Rapid Elimination of Chlorinated Solvents

Case Study Highlights:

-

Combined approach using 3 REGENESIS remediation products resulted in >99% reduction in CVOC concentrations

-

90% reduction goal achieved within 4 months post-application

-

Ongoing monitoring indicates the continued effectiveness of the treatment, with additional reductions expected in the following months

In Southern California, a retail facility with an active food service tenant faced significant groundwater contamination from chlorinated solvents, primarily tetrachloroethylene (PCE) and trichloroethylene (TCE), resulting from a historical release at a former dry cleaners on-site, which also impacted adjacent properties. Despite previous remediation efforts, high contaminant concentrations persisted, feeding a contaminant plume. Using 3-D Microemulsion® (3DME), our sulfidated micron-Scale ZVI : S-MicroZVI® , and Bio Dechlor Inoculum Plus® (BDI Plus), the site achieved a greater than 99% reduction in CVOC concentrations and halted plume migration through biologically enhanced reductive dechlorination (ERD) and in situ chemical reduction (ISCR), meeting the site’s performance goals.

High levels of TCE Remediated at Historic Chemical Works

Award-winning In Situ Remediation of DNAPL Achieves Remedial Goals

Case study highlights:

- Once considered one of the most environmentally contaminated sites in the UK

- REGENESIS designed and delivered a suitable and pragmatic in situ groundwater solution on behalf of Vertase FLI for a portion of the site, fitting in with the wider remediation works and site redevelopment programme.

- Combined ERD and ISCR treatment using S-MicroZVI® and 3-D Microemulsion®

- 90% TCE mass removal achieved in 12 months, exceeded the remedial goal, allowing the site redevelopment to continue apace.

- Multiple lines of evidence show ongoing, long-term reductive dechlorination, without VC stall.

- Winner of the Brownfield Award 2024 ‘Best Application of Remediation Technologies‘

Or watch the 5-min project video with site footage and interviews

In Situ Chlorinated Solvent Treatment Protects Municipal Pumping Station

Remediation of a former dry cleaner site in Värnamo, Sweden

In situ remediation of groundwater impacted with high levels Tetrachloroethene (PCE) was completed at a former dry cleaning site, as the temporary installed groundwater recirculation system proved too expensive to run as a permanent solution. RGS Nordic carried out soil remediation using muliphase extraction and worked with REGENESIS to provide a remediation solution for the groundwater plume. Read the case study to find out about the remedial design, application and the results.

Highlights

- Example of a sustainable solution as no further operation cost or energy use required and it produced no waste for disposal

- Enhanced Reductive Dechlorination using a mix of REGENESIS electron donors delivers reduction in total chlorinated solvents of 99.6%

- 8 years of monitoring data shows no rebound in parent or daughter contaminant concentrations

- Downstream municipal pumping station is now protected from further contaminant ingress without the need for a protective pump & treat system

2m 39s reading time

Treatment Solution for Large TCE Plume Saves Client $380,000

Case study highlights

At a former manufacturing facility high levels of chlorinated solvents had been released into the groundwater, creating a large plume extending to the nearby river. A combined in situ biogeochemical reduction solution rapidly mitigated the threat to river:

-

Large TCE plume effectively treated using combined technology solution from REGENESIS, including PlumeStop® and S-MicroZVI®

-

Accurate mapping of CVOC flux zones using FluxTracers® saves millions in project cost

-

Safe and efficient installation meets time and budget requirements

6m 38s reading time

Cost-effective In Situ Remediation of Chlorinated Solvents in Svenljunga, Sweden

Cost-effective In Situ Remediation of Chlorinated Solvents in Svenljunga, Sweden

In situ remediation of groundwater impacted with Trichloroethylene (TCE) was completed at a former fur factory in Svenljunga, Sweden, as it had been determined that excavation or thermal treatment would have been too expensive. A targeted application of 3-D Microemulsion® was performed using direct push technology (DPT) to complete the injections. Validation sampling showed that the concentrations in the groundwater and soils had been reduced by approx. 95%, to well below the remedial targets.

2m 31s reading time

About the Remediation Technology

3-D Microemulsion (3DME) is an engineered electron-donor emulsion that offers a steady and long-term source of staged-release hydrogen (in the order of 4 to 5 years from a single application) to enhance the reductive dechlorination (ERD) of chlorinated compounds. It has been optimized to distribute widely upon injection, allowing for high volume applications, reducing the number of injection points and events required onsite. Click the logo to learn more about how 3DME works.

Reductive Dechlorination Approach Treats Large Chlorinated Solvent Plume

Case study highlights:

- Innovative combined remedy on active site effectively eliminates risk to adjacent property

- Remedy from REGENESIS chosen based on proven effectiveness in treating similar large CVOC plumes

- Design Verification Testing and placement validation guide a successful remedial application

This case study reviews the successful in-situ treatment of chlorinated solvents at a former food processing plant located in a suburb south of Indianapolis. PlumeStop, S-MicroZVI, 3DME and BDI Plus were used in combination to strongly inhibit CVOC plume migration near the site property boundary while enhancing abiotic and biotic degradation of CVOCs at this location and in the upgradient plume area. Patriot Engineering and Environmental, Inc. (Patriot), a leading consulting firm based in Indianapolis, investigated the site, discovering contaminants had migrated from an unidentified source and formed a large plume. In addition, it was found that the plume was being pulled toward a former (now inactive) public water supply well. The primary chlorinated volatile organic compounds (CVOCs) detected in the plume were tetrachloroethene (PCE), trichloroethene (TCE), and cis-1,2-dichloroethene (cis-DCE).

98% PCE Reduction Achieved After 16 Months

The site is a former dry-cleaning supply distribution business that operated from 1957 to 2000. The former facility provided laundry chemicals, including detergents and spotting chemicals, packaging products such as hangers and polyethylene bags, and bulk deliveries of tetrachloroethene (PCE). Remediation at the site was completed in two primary phases. The first phase was a targeted excavation and soil mixing event focused on addressing the highly impacted shallow soils and smear zone. The second phase was focused on treating the groundwater PCE plume onsite and preventing further plume migration offsite.

Case study highlights:

- High PCE concentrations were detected in soil and groundwater during a site investigation

- A pragmatic, phased approach was used to target PCE in soil and groundwater

- The multi-component treatment was immediately effective and has maintained 98% PCE reduction in onsite groundwater

4m 23s reading time

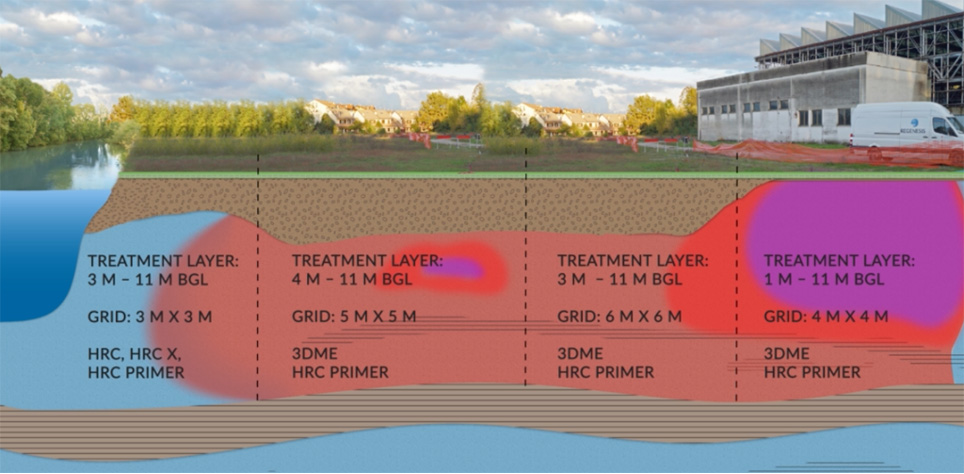

DNAPL to Non-Detect: 6 Orders of magnitude reduction of chlorinated solvents

Combined in situ sorption and biological degradation leads to site closure of large manufacturing site in Northern Italy

Chlorinated solvents were used for many years at a former manufacturing facility in Northern Italy. This resulted in contamination of the groundwater underlying a large proportion of this 60,000 m2 site. Groundwater concentrations of up to 155,000 μg/L TCE meant there was a suspected presence of Dense Non Aqueous Phase Liquid (DNAPL) on parts of the site. The contamination posed an unacceptable risk to both on- and off-site receptors and it was determined that active remediation was required on a large proportion of the site.

Remediation Strategy:

REGENESIS created a strategy comprising Enhanced Reductive Dechlorination (ERD) tailored to contaminant concentrations and local geology, across the entire impacted area. This strategy was coupled with an injectable Permeable Reactive Barrier (i-PRB) at the site boundaries. This in situ remediation approach proved to be successful, leading the site to closure after having reached stably very stringent concentrations (VC<0.5 μg/l; TCE<1.5 μg/l) and obtaining up to 6 orders of magnitude reduction in concentrations.

Suite of REGENESIS products applied for ERD: 3-D Microemulsion®, HRC®, HRC-X®, HRC Primer®.

Injectable Permeable Reactive Barrier : PlumeStop®Liquid Activated Carbon™ (CAC)

6m 30s reading time

PlumeStop Treatment of Chlorinated Solvents in a Bedrock

Successful pilot study uses colloidal activated carbon to protect

nearby surface waters, United Kingdom

Introduction

REGENESIS was asked to provide a remediation solution for a Trichloroethylene (TCE) plume in the UK. We worked closely with Golder to design and implement a novel solution that combined Plumestop, HRC and BDI+ to sorb and biologically degrade the contamination, rapidly and effectively reducing contamination downstream to nondetectable

levels.

Case Study Highlights

This pilot study shows that treatment of chlorinated solvent plumes is possible using PlumeStop even with challenging conditions such as a: co-mingled plume, fractured bedrock setting, and a highly variable hydraulic conductivity.

The PlumeStop in situ permeable reactive barrier rapidly reduced downgradient contaminant concentrations and maintained these through a combination of sorption and biological degradation,protecting the adjacent surface water receptor.

3m 50s reading time

In Situ Remediation of CHCs within a Bedrock Aquifer, Germany

Case study: High concentrations of chlorinated hydrocarbons (CHCs) were observed in a sandstone bedrock underneath a school in Bavaria, southwest Germany. Environmental Consultant Wood worked with REGENESIS to develop an in-situ groundwater remediation solution for the site.Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español