Reductive Dechlorination Approach Treats Large Chlorinated Solvent Plume

Case study highlights:

- Innovative combined remedy on active site effectively eliminates risk to adjacent property

- Remedy from REGENESIS chosen based on proven effectiveness in treating similar large CVOC plumes

- Design Verification Testing and placement validation guide a successful remedial application

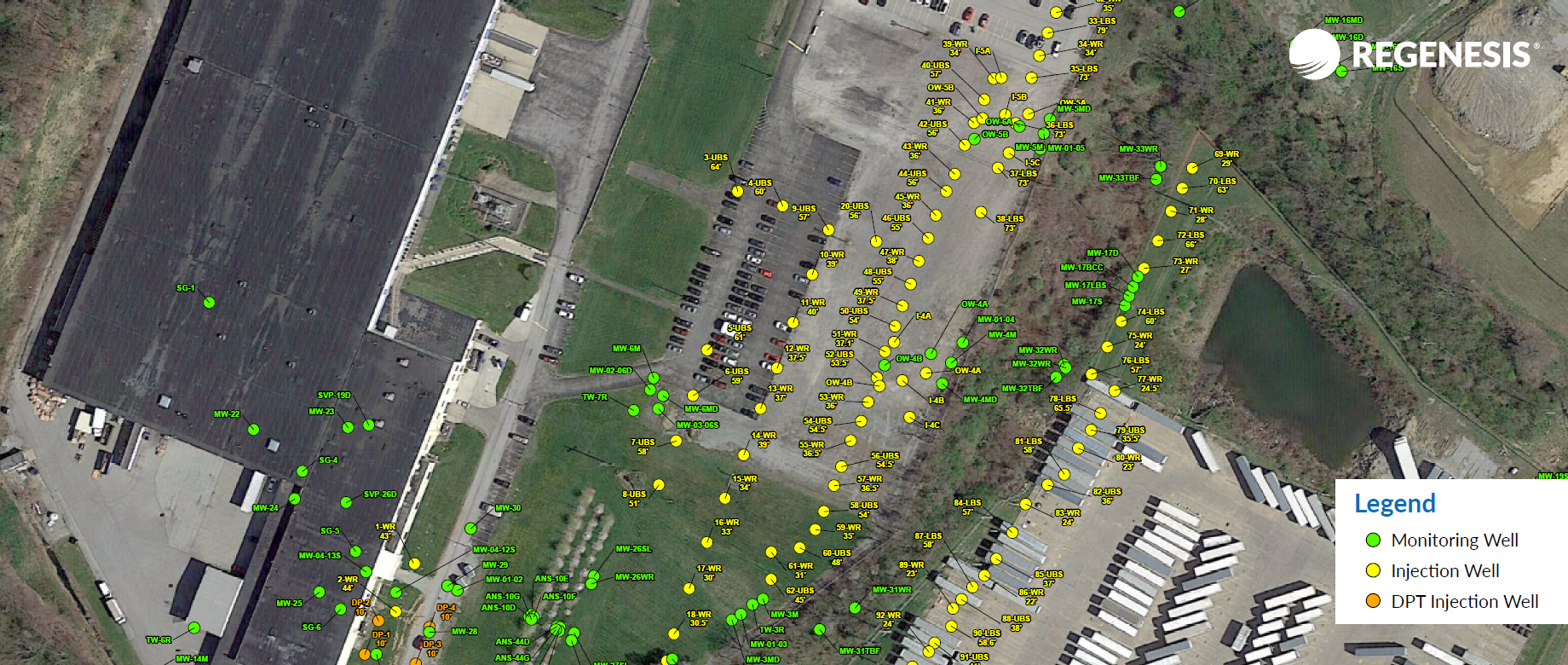

This case study reviews the successful in-situ treatment of chlorinated solvents at a former food processing plant located in a suburb south of Indianapolis. PlumeStop, S-MicroZVI, 3DME and BDI Plus were used in combination to strongly inhibit CVOC plume migration near the site property boundary while enhancing abiotic and biotic degradation of CVOCs at this location and in the upgradient plume area. Patriot Engineering and Environmental, Inc. (Patriot), a leading consulting firm based in Indianapolis, investigated the site, discovering contaminants had migrated from an unidentified source and formed a large plume. In addition, it was found that the plume was being pulled toward a former (now inactive) public water supply well. The primary chlorinated volatile organic compounds (CVOCs) detected in the plume were tetrachloroethene (PCE), trichloroethene (TCE), and cis-1,2-dichloroethene (cis-DCE).

Injectable PRB provides rapid remediation of chlorinated plume allowing redevelopment within months

Stringent regulatory targets achieved in short timescale, despite challenging site conditions

Historical industrial activities at a former silver frames manufacturing facility in Central Italy had caused chlorinated solvent contamination in the subsurface, which was extending beyond the site boundary. As the site was undergoing redevelopment into residential buildings, the construction company had a strict deadline for remediation to be completed and so a strategy was needed to avoid the long-term installation of active pumping equipment onsite.

Highlights:

- An in situ permeable reactive barrier (iPRB) was installed combining PlumeStop, S-MicroZVI and BDI Plus reagents

- Additional Design Verification Testing (DVT) was completed by REGENESIS prior to full-scale works

- Remediation targets and the client’s economic requirements were achieved on time and within budget, under a guaranteed contract

4m 44s reading time

“REGENESIS has been supportive throughout all the steps, starting before our remediation design with the remedial investigation activities. Their input was crucial to identify how to best design the treatment and resulted in a very straightforward project for my client, meeting goals in a timely manner, without any surprises.”

Alessandro Lucchesini, Technical Manager, CECAM

a.lucchesini@cecamsrl.it | +39 335 835 05588

Combined ISCR and ERD remedial approach knocks down PCE concentrations in Poland

Rapid groundwater treatment achieved at manufacturing plant, without daughter product build-up

At an active manufacturing plant in the region of Greater Poland, in the West of the country, historical perchloroethylene (PCE) contamination was found to be impacting both soil and groundwater. Environmental company PROTE determined that contamination originated from a number of spills and leakages that occurred over the >20 years of manufacturing on the site

The canal adjacent to the site was identified as a potential downgradient receptor vulnerable to impact from offsite advection of the contamination. Therefore remediation was driven by a requirement to remove the site owner’s potential liability, whilst being completed within strict budgetary restrictions.

Highlights:

- Safe and easy co-injection of PlumeStop and S-MicroZVI

- A grid of 30 injection wells was used, with a 4m spacing between wells

- A rapid, significant drop in PCE concentrations was achieved in the entire treatment area, with no daughter products observed

- Monitoring is ongoing

2m 4s reading time

“The collaboration with REGENESIS, both during the design phase and the operational phase of the remediation works, has enabled us to apply cutting-edge technologies that reached the remediation objectives in a short period of time, whilst respecting the surrounding environment and minimising impacts on the commercial activities on the site.”

Michal Tatera, Kierownik Projektu ds. Ochrony Środowiska, PROTE Technologie dla Środowiska Sp. z o.o.

225m Permeable Reactive Barrier Treats TCE and Chromium (VI)

Sustainable and cost-effective remediation of a co-mingled plume in a sensitive chalk aquifer

A 48 hectare site in the UK was to be redeveloped for mixed commercial and residential use. The existing site included a mix of historic and existing industrial land use, including a metal plating works, surrounded by agricultural land and residential housing. The Mott MacDonald engaged early with REGENESIS regarding potential options for remediation.

Case Study Highlights:

- A large-scale remediation project with challenging conditions: geology, underground services, ongoing site use and multiple stakeholders

- Treatment of a co-mingled chromium (VI) and TCE plume via enhanced biological dechlorination and chemical reduction, using: S-MicroZVI,

3-D Microemulsion and BDI Plus - Pilot study proves appropriateness of the proposed in situ remedial solution, allowing regulatory sign off for the full scale works.

- Post remediation monitoring results to date show significant chromium reduction and TCE below detection limits

98% PCE Reduction Achieved After 16 Months

The site is a former dry-cleaning supply distribution business that operated from 1957 to 2000. The former facility provided laundry chemicals, including detergents and spotting chemicals, packaging products such as hangers and polyethylene bags, and bulk deliveries of tetrachloroethene (PCE). Remediation at the site was completed in two primary phases. The first phase was a targeted excavation and soil mixing event focused on addressing the highly impacted shallow soils and smear zone. The second phase was focused on treating the groundwater PCE plume onsite and preventing further plume migration offsite.

Case study highlights:

- High PCE concentrations were detected in soil and groundwater during a site investigation

- A pragmatic, phased approach was used to target PCE in soil and groundwater

- The multi-component treatment was immediately effective and has maintained 98% PCE reduction in onsite groundwater

4m 23s reading time

PlumeStop and S-MicroZVI Application Paves The Way For Redevelopment

Case study highlights

This case study reviews a contaminated chlorinated solvent site in northern California, USA, where advanced design verification testing and predictive modeling methods were used to guide a remarkably successful in-situ remediation effort:

-

Highly successful remediation solution using colloidal technologies: PlumeStop and S-MicroZVI

-

Complete reduction of PCE, TCE and daughter products in the treatment areas

-

Flux-based predictive modeling used to optimise remediation to meet two-year timeline

-

Remedial objectives achieved allowed redevelopment of the property

Combined ISCR and in situ sorption of a PCE plume on school grounds in Northern Italy

An ongoing manufacturing facility located within a major Italian city created a widespread tetrachloroethene (PCE) contaminant plume in the underlying aquifer. The highly aerobic aquifer has inhibited natural attenuation, with no daughter products detected even after many years.

Environmental company TAUW is in charge of this site and has implemented hydraulic containment within the factory grounds, as required by law. However, there remained a need to target the plume beyond the site boundary, for which they outlined an in situ solution in collaboration with Prof. Marco Petrangeli Papini from Università La Sapienza di Roma.

Case study highlights:

- Safe and easy co-injection of PlumeStop and S-MicroZVI

- 50m long in situ barrier was applied with minimal interference with the school activities

- Significant and rapid decrease of PCE concentrations in all 3 monitoring wells immediately downgradient

4m 47s reading time

Over 8 Million Cubic Feet of Groundwater Treated In 13 Days

This case study reviews the site of a large-scale enhanced reductive dechlorination (ERD) treatment of chlorinated volatile organic compounds (CVOCs) applied in a fractured bedrock aquifer at a voluntary remediation site in Pennsylvania. REGENESIS Remediation Services (RRS) began the application in May 2020 and completed it in less than 13 days, averaging nearly 7,000 gallons of fluid volume injected per day at this active facility. In total, more than 260,000 combined pounds of 3-D Microemulsion, Chemical Reducing Solution (CRS) and Bio-Dechlor INOCULUM Plus (BDI Plus) were injected for ERD treatment of the CVOCs. The extensive injection well network and large injection volume required RRS to develop an innovative injection process and containment design. Two 21,000-gallon frac tanks were delivered to the site to hold deoxygenated water used for mixing and to chase product injections. Mixing for the main high-flow system was performed in two large polyethylene tanks that were constantly recirculated to ensure a homogenous mixture.

Case study highlights:

- 8 million cubic feet of CVOC impacted groundwater treated

- 88,000 gallons of ERD remedial amendments applied in less than 13 days using novel, innovative tooling and application approach

- The project was completed more than 40% faster than originally scheduled.

7m 30s reading time

Colloidal Activated Carbon Barrier Protects Neighborhood from Chlorinated Solvent Plume

This case study reviews a field-scale pilot test for in situ groundwater treatment of chlorinated volatile organic compounds (CVOCs) at high concentrations, in a fast-moving, aerobic aquifer beneath a residential neighborhood. The CVOCs were treated using a unique combination of remediation technologies, symbiotically promoting sorption-enhanced reductive dechlorination (ERD) via biotic and abiotic processes. Hamp, Mathews & Associates, Inc., a leading environmental consultant, enlisted REGENESIS to design and install an in situ PRB to fully treat the tetrachloroethene (PCE), trichloroethene (TCE), cis-1,2-DCE (cis-DCE), and vinyl chloride, converting them into nontoxic end products such as ethene, ethane, carbon dioxide, and chloride.

Case study highlights:

- A combined remedy approach using activated carbon and zero valent iron reduces risk of exposure to a residential neighborhood

- PlumeStop permeable reactive barrier (PRB) demonstrated effective in eliminating contaminants in an extreme contaminant flaux aenvironment

- Soil cores and groundwater samples confirmed consistent PlumeStop distribution in the in situ PRB

11m 59s reading time

Combined Amendment Approach Treats Chlorinated Solvents

This case study reviews a formerly undeveloped site in downtown Jacksonville that was impacted with chlorinated solvents in the groundwater and metal-impacted soils. To treat the chlorinated solvent groundwater plume, Terracon selected multiple technologies from REGENESIS, including PlumeStop, zero-valent iron (ZVI), Bio-Dechlor Inoculum Plus (BDI Plus), and Hydrogen Release Compound (HRC). The site required remediation prior to moving forward with development. Ryan Companies US, Inc. (Ryan) was under contract to purchase the property from the site owner and was seeking an expedited closure of the site prior to completion of construction. Ryan plans to develop the site with a nine-story office building and an associated nine-level parking deck. Site rehabilitation through remediation and regulatory closure is being sought through Florida Department of Environmental Protection (FDEP) voluntary cleanup. Environmental engineering and consulting firm Terracon evaluated a variety of remedial technologies as well as existing site conditions to determine the most appropriate application for the site.

Case study highlights:

- Combined remedy approach ensured effective remediation.

- FDEP Voluntary Cleanup program provided tax credits making the remediation and redevelopment possible.

- Remediation allowed the undeveloped block to be developed into a nine-story office building in a growing area of downtown Jacksonville.

6m 39s reading time

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español