Rapid Elimination of Chlorinated Solvents

Case Study Highlights:

-

Combined approach using 3 REGENESIS remediation products resulted in >99% reduction in CVOC concentrations

-

90% reduction goal achieved within 4 months post-application

-

Ongoing monitoring indicates the continued effectiveness of the treatment, with additional reductions expected in the following months

In Southern California, a retail facility with an active food service tenant faced significant groundwater contamination from chlorinated solvents, primarily tetrachloroethylene (PCE) and trichloroethylene (TCE), resulting from a historical release at a former dry cleaners on-site, which also impacted adjacent properties. Despite previous remediation efforts, high contaminant concentrations persisted, feeding a contaminant plume. Using 3-D Microemulsion® (3DME), our sulfidated micron-Scale ZVI : S-MicroZVI® , and Bio Dechlor Inoculum Plus® (BDI Plus), the site achieved a greater than 99% reduction in CVOC concentrations and halted plume migration through biologically enhanced reductive dechlorination (ERD) and in situ chemical reduction (ISCR), meeting the site’s performance goals.

New York Brownfield Site Achieves Site Closure

Case study highlights

In situ remedy replaces ex situ system and achieves PCE and TCE cleanup targets at former metals manufacturing site:

-

a PlumeStop permeable reactive barrier (PRB) replaces pump-and-treat system and achieves site closure

-

Concentrations reduced from 500 µg/L to below 1 µg/L for 6 consecutive quarters

-

Significant cost and energy savings achieved by decommissioned pump-and-treat system

7m 47s reading time

At a former metals manufacturing facility in upstate New York, historic use of chlorinated solvents had resulted in groundwater contamination with tetrachloroethene (PCE) and trichloroethene (TCE). A pump and treat system had been operational on the site for 10 years, successfully reducing contaminant concentrations, but could not reach the clean up targets required for site closure.

Benchmark, a leading engineering and redevelopment consulting company, quickly developed an in situ approach to achieve the project objectives and facilitate site closure. After evaluating remedial alternatives, Benchmark proposed a new Corrective Action Plan (CAP), specifying the in situ application of PlumeStop® (colloidal activated carbon), Hydrogen Release Compound® (HRC), a controlled-release electron donor, and Bio-Dechlor INOCULUM Plus® (BDI Plus), a bioaugmentation culture containing Dehalococcoides sp. and other beneficial microbes.

Effective In-Situ Treatment of a 1km PCE Plume in Finland

Case study highlights:

In Eastern Finland, a fast-moving PCE (perchloroethene) plume beneath a metal-processing facility was remediated to reduce impacts on a municipal drinking water source.

In Eastern Finland, a fast-moving PCE (perchloroethene) plume beneath a metal-processing facility was remediated to reduce impacts on a municipal drinking water source.

- PCE concentrations were reduced to below the drinking water limit at the municipal water supply well (concentration reductions of approximately 80% in the plume within months and 90 to 95% by 18 months)

- Results indicate that the combined treatment approach can be successfully applied in cold groundwater aquifers with low organic carbon content

- Integrated source area grid treatment (ERD) and plume barrier treatment (PlumeStop®) is an effective strategy for treating elongated chlorinated solvent plumes

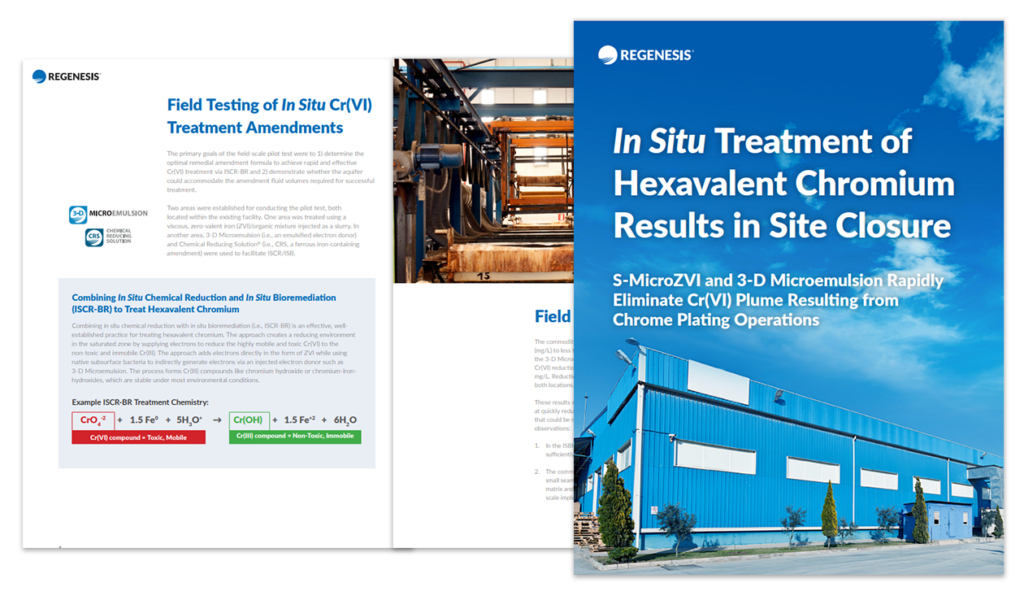

In Situ Treatment of Hexavalent Chromium Results in Site Closure

Case study highlights:

This case study focuses on the successful remediation of hexavalent chromium (Cr(VI)) contamination at a chrome plating facility in the Midwest of North America. Decades of ineffective pump & treat (P&T) operations led to the need for a cost-effective and rapid solution to achieve regulatory closure.

- Commodity ZVI and 3-D Microemulsion/CRS rapidly reduced Cr(VI) concentrations, achieving remarkable reductions within months.

- S-MicroZVI® and 3-D Microemulsion offered improved distribution and reactivity, addressing previous limitations in the remediation process.

- The use of S-MicroZVI® and 3-D Microemulsion led to a rapid 99% reduction in Cr(VI) concentrations, securing regulatory closure for a long-standing contamination case.

2m 55s reading time

Remediation of BTEX and Chlorinated Solvents at Volvo Car Gent

Long-term monitoring shows success of in situ groundwater treatment at an active car manufacturer in Belgium

Background

Volvo Car Gent is a car manufacturing facility in the port district of Ghent, in the west of Belgium. Historic handling and storage of chemicals has led the soils and groundwater below the plant becoming contaminated with Petroleum Hydrocarbons (including BTEX) and Chlorinated Solvents.REGENESIS was asked to provide a solution to treat two plumes and prevent off-site migration, whilst keeping any disruptions to Volvo Car Gent operations to an absolute minimum. Artemis Milieu and REGENESIS worked closely together with client Volvo Car Gent, to deliver the most appropriate and effective remediation solution for the site.

Case Study Highlights

- The full-scale remediation addressed two plumes in two treatment areas with cost-effective in situ barrier and grid injections

- The combined treatment approach used ISCO, Sorption & Enhanced Biodegradation as well as Aerobic and Anaerobic Biostimulation to address the contamination.

- Challenges: operational plant and restricted access

- Client quote, remediation cost and long-term result graphs included

2m 32s reading time

Treatment Solution for Large TCE Plume Saves Client $380,000

Case study highlights

At a former manufacturing facility high levels of chlorinated solvents had been released into the groundwater, creating a large plume extending to the nearby river. A combined in situ biogeochemical reduction solution rapidly mitigated the threat to river:

-

Large TCE plume effectively treated using combined technology solution from REGENESIS, including PlumeStop® and S-MicroZVI®

-

Accurate mapping of CVOC flux zones using FluxTracers® saves millions in project cost

-

Safe and efficient installation meets time and budget requirements

6m 38s reading time

Reductive Dechlorination Approach Treats Large Chlorinated Solvent Plume

Case study highlights:

- Innovative combined remedy on active site effectively eliminates risk to adjacent property

- Remedy from REGENESIS chosen based on proven effectiveness in treating similar large CVOC plumes

- Design Verification Testing and placement validation guide a successful remedial application

This case study reviews the successful in-situ treatment of chlorinated solvents at a former food processing plant located in a suburb south of Indianapolis. PlumeStop, S-MicroZVI, 3DME and BDI Plus were used in combination to strongly inhibit CVOC plume migration near the site property boundary while enhancing abiotic and biotic degradation of CVOCs at this location and in the upgradient plume area. Patriot Engineering and Environmental, Inc. (Patriot), a leading consulting firm based in Indianapolis, investigated the site, discovering contaminants had migrated from an unidentified source and formed a large plume. In addition, it was found that the plume was being pulled toward a former (now inactive) public water supply well. The primary chlorinated volatile organic compounds (CVOCs) detected in the plume were tetrachloroethene (PCE), trichloroethene (TCE), and cis-1,2-dichloroethene (cis-DCE).

Injectable PRB provides rapid remediation of chlorinated plume allowing redevelopment within months

Stringent regulatory targets achieved in short timescale, despite challenging site conditions

Historical industrial activities at a former silver frames manufacturing facility in Central Italy had caused chlorinated solvent contamination in the subsurface, which was extending beyond the site boundary. As the site was undergoing redevelopment into residential buildings, the construction company had a strict deadline for remediation to be completed and so a strategy was needed to avoid the long-term installation of active pumping equipment onsite.

Highlights:

- An in situ permeable reactive barrier (iPRB) was installed combining PlumeStop, S-MicroZVI and BDI Plus reagents

- Additional Design Verification Testing (DVT) was completed by REGENESIS prior to full-scale works

- Remediation targets and the client’s economic requirements were achieved on time and within budget, under a guaranteed contract

4m 44s reading time

“REGENESIS has been supportive throughout all the steps, starting before our remediation design with the remedial investigation activities. Their input was crucial to identify how to best design the treatment and resulted in a very straightforward project for my client, meeting goals in a timely manner, without any surprises.”

Alessandro Lucchesini, Technical Manager, CECAM

a.lucchesini@cecamsrl.it | +39 335 835 05588

225m Permeable Reactive Barrier Treats TCE and Chromium (VI)

Sustainable and cost-effective remediation of a co-mingled plume in a sensitive chalk aquifer

A 48 hectare site in the UK was to be redeveloped for mixed commercial and residential use. The existing site included a mix of historic and existing industrial land use, including a metal plating works, surrounded by agricultural land and residential housing. The Mott MacDonald engaged early with REGENESIS regarding potential options for remediation.

Case Study Highlights:

- A large-scale remediation project with challenging conditions: geology, underground services, ongoing site use and multiple stakeholders

- Treatment of a co-mingled chromium (VI) and TCE plume via enhanced biological dechlorination and chemical reduction, using: S-MicroZVI,

3-D Microemulsion and BDI Plus - Pilot study proves appropriateness of the proposed in situ remedial solution, allowing regulatory sign off for the full scale works.

- Post remediation monitoring results to date show significant chromium reduction and TCE below detection limits

98% PCE Reduction Achieved After 16 Months

The site is a former dry-cleaning supply distribution business that operated from 1957 to 2000. The former facility provided laundry chemicals, including detergents and spotting chemicals, packaging products such as hangers and polyethylene bags, and bulk deliveries of tetrachloroethene (PCE). Remediation at the site was completed in two primary phases. The first phase was a targeted excavation and soil mixing event focused on addressing the highly impacted shallow soils and smear zone. The second phase was focused on treating the groundwater PCE plume onsite and preventing further plume migration offsite.

Case study highlights:

- High PCE concentrations were detected in soil and groundwater during a site investigation

- A pragmatic, phased approach was used to target PCE in soil and groundwater

- The multi-component treatment was immediately effective and has maintained 98% PCE reduction in onsite groundwater

4m 23s reading time

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español