This was important on this deep site, in order to minimize the number of injection points required on the site.

Fixed injection points were installed and a single application of the reagents was completed. The injectable substrates were combined at a central mixing location and then pumped into several injection points simultaneously. The process was repeated until the all of the target areas were treated.

Reagent mixing and injection into fixed wells

3-D Microemulsion (3DMe)®

3DMe provides an immediate, mid-range and long-term, controlled release supply of hydrogen (electron donor) to rapidly create and then sustain anaerobic conditions. This will reduce the Cr(VI) to Cr(III), which will then settle out as a solid. Reversion to natural conditions following the 3DMe treatment (in perhaps five years or more) will not cause this process to reverse.

3DMe is also designed to distribute over very wide areas from each injection point. This is achieved through the molecule having hydrophilic and oliophilic properties hence upon mixing with water, 3DMe forms a microemulsion made of tiny micelles, which propagate through and coat the aquifer. This micelles are also able to transport MRC molecules within them, creating a wide and effective treatment zone, which is then sustained for many years.

Metals Remediation Compound (MRC)®

MRC is a controlled release remediation product designed specifically for the treatment of hexavalent chromium (Cr(VI)) in groundwater. MRC’s active compound is an ester of cysteine (a sulfur-containing amino acid) on a carbon backbone molecule of glycerol and sorbitol. A cysteine-based product such as MRC is well suited for in situ Cr(VI) immobilisation, since it has a strong affinity for metal contaminants and does not alter the properties of the subsurface. The active compound in MRC (sorbitol hexacysteinate) is embedded in a polylactate matrix that provides a carbon source and electron donor for subsurface bacteria. This combination of materials makes MRC a viscous but injectable material that slowly releases the cysteine ester to a contaminated aquifer via hydrolysis by water or enzymatic action by microbes. MRC’s slow release property allows for a longevity of 12 to 18 months in an aquifer, allowing for an effective approach to metals immobilisation.

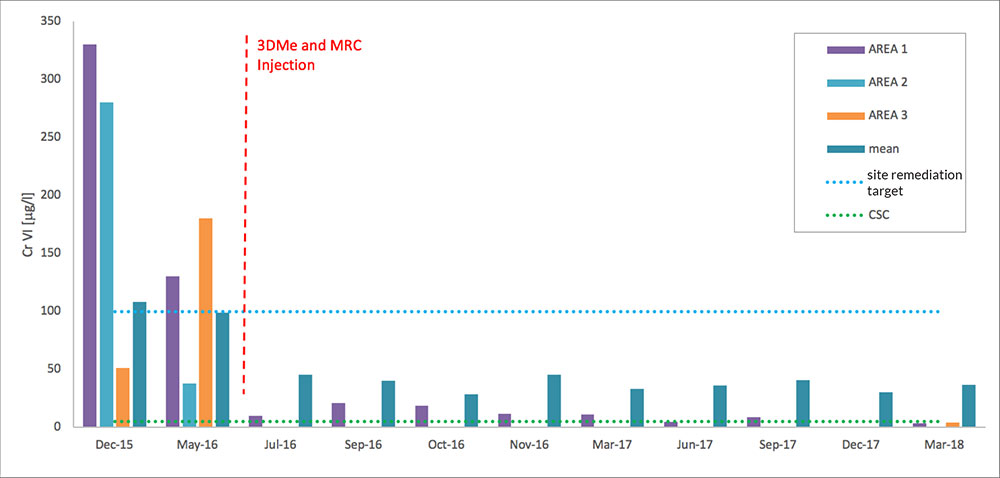

Chromium VI concentrations in groundwater before and after treatment.

Area 1 and 2 need to reach the site remediation target, Area 3 needs to reach CSC

Results

Validation monitoring shows very good substrate distribution at all but one out of thirteen monitoring points. The reduction of the Oxidation- Reduction Potential (ORP) and dissolved oxygen with the simultaneous increase of the Total Organic Carbon (TOC), as well as an increase in iron and manganese, clearly showed the desired trend. The analytical results showed a rapid and significant reduction of CrVI targeting values often below the 5 μg/l limit, with a removal efficiency of 90% on average.

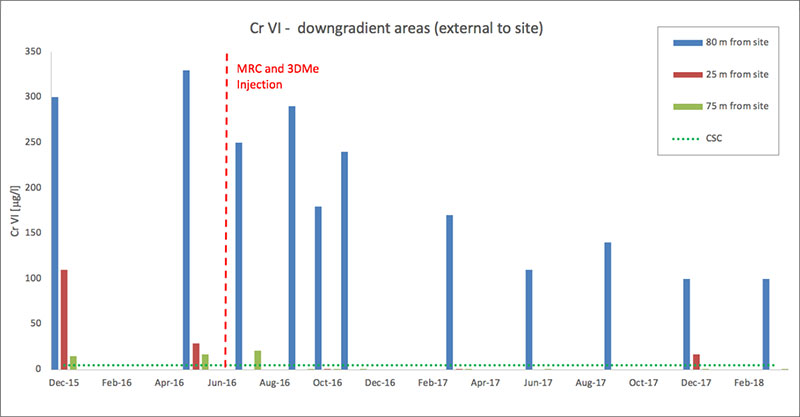

Downgradient Chromium VI concentrations at 25m (red), 75m (green) and 80m (blue) from the site

What’s Special?

- The ability of 3DMe to self-distribute over a wide radius of influence from each injection point allowed the injection grid to be widely spaced. This minimised the number of application wells, which, given the depth of the treatment, greatly reduced the remedial costs.

- Treatment of Cr(VI) was very rapid and sustained despite the aquifer being very aerobic and fast flowing.

- Even though the aquifer was very fast-flowing, the products have not suffered from wash-out and continue to successfully treat the target areas over an extended period of time.

- The seasonal variation in groundwater level at the site has the potential to mobilise contaminants into the groundwater during periods of high precipitation. The longevity of the reagents allows this contaminant influx to be addressed and avoid rebound.

- The injection technology selected saved money by avoiding the use of clustered-wells. The injection rate was high, saving time on site.

- The results of the remediation can be seen over 20m downgradient, through a significant reduction of Cr(VI) in offsite monitoring wells, providing rapid benefit to the environment on and off the site.

Successful 12-Month Pilot Trial of Enhanced Reductive Dechlorination

With RGS Nordic and Nordic Envicon

Introduction

![]() REGENESIS were approached by RGS Nordic and Nordic Envicon to form part of a specialist team to design a remedial scheme for a former aerospace factory in Finland.

REGENESIS were approached by RGS Nordic and Nordic Envicon to form part of a specialist team to design a remedial scheme for a former aerospace factory in Finland.

An area of over 100,000m2 is impacted by a chlorinated solvent plume in the groundwater, comprising predominantly cis-1,2-dichloroethylene (DCE) contamination. The first phase of these works comprised a pilot trial, to demonstrate the applicability and efficacy of the suggested treatment method ahead of full-scale deployment.

An area of over 100,000m2 is impacted by a chlorinated solvent plume in the groundwater, comprising predominantly cis-1,2-dichloroethylene (DCE) contamination. The first phase of these works comprised a pilot trial, to demonstrate the applicability and efficacy of the suggested treatment method ahead of full-scale deployment.

Download the PDF 2m 21s reading time

Remediation Approach

The site had many challenges that needed to be overcome in order to deliver a cost-effective scheme of works:

- Complex heterogeneous formation, comprising sands, gravels, silts and crystalline bedrock;

- Extremely large plume (>100,000m2 of which 60,000m2 requires treatment);

- Conflicting seasonal groundwater flow directions;

- Full-scale works will be required to deliver a fully remediated site within two years.

After completing an in-situ remediation option appraisal the team agreed that the full-scale strategy should comprise a series of ‘barriers’ (treatment zones through which groundwater would continue to flow, but in which the contamination would be degraded) perpendicular to groundwater flow.

This configuration would minimize the number of injection points, reducing application costs, without compromising treatment efficiency. The electron donor which was suggested was 3-D Microemulsion® (3DMe).

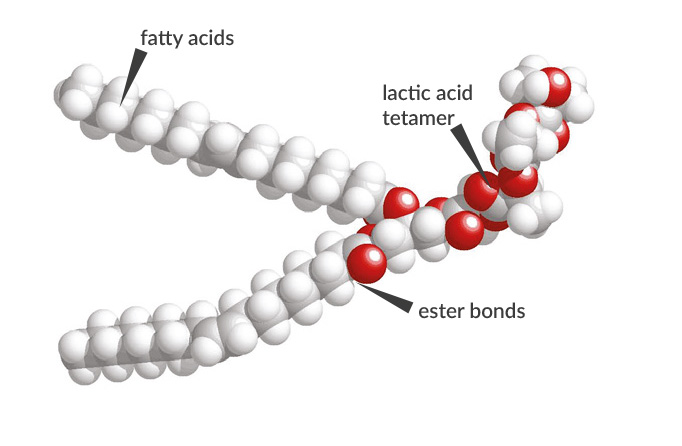

Fig. 1 – The molecular structure of 3-D Microemulsion

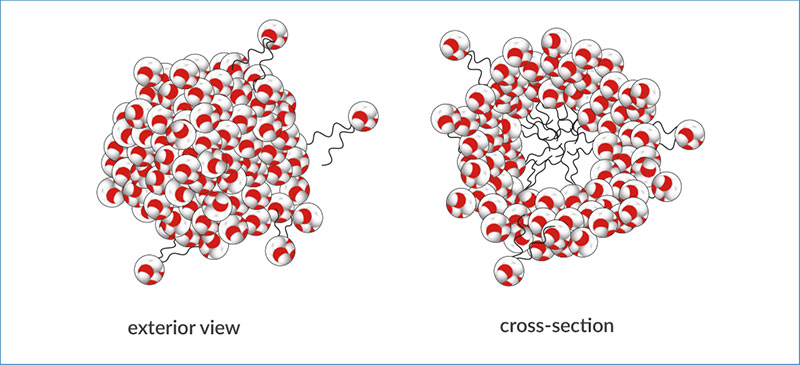

Fig. 2 – The 3 Stage Release profile of 3DMe

3DMe provides three stages of electron donor release from a single concentrate of specially designed polar molecules. When mixed with water on site, 3DMe forms a high-volume microemulsion, without the requirement of emulsifiers.

Upon injection into the groundwater, 3DMe initially moves out into the formation and adsorbs to the soil particles. As the molecule is designed to be appropriately soluble, it then gradually dissolves back into the groundwater, where it ferments to drive enhanced reductive dechlorination (ERD), but also reaches its critical micelle concentration (300 ppm), reforms as a microemulsion and moves further out from the injection point.

This process repeats to ‘self-distribute’ the 3DMe over large distances within the subsurface, without it washing away. This mechanism allows for wider injection spacing which reduced the number of injection locations.

Fig. 3 – 3DMe micelle representation

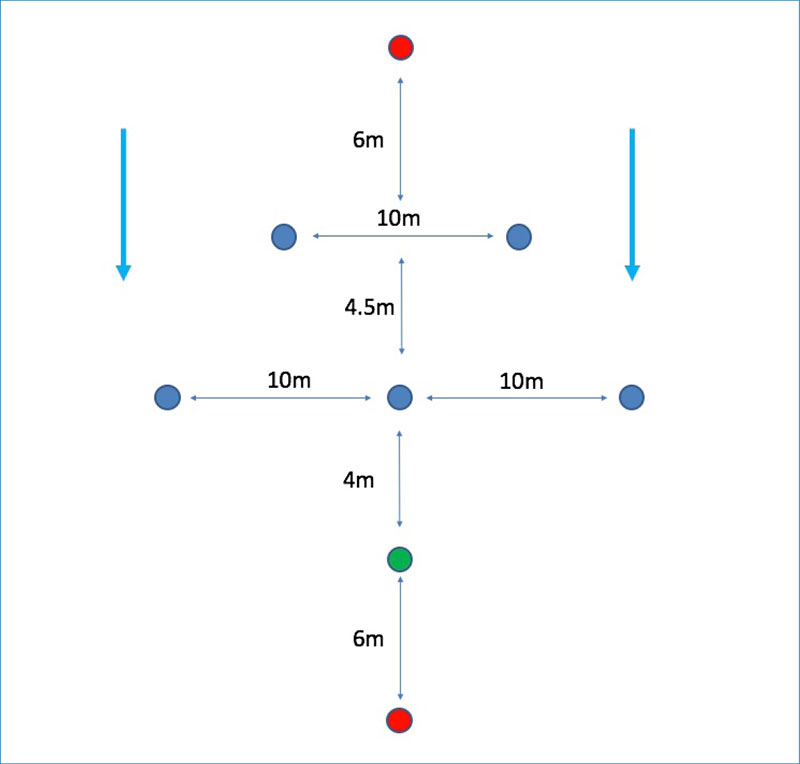

Fig. 4 – Injection configuration

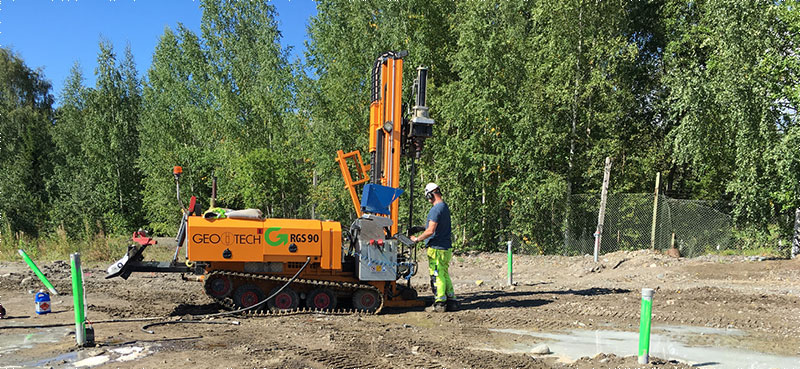

Pilot Trial Application

Prior to a full-scale application being completed, it was determined that a pilot test should be completed. The intention was to determine how well the heterogeneous formation would accept the application, verify the injection spacing and confirm the efficacy of the treatment. A 20m wide barrier was installed perpendicular to groundwater flow. This consists of 5 injection points, forming two rows with 10m spacing within the rows and 4.5m in between rows (see fig. 4) This created an effective injection spacing of 5m perpendicular to groundwater flow.

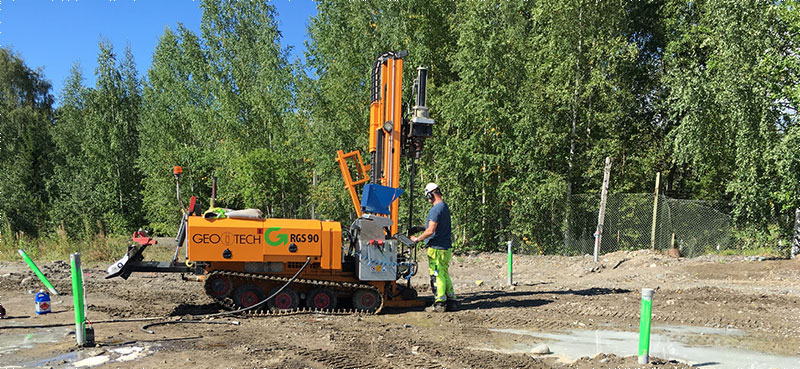

Direct push injection was used, with the requisite dose of 3DMe injected at each location from 4m BGL (groundwater level) to 10m BGL (top of the competent bedrock).

Fig. 5 – Injection works on site

Fig. 6 – Injection works on site

Results

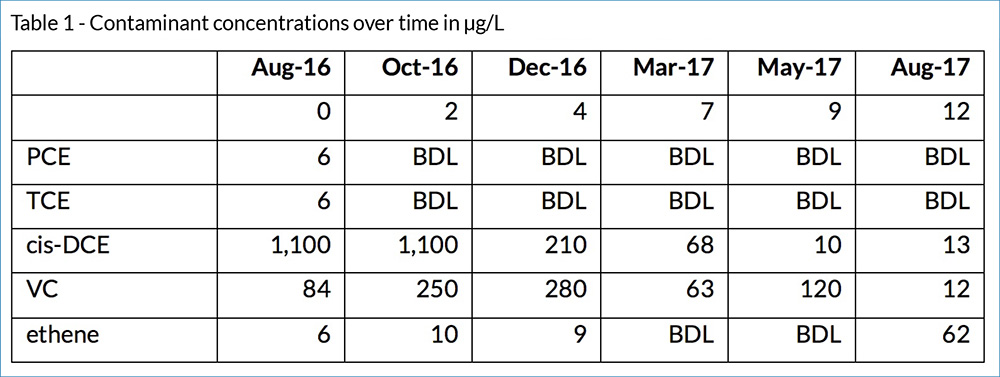

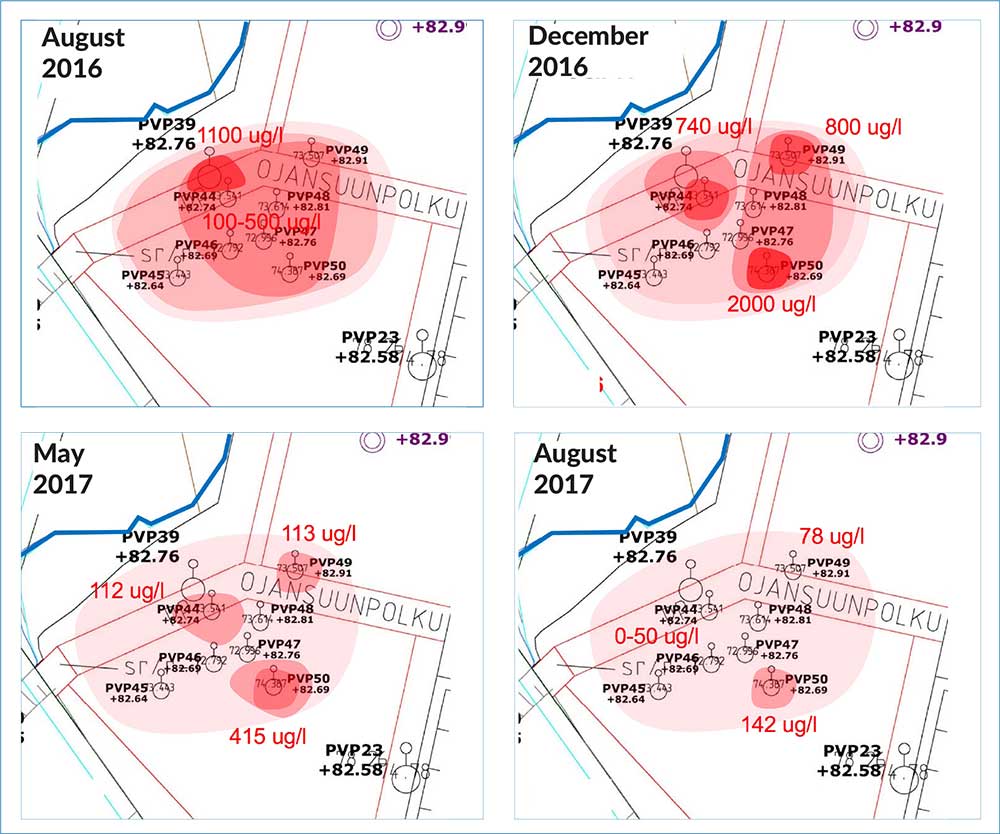

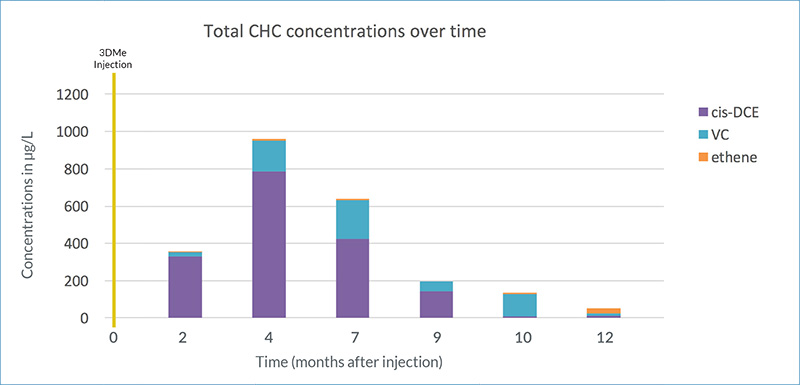

Validation was completed over 12 months following application. During this period the small amounts of PCE and TCE were reduced in the groundwater to below detection limit. The main cis-1,2-DCE contamination was reduced by 99% to 13μg/L, well below the remedial target of 500μg/L. Sequential production and degradation of daughter products showed that full reductive dechlorination was achieved, with vinyl chloride (VC) concentrations peaking at 280μg/L, but then quickly decreasing to 12μg/L by the end of the validation period. Full reductive dechlorination was also evidenced by the production of ethene throughout the treatment.

Fig. 7 – Contaminant concentrations plots in target area over time

Fig. 8 – Total CHC concentrations over time

Conclusion

- The pilot trial demonstrated the ability to apply 3DMe on a wide grid in a heterogeneous formation.

- The treatment successfully reduced the contaminant of concern by 98%, well below the remedial target values.

- Full reductive dechlorination of the contaminant was achieved.

- The pilot trial allows for the full scale treatment to be accurately designed and programmed.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español