High-Mass Petroleum Hydrocarbons Treated to Achieve Closure

Case Study Highlights:

-

PersulfOx injected into subsurface during 3 treatment rounds, sequenced ±2 months apart

-

Toluene reduced by an average of 94% and below the toluene Site-Specific Target Levels (SSTLs) in all 5 performance monitoring wells

-

Toluene remains below its SSTL following the injection of PersulfOx

A former US electric service company reported a release during a UST removal completed at the site in 1988. Previous remediation by others included aggressive fluid vapour recovery events completed from 2004 to 2008 and from 2019 to 2020 to address the release, along with groundwater monitoring. Despite these efforts, high concentrations of petroleum hydrocarbons (PHC) remained. Following years of remediation, the final selection and successful application of PersulfOx® effectively reduced high concentrations of toluene in groundwater below the site cleanup goal. The remediation achieved the site target cleanup objectives and received regulatory closure for the decades-old release incident.

Protection of a chalk stream using an injected permeable reactive barrier

Integrated remediation of petroleum hydrocarbons in soils and groundwater

At a brownfield redevelopment site in Hertfordshire, UK, petroleum hydrocarbon contamination originating from historic fuel storage tanks leaks, required remediation to protect the adjacent sensitive and protected chalk stream.

Working with the Environmental Contractor Rake Remediation, REGENESIS helped devise an efficient and integrated remediation strategy, that has been delivered in two phases.

Read the case study

1m 28s reading time

-

Watch the project video

-

Explore treatment options for petroleum hydrocarbons

98% PCE Reduction Achieved After 16 Months

The site is a former dry-cleaning supply distribution business that operated from 1957 to 2000. The former facility provided laundry chemicals, including detergents and spotting chemicals, packaging products such as hangers and polyethylene bags, and bulk deliveries of tetrachloroethene (PCE). Remediation at the site was completed in two primary phases. The first phase was a targeted excavation and soil mixing event focused on addressing the highly impacted shallow soils and smear zone. The second phase was focused on treating the groundwater PCE plume onsite and preventing further plume migration offsite.

Case study highlights:

- High PCE concentrations were detected in soil and groundwater during a site investigation

- A pragmatic, phased approach was used to target PCE in soil and groundwater

- The multi-component treatment was immediately effective and has maintained 98% PCE reduction in onsite groundwater

4m 23s reading time

PlumeStop and S-MicroZVI Application Paves The Way For Redevelopment

Case study highlights

This case study reviews a contaminated chlorinated solvent site in northern California, USA, where advanced design verification testing and predictive modeling methods were used to guide a remarkably successful in-situ remediation effort:

-

Highly successful remediation solution using colloidal technologies: PlumeStop and S-MicroZVI

-

Complete reduction of PCE, TCE and daughter products in the treatment areas

-

Flux-based predictive modeling used to optimise remediation to meet two-year timeline

-

Remedial objectives achieved allowed redevelopment of the property

In situ groundwater remediation following an oil-tanker spill

Integrated chemical and biological approach rapidly remediates MTBE and petroleum hydrocarbons

Introduction

A fuel tanker truck over-turned on a small road in northern Italy, spilling over 36,000L of diesel and petrol. The fuel impacted a canal, flood defences, soils and groundwater in the immediate vicinity.

A site investigation was completed concurrently with an emergency oil-spill response, in order to identify the subsurface contamination, build an initial Conceptual Site Model (CSM) and develop plans for remediation. MTBE, petroleum hydrocarbons (TPH) and BTEX were found to be within the soil – concentrated within the capillary fringe. The groundwater was also found to be impacted and requiring remediation. A remedial options appraisal was completed, considering technical feasibility, sustainability, time and cost and a combined in situ chemical oxidation (ISCO) and enhanced aerobic natural attenuation (ENA) approach was chosen.

Case Study Highlights

Read the case study to learn:

-

How BELFOR has implemented the integrated remedial approach of In situ chemical oxidation (ISCO) and enhanced natural attenuation (ENA)

-

Monitoring results for MTBE over time

-

How site closure has been achieved two years after the oil spill event

- The success factors of this project

Performance-Based Objectives Achieved at Scott AFB

This case study reviews the Corrective Action Plan (CAP) at Scott Air Force Base, a large military base located in Southwestern Illinois that was contaminated with petroleum impacted soil. One month following the application of PetroFix®, contaminant levels reached non-detect. Benzene continued to remain non-detect through March 2020 and the site was recommended for no further action.

The final CAP Addendum proposed two rounds of groundwater treatment by injection at Former Tank 85 to reduce benzene concentrations below the groundwater remediation objectives. The first round of injections was completed in February through March 2018 and consisted of the use of REGENESIS’ RegenOx®, coupled with ORC Advanced® to stimulate aerobic bioremediation. The initial injection was successful in reducing most contaminants within the affected area. The second round of injections at the former UST was completed in March 2019 using REGENESIS’ PetroFix micron-scale remedial fluid.

Case study highlights:

- Impacted soil was caused by leaking underground piping and removal of two large UST’s

- Second round of direct push injections included PetroFix to treat lingering BTEX

- One month following application of PetroFix, BTEX levels were at non-detect and have continued to remain at that level for 5 sampling events

5m 25s reading time

First Application of PetroFix at Petrol Filling Station in Sweden

Integrated groundwater treatment strategy using RegenOx, ORC-Advanced and PetroFix yields a 98% reduction in groundwater contaminant

concentrations

Introduction

RGS Nordic was asked by Circle K to remediate groundwater contaminated with gasoline at an active Petrol Filling Station (PFS) in Nykvarn, Sweden. During the site investigation, petroleum hydrocarbon contamination was identified within the fill material around the underground storage tank (UST) farm.

RGS Nordic was required to deliver a remediation strategy that posed minimal disruption to the commercial operations of the PFS. The chosen remediation strategy combined targeted excavation, in situ chemical oxidation (ISCO), in situ sorption, and enhanced aerobic biodegradation using a range of complementary REGENESIS technologies: RegenOx®, ORC-Advanced® and PetroFix®.

Case Study Highlights

- The integrated remediation treatment strategy ensured that optimum treatment efficiency was maintained throughout the phases of works, resulting in:

- The amount of excavation and offsite disposal was minimised.

- All underground infrastructure remained in situ.

- All works were completed at an active petrol filling station with minimal disruption to the commercial operations of the facility.

- 12-month period monioring results show reductions of >98% of the gasoline range of petroleum hydrocarbon concentrations in the groundwater.

4m 32s reading time

Remediation Products Applied

Please click on the logos below for more product information.

Pesticides, VOCs and petroleum hydrocarbons remediated with a suite of in situ technologies

Shallow aquifer treatment using RegenOx, PersulfOx, ORC Advanced and PlumeStop at a former industrial site, UK

This project was Highly Commended in the Brownfield Awards 2020 in the category of ‘Best Remediation of a Smaller Site’.

Located in East Anglia, this industrial site had been occupied by a timber yard, incinerator, fuel storage tanks and a saw mill. These were later demolished and the site-use changed to light commerical and a car park for a FTSE 100 Company. It was decided that the site should be prepared for redevelopment and a due diligence site investigation was carried out by Ramboll to support lease surrender.

It was discovered that in a corner of the site, the soils and groundwater were impacted with a wide range of contaminants including petroleum hydrocarbons, volatile organic compounds (VOC’s) including BTEX, trimethylbenzene, pentachlorophenol and a mix of pesticides, including organochlorine pesticides (Dieldrin) and gamma-HCH (Lindane). Soilfix worked closely with Ramboll and REGENESIS to deliver a tailored multi-phase remediation solution for the site, including in situ remediation using a suite of REGENESIS’ remediation technologies.

REGENESIS services team carried out the groundwater remediation works on-site which included a combination of in situ chemical oxidation, sorption and enhanced biological degradation. Click the case study link to find out more, or watch the project video.

7m 3s reading time

“The project was a great success. Not only did we meet the betterment-based objectives that we agreed with the Client’s consultant Ramboll; for many of the contaminants we ended up meeting the stringent criteria that were originally derived by the risk assessment. This enabled the Client to surrender their lease on their programme. We felt this was largely down to the project team approach that we took with REGENESIS, from conception through to validation and completion of the project.”

Steve Jackson, Director, Soilfix

Case study highlights:

- Soilfix, Ramboll and REGENESIS worked together to develop a tailored multi-phase remediation solution.

- Integrated application of remediation products: RegenOx, PersulfOx, PlumeStop and ORC Advanced.

- Validation results show a rapid and sustained reduction in the concentration of all contaminants of concern (COCs).

- Remedial targets were achieved in time for lease surrender, with all stakeholders satisfied with the works completed.

In Situ pilot remediation of gasworks impacted groundwater, Stockholm, Sweden

Introduction

In the north-east of Central Stockholm, a historical industrial site was earmarked for redevelopment. Part of the site comprised a former gasworks, where historical operations have caused a complex mix of contaminants to impact the surrounding soil, groundwater and shoreline sediments.

The large site is due to be redeveloped in a series of parcels including a road, industrial park, residential homes and schools. Remediation is required to ensure the human health risk is removed as part of the restoration of the site. The impacted groundwater also represents an environmental risk and requires treatment. Risk assessments were used to determine that remediation was required to a depth of 20m BGL. The geology of the site is heterogeneous, comprising a shallow made ground, a clay layer and underlying coarse sands.

The sands are highly impacted with a range of gas works contamination included creosote NAPLs and high levels of benzene. The saturated clays are also impacted with dissolved phase contamination. Due to contaminants, concentrations and superficial geologies, a range of remedial methods would be required to ensure the most appropriate was used in each scenario. Therefore, RGS Nordic engaged REGENESIS to design a series of pilot tests utilising several in-situ methods. The results from these trials would then be used to shape the full-scale remediation strategy for the entire gasworks site area.

Combined In Situ Remediation Approach and Planning

REGENESIS proposed a pilot-scale combined remediation approach comprising:

- Enhanced desorption using PetroCleanze to target high concentrations of soil-bound contaminants of concern (COC’s) in the sands,

- In Situ Chemical Oxidation (ISCO) using both RegenOx and PersulfOx to target medium to high dissolved phase and soil-bound PAHs in the sandy soil, and

- Enhanced aerobic degradation using ORC-Advanced to target the low dissolved phase benzene and naphthalene concentrations in the clay.

Results

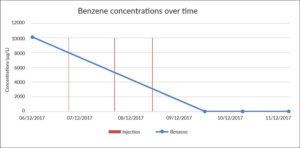

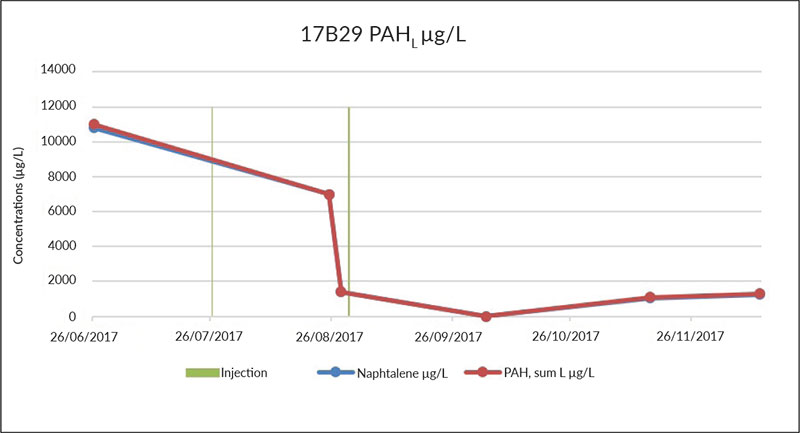

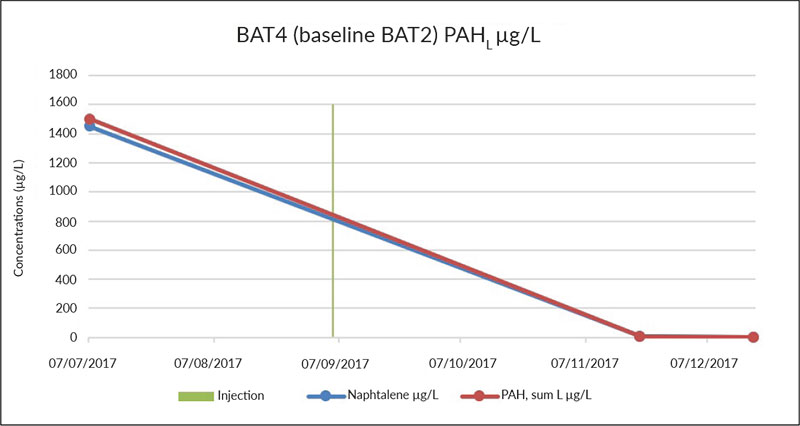

Groundwater samples were collected 3-4 months after the application of REGENESIS remediation products, see graphs 1 to 3. The results are displayed below:

Enhanced Desorption using PetroCleanze

>95% reduction in dissolved phase benzene was achieved with the addition of PetroCleanze. The treatment for PAHs was found to be less effective, primarily due to the low baseline PAH concentrations which were below the optimum treatment concentration range for PetroCleanze.

ISCO using RegenOx and PersulfOx

>90% reduction in dissolved phase benzene and PAHs was observed using PersulfOx. In the RegenOx trial, dissolved benzene concentrations were found to decrease by 80%, while PAH levels increased slightly, potentially due to large volumes of desorbed COCs being released into groundwater post-treatment.

Enhanced Aerobic Biodegradation using ORC-Advanced

A sustained reduction in Naphthalene and benzene (despite suspected influx into the test area) was achieved using ORC-Advanced in the saturated clay.

Conclusion

- A wide range of contaminant concentrations were treated effectively using a combined in-situ remediation approach.

- Substantial reductions in COC concentrations were achieved despite the challenging geological setting.

- The results from the pilot tests show that all areas of the gasworks site can be successfully remediated in-situ using REGENESIS remediation products, providing significant cost savings when compared with conventional techniques

Treatment of site impacted with high levels of petroleum hydrocarbons, Cambridge, UK

Achieving remediation objectives on a busy construction site

Summary

REGENESIS was tasked with the remediation of a former vehicle repair garage impacted with high levels of petroleum hydrocarbons, including some Light Non Aqueous Phase Liquid (LNAPL). Construction of new student accommodation facilities had already commenced on the site when the contamination was discovered. Rapid remediation was needed due to the requirement to complete the construction in time for the start of the new academic year.

The remediation objectives were betterment of the environment through a reduction in LNAPL levels and dissolved phase TPH concentrations. This was to be achieved amongst significant access limitations on the building site and without impacting the construction schedule.

Treatment

Recoverable LNAPL was removed through skimming via wells drilled at the site boundary. RegenOx was then used to chemically oxidise the residual sheen of free product in the wells. An application of ORC-Advanced was also used to provide a controlled release of dissolved oxygen and enhanced aerobic biological degradation of a proportion of the residual dissolved phase contamination.

Recoverable LNAPL was removed through skimming via wells drilled at the site boundary. RegenOx was then used to chemically oxidise the residual sheen of free product in the wells. An application of ORC-Advanced was also used to provide a controlled release of dissolved oxygen and enhanced aerobic biological degradation of a proportion of the residual dissolved phase contamination.

Following a successful pilot comprising injection of RegenOx into 3 fixed wells: 2 full scale injection campaigns were completed comprising injection of RegenOx and ORC-Advanced into a grid of 19 wells located by the site boundary.

What’s Special?

-

Full-scale injection of RegenOx and ORC-Advanced was completed despite considerable access limitations due to construction works.

-

Remediation objectives were rapidly achieved.

-

The works were completed without impacted the construction project programme, during the latter stages of the site redevelopment.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español