Reducing Time and Cost-to-Closure at UST Release Sites

A multi-site case study

In recent years, environmental consulting firm BJAAM has been using PetroFix® to eliminate risks and obtain regulatory closures at petroleum hydrocarbons impacted UST sites. In this multi-site review we have included 6 sites where BJAAM effectively used PetroFix in support of their risk-based corrective action site closure strategy.

Highlights:

- Site closure achieved at four sites, with the other two eligible for site closure imminently

- Site outcomes have led to significant cost savings for BJAAM’s clients and gained confidence from state UST regulatory agencies in the US.

Remediation Goals Met Post PetroFix Application

UST release site now poised for closure

After reviewing the available remedial options, Advanced Environmental Technologies, LLC (AET), a leading environmental consulting and engineering firm in the US, determined PetroFix® Remediation Fluid would provide the most economical and efficient means to reduce concentrations below the groundwater cleanup target levels and achieve site closure for this former petrol filling station.

Case study highlights:

- Injecting PetroFix was the lowest cost option and fastest route to site closure

- An air sparge/multi-phase extraction (AS/MPE) system provided significant reductions to PHC concentrations, but was unable to meet required cleanup levels.

- PetroFix application quickly achieves cleanup goals and sustains reductions for over two years (and counting)

4m 21s reading time

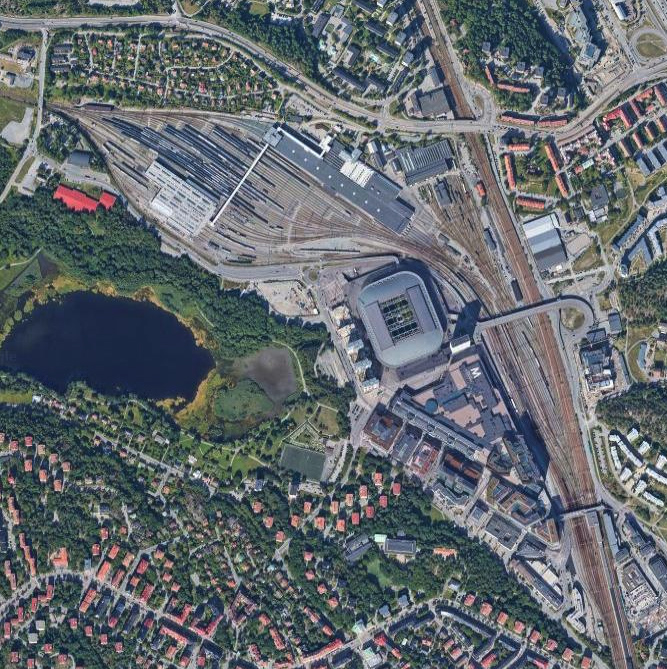

Remediation of the largest train maintenance depot in Northern Europe

Integrated remedial approach achieves >99% contaminant reduction and prevents future recontamination

The Swedish rail authority required that an entirely in situ remediation strategy be implemented across the largest train maintenance depot in northern Europe, located in Hagalund, Sweden.

The contaminated area was approximately 7,500m2, within which 30,000m3 contaminated soil and groundwater required treatment. As part of the remedial works, Swedish remediation contractor Envytech installed a network of additional monitoring wells across the site. This was done to better delineate the plume and identify any unknown contamination prior to commencement of remediation.

Remediation strategy and products applied:

The investigations identified LNAPL across much of the northern area of the site, which required a revised groundwater remediation strategy comprising:

- Dual-phase extraction (DPE) to target the LNAPL, followed by;

- In situ chemical oxidation (RegenOx®);

- Enhanced aerobic bioremediation (ORC-Advanced®); and

- Adsorption & biodegradation (PetroFix®).

Case study highlights:

- Carefully designed integrated remediation strategy used physical, chemical, sorptive and biological treatment

- Innovative use of PetroFix Permeable Reactive Barriers (PRBs) completed to prevent residual contaminant egress from outside of the treatment area and protect against future spills

- Significant reductions of petroleum hydrocarbons have been achieved onsite – starting with LNAPL and reaching stringent target values – within nine months

2m 46s reading time

Double pilot study treats TPH at redevelopment site in the Netherlands

PetroFix injection and excavation applications trialled at former workshop and petrol filling station

Introduction

An area in the south west of the Netherlands is to be redeveloped into residential properties. High levels of petroleum hydrocarbons (kerosene, lamp oil and fuel) up to NAPL, had been found at the site.

Remedial action was required to reduce the risk to potential new residents. The environmental company ATKB decided to complete a double pilot trial with PetroFix®. Full-scale treatment has been planned to commence within 12 months of the pilot application. Read the profile to learn what the pilot trial entailed.

1m 54s reading time

Injectable permeable reactive barrier stops MTBE and benzene plume

Pilot-scale application of PlumeStop and ORC Advanced in the form of an injected permeable reactive barrier proves an effective solution to a long plume under a residential property in Belgium. Full-scale treatment has been scheduled.Read More

Effectively Engineering Rapid Closure of UST Release Sites

This multi-site case study reviews eight underground storage tank (UST) sites where the leading global environmental consulting firm Antea® Group has closed the site or positioned it to be on-track for closure using PetroFix.

Antea Group is amongst the first environmental consulting companies to recognize and adopt PetroFix as a tool to rapidly reduce PHC impacts and achieve remedial objectives in groundwater. Applying PetroFix with economic efficiency, the company successfully advanced a portfolio of legacy UST release sites through the closure process over a short timeframe. In this effort, Antea Group sought and obtained approvals through multiple state regulatory agencies, self-completed the designs to determine dosing and injection layouts, implemented PetroFix treatments using different in situ application methods, and conducted performance monitoring to demonstrate remedial objective attainment.

Multi-site case study highlights:

- Case studies of eight UST sites closed or on-track for site closure using PetroFix, including contaminants treated, approach, remedial design and results

- Antea Group applied PetroFix using in situ application methods which included direct push injections through grid and barrier arrays and excavation emplacement

- Why Antea Group readily adopted a promising new remedial amendment for site closures

13m 45s reading time

PetroFix in situ PRB replaces cut-off wall design to benefit redevelopment project

Remediation project wins ‘Brownfield Redevelopment Project of the Year’ in Ground Engineering Awards

At the site of a former storage and distribution depot in Coventry, the soils and groundwater were impacted with petroleum hydrocarbons from previous site usage, which included a petrol filling station that had been located just north of the site and also across part of the site itself. Cundall created a multi-phased remediation strategy with Alto Construct to deal with the soils and asked REGENESIS to carry out the groundwater remediation.

REGENESIS installed a PetroFix activated carbon permeable reactive barrier at the edge of the site to capture and promote the biological degradation of high levels of dissolved phase contamination migrating on-site, to protect the redevelopment site as well as the adjacent river.

Case study highlights

- 40m long in situ barrier installation completed within 5 days

- Small working footprint – no disruption to construction works

- This alternative solution provides immediate and long-term groundwater treatment

- GE Awards 2020 winner: The judges commented on the innovative method and recognised the reduced programme and significantly reduced quantities of soil sent to landfill, minimising environmental impact.

2m 25s reading time

Preventative treatment: Petrofix coating allows installation of pipeline through contaminated zone, Germany

A new underground pipeline was required to be installed across a complex chemical plant in southwestern Germany. It was found that part of the pipeline would intersect an area of soil and groundwater impacted with petroleum hydrocarbons and BTEX compounds.

Case Study Highlights:

- Total Petroleum Hydrocarbons and BTEX contamination, up to approx. 10,000 mg/kg

- Topical application of PetroFix onto the excavation base and sides to prevent the occurrence of recontamination

- The combination of sorption and biological degradation results in long term protection of the pipeline and avoidance of potential contaminant migration into and along the pipe bedding

- Results: Monitoring showed that there was 94% less petroleum hydrocarbons in MW-1 compared to MW-2

3m 17s reading time

In situ groundwater remediation following an oil-tanker spill

Integrated chemical and biological approach rapidly remediates MTBE and petroleum hydrocarbons

Introduction

A fuel tanker truck over-turned on a small road in northern Italy, spilling over 36,000L of diesel and petrol. The fuel impacted a canal, flood defences, soils and groundwater in the immediate vicinity.

A site investigation was completed concurrently with an emergency oil-spill response, in order to identify the subsurface contamination, build an initial Conceptual Site Model (CSM) and develop plans for remediation. MTBE, petroleum hydrocarbons (TPH) and BTEX were found to be within the soil – concentrated within the capillary fringe. The groundwater was also found to be impacted and requiring remediation. A remedial options appraisal was completed, considering technical feasibility, sustainability, time and cost and a combined in situ chemical oxidation (ISCO) and enhanced aerobic natural attenuation (ENA) approach was chosen.

Case Study Highlights

Read the case study to learn:

-

How BELFOR has implemented the integrated remedial approach of In situ chemical oxidation (ISCO) and enhanced natural attenuation (ENA)

-

Monitoring results for MTBE over time

-

How site closure has been achieved two years after the oil spill event

- The success factors of this project

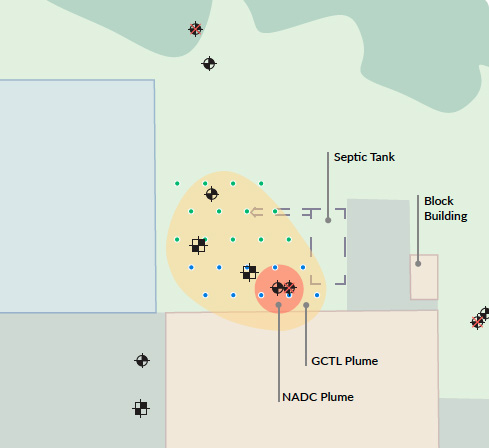

Petrofix Applied At Regional Airport Site To Treat BTEX

A Petroleum hydrocarbon release caused by leaking underground storage tanks (USTs) required remediation at the Dare County Regional Airport in Outer Banks, North Carolina.

After the leak was discovered in 2008, a contractor removed two 50,000-gallon concrete underground storage tanks and four steel USTs that were previously used to store fuel at the site. Additionally, 455 tons of hydrocarbon-impacted soil and approximately 300 tons of sludge were excavated during the tank closure activities. Sampling performed at the time of the UST closures identified hydrocarbon-impacted soil at the locations of the concrete tanks and along the fuel distribution pipe.

Case study highlights:

- This former Naval Auxiliary Air Station site is one of three sites in the region where PetroFix has been applied to address PAHs

- After years of monitoring and remediation attempts, PetroFix was chosen because of its proven ability to reduce petroleum contaminants and ensure site closure

- Visual confirmation in soil cores and monitoring wells allows the field crew to make real-time adjustments to ensure proper distribution

- PetroFix is being used on other CERCLA/RCRA-funded sites to quickly reduce contaminant levels and accelerate site closure

10m 7s reading time

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español