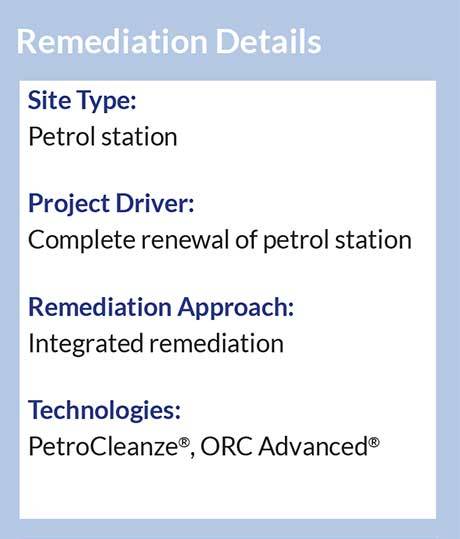

Integrated remediation at a motorway petrol station in Lombardia, Italy

Introduction

A large petrol station located along one of the busiest motorways in northern Italy was undergoing extensive reconstruction, including the demolition of existing buildings, removal of above- and below-ground structures; as well as remediation. The existing underground fuel tanks (USTs) were removed and the contaminated soil surrounding the USTs was excavated to a depth of 5m BGL.

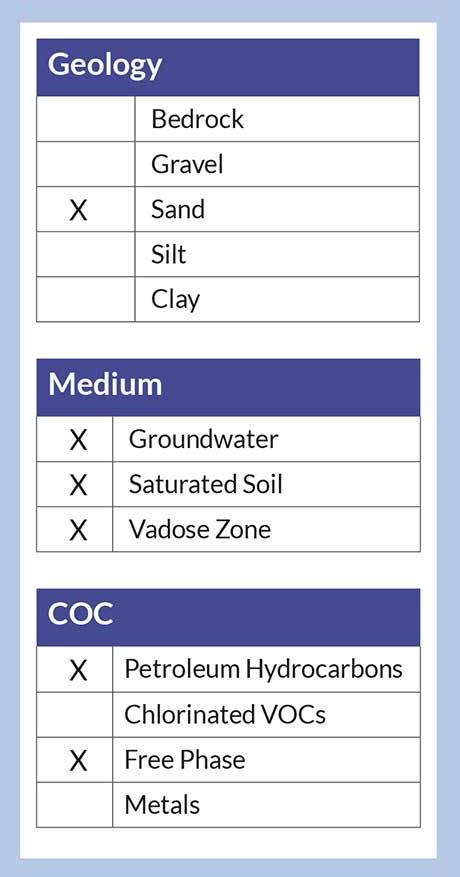

The geology consists of a highly permeable soil comprising sand and gravel to approx. 40m BGL. The average groundwater level is at approximately 4m to 6m BGL, where an extensive contaminant smear zone was observed.

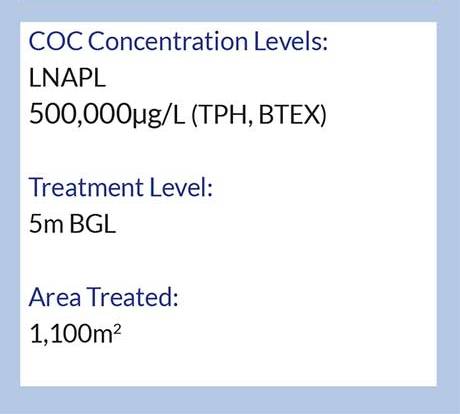

The main excavation was approx. 1,100m2 and 5m deep, with the extent and depth limited by the proximity of the motorway (as well as the presence of groundwater).

The soil at the bottom of the excavation was highly impacted with Total Petroleum Hydrocarbons (TPHs) and BTEX compounds, with concentrations of up to 10,000mg/kg. The groundwater inside the excavation was highly contaminated, with evidence of Light Non Aqueous Phase Liquid (LNAPL) and average concentrations in the range of 500,000μg/L.

Design Approach & Planning

For any treatment approach on this site, to be effective in improving the groundwater quality, it would have to be able to address this secondary source in addition to treating the residual dissolved contamination. The remedial approach also needed to be rapid and effective, in order to allow for immediate back filling. This was because a delay in the construction program would result in a loss of income if the petrol station was not opened on time.

For any treatment approach on this site, to be effective in improving the groundwater quality, it would have to be able to address this secondary source in addition to treating the residual dissolved contamination. The remedial approach also needed to be rapid and effective, in order to allow for immediate back filling. This was because a delay in the construction program would result in a loss of income if the petrol station was not opened on time.

REGENESIS and the Environmental Consultant created an intelligent treatment strategy that took these challenges on board. The remediation approach comprised:

Phase I: Removal of the main contaminant mass present in the saturated soil. This was achieved via Enhanced Chemical Desorption using PetroCleanze, followed by physical abstraction using a vacuum tanker;

Phase II: In Situ biodegradation of the residual dissolved contamination over a period of 9 to 12 months following back fill, via Enhanced Aerobic Biodegradation using ORC Advanced.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

When applied in excavation areas, application is quick and desorbed contaminants can be recovered really easily. Usually two to three application and abstraction rounds are required to remove the bulk of the contamination. PetroCleanze is an inorganic technology and therefore avoids introducing a large oxygen demand (as occurs with using surfactants) and promotes enhanced biological degradation of the residual contamination.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

When applied in excavation areas, application is quick and desorbed contaminants can be recovered really easily. Usually two to three application and abstraction rounds are required to remove the bulk of the contamination. PetroCleanze is an inorganic technology and therefore avoids introducing a large oxygen demand (as occurs with using surfactants) and promotes enhanced biological degradation of the residual contamination.

Phase I – Enhanced Desorption and Extraction

- Before application, the excavation was divided in seven segments, leaving some pathways for excavator passage. For each segment, a specific PetroCleanze application dose was defined.

- PetroCleanze was applied in each sub-area through the dig and mixed directly with the remaining impacted soil. Due to the high contaminant mass present in some of the areas, LNAPL appeared on the water in less than one hour after the first application (the photos shown overleaf were taken 30 minutes after application).

- The LNAPL was subsequently removed by selective pumping using a vacuum tanker.

- Repeated soil mixing and desorbed LNAPL removal took place over the following days across the whole area (for a maximum of 3 cycles in the most contaminated areas).

- The repeated soil-mixing allowed for ongoing desorption and removal of the contamination without the need to add more PetroCleanze. This process was continued for all the sub-areas until no more recoverable free phase was present.

- Finally, a short period of de-watering was completed to remove part of the residual dissolved phase contamination, with water samples taken before and after.

Phase II – Enhanced Aerobic Natural Attenuation

Following the initial excavation and enhanced desorption treatment, an ORC Advanced application was completed. This targeted the residual dissolved phase contamination. The ORC Advanced provided a controlled release of dissolved oxygen in order to stimulate and maintain enhanced aerobic biological degradation of the groundwater contamination for 9-12 months from the single application. This meant that the excavation could be immediately back filled and the construction continued. The remediation of the dissolved phase contamination therefore continued in situ, with no further operational costs and no disruption to the build programme.

To optimise the application process onsite, a pelletised version of ORC Advanced was chosen. This is because they can be applied directly in the excavation without the need for pre-mixing with water. The Pellets also minimise dust formation during application. The pit application was cost-effective, as it did not require additional equipment to be used on site and the application and mixing was safe, quick and straightforward.

Results

- The remediation activities were completed in approximately 40 days on site, which included the product applications, soil mixing, selective pumping and final pump and treat.

- During this period, more than 400L of petroleum hydrocarbon LNAPL was successfully recovered, as well as approx. 100m3 of highly contaminated groundwater with TPH concentrations in the 100,000-1,000,000μg/L range.

- In addition, 280m3 of contaminated groundwater was removed during the final pump and treat activity (before the ORC Advanced application).

- During desorption and removal, no increase in dissolved phase concentrations was seen in the wells immediately downgradient of the excavation, or on the site boundary. This showed that all desorbed contaminants were successfully extracted during the treatment process.

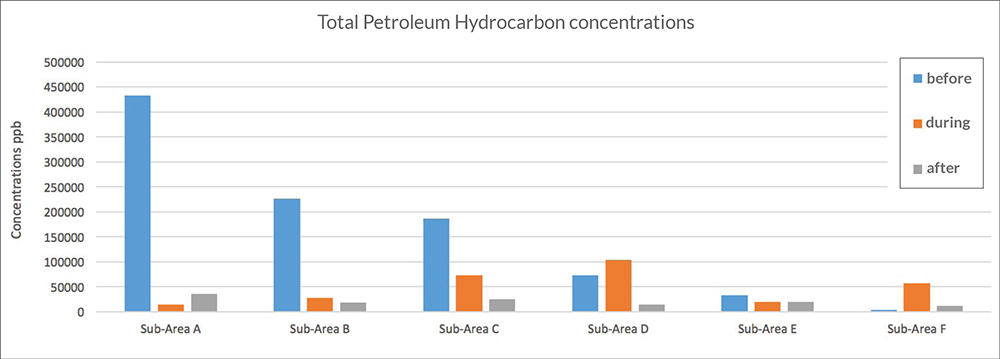

- Subsequent groundwater monitoring shows a significant decrease in concentrations, avoiding any potential delay to the construction programme. The figure below shows the petroleum hydrocarbon concentrations for each sub-area at baseline (blue), during treatment (orange) and after pump and treat (grey).

Conclusion

- The site was remediated on time without disruption to the construction program through the use of enhanced desorption and removal, followed by in situ enhanced aerobic biological degradation.

- An integrated remedial approach was created to target each contaminant type/phase, through excavation of impacted soils, enhanced desorption and extraction of LNAPL and high levels of TPH in the groundwater contamination, to biological degradation of the residual dissolved phase contamination.

- Treatment was limited to the target area with the remediation works producing no increase in downgradient contaminant concentrations.

Integrated Remediation of a Petrol Filling Station, Middlesex, UK

Integrated remediation of a former petrol station using enhanced pump and treat, excavation application and barrier injection.Read More

Rapid, Effective Remediation of Free Product at an Active Rail Depot, UK

Augmented Pump and Treat, In Situ Chemical Oxidation (ISCO) and Enhanced Natural Attenuation (ENA) completed under rail lines by REGENESIS Remediation Services. Read More

In Situ Remediation of Petroleum Hydrocarbons at Rail Depot, Bristol, UK

Surface petroleum hydrocarbon contamination had resulted from historic and on-going leaks at a train maintenance depot near Bristol, where trains were stabled overnight. REGENESIS was asked to design a remedial approach for a hotspot treatment of this contamination within one of the rail tracks.ORC Advanced Socks were installed in wells for the treatment of the dissolved phase contaminants in groundwater. The quick application showed the ease of installation, with only validation of the groundwater required to provide evidence of treatment. The ORC Advanced provided a >90% reduction in the groundwater within the hotspot area.

Remediation of a Diesel Plume at an Active Rail Facility in Yorkshire, UK

Enhanced Natural Attenuation of a TPH Plume using ORC Advanced as part of an integrated treatment train solution provided by AECOM.Read More

Innovative Combined Amendment Approach Successfully Applied to Treat PHC Levels

Project Highlights

- Site previously treated with a series of RegenOx® and ORC Advanced® amendments significantly reduces plume concentrations. Remaining hot spot was then treated with turn-key injection application of PersulfOx® and ORC Advanced technologies bringing closure to facility

- Successful turn-key treatment of offsite hot spot completed within five days

Project Summary

An active gas station, identified by the State of Washington Department of Ecology as one of five LUST sites within one mile of Vancouver’s three groundwater monitoring wells, had entered into the state’s Voluntary Cleanup Program (VCP) in 2006 subsequent to shutdown of the onsite air-sparge/vapor extraction (AS/VE) system. This system had historically been employed at the site to supply oxygen for remedial purposes and address subsurface contamination that was first discovered beneath the dispenser islands in 1993. While prior applications of RegeneOx and ORC Advanced were effective in mitigating onsite contamination, PHC levels remained above MTCA criteria offsite hindering achievement of regulatory closure.

Antea® Group—the environmental consulting firm charged with remediation—partnered with REGENESIS® to implement a remedial strategy and technical design, which included the turn-key injection application of PersulfOx and ORC Advanced technologies to address petroleum hydrocarbons (PHCs) using an in situ chemical oxidation (ISCO) and enhanced aerobic remediation approach. The hot spot injection application included one event of PersulfOx coapplied with ORC Advanced, using direct push technology (DPT) injection points throughout the 3200 sq. ft. treatment area through 40 DPT injection points.

Technology Description

RegenOx – An injectable two-part advanced in situ chemical oxidation (ISCO) reagent that combines a solid sodium percarbonate-based alkaline oxidant (Part A) with a liquid mixture of sodium silicates, silica gel and ferrous sulfate (Part B), resulting in a powerful technology that treats and destroys a wide range of target contaminants including both petroleum hydrocarbons and chlorinated compounds.

PersulfOx – An advanced ISCO reagent and all-in-one product with a built-in patented catalyst destroys organic contaminants found in groundwater and soil through abiotic chemical oxidation reactions.

ORC Advanced – An engineered, oxygen-release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced produces a controlled release of molecular oxygen accelerating aerobic biodegradation processes up to 100 times f aster than natural degradation rates.

Results

For the final application event, following five on-site working days, REGENESIS completed the hot spot application process during which 9,753 lbs. of PersulfOx and 2,240 lbs. of ORC Advanced were applied to the designated treatment area. First quarter sampling results post-application showed concentrations below MTCA criteria. Following three quarters of monitoring, remediation of this site will be complete.

About the Client

Antea Group is an international engineering and environmental consulting firm specializing in full-service solutions in the fields of environment, infrastructure, urban planning and water. With more than 3,000 employees in over 100 offices around the world, Antea Group serves clients ranging from global energy companies and manufacturers to national governments and local municipalities.

Efficient Application of Combined Amendments Reduces PHC Concentrations Below Washington MCTA Levels

Project Highlights

- In Situ injection application of PlumeStop® Liquid Activated Carbon™ and ORC Advanced® brings closure to facility identified as Leaking Underground Storage Tank (LUST) site

- REGENESIS® Remediation Services (RRS) used a multi-point approach to efficiently inject the combined amendments, completing the application within 24 hours

- PHCs in groundwater and soil reduced below Washington Department of Ecology’s Model Toxics Control Act (MTCA)

2m 34s reading time

Project Summary

An active gas station in Bothell, Washington was listed as a LUST site by the State of Washington Department of Ecology after two subsurface investigations detected petroleum hydrocarbon (PHC) impacted soil and groundwater. Entering into the state’s Voluntary Cleanup Program (VCP) in 2001, the site continuously failed to meet regulatory requirements defined in the MTCA, despite several years of cleanup efforts using a soil vapor extraction (SVE) system and an air sparge (AS) system to remove contaminant concentrations from beneath the site. Charged with remediation, Antea® Group partnered with REGENESIS to implement a solution, which included in situ injection applications of PlumeStop and ORC Advanced technologies.

REGENESIS injected approximately 200 gallons of PlumeStop using strategically placed point locations to rapidly reduce contaminant concentrations. Direct Push Technology (DPT) was employed to advance injection points throughout the treatment zone. The following day, the solution was increased, for a total of 835 gallons of PlumeStop solution (as applied with water) injected within the targeted treatment interval to deliver the full volume of remediation ammendment and complete the application on schedule. A total of nine (9) PlumeStop DPT injection points were cleared to 5 ft. bgs pre-injection.

Additionally, 120 lbs. of ORC Advanced were applied in cleared boreholes via a backfilling method, which involved drilling to the target depth, retracting the rods and pouring the ORC Advanced slurry down open boreholes to approximately 5 ft. bgs in order to properly abandon points.

Technology Description

PlumeStop – An innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation. PlumeStop is composed of very fine particles of activated carbon (1-2μm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and enhancing permanent contaminant biodegradation.

ORC Advanced – An engineered, oxygen-release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced produces a controlled release of molecular oxygen accelerating aerobic biodegradation processes up to 100 times f aster than natural degradation rates.

Results

During the course of the injection and at the end of the application, increases in groundwater levels, ORP (oxidation reduction potential), and dissolved oxygen were observed in monitoring wells in the treatment area. The successful application of both technologies was achieved within approximately 24 hours, despite the challenging glacial till geology known to the region. With field modifications, RRS was able to not only mitigate surfacing issues by switching to injection via injection-well application, but also achieve the desired distribution of the remediation substrate in the subsurface. The first quarter sampling results indicate that the contaminant concentrations are at non-detect. Following monitoring events over the next three quarters, this site will be closed and issued a No Further Action (NFA) from the Washington Department of Ecology.

About the Client

Antea Group is an international engineering and environmental consulting firm specializing in full-service solutions in the fields of environment, infrastructure, urban planning and water. With more than 3,000 employees in over 100 offices around the world, Antea Group serves clients ranging from global energy companies and manufacturers to national governments and local municipalities.

Treatment of a Diverse Range of Contaminants, Emilia Romagna, Italy

Treatment of a very low permeability geology with mixed contaminants at varying concentrations, using multiple application methods and a range of different REGENESIS products.Read More

Remediation of a Former Builder’s Yard, Bedfordshire, UK

Case study on the cost-effective treatment of TPH and PAH at a brownfield site in the UK. Read More

Remediation of Impacted Groundwater on a Busy Construction Site, UK

REGENESIS was asked to provide a remedial solution to mitigate against the off-site migration of the contaminated groundwater. We designed a PlumeStop barrier and was subsequently employed as subcontractor on the works. The barrier injections were made along the downgradient boundary of the site, targeting the groundwater in a gravel formation at 2 – 5m BGL. On this site, PlumeStop was co-injected with ORC-Advanced to enhance the aerobic biodegradation processes in the subsurface.Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español