Site Goals Met Within 60 Days

Case study highlights:

This case study reviews the confidential site of a large-scale in situ groundwater treatment of trichloroethene (TCE) at a former industrial manufacturing facility with challenging project objectives and an agressive remediation timeline.

-

TCE eliminated within 60 days post-application

-

This reduction has been continuously maintained more than 5 years to date.

-

The highly controlled PlumeStop injection resulted in no ‘day lighting’ or ‘surfacing’ inside the building.

A collaborative remedial design and strategic implementation effort between REGENESIS and the consulting firm resulted in the project’s success. This collaboration led to a dynamic remediation application strategy entailing planned, in-field adjustment to the design based on information obtained and assessed during remediation. An innovative remediation approach was needed to meet a very stringent deadline for the work’s completion. Through careful planning and scheduling, RRS met the implementation deadline, which included work inside an active warehouse and retail business.

TCE and low concentrations of other chlorinated volatile organic compounds (CVOCs), cis-1,2-dichloroethene, vinyl chloride, and 1,1,1-trichloroethane, were treated using an innovative sorption-enhanced reductive dechlorination (ERD) approach that virtually eliminated groundwater contaminants within 60 days of application. The permeable reactive barrier (PRB) installed at the site property boundary has eliminated TCE for over five years, meeting the application’s performance objectives by cutting off the site’s contribution to a more extensive groundwater TCE plume.

Over 8 Million Cubic Feet of Groundwater Treated In 13 Days

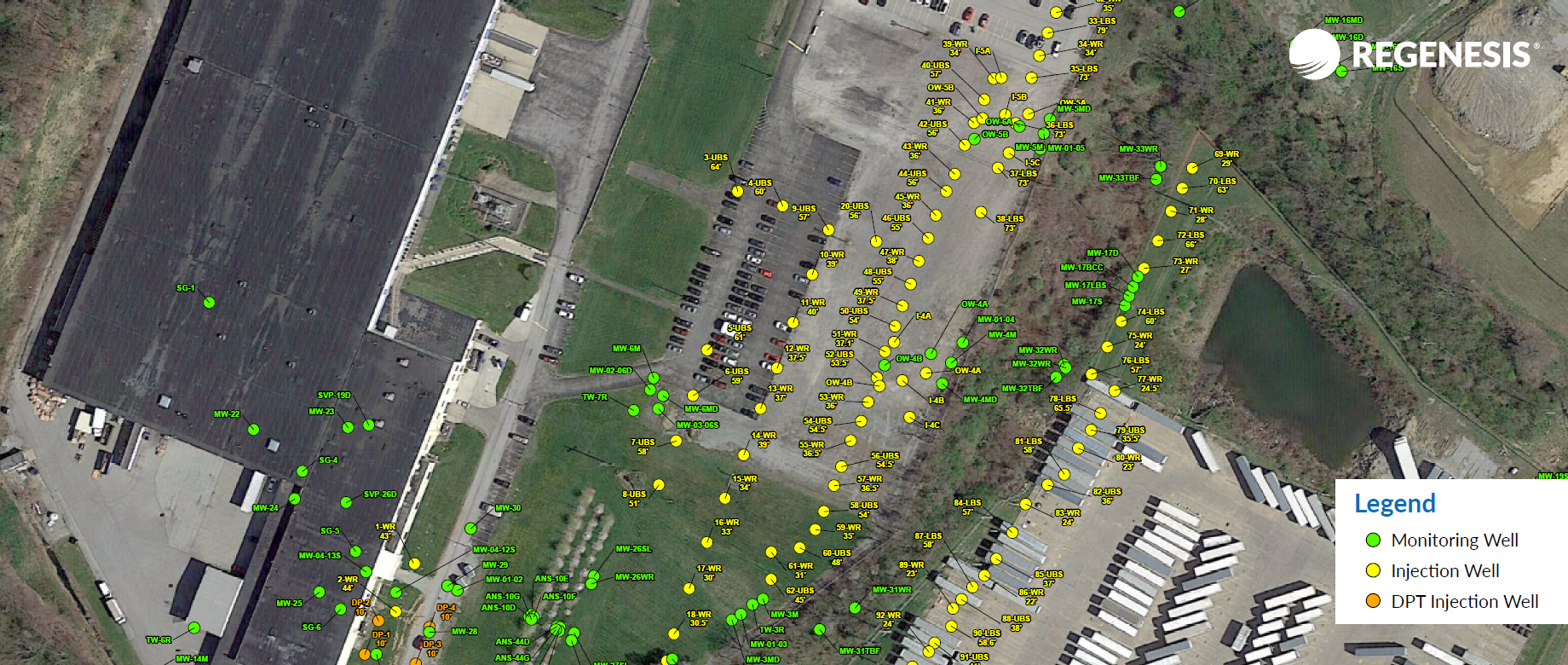

This case study reviews the site of a large-scale enhanced reductive dechlorination (ERD) treatment of chlorinated volatile organic compounds (CVOCs) applied in a fractured bedrock aquifer at a voluntary remediation site in Pennsylvania. REGENESIS Remediation Services (RRS) began the application in May 2020 and completed it in less than 13 days, averaging nearly 7,000 gallons of fluid volume injected per day at this active facility. In total, more than 260,000 combined pounds of 3-D Microemulsion, Chemical Reducing Solution (CRS) and Bio-Dechlor INOCULUM Plus (BDI Plus) were injected for ERD treatment of the CVOCs. The extensive injection well network and large injection volume required RRS to develop an innovative injection process and containment design. Two 21,000-gallon frac tanks were delivered to the site to hold deoxygenated water used for mixing and to chase product injections. Mixing for the main high-flow system was performed in two large polyethylene tanks that were constantly recirculated to ensure a homogenous mixture.

Case study highlights:

- 8 million cubic feet of CVOC impacted groundwater treated

- 88,000 gallons of ERD remedial amendments applied in less than 13 days using novel, innovative tooling and application approach

- The project was completed more than 40% faster than originally scheduled.

7m 30s reading time

PetroFix Pilot Study Leads To Successful Full-Scale Application

This case study reviews a full-scale PetroFix remediation program that was designed and implemented at seven locations to treat petroleum hydrocarbons (PHCs) following a successful field pilot test.

Two post-injection groundwater sampling events were completed in June and September 2019. In December 2019, a supplemental PetroFix injection was completed in the PHC source area onsite following the PersulfOx and ORC-A pretreatment step and groundwater equilibration. Additionally, a new treatment area was added where a small quantity of PetroFix was injected.

Case study highlights:

- Previous pilot testing results provided promising results leading to a full-scale application

- PetroFix is designed to remediate petroleum contamination completely at the lowest total cost to closure

- Site closure strategy included reducing groundwater concentrations, inhibiting plume migration, and demonstrating plume stability site-wide

7m 54s reading time

Multiple Lines of Evidence Show CVOCs Degrading on PlumeStop, Leading Site to NFA Status

This case study reviews one of the original PlumeStop® pilot tests for in situ groundwater treatment of chlorinated volatile organic compounds (CVOCs or chlorinated solvents) at a former dry cleaner location in Marina, California. REGENESIS treated the CVOCs using a novel, sorption-enhanced reductive dechlorination (ERD) approach. This approach consisted of immediate sorption followed by the sequential elimination of chlorine from the CVOC molecules, transforming them into non-toxic end products such as ethene, carbon dioxide, and chloride.

Case study highlights:

- Combined remedy approach proves successful in treating chlorinated solvents at former dry cleaner

- This site provided ideal challenge conditions to demonstrate complete biodegradation using a sorption-ERD approach

- The site was granted NFA status in June 2019 as a result of this pilot study

9m 31s reading time

In situ groundwater remediation following an oil-tanker spill

Integrated chemical and biological approach rapidly remediates MTBE and petroleum hydrocarbons

Introduction

A fuel tanker truck over-turned on a small road in northern Italy, spilling over 36,000L of diesel and petrol. The fuel impacted a canal, flood defences, soils and groundwater in the immediate vicinity.

A site investigation was completed concurrently with an emergency oil-spill response, in order to identify the subsurface contamination, build an initial Conceptual Site Model (CSM) and develop plans for remediation. MTBE, petroleum hydrocarbons (TPH) and BTEX were found to be within the soil – concentrated within the capillary fringe. The groundwater was also found to be impacted and requiring remediation. A remedial options appraisal was completed, considering technical feasibility, sustainability, time and cost and a combined in situ chemical oxidation (ISCO) and enhanced aerobic natural attenuation (ENA) approach was chosen.

Case Study Highlights

Read the case study to learn:

-

How BELFOR has implemented the integrated remedial approach of In situ chemical oxidation (ISCO) and enhanced natural attenuation (ENA)

-

Monitoring results for MTBE over time

-

How site closure has been achieved two years after the oil spill event

- The success factors of this project

PlumeStop Treatment of Chlorinated Solvents in a Bedrock

Successful pilot study uses colloidal activated carbon to protect

nearby surface waters, United Kingdom

Introduction

REGENESIS was asked to provide a remediation solution for a Trichloroethylene (TCE) plume in the UK. We worked closely with Golder to design and implement a novel solution that combined Plumestop, HRC and BDI+ to sorb and biologically degrade the contamination, rapidly and effectively reducing contamination downstream to nondetectable

levels.

Case Study Highlights

This pilot study shows that treatment of chlorinated solvent plumes is possible using PlumeStop even with challenging conditions such as a: co-mingled plume, fractured bedrock setting, and a highly variable hydraulic conductivity.

The PlumeStop in situ permeable reactive barrier rapidly reduced downgradient contaminant concentrations and maintained these through a combination of sorption and biological degradation,protecting the adjacent surface water receptor.

3m 50s reading time

Colloidal Activated Carbon Barrier Protects Neighborhood from Chlorinated Solvent Plume

This case study reviews a field-scale pilot test for in situ groundwater treatment of chlorinated volatile organic compounds (CVOCs) at high concentrations, in a fast-moving, aerobic aquifer beneath a residential neighborhood. The CVOCs were treated using a unique combination of remediation technologies, symbiotically promoting sorption-enhanced reductive dechlorination (ERD) via biotic and abiotic processes. Hamp, Mathews & Associates, Inc., a leading environmental consultant, enlisted REGENESIS to design and install an in situ PRB to fully treat the tetrachloroethene (PCE), trichloroethene (TCE), cis-1,2-DCE (cis-DCE), and vinyl chloride, converting them into nontoxic end products such as ethene, ethane, carbon dioxide, and chloride.

Case study highlights:

- A combined remedy approach using activated carbon and zero valent iron reduces risk of exposure to a residential neighborhood

- PlumeStop permeable reactive barrier (PRB) demonstrated effective in eliminating contaminants in an extreme contaminant flaux aenvironment

- Soil cores and groundwater samples confirmed consistent PlumeStop distribution in the in situ PRB

11m 59s reading time

Petrofix Applied At Regional Airport Site To Treat BTEX

A Petroleum hydrocarbon release caused by leaking underground storage tanks (USTs) required remediation at the Dare County Regional Airport in Outer Banks, North Carolina.

After the leak was discovered in 2008, a contractor removed two 50,000-gallon concrete underground storage tanks and four steel USTs that were previously used to store fuel at the site. Additionally, 455 tons of hydrocarbon-impacted soil and approximately 300 tons of sludge were excavated during the tank closure activities. Sampling performed at the time of the UST closures identified hydrocarbon-impacted soil at the locations of the concrete tanks and along the fuel distribution pipe.

Case study highlights:

- This former Naval Auxiliary Air Station site is one of three sites in the region where PetroFix has been applied to address PAHs

- After years of monitoring and remediation attempts, PetroFix was chosen because of its proven ability to reduce petroleum contaminants and ensure site closure

- Visual confirmation in soil cores and monitoring wells allows the field crew to make real-time adjustments to ensure proper distribution

- PetroFix is being used on other CERCLA/RCRA-funded sites to quickly reduce contaminant levels and accelerate site closure

10m 7s reading time

Remediation of chlorinated solvents under a commercial development, Belgium

Summary:

In Belgium, the former Ubell metal-working factory, which had stood abandoned since the 1990’s, was chosen by Spaque to be redevelopment for commercial use. Significant amounts of chlorinated solvents had been observed in the groundwater, both widespread and with high concentrations in the source area. Reductive dechlorination was seen to be occurring naturally, but was stalling at cis-1,2 DCE due to a carbon-limited system. REGENESIS designed a remediation approach that would use a slow release electron donor to enhance and maintain full and effective reductive dechlorination (Enhanced Reductive Dechlorination (ERD)) of the target contamination.

Case study highlights:

- How a single application of 3DME resulted in the full reductive dechlorination of a large plume of chlorinated solvents

- How this simple and inexpensive treatment allowed the redevelopment of a highly impacted brownfield site, while allowing construction and economic use to go ahead unimpeded by the remediation occurred beneath the ground

4m 38s reading time

Performance-Based Objectives Achieved at Scott AFB

This case study reviews the Corrective Action Plan (CAP) at Scott Air Force Base, a large military base located in Southwestern Illinois that was contaminated with petroleum impacted soil. One month following the application of PetroFix®, contaminant levels reached non-detect. Benzene continued to remain non-detect through March 2020 and the site was recommended for no further action.

The final CAP Addendum proposed two rounds of groundwater treatment by injection at Former Tank 85 to reduce benzene concentrations below the groundwater remediation objectives. The first round of injections was completed in February through March 2018 and consisted of the use of REGENESIS’ RegenOx®, coupled with ORC Advanced® to stimulate aerobic bioremediation. The initial injection was successful in reducing most contaminants within the affected area. The second round of injections at the former UST was completed in March 2019 using REGENESIS’ PetroFix micron-scale remedial fluid.

Case study highlights:

- Impacted soil was caused by leaking underground piping and removal of two large UST’s

- Second round of direct push injections included PetroFix to treat lingering BTEX

- One month following application of PetroFix, BTEX levels were at non-detect and have continued to remain at that level for 5 sampling events

5m 25s reading time

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español